Patents

Literature

69results about How to "Solve effective use" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

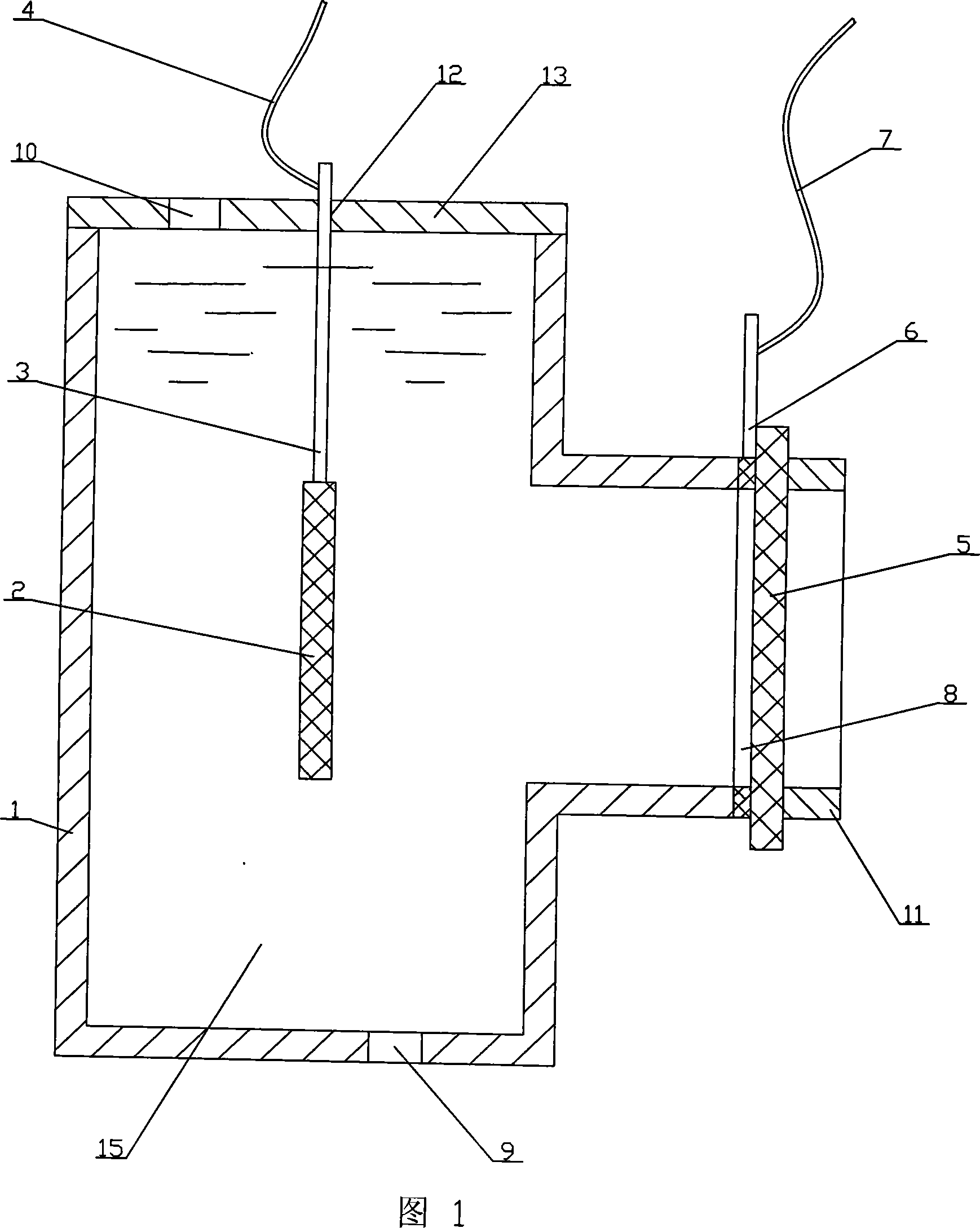

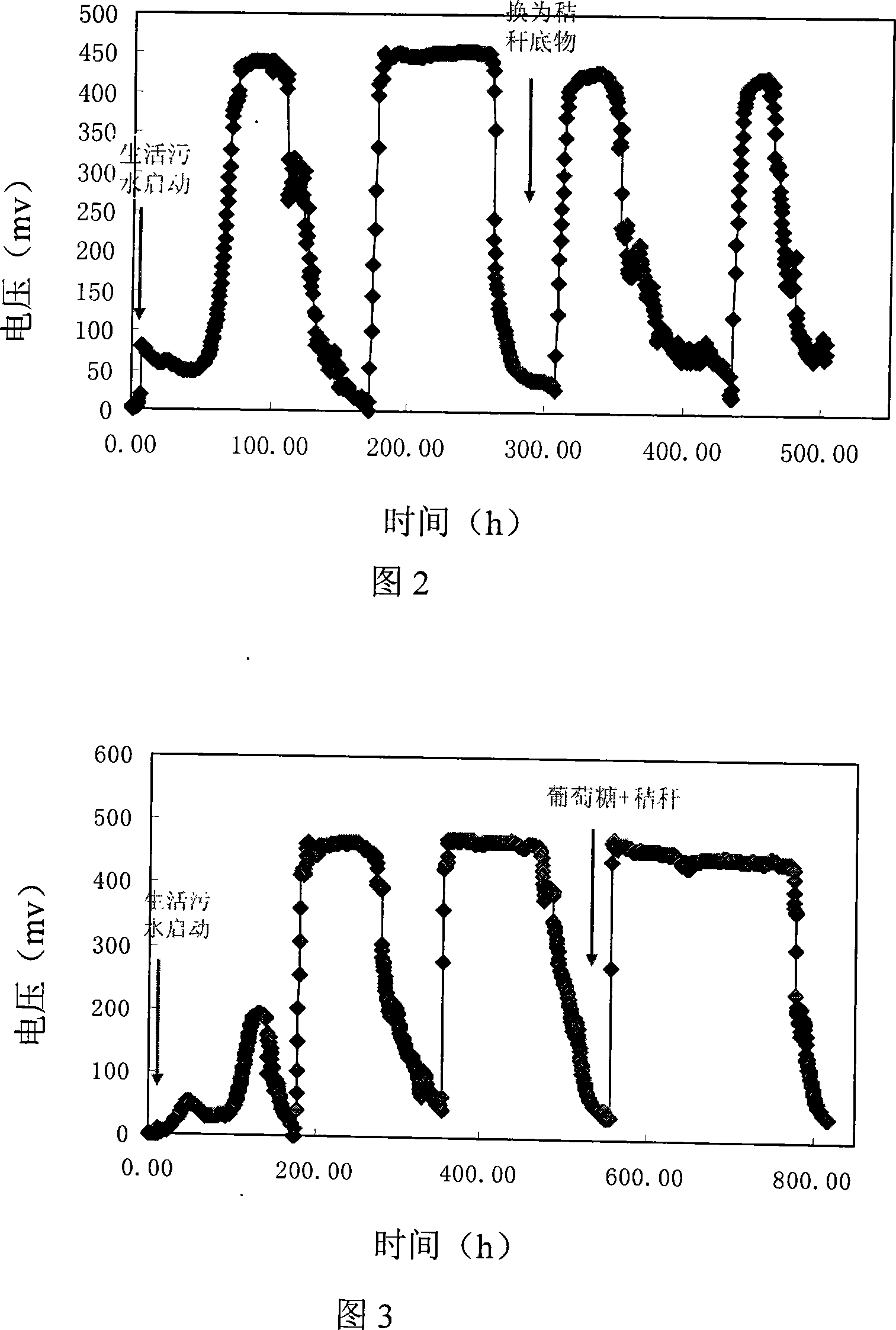

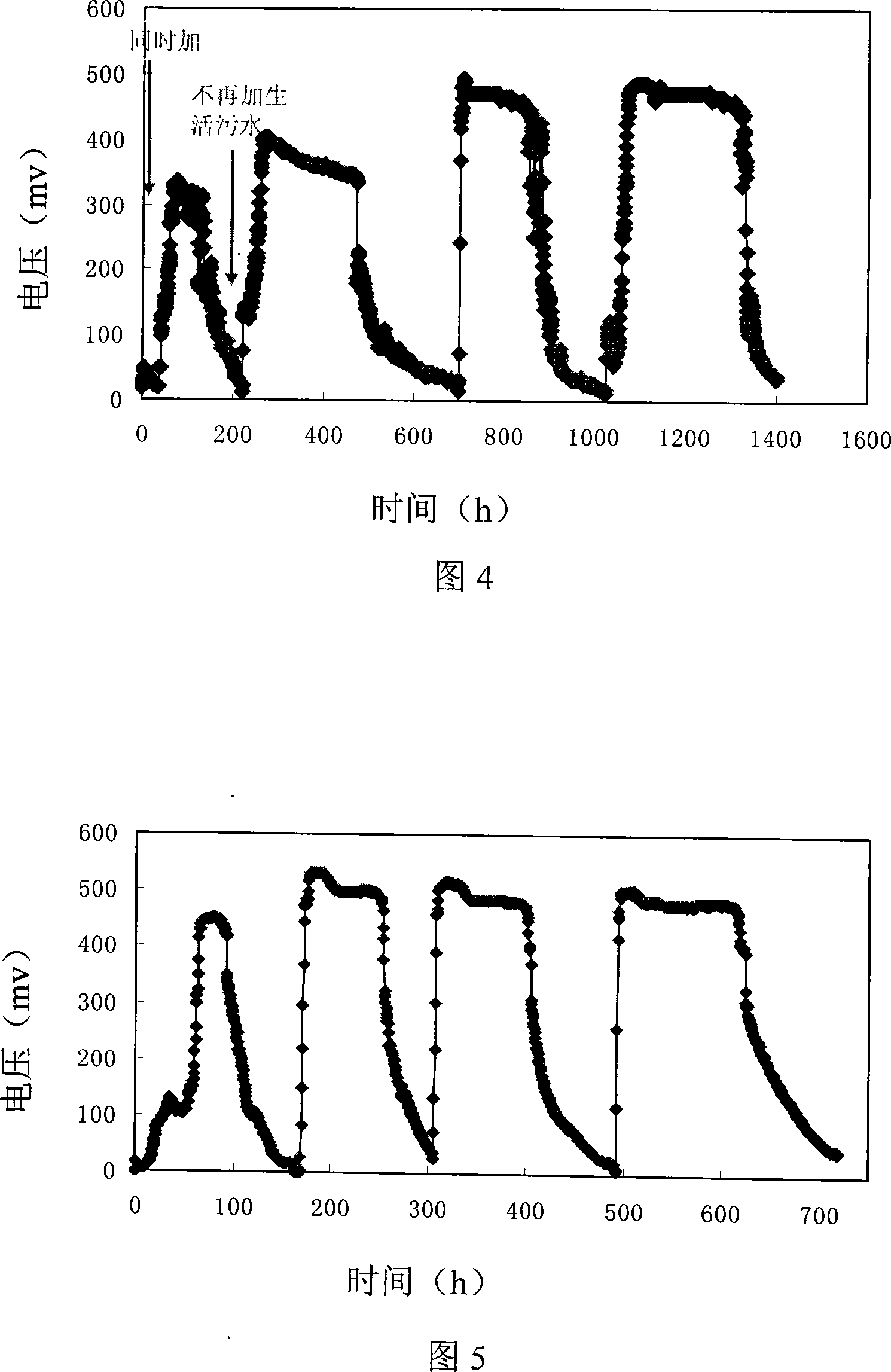

Method for microbe fuel battery and power generation by using straw stalk

InactiveCN101188306ADoes not affect mass transferImprove efficiencyBiochemical fuel cellsElectricityFuel cells

A microbiological fuel cell and a method for generating electricity by use of straws relate to a fuel cell and a method for generating electricity. The invention solves the problem that crop straws are not used efficiently, and particularly straw solids are not directly used in MFC. The microbiological fuel cell of the invention is composed of a container, catalytic anodes, anode wires, air cathodes, cathode wires, a cathode cover and a sealing cover. The method of the invention includes the steps of the pretreatment of the straws, the detoxifying treatment of the straws to obtain a straw solid substrate and a straw liquid substrate, the start-up of the cell, the treatment of the straw solid substrate or the straw liquid substrate. When the electricity is generated by the invention by using the straw solid substrate, the maximum power of the cell reaches 502mW / m<2>, and the degradation rate is about 45percent. When the electricity is generated by using the straw liquid substrate, the maximum power reaches 1288m W / m<2>, and the degradation rate of COD is 60 percent. The invention has the advantages of simple technology, convenient operation, high efficiency, no pollution, reduction of cost and relief of the energy crisis, and the straws in rural areas can be used efficiently.

Owner:HARBIN INST OF TECH

Method of producing microbiological active organic fertilizer using waste mushroom dregs

InactiveCN1724481ASolve effective useAvoid pollutionBio-organic fraction processingOrganic fertiliser preparationMushroomFermentation

Disclosed is a process for preparing microbiologically active organic fertilizer by utilizing discarded mushroom residue, which comprises the following steps, disintegrating the discarded mushroom residue, mixing with disintegrated stalks of agronomic crops or leftover bits and pieces of food processing factories, moistening with water, making the water content of the material to be about 65-70%, inoculating 2-8% of enzyme production composite microorganism agent, placing them in a fermenting tank, sealing for fermentation 5-15 days at a predetermined temperature, ventilating 15 minutes for every 24 hours during the fermentation process, when the biomass and enzyme vitality of the microorganism reach index point, the microbiologically active organic fertilizer can be obtained. The invention solves the problem of environmental pollution existed in the conventional treatment process for discarded mushroom residue.

Owner:迟乃玉

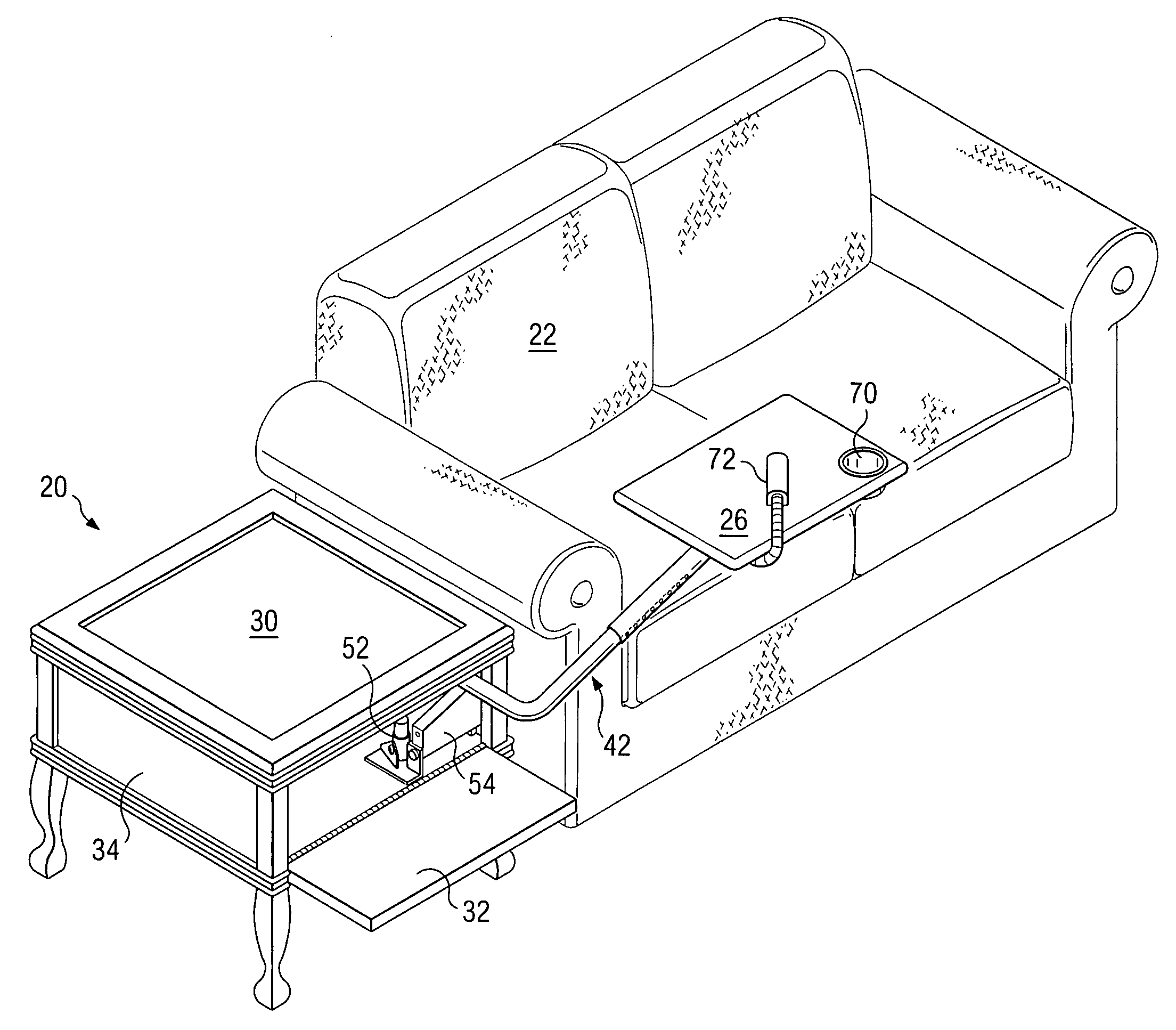

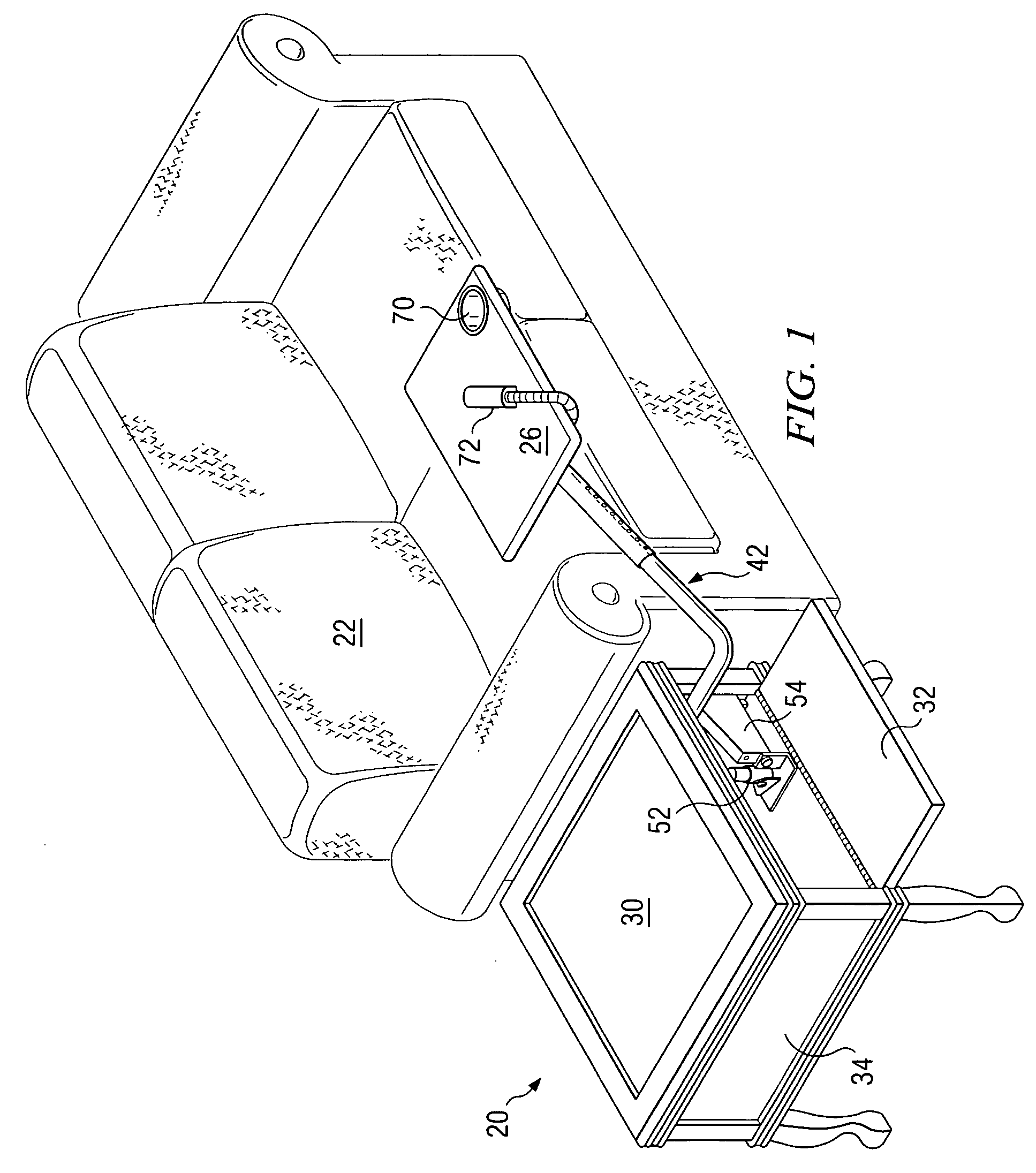

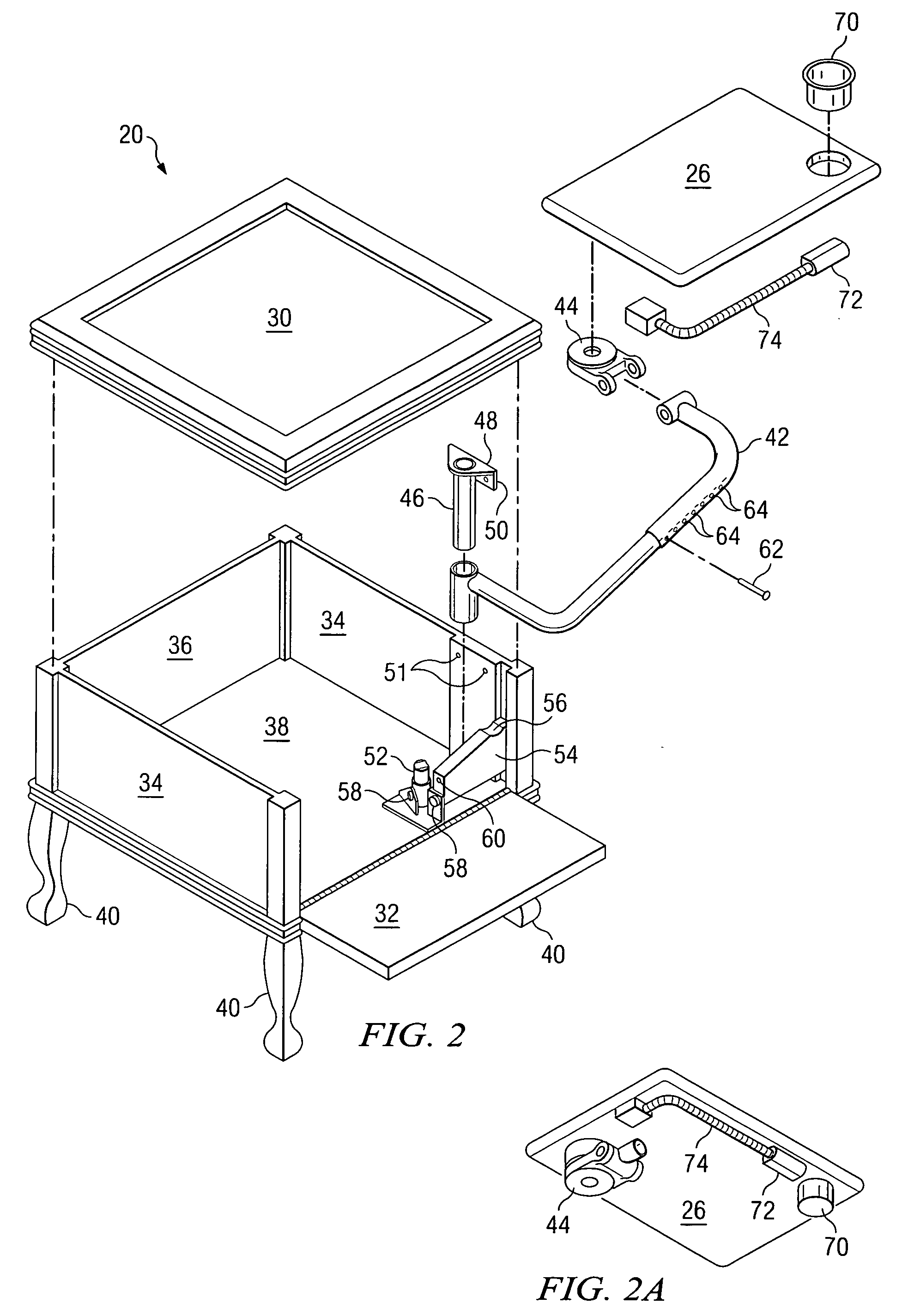

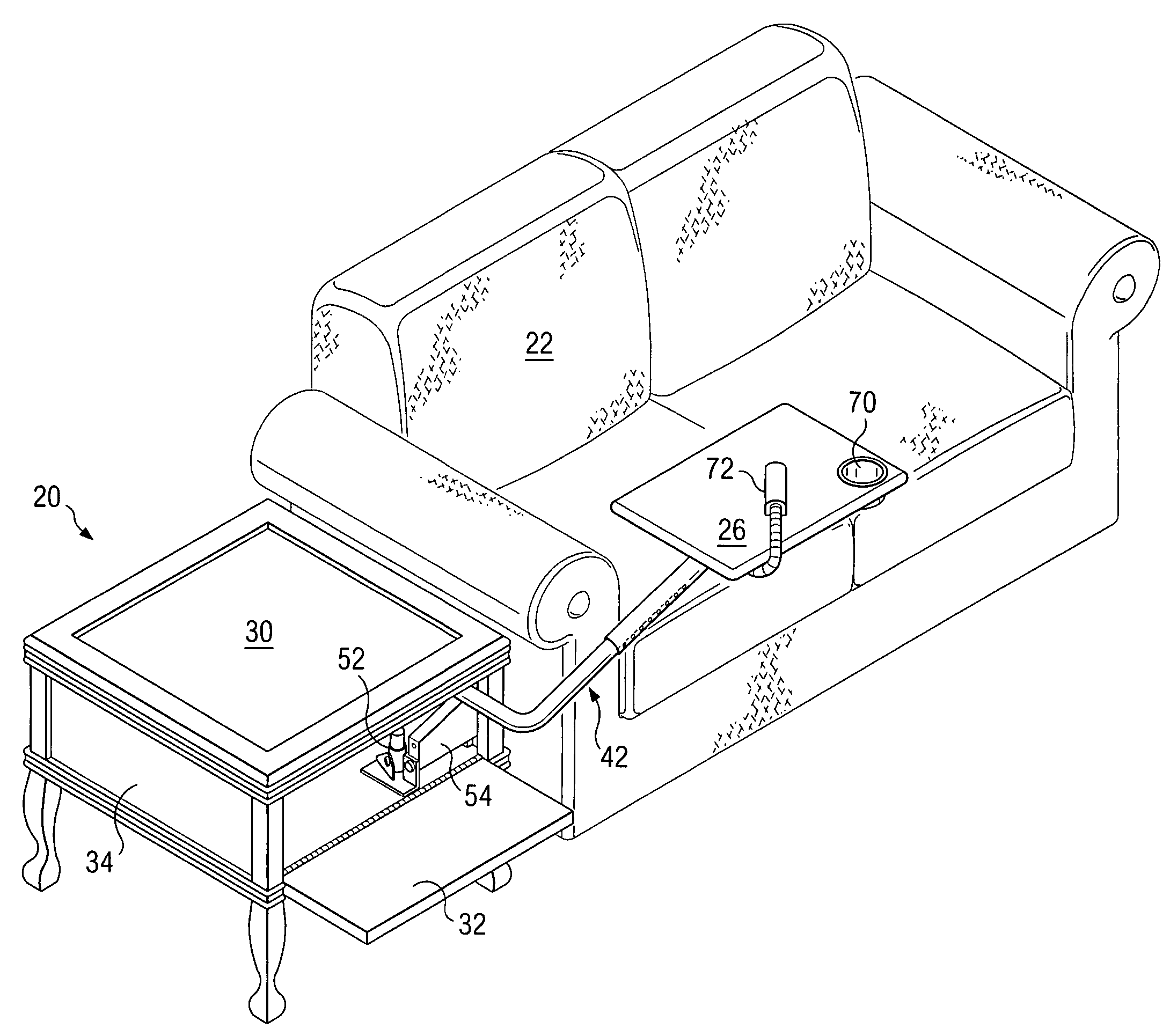

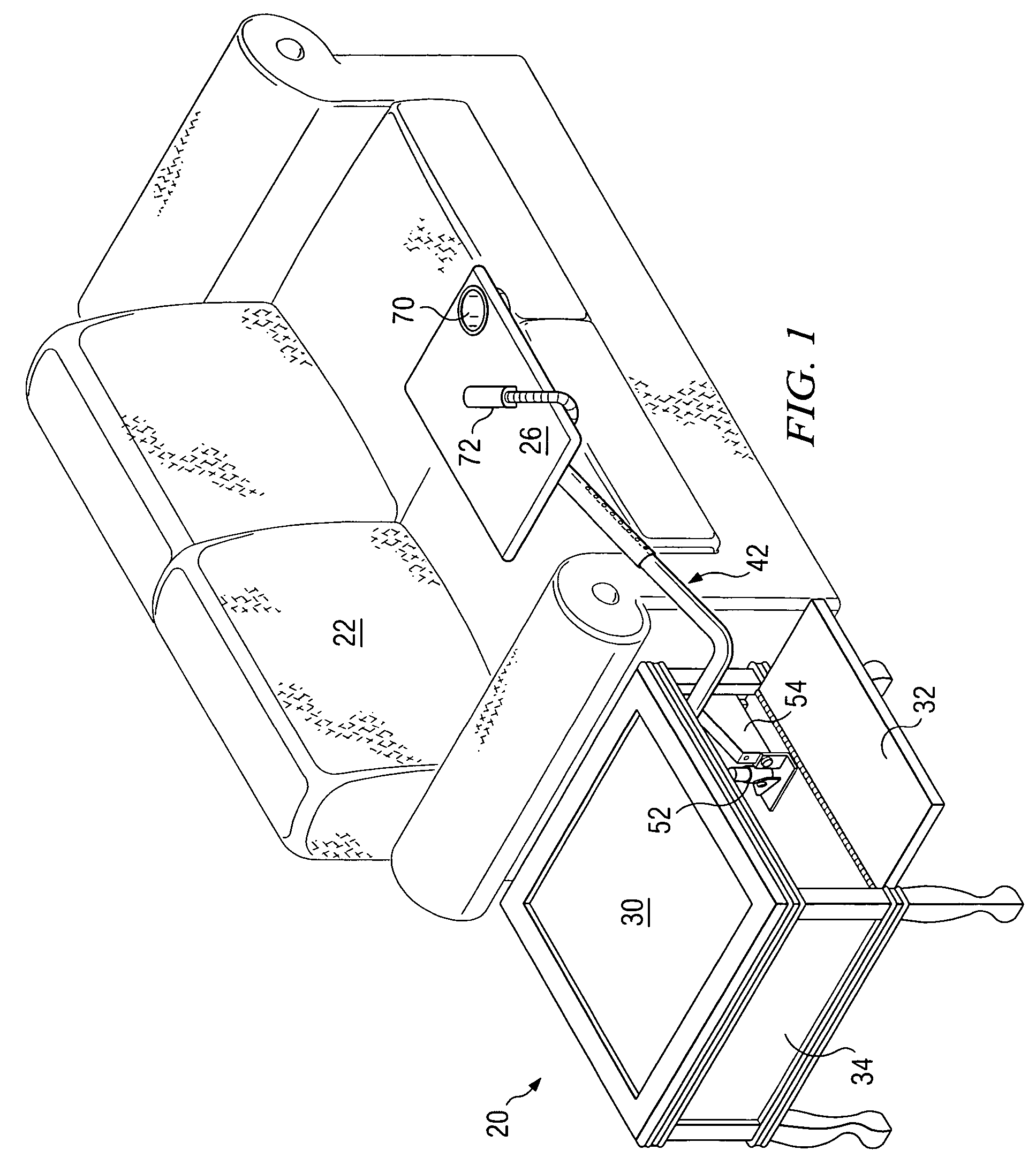

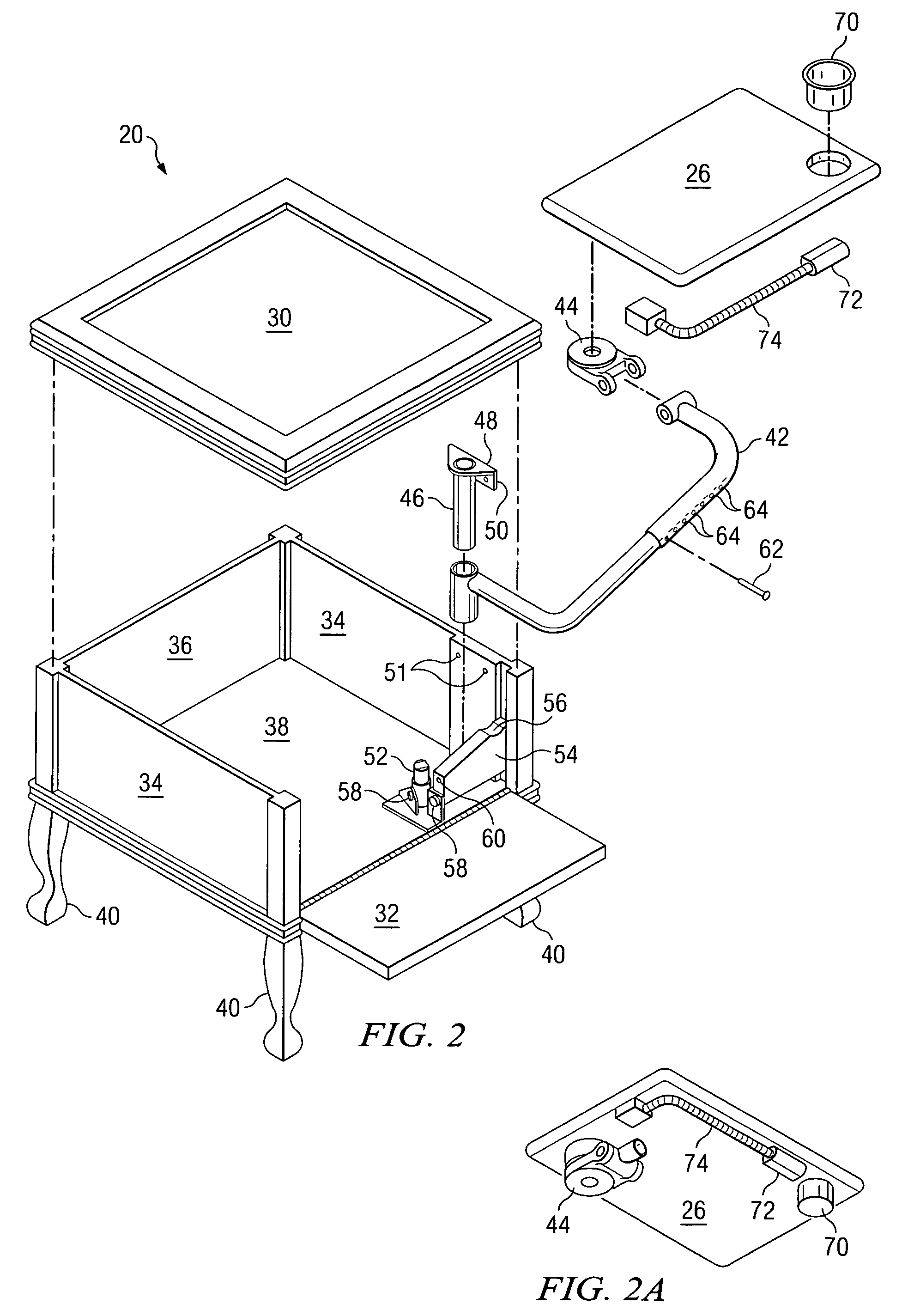

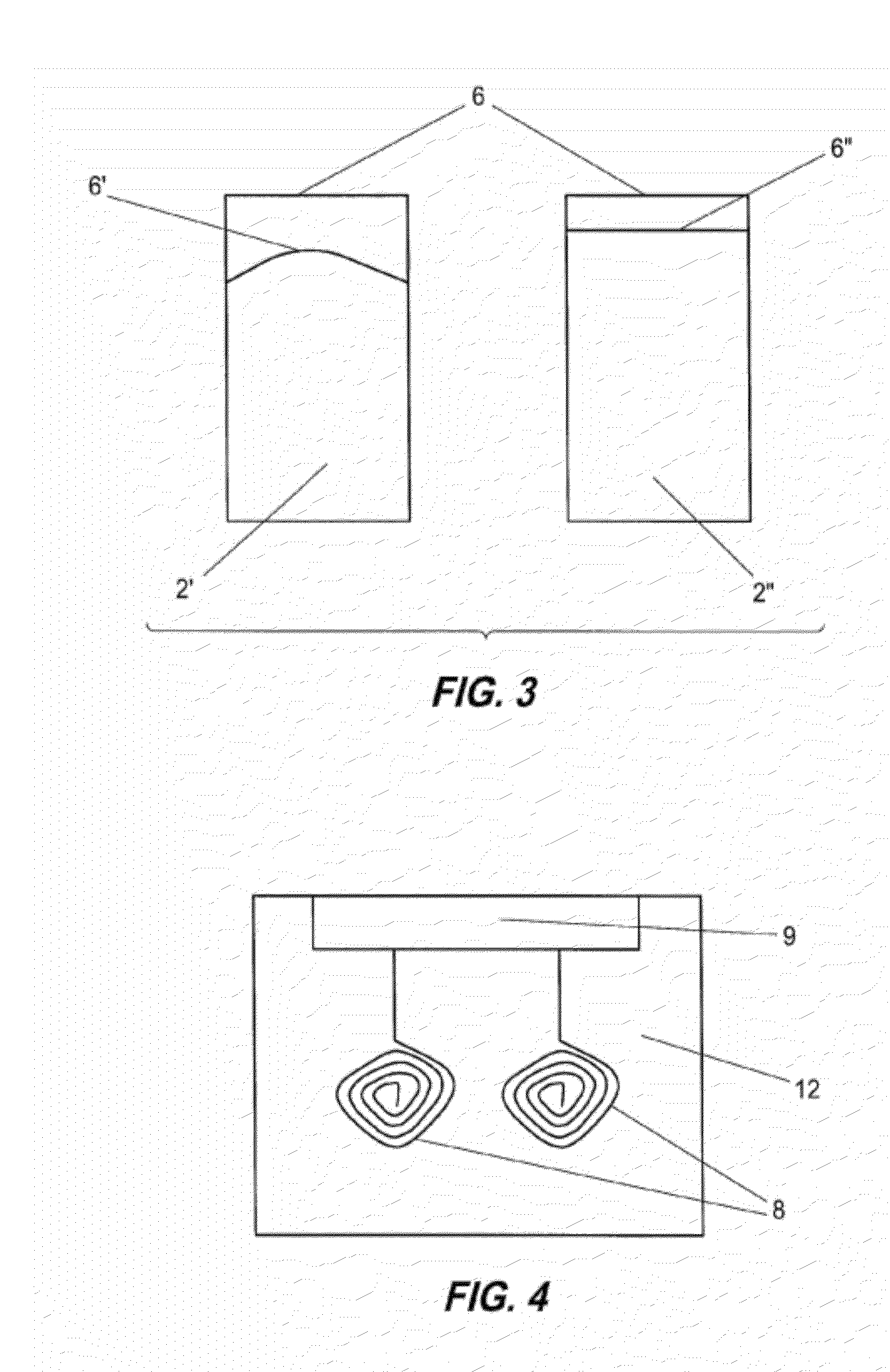

Multi-functional table

ActiveUS20060156962A1Less spaceSmall size tableCabinetsRevolvable tablesEngineeringSpace requirements

A multi-functional table comprises an adjustable second support surface recessed below the upper support surface which extends outward therefrom for use as by a person seated adjacent to the table. When not in use, the second support surface is stored beneath the upper support surface of the table, requiring no additional storage or space requirements for the second support surface.

Owner:HOLT GARY W

Multi-functional table

Owner:HOLT GARY W

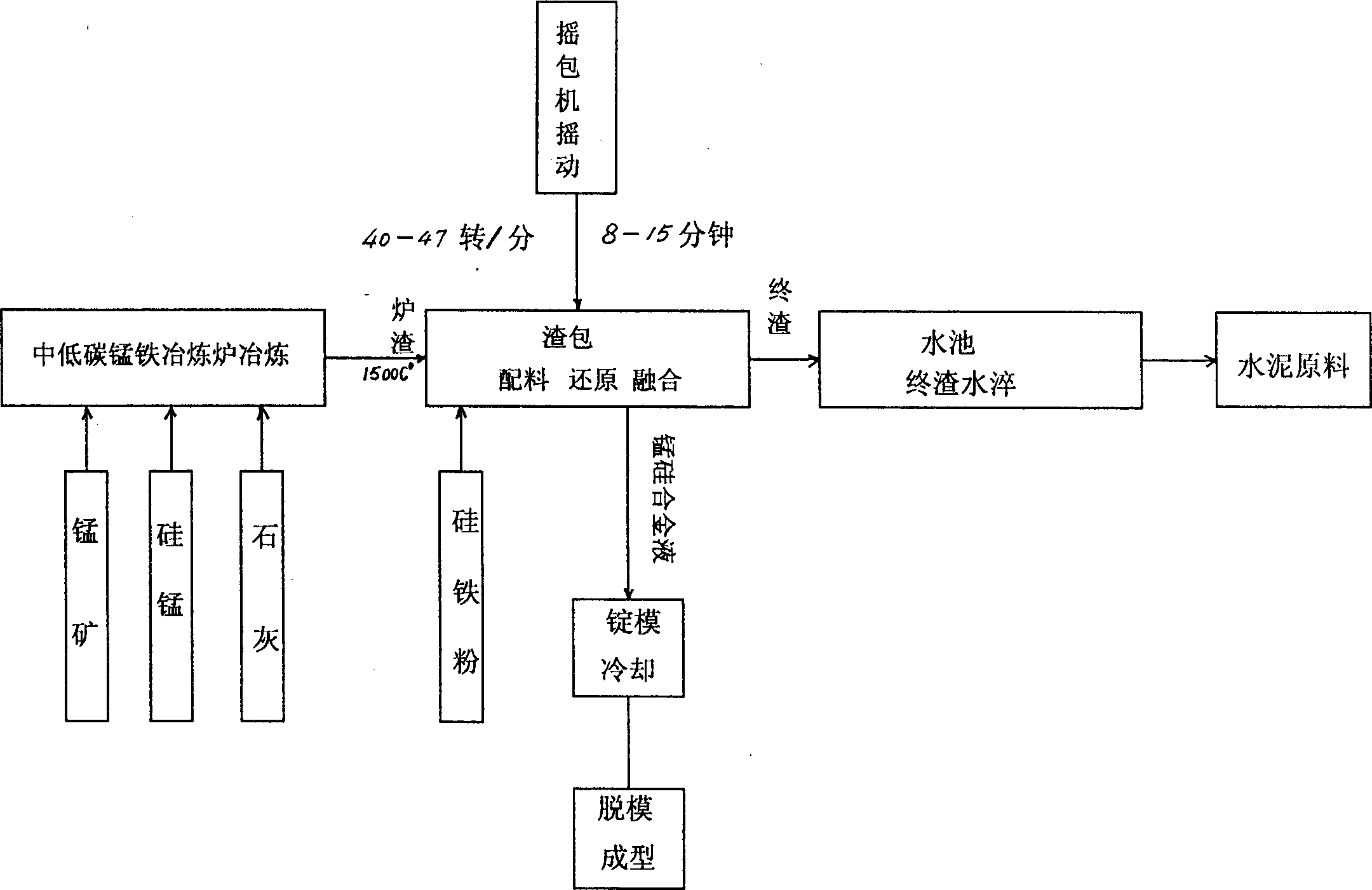

Process for preparing Mn-Si alloy from slags generated by smelting low-carbon ferromanganese

A process for preparing Mn-Si alloy from the slags generated in smelting low-carbon ferromaganese includes such steps as slagging, loading in slag ladle, adding ferrosilicon powder, and sufficient waving for reducing reaction to generate Mn and SiO2 and fuse the Mn and ferrosilicon together at 1500 deg.C to obtain Mn-Si alloy moulding, cooling and demoulding. The residual dregs can be used as rawmaterial of cement as its managanese oxide content is greatly reduced.

Owner:纪翔

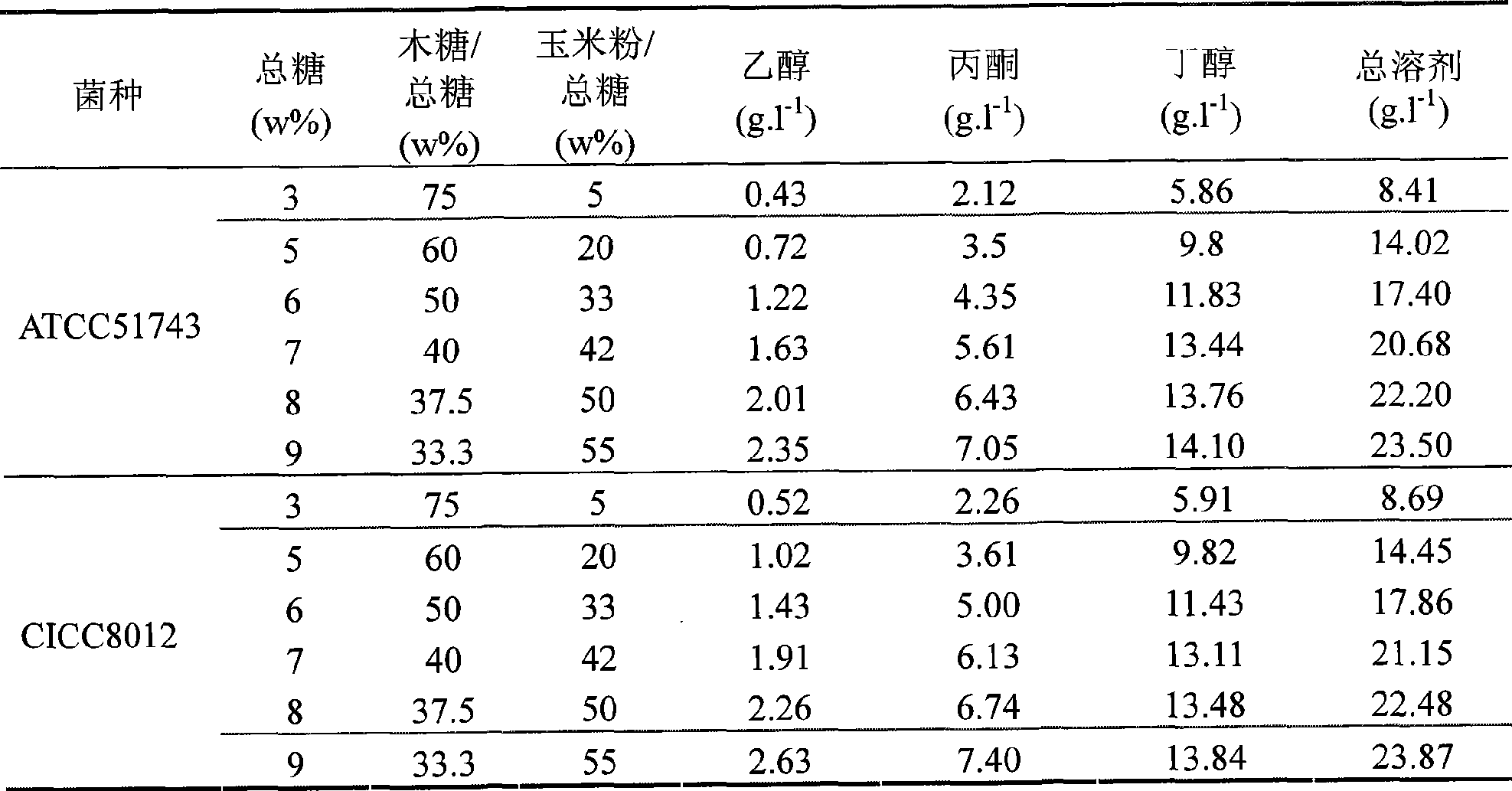

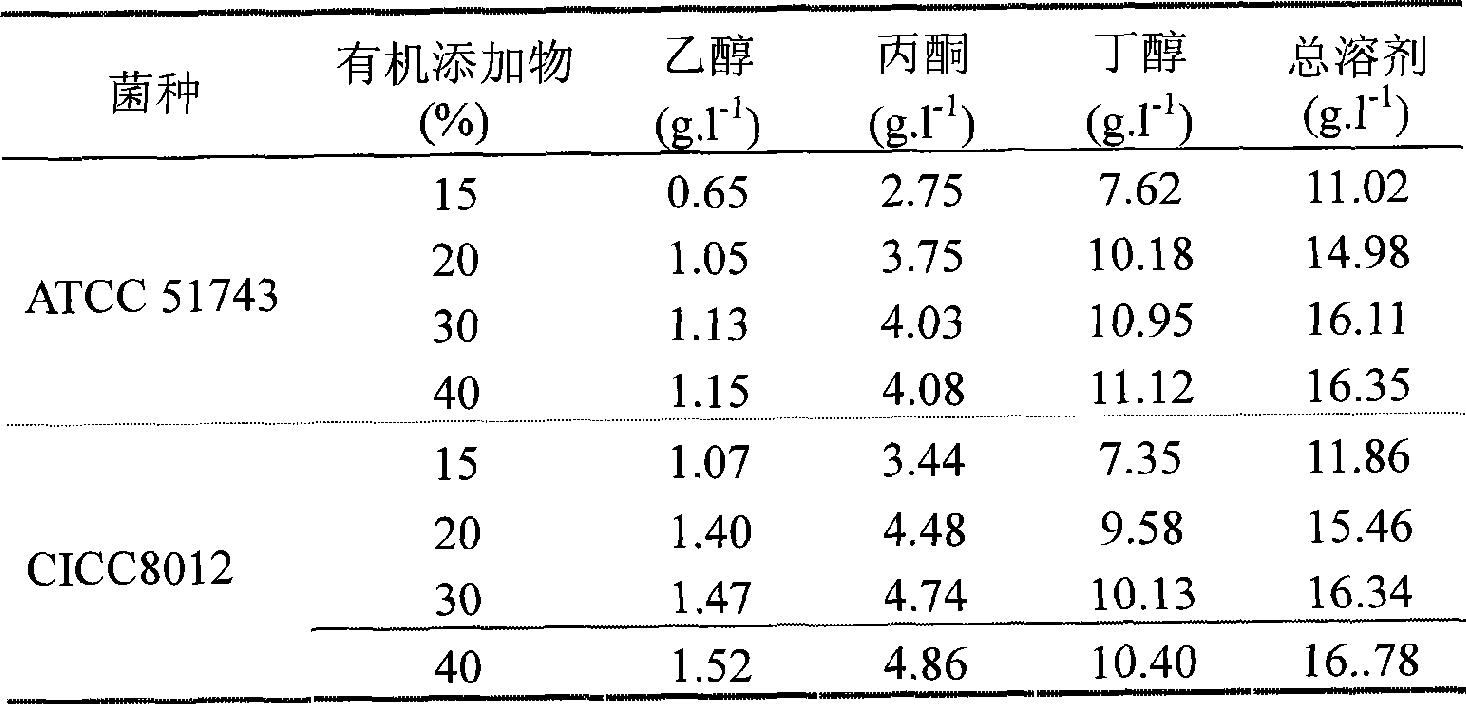

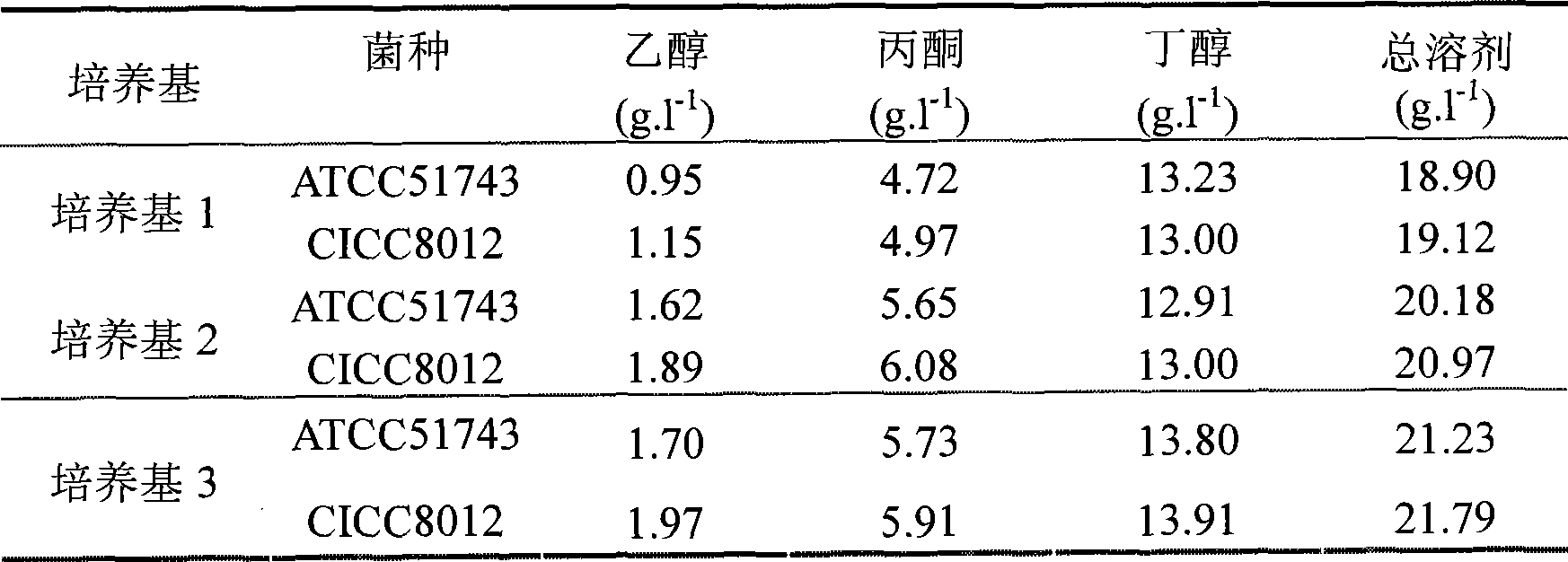

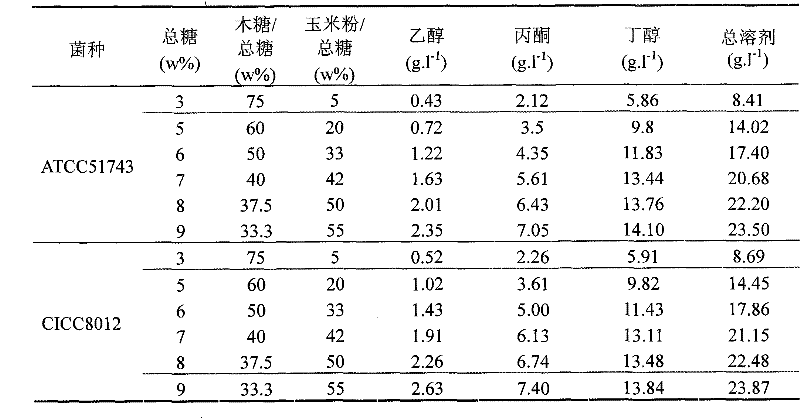

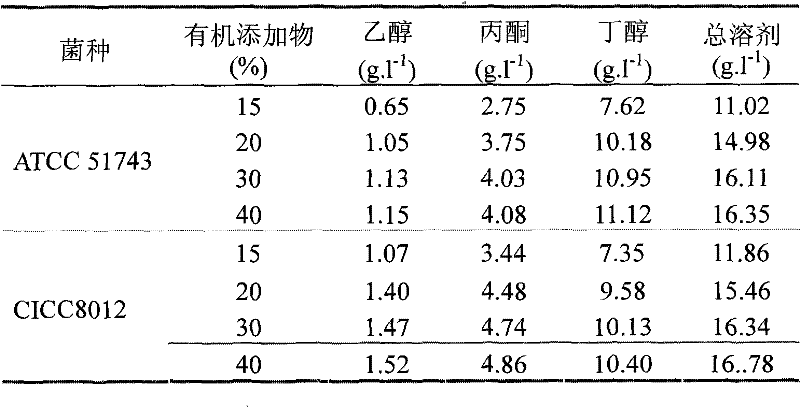

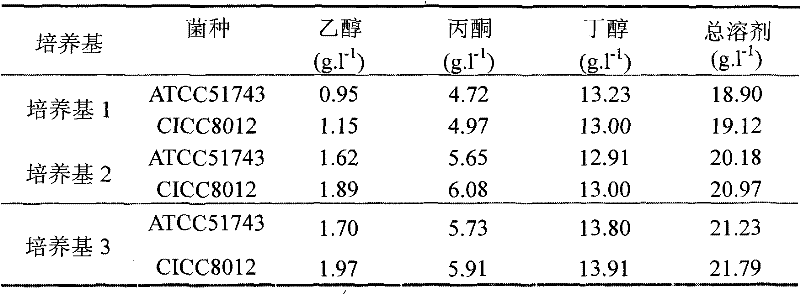

Method for producing acetone-butanol by co-fermentation of pentoses and hexose

ActiveCN101440381AEnsure safetyRealize comprehensive utilizationMicroorganism based processesFermentationCelluloseLiquid fuel

The invention provides a method for producing acetone butanol by jointly fermenting pentose and hexose. The method comprises the following steps: the pentose and the hexose are mixed, the weight of the pentose against the total weight of the mixture is between 5 and 75 percent, the mixture is added with a nitrogen source or a phosphorus source to obtain a raw material, and the raw material is subjected to cooking sterilization to obtain cooking mash; the cooking mash is cooled to a temperature of below 42 DEG C and injected with strains and fermented; and the fermented solution is filtered, distilled and rectified to obtain final acetone, butanol and ethanol products. By the invention, the method which effectively utilizes the joint fermentation of the pentose and the hexose to produce the acetone butanol is obtained. According to local conditions, lignocellulose is utilized to hydrolyze pentose and the hexose for joint fermentation to produce the acetone butanol, thereby realizing waste reutilization, facilitating environmental protection, promoting diversification of energy structure in China, ensuring safety of liquid fuel in China and having positive significance on improving creativity and research capability in the field of preparing biomass liquid fuel in China.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

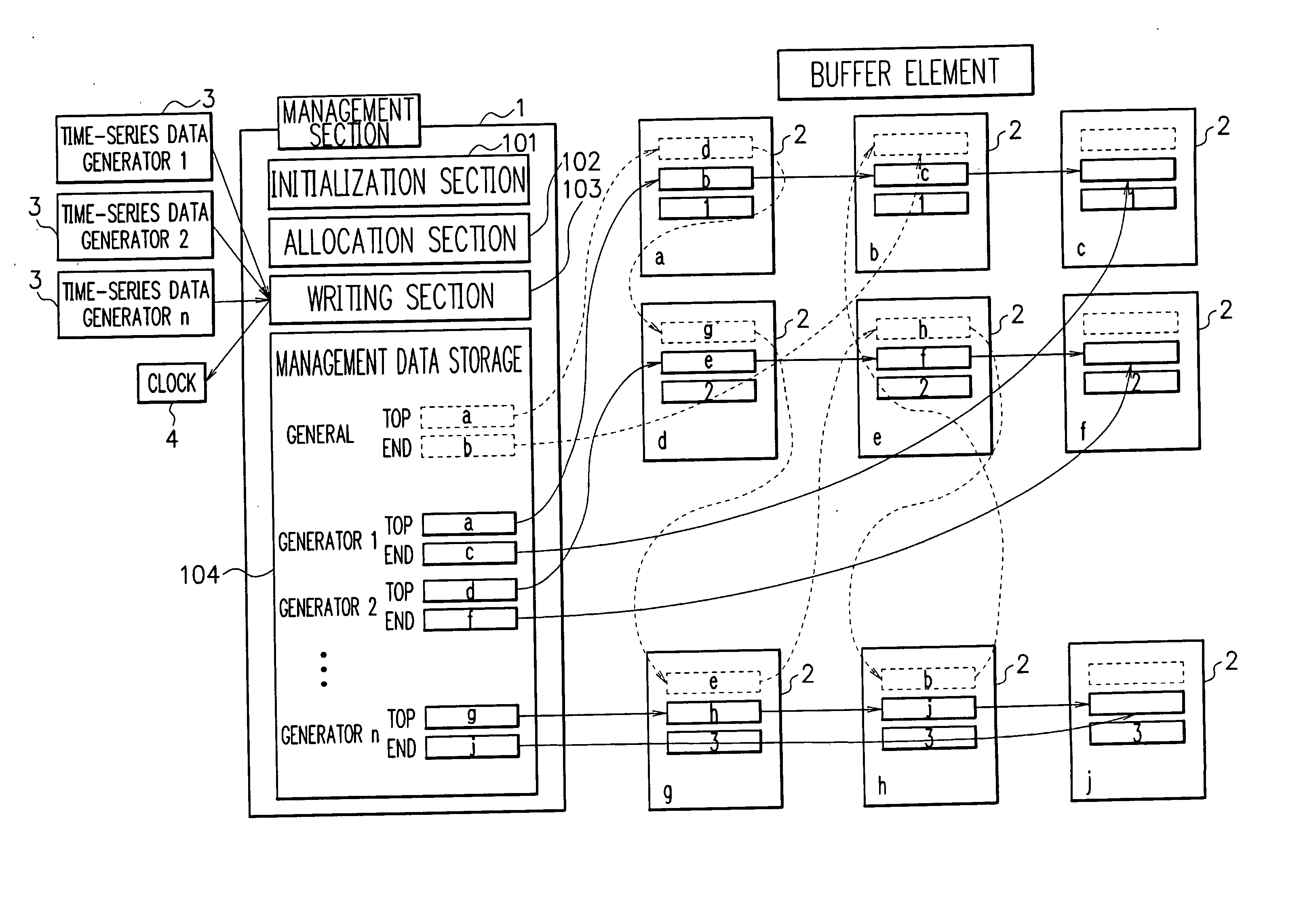

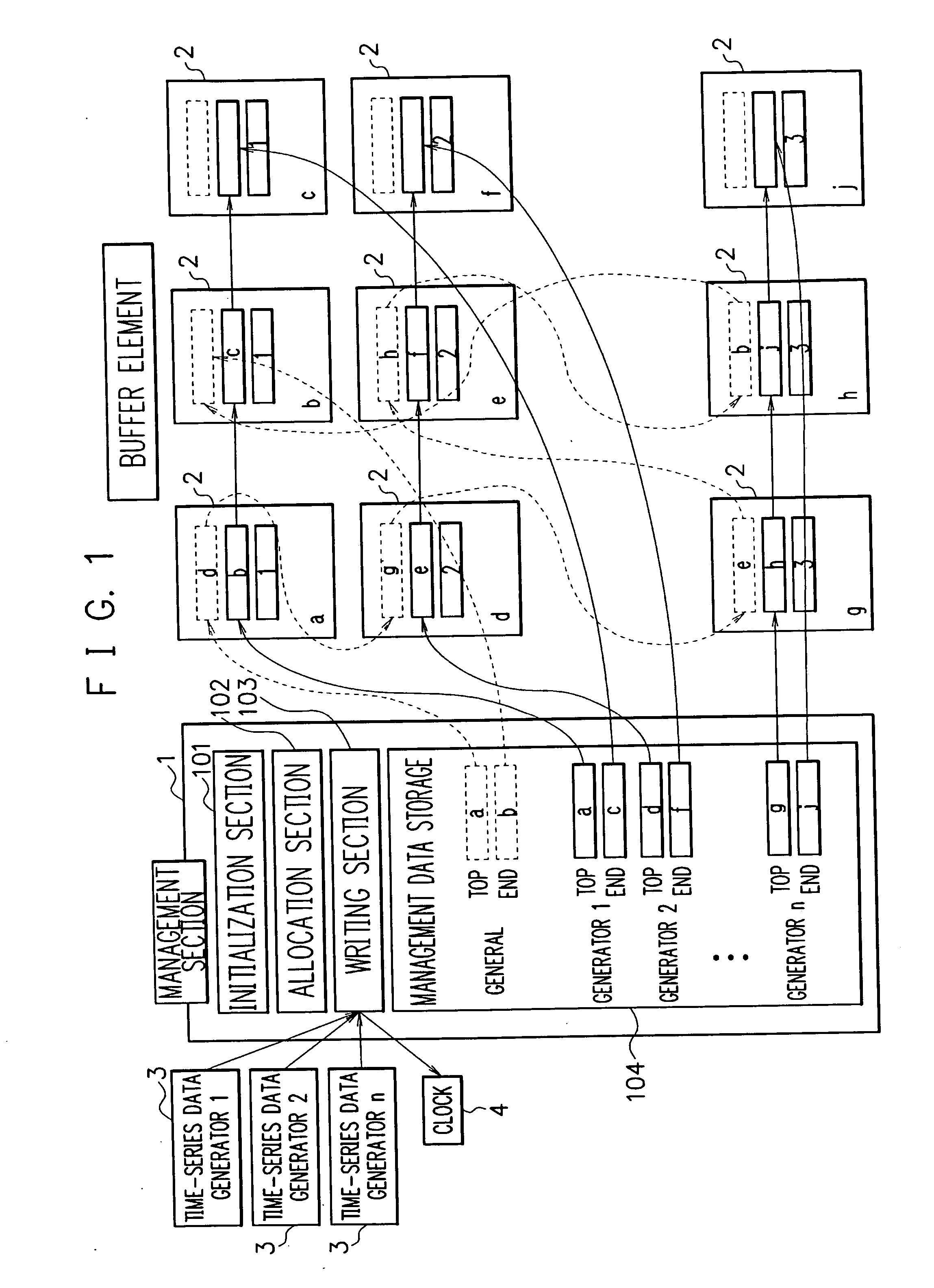

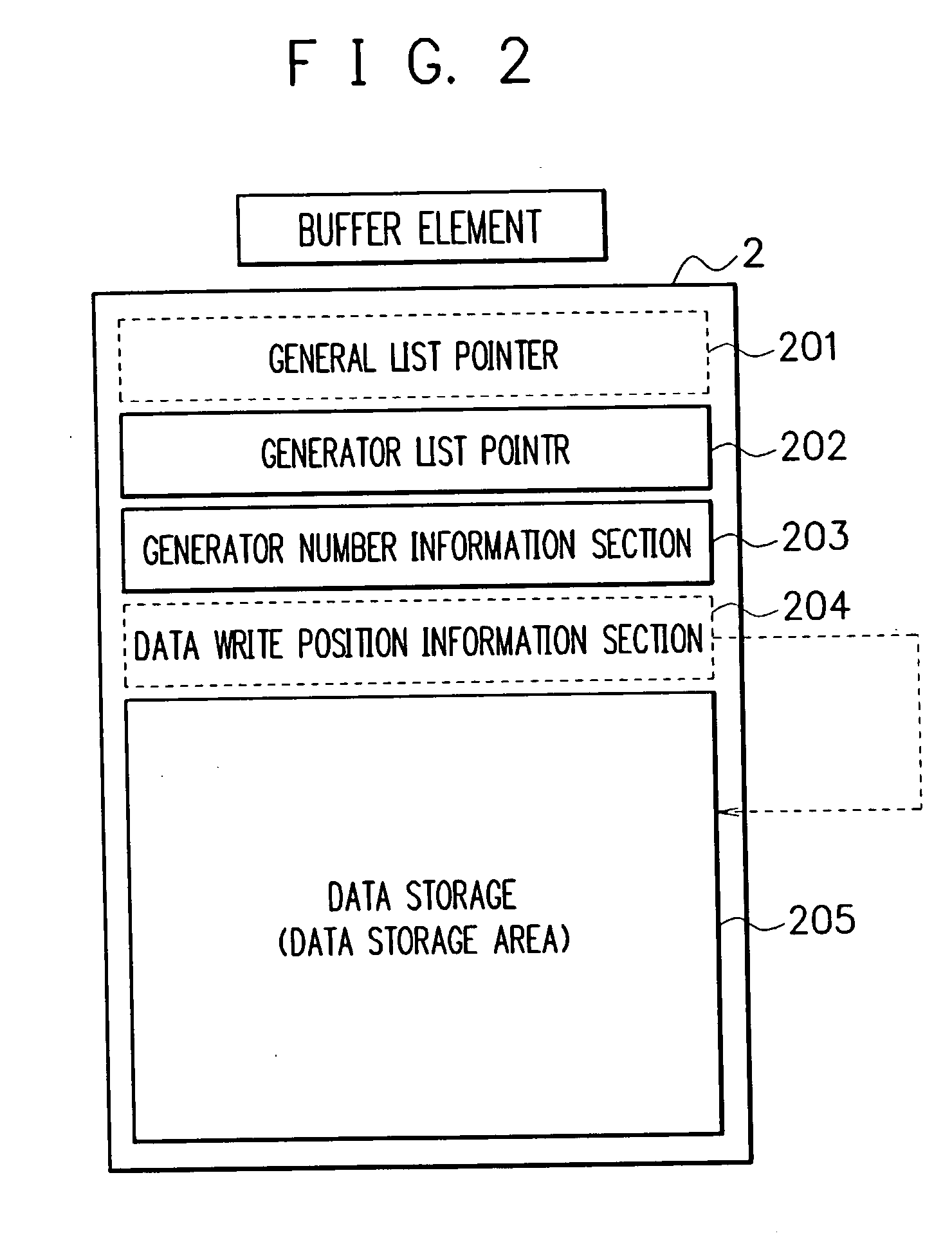

Method, device, system and program for time-series data management

InactiveUS20060056436A1Eliminate overheadImprove efficient useError preventionTransmission systemsManagement systemReal-time computing

A time-series data management method, a time-series data management device, a time-series data management system, and a time-series data management program capable of eliminating overhead due to exclusive access control and improving the efficient use of a buffer as well as enabling the start position of the oldest or nearly oldest data to be specified easily. A buffer for storing time-series data from a plurality of time-series data generators is divided into a plurality of buffer elements to manage time-series data. The buffer elements are dynamically allocated to the respective time-series data generators.

Owner:NEC CORP

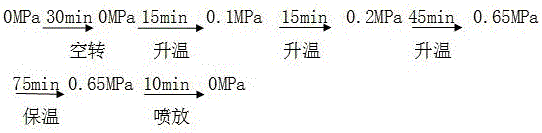

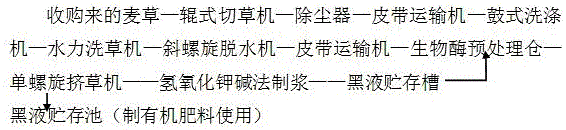

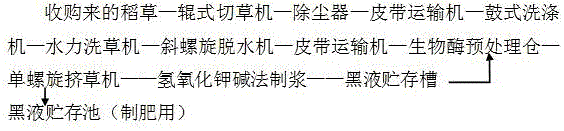

Method for producing potassium fulvate organic fertilizer by biological enzyme pretreatment and potassium hydroxide alkaline process wheat straw pulping black liquid extraction

InactiveCN106631564AImprove biological activityRetain inorganic nutrientsOrganic chemistryPulp by-products recoveryProduction lineMaterials preparation

The invention provides a method for producing a potassium fulvate organic fertilizer by biological enzyme pretreatment and potassium hydroxide alkaline process wheat straw pulping black liquid extraction, and belongs to the field of fertilizer production. The method comprises the three parts of pretreating wheat straw pretreatment black liquid by biological enzymes, extracting potassium hydroxide alkali process wheat straw boiling black liquid, and producing a finished product of the potassium fulvate organic fertilizer, wherein the process of pretreating wheat straw pretreatment black liquid by biological enzymes comprises the steps of wet process material preparation, wheat straw pretreatment by biological enzymes, and storage of black light containing rich potassium fulvic acid; the potassium hydroxide alkaline process wheat straw pulping extraction black liquid comprises extrusion of biological enzyme pretreatment wheat straws, mixing of wheat straws and potassium hydroxide medicine liquid in a pre-soaking machine, steaming ball steaming boiling spray discharging, and steamed and boiled black liquid collection and storage. The organic fertilizer production line comprises black liquid evaporation and concentration, guniting pelleting machine treatment, hot and cold sieving system treatment and organic fertilizer finished product packaging. The paper making black liquid is changed from waste into valuable materials; through biological enzyme pretreatment, the high-activity potassium fulvate organic fertilizer is produced.

Owner:宁夏同创秸科生物科技有限公司

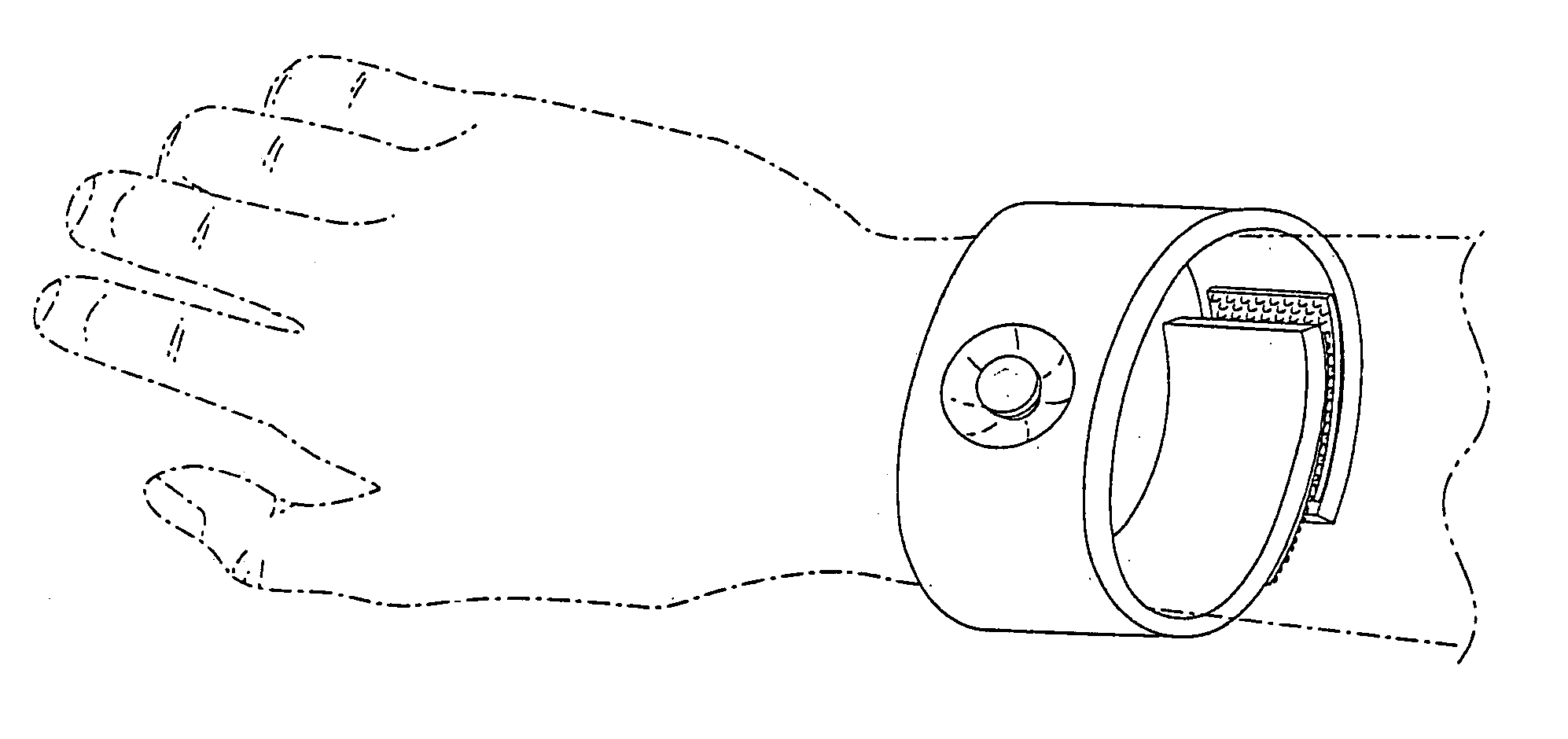

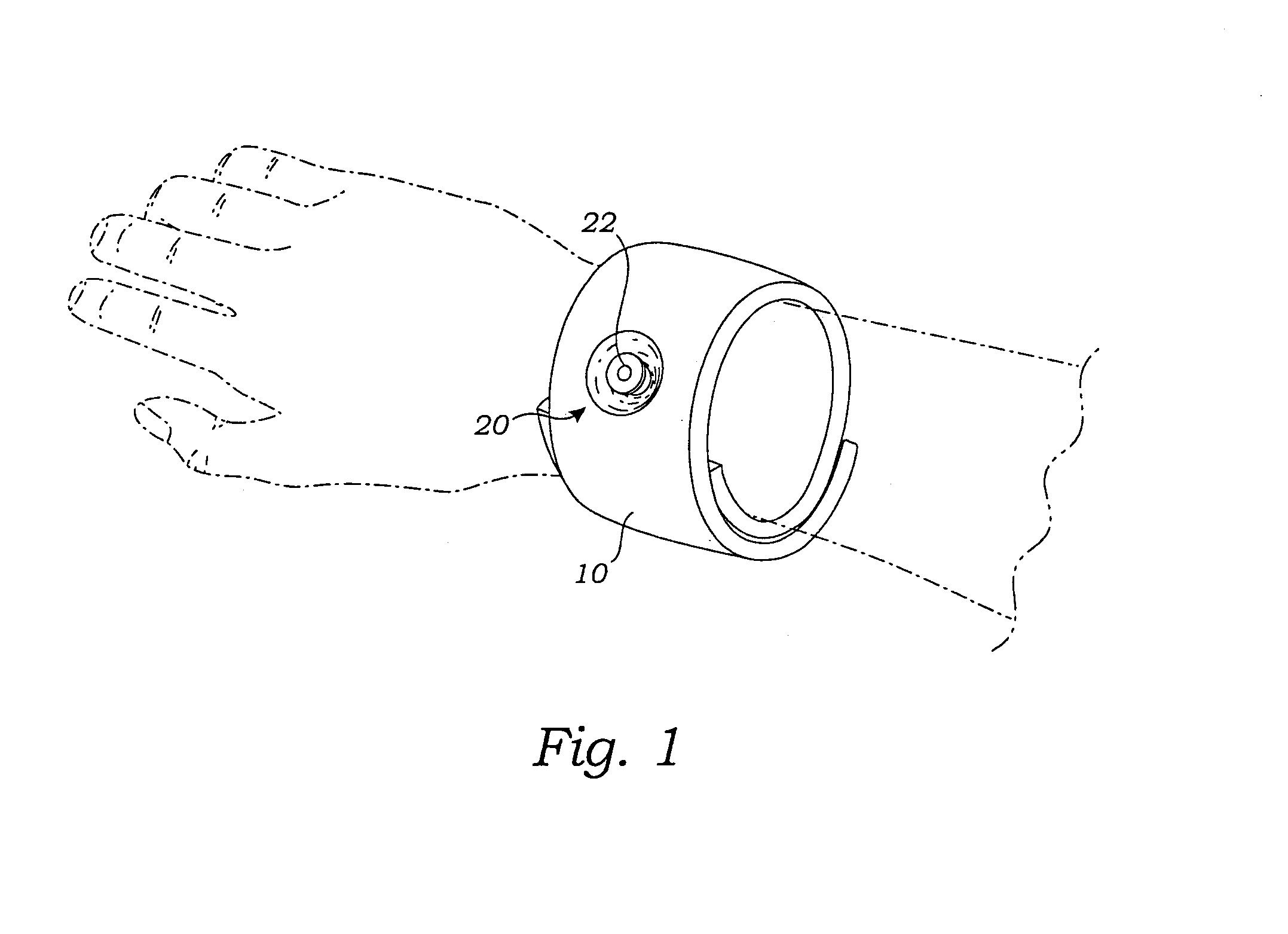

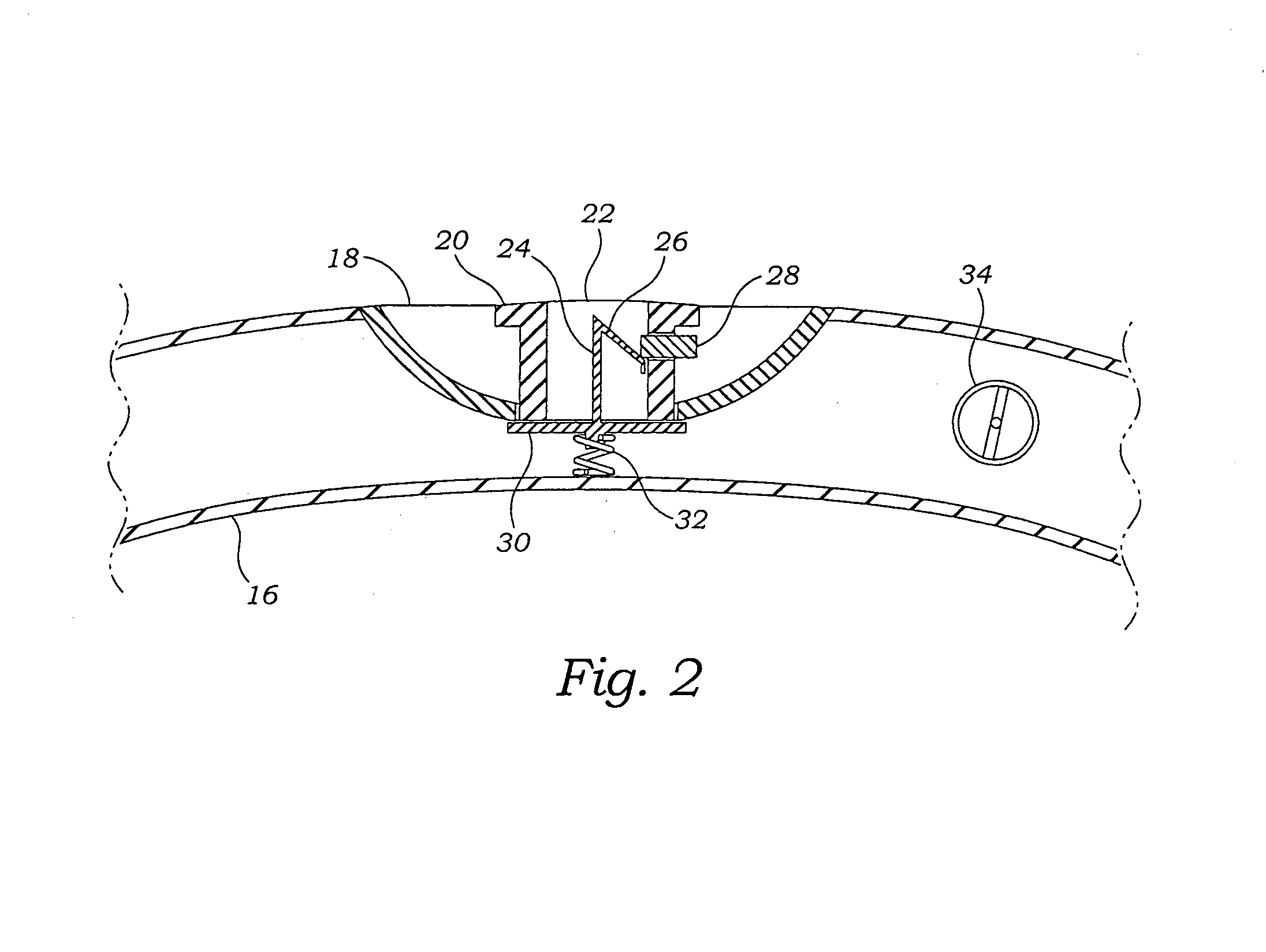

Emergency air supply worn as normal apparel

InactiveUS7156092B2Improve securitySolve effective useRespiratorsBreathing masksRecreationWater activity

Provides an emergency air supply system that is worn around the arm, presumably the wrist, and intended for use in air restrictive emergency conditions. Primarily it has been designed for the need to improve safety for water recreation or water sports where an individual is often caught gasping for air. This device is purposely designed to be no more obtrusive than a piece of clothing, such as a bathing suit, or a watch band would be, in order that it does not unduly restrict the water activity or water sport or any other potentially air restrictive activity you may engage in. The design is intended to encourage usage and increase safety, by way of its structural design that uses the strap-band itself as the mechanical structure of the entire mechanism. Thus creating a unique compact design, that is convenient to wear and provides air when you most need it.

Owner:OTTER RUSSELL WOLFE

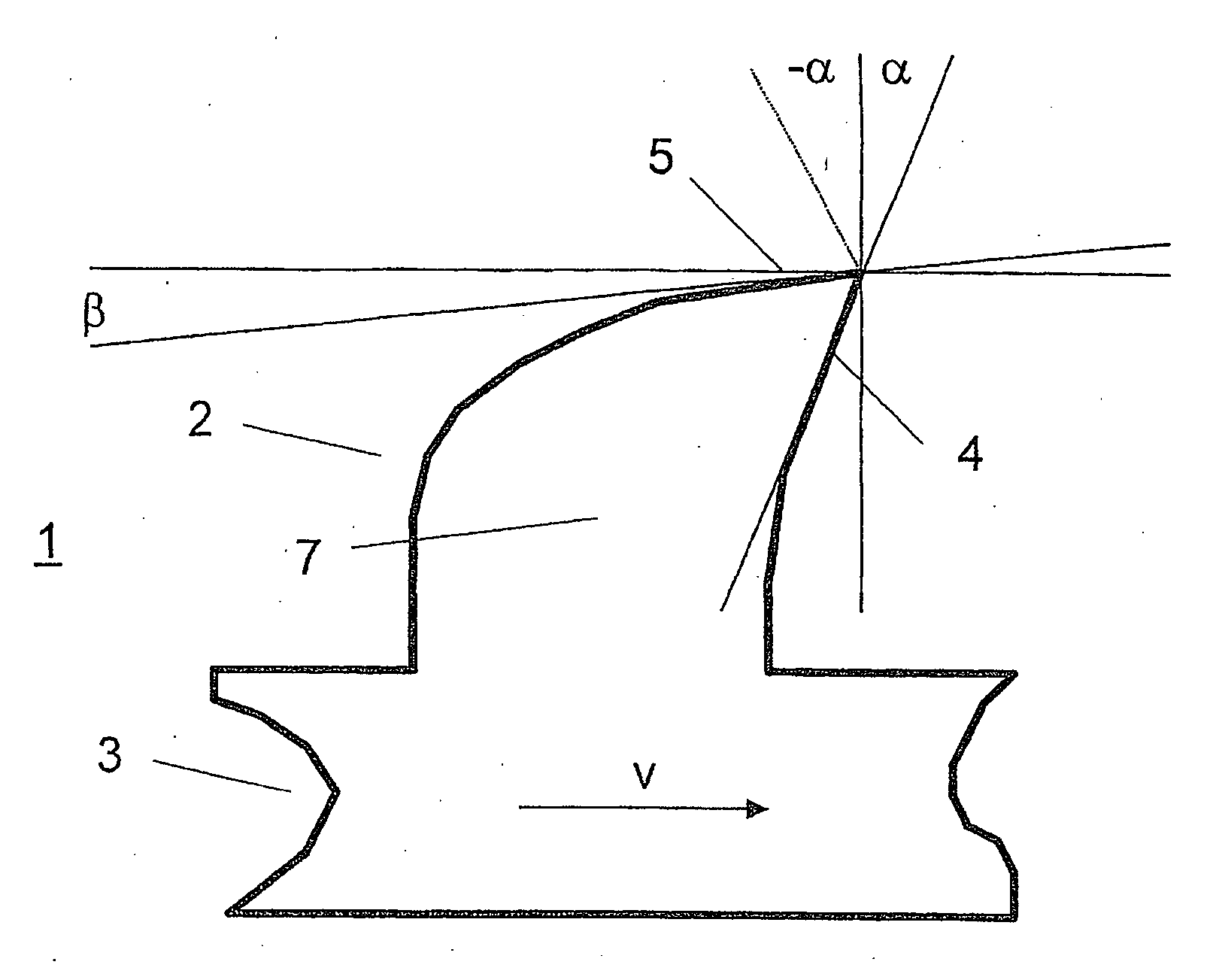

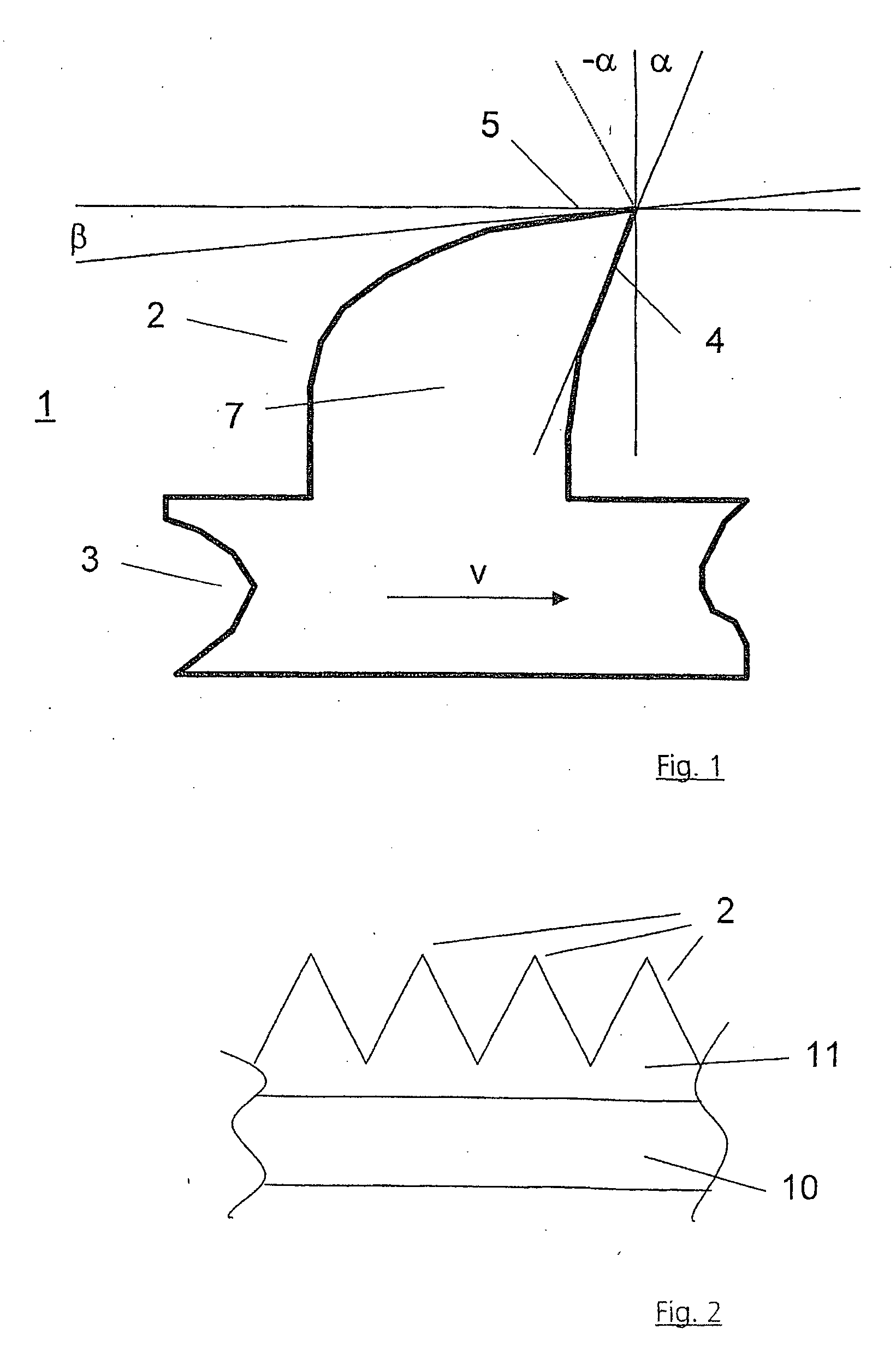

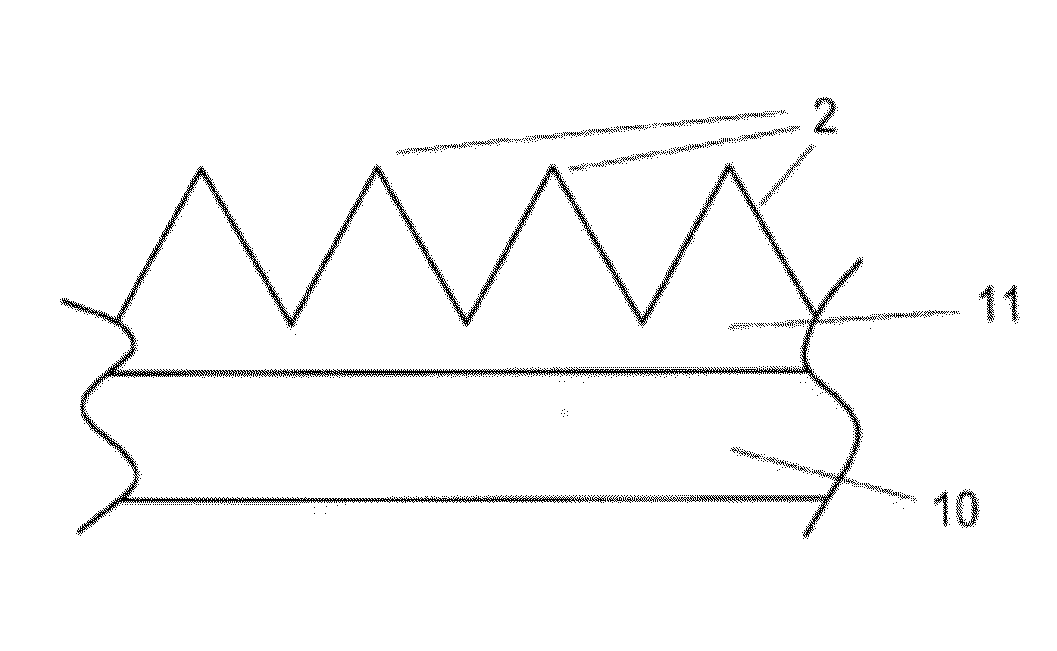

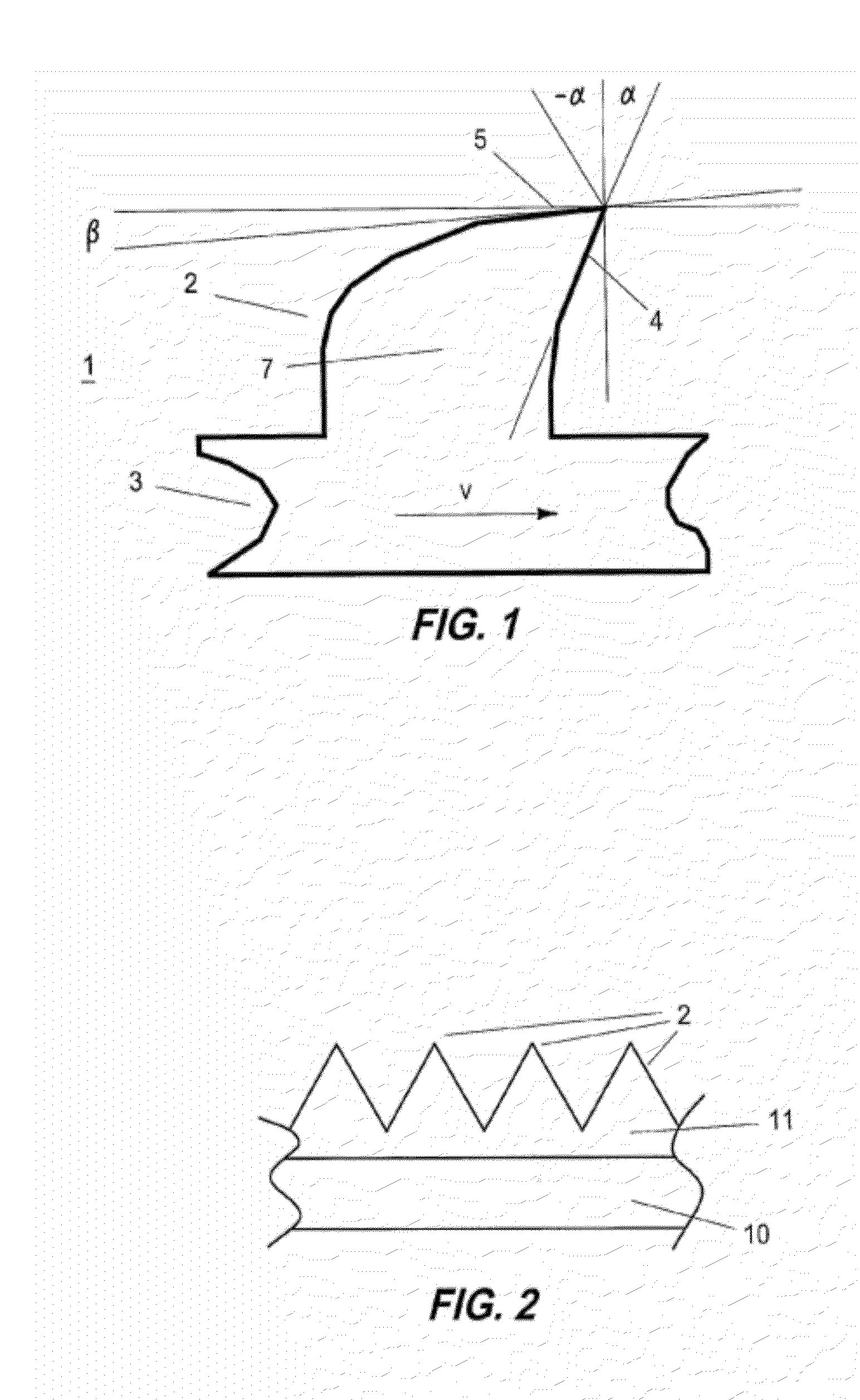

Saw band and method for the production of a saw band

InactiveUS20080052922A1Convenient coatingLess loadMetal sawing devicesMetal sawing tool makingBorideCarbide

A saw band of steel for a band-sawing machine has a band back and a row of teeth having a number of teeth, at least the row of teeth being provided with a hard material coating. According to the invention, this coating comprises one or more metals of subgroups IV, V or VI of the periodic system or aluminum or silicon and / or their nitrites, oxides, carbides, carbonitrides or borides of the aforementioned metals or mixtures thereof. A method according to the invention is a vacuum coating method, for example as PVD or paCVD.

Owner:OERLIKON TRADING AG TRUEBBACH

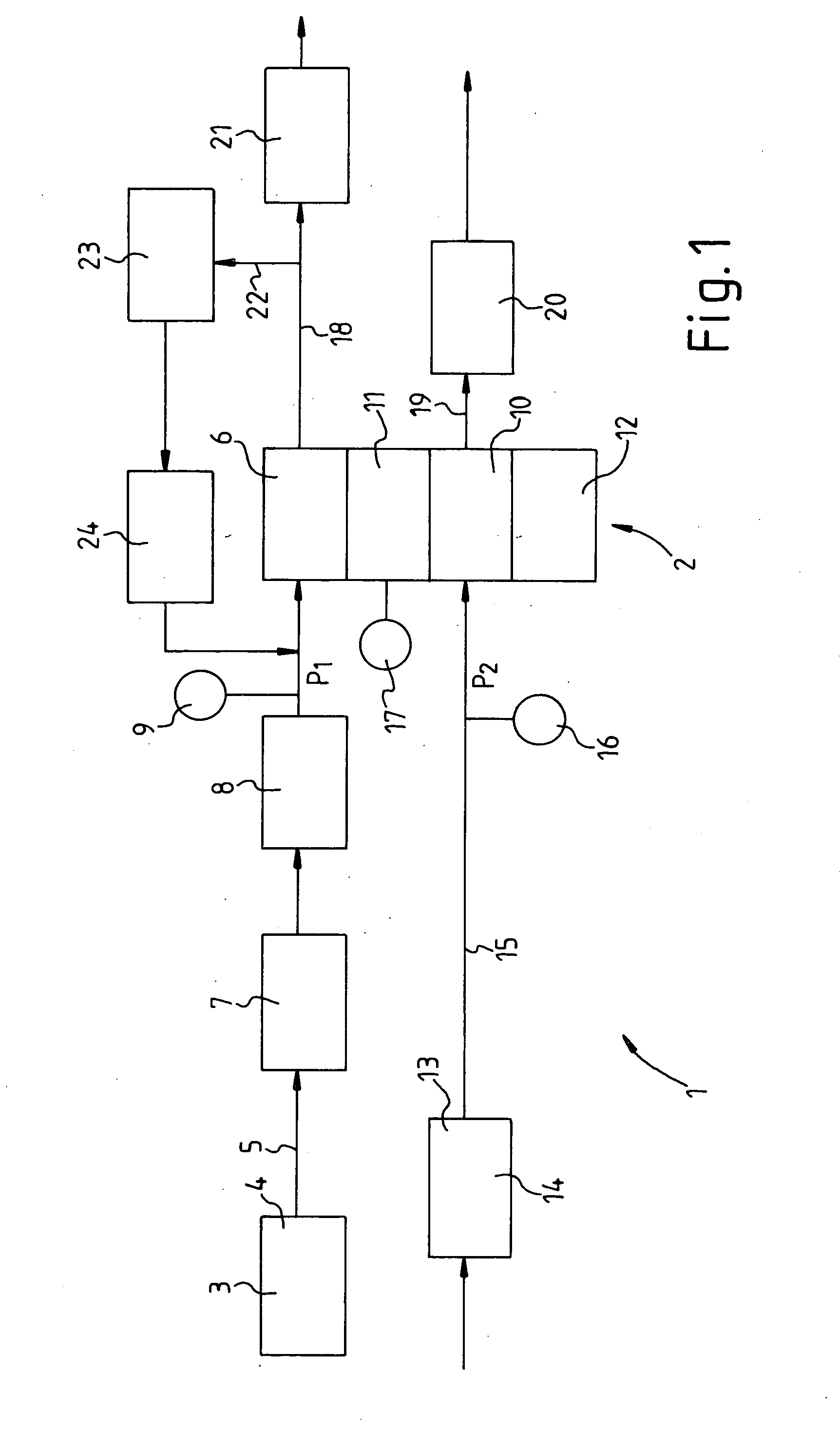

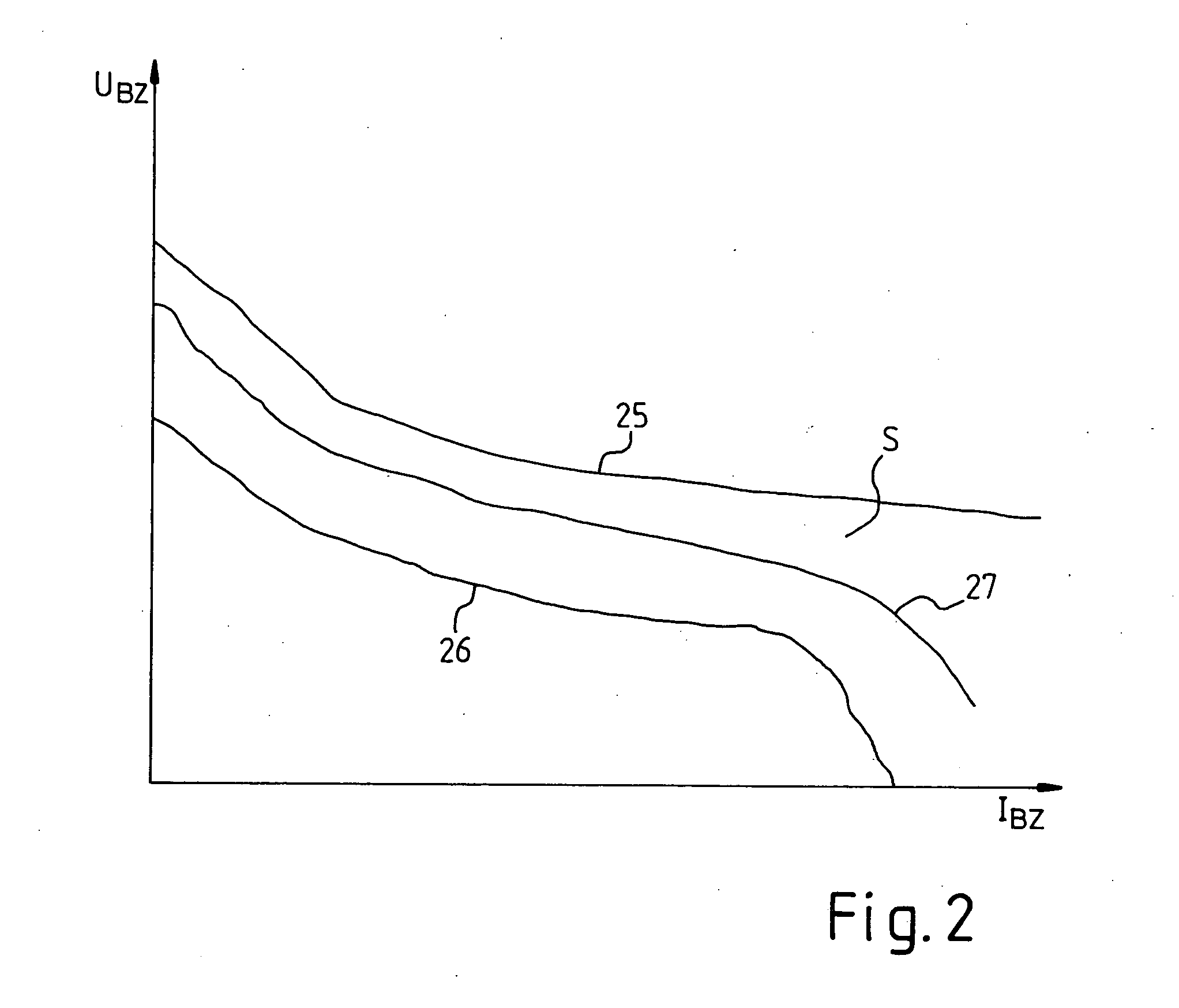

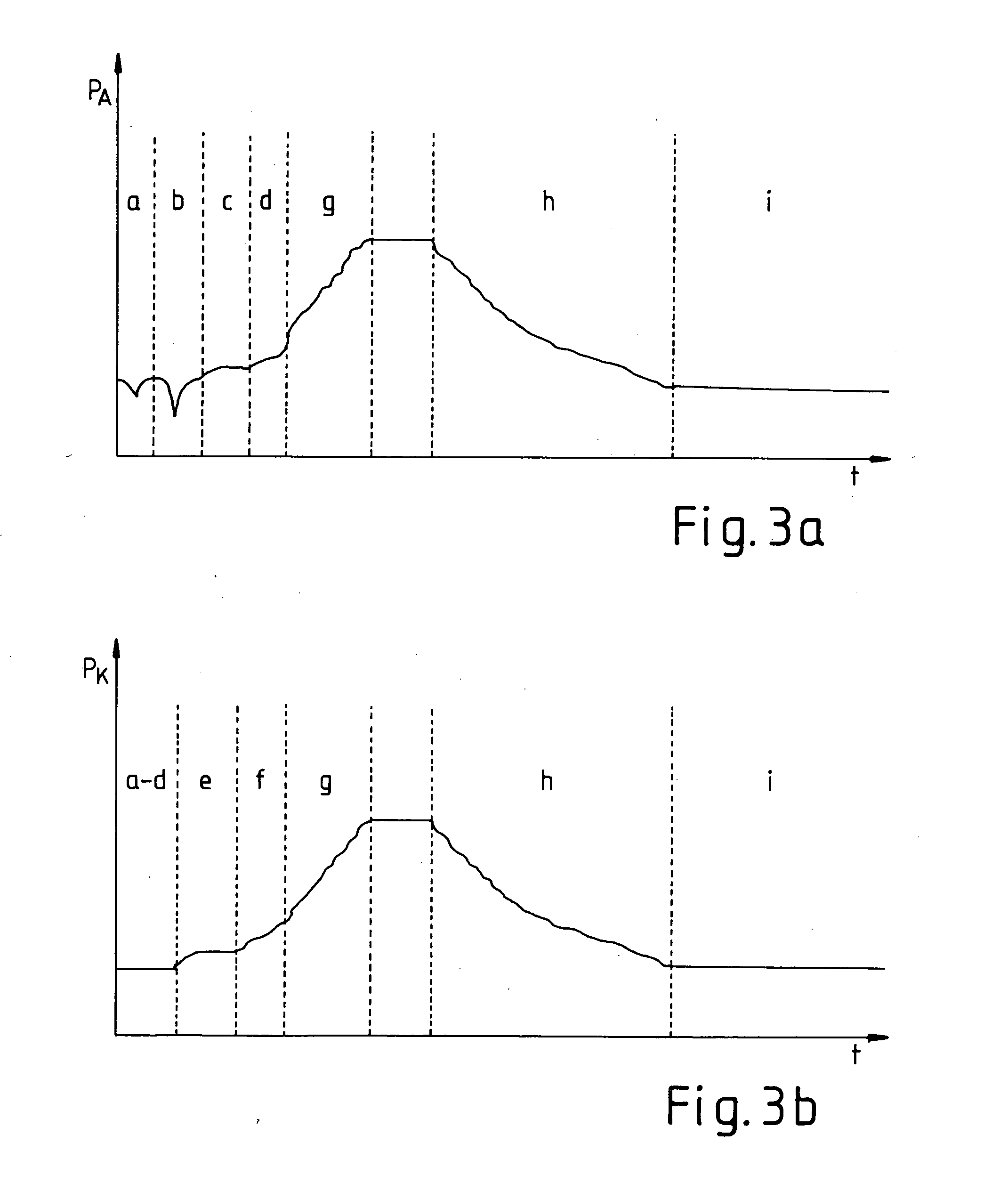

Apparatus for controlling a fuel cell device, and a fuel cell device

InactiveUS20050014042A1Improve reliabilityImprove securityFuel cell heat exchangeSolid electrolyte fuel cellsFuel cellsEnergy supply

An apparatus for controlling a fuel cell device for energy supply in a finished end product has a control unit for an operation of the fuel cell device, the control unit being formed so as to control control operational points in predetermined phases during the operation and to obtain an adjustable value of at least one device variable of the fuel cell device and to evaluate it with respect to at least one previously determined value of the device variable of the fuel cell device.

Owner:ROBERT BOSCH GMBH

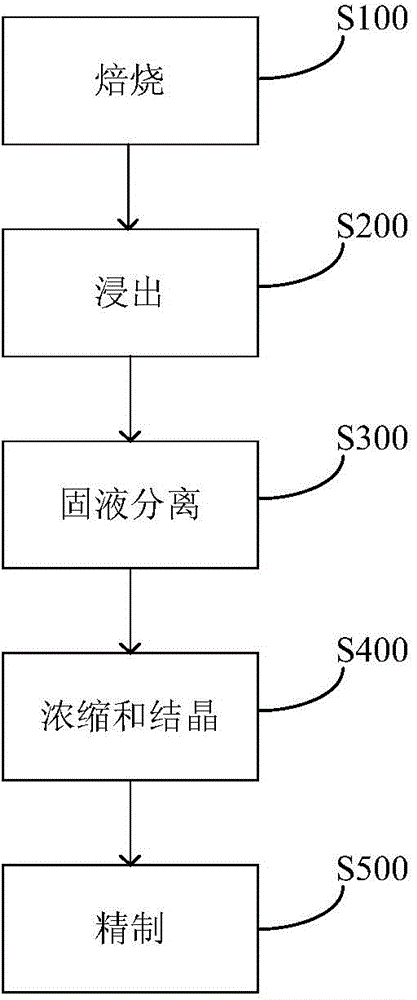

Method for producing aluminum oxide

The invention provides a method for producing aluminum oxide. The method comprises the following steps: mixing an aluminum-bearing mineral raw material with a roasting additive for roasting so as to obtain a roasted clinker, wherein the roasting additive is acid sulfate or a mixture of sulfate and sulfuric acid, and the molar ratio of sulfate and sulfuric acid is 1:1; immersing the roasted clinker by water to obtain leacheate; carrying out solid-liquid separation on the leacheate to obtain an infusion solution and filter residues; concentrating the infusion solution and standing for crystallization so as to obtain an aluminum salt coarse product; dissolving the aluminum salt coarse product in water and adjusting the pH value of the obtained solution to 8.5 by using ammonium water, and then filtering to obtain aluminum oxide. Aluminum oxide can be quickly and effectively produced by virtue of the method, and the method is relatively low in roasting temperature and energy-saving and has no special requirements for the content of aluminum oxide in the mineral raw material. The obtained product is high in purity and has few tailings, so that secondary pollution can be effectively avoided.

Owner:TSINGHUA UNIV +1

Method for utilizing biological enzyme pretreatment + potassium hydroxide alkaline process straw pulping to extract black liquor to produce potassium fulvic acid organic fertilizer

InactiveCN106699245AImprove biological activityRetain inorganic nutrientsPretreatment with alkaline reacting compoundsClimate change adaptationPotassiumPotassium hydroxide

The invention relates to a method for utilizing biological enzyme pretreatment + potassium hydroxide alkaline process straw pulping to extract black liquor to produce a potassium fulvic acid organic fertilizer and belongs to the field of organic fertilizer production. The method for producing the organic fertilizer comprises black liquor extraction after biological enzyme pretreatment, black liquor extraction after potassium hydroxide alkaline process straw cooking and production of the finished potassium fulvic acid organic fertilizer. According to the method, waste is turned into wealth, the novel biological enzyme pretreatment technology is utilized to extract the natural bioactive substance - fulvic acid which is very high in chemical activity and biological activity from the straw. Besides, inorganic nutrient such as nitrogen, potassium, calcium, magnesium, sulfur and silicon in straw stalk is reserved.

Owner:宁夏同创秸科生物科技有限公司

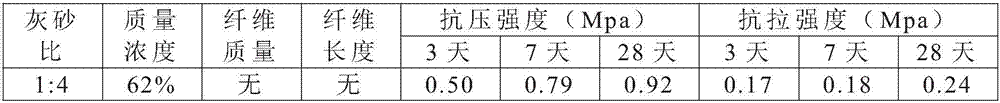

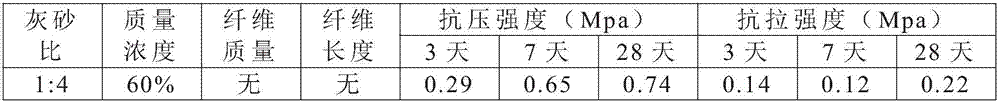

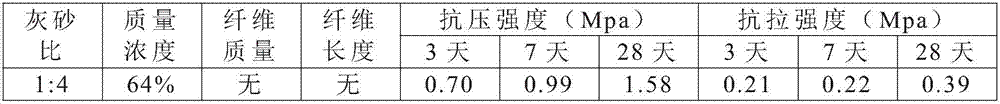

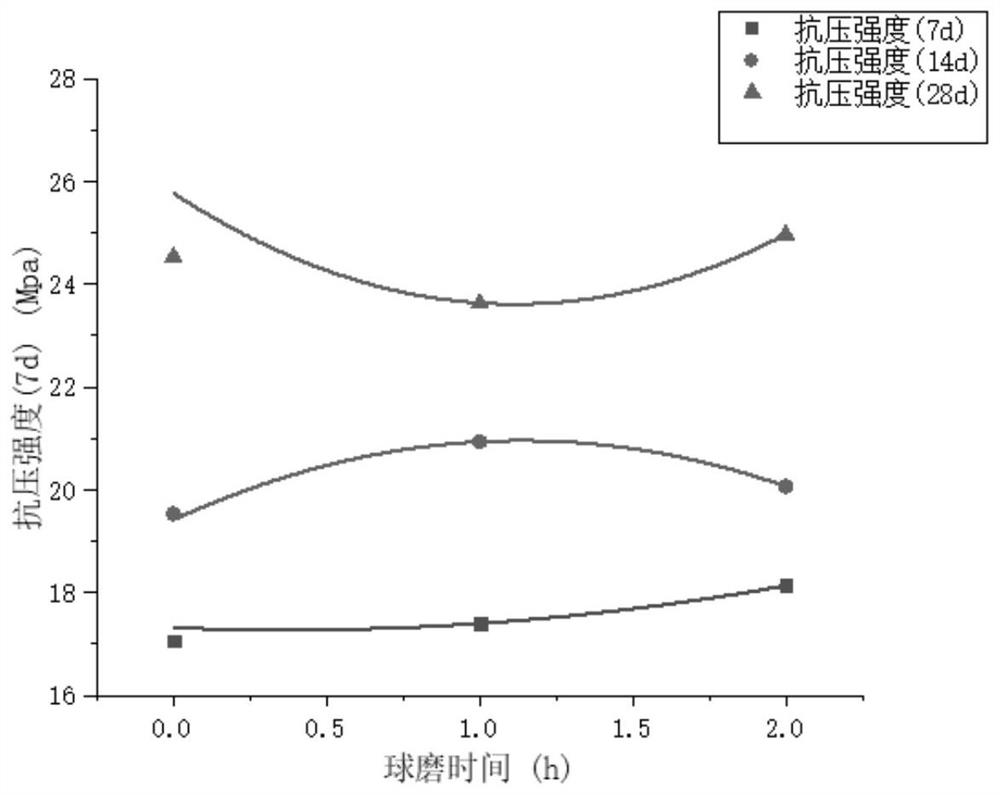

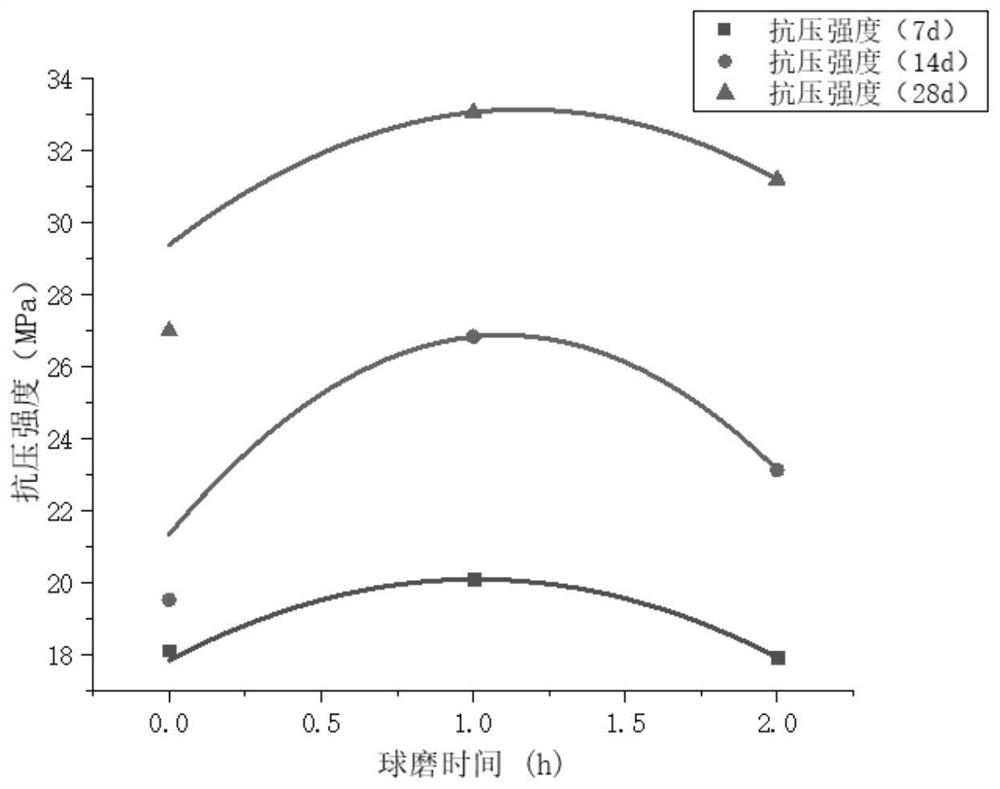

Application of polypropylene fiber-containing cemented filling material to filling mining

InactiveCN107500634AMeet the filling strength requirementsImprove mechanical propertiesMaterial fill-upFilling materialsSlurry

The invention discloses application of a polypropylene fiber-containing cemented filling material to filling mining, belonging to the technical field of filling materials for mines. The invention also provides the filling material, comprising polypropylene fiber, cement and mine tailings. The invention also provides filling slurry. The filling slurry comprises 1-3 parts of polypropylene fiber, 200-260 parts of cement, 975-1074 parts of fine tailings and 664-813 parts of water, wherein the fiber has a length of 6-12 cm, and the mass concentration of the filling slurry is 60-64% after mixing and stirring. According to the invention, doping of polypropylene fiber into the polypropylene fiber-containing cemented filling material can effectively overcome the problems of low strength and proneness to cracking of a fine-tailing filling body after curing and improve the compressive performance and fracture resistance of the filling body. With the fiber-containing filling material, the compressive strength and tensile strength of the filling body can meet the requirements of mining on the strength of the filling body, unit consumption of filling cement per cubic meter is reduced, and the utilization rate of the fine tailings is improved, so the polypropylene fiber-containing cemented filling material is an innovative filling material for mines and has a wide application range and good promotion value.

Owner:CENT SOUTH UNIV +1

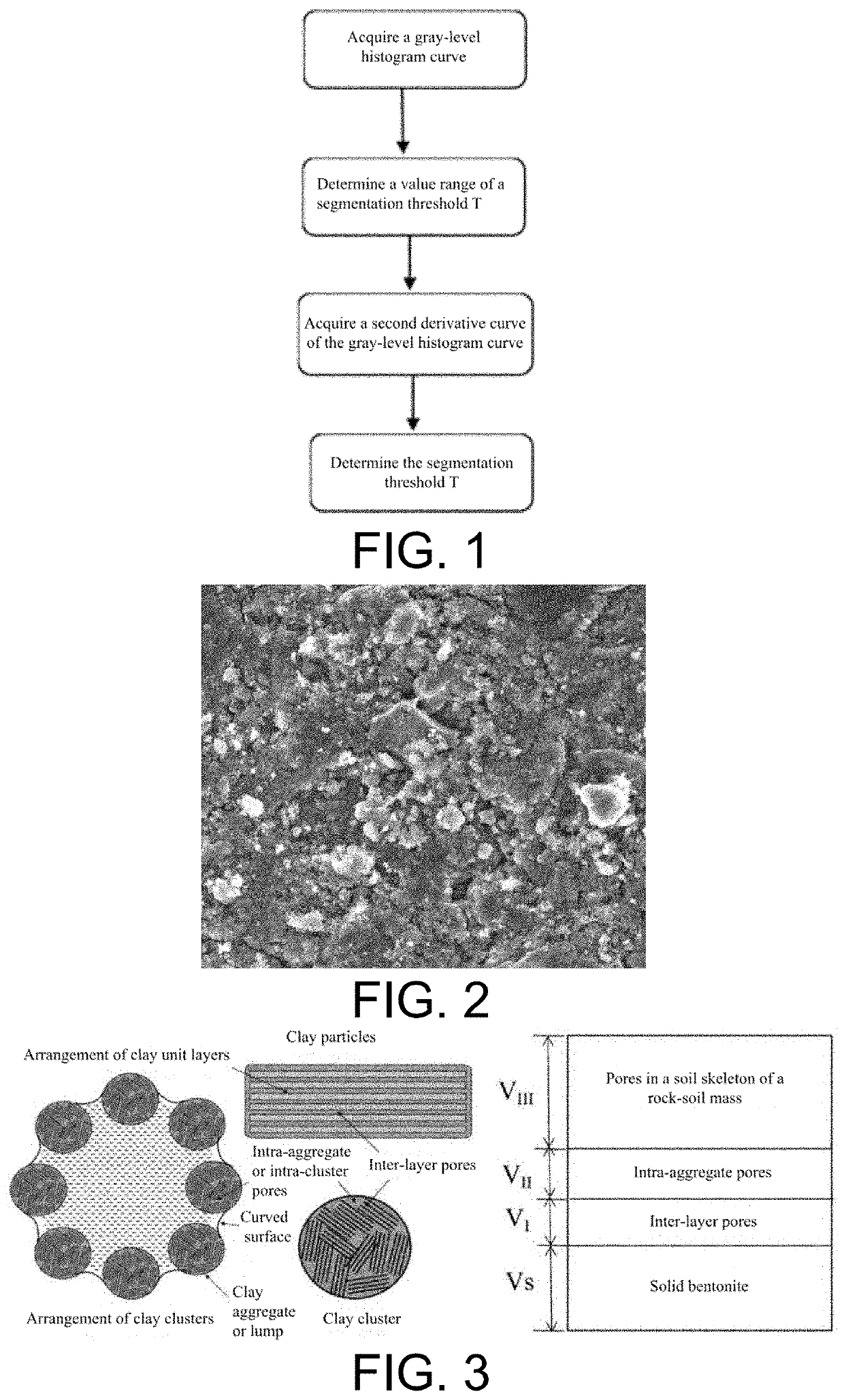

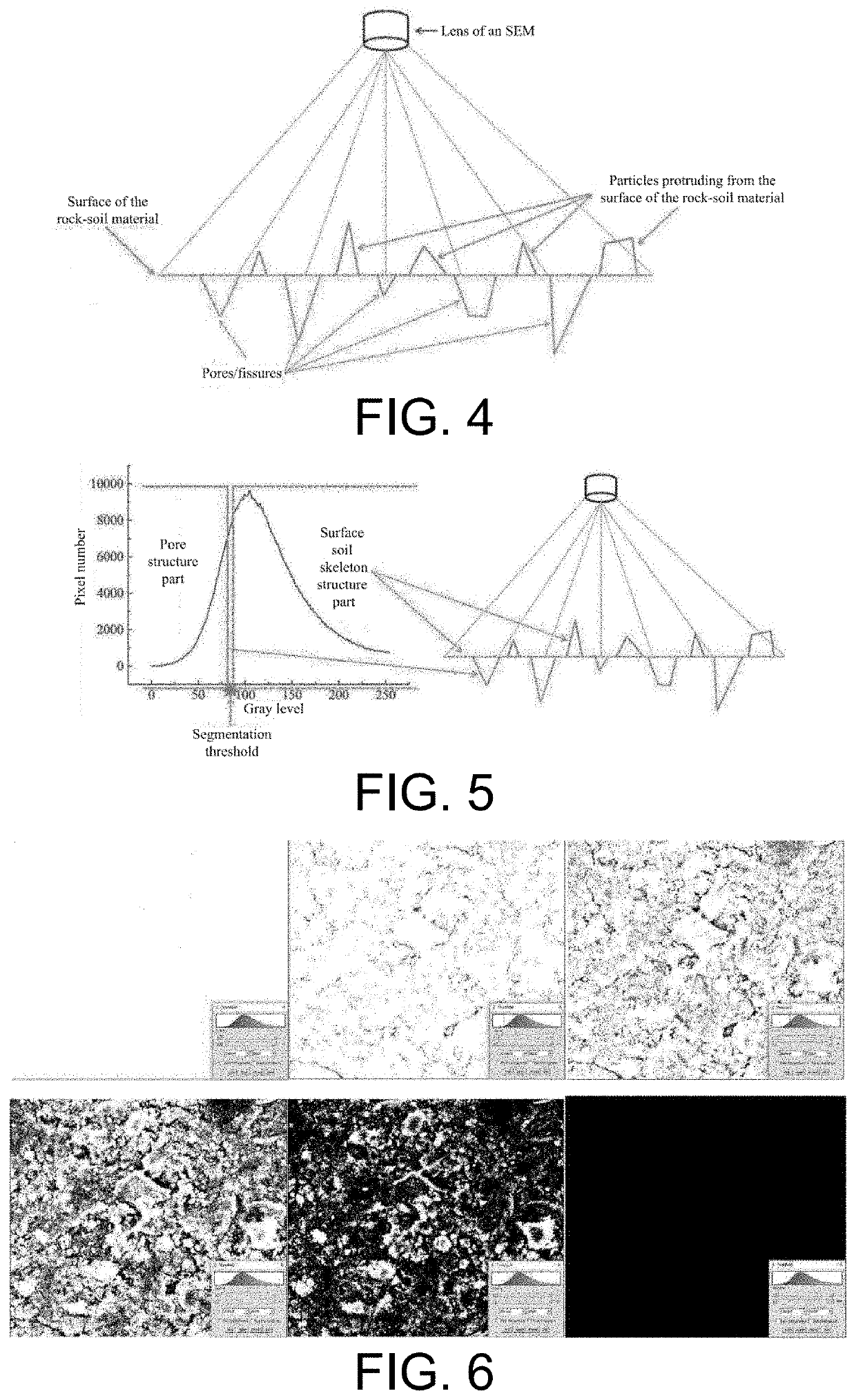

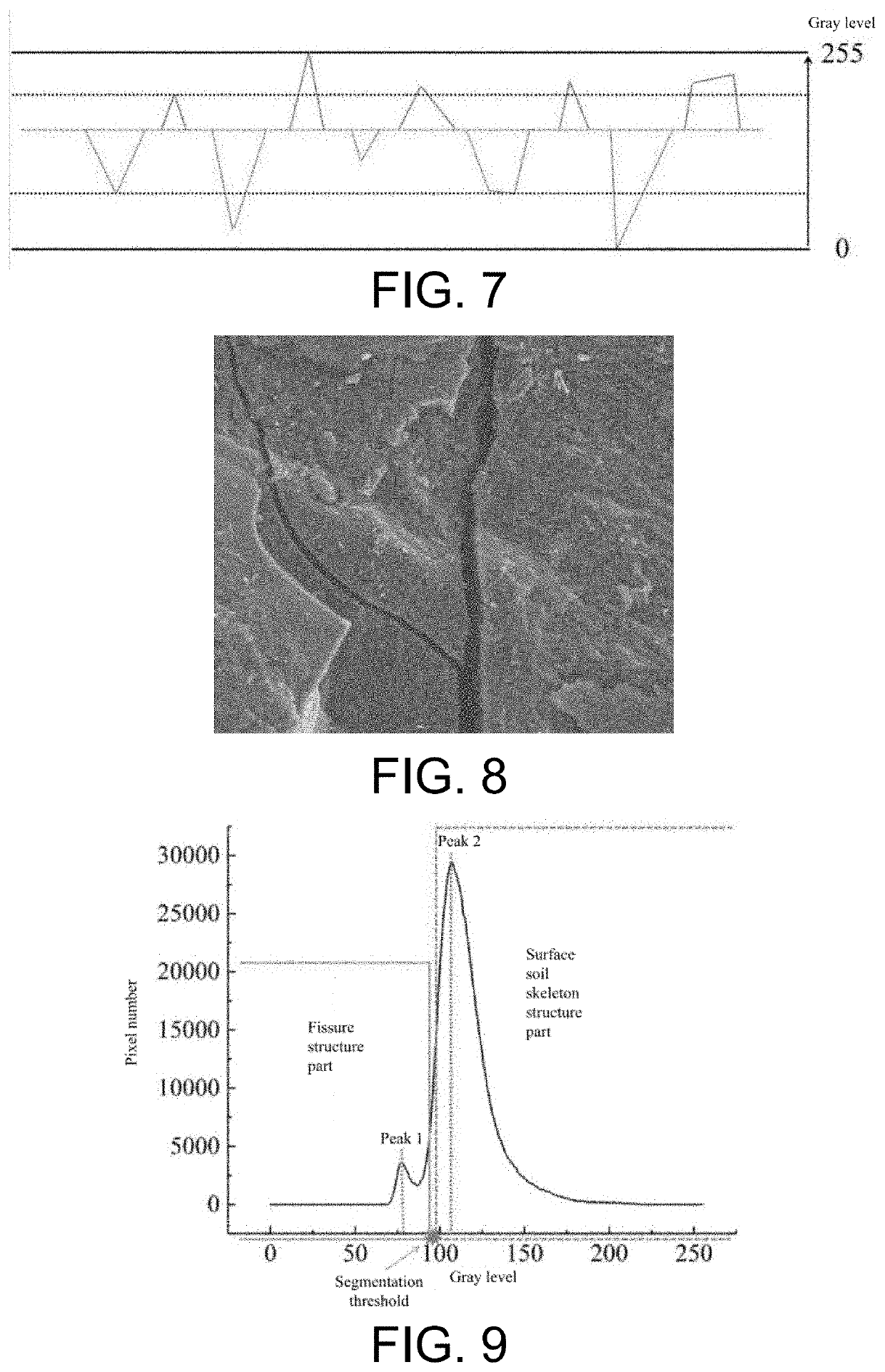

Method for determining segmentation threshold of digital image of rock-soil material

InactiveUS20210201497A1Complicated processAccurately studyImage enhancementImage analysisSoil skeletonSoil science

A method for determining a segmentation threshold of a digital image of a rock-soil material is disclosed. The method comprises the following steps: S1: acquiring a gray-level histogram curve of an SEM image of the rock-soil material; S2: determining a value range of a segmentation threshold T according to the gray-level histogram curve; S3: acquiring second derivatives of the gray-level histogram curve; and S4: determining the segmentation threshold T according to the second derivatives of the gray-level histogram curve and the value range of the segmentation threshold T. The present invention can rapidly and accurately determine the segmentation threshold of the digital image of the rock-soil material, and accurately distinguish a pore or fissure structure from a surface soil skeleton structure of the rock-soil material in the digital image.

Owner:CHINA UNIV OF MINING & TECH +1

Method of producing microbiological active organic fertilizer using waste mushroom dregs

InactiveCN1724481BSolve effective useAvoid pollutionBio-organic fraction processingOrganic fertiliser preparationMushroomFermentation

Owner:迟乃玉

Biological-material-tall stove

InactiveCN1936429AEasy centralized processingEasy to addDomestic stoves or rangesEnergy inputHearthBiological materials

This invention relates to a biological material ball stove including a fan, a secondary wind pipe, a valve, a flowmeter, a supply pipe, a gasification agent pipe, a loop air pre-heating chamber, a loop air conduction chamber, a stove head, a stove body, a heat preservation layer, an inner container and biological material balls, in which, the upper part of outside of the stove is a water tank made of stainless steel, the fan is connected with the loop air pre-heating chamber at the bottom of the hearth via a gasification agent pipe, the heat preservation layer, the inner container and the hearth are orderly placed in the body, a grate is under the hearth and the stove head is above it, the loop air conduction chamber is at the bottom of the head, the secondary wind pipe and the chimney are at the outside wall of the conduction chamber with a stage along the internal wall for placing a stove cover.

Owner:刘春生

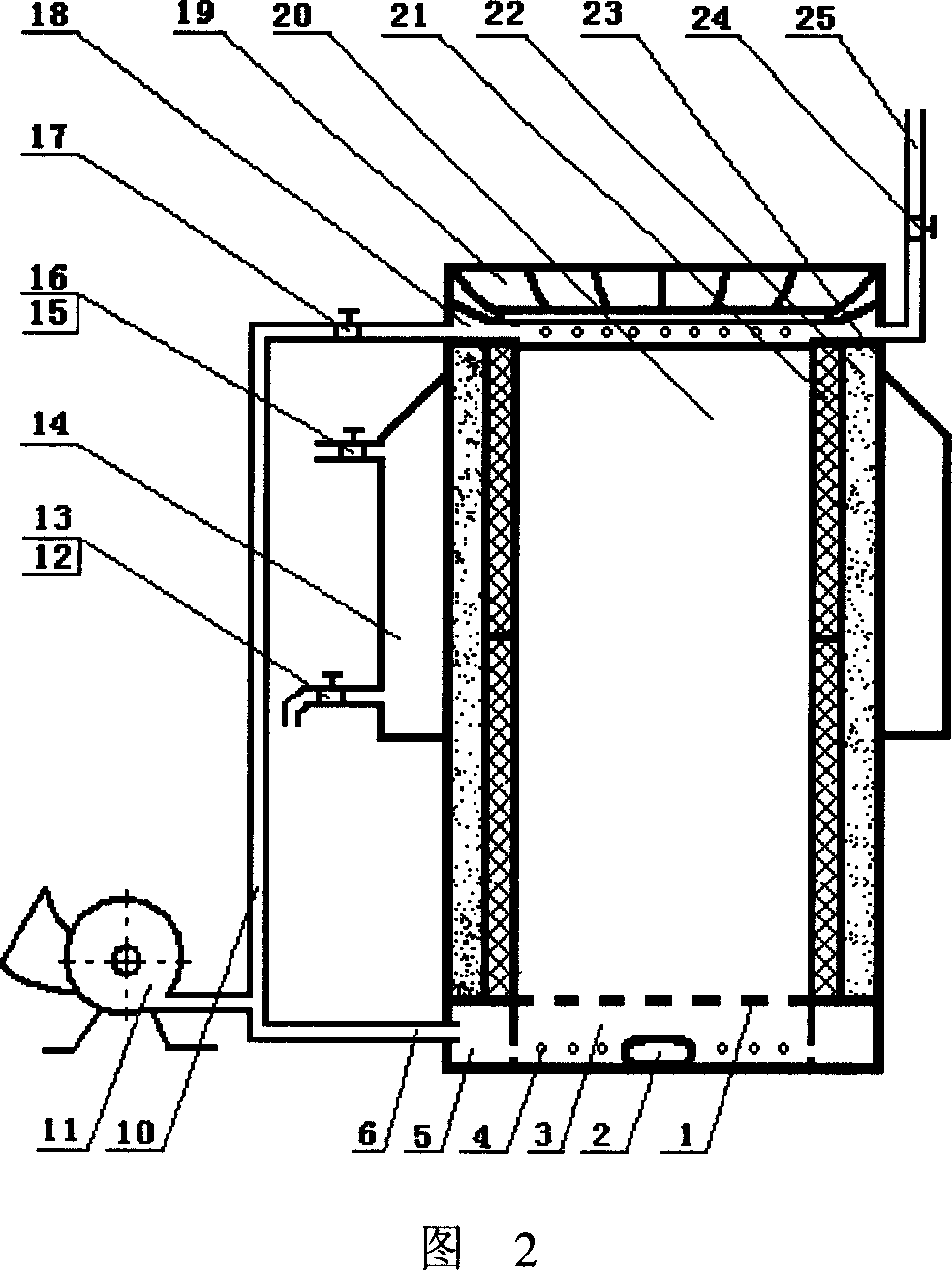

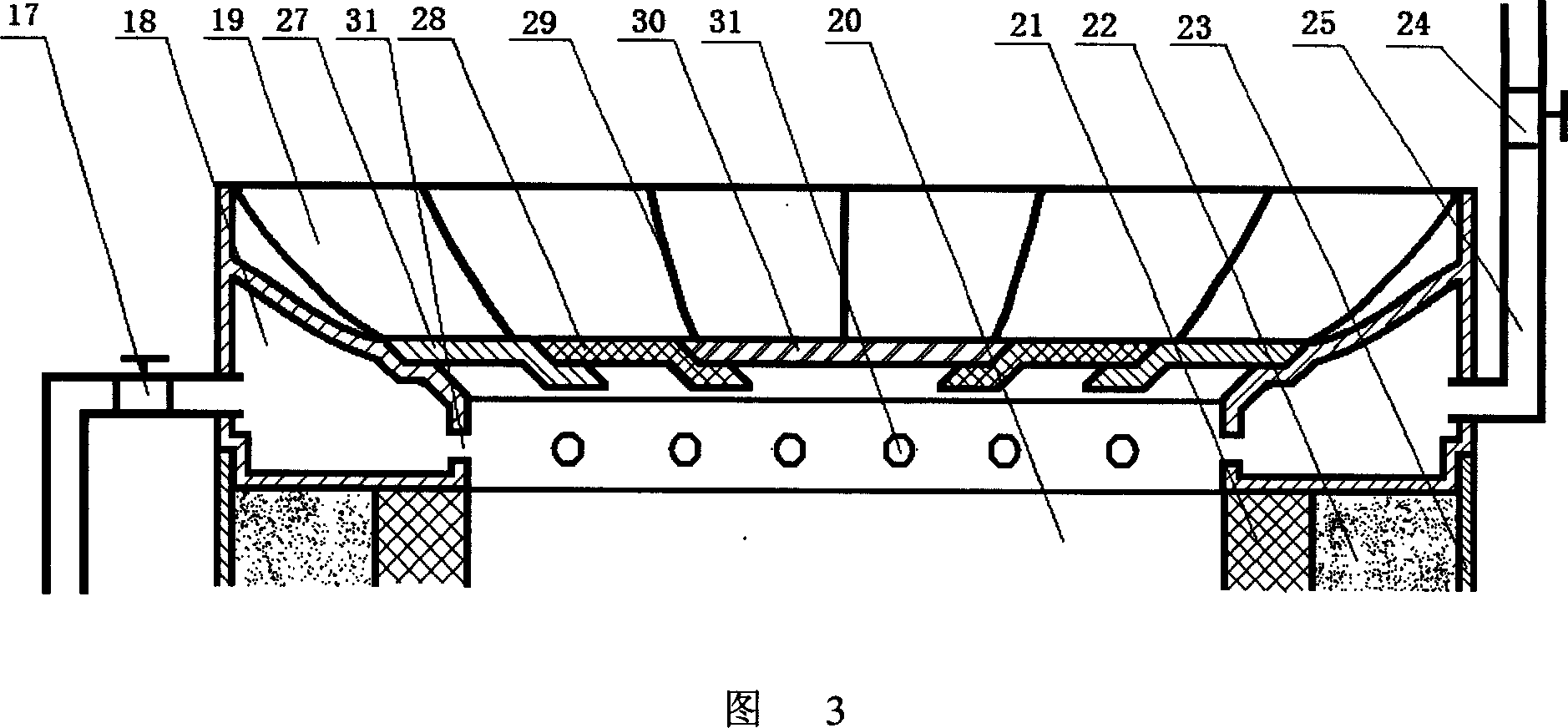

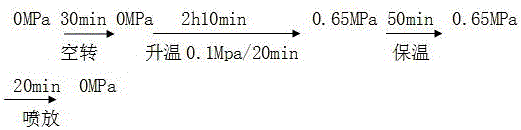

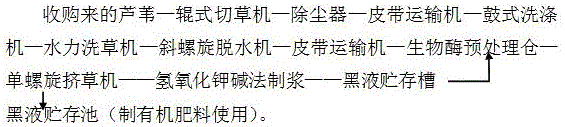

Production method of potassium fulvate organic fertilizer prepared from black liquor extracted through biological enzyme pretreatment and potassium hydroxide alkaline reed pulping

PendingCN106747973AEnhanced adhesion and fast absorptionSmall particlesSewage/sludge fertilisersFertilizer mixturesChemistryPotassium hydroxide

The invention discloses a production method of a potassium fulvate organic fertilizer prepared from black liquor extracted through biological enzyme pretreatment and potassium hydroxide alkaline reed pulping, and belongs to the field of fertilizer production. The production method comprises the following steps: using biological enzymes to process reeds to extract black liquor; boiling reeds to extract black liquor through a potassium hydroxide alkaline method, and producing finished products of potassium fulvate organic fertilizer. The biological enzyme pretreatment comprises steps of preparing raw materials through a wet method, using biological enzymes to process reeds, and storing the black liquor rich in potassium fulvate. The potassium hydroxide alkaline method comprises the following steps: extruding reeds, which has been preprocessed by biological enzymes, mixing the reeds with potassium hydroxide in a pre-soaking machine, boiling and steaming the mixture in a steam ball, and collecting the black liquor after steaming and boiling. The organic fertilizer production comprises steps of black liquor evaporation and concentration, pulp spraying and granulation, hot-cold sieving, and finished product package. The wastes are converted into valuable resources. The soil particle structure is improved. The soil is loosened. The water and fertilizer retaining performance of soil is enhanced.

Owner:宁夏同创秸科生物科技有限公司

Coating material, coating and aluminum foil

InactiveUS20050058827A1Solve effective useEfficient use ofGlass/slag layered productsSpecial surfacesCross-linkFilling materials

A coating material, in particular for high temperature applications, comprises a binding agent and at least one filler material, which can be deposited on a metal surface. For this, the binding agent contains at least one siloxane with an organic residual share of less than 25 weight %. It is preferable if the siloxane or siloxanes is (are) cross-linked three and / or four times.

Owner:NANOX

Loquat leaf beverage processing method

InactiveCN101310627AGood economic and social benefitsReduce process costFood preparationNutrientOrchard

The invention discloses a method for processing a loquat leaf beverage, which comprises the steps of cleaning, disinsectization, sterilizing, rinsing, spreading and drying, water extracting, cooling and filtrating, blending, sterilizing and stocking. The processing method extracts the functional substances of the loquat leaf according to the characteristic that the loquat leaf is rich in compounds containing flavone, comparatively more inorganic salt, protein, glucide, amino acid needed by the human body and other nutrients, different edulcorants, antioxidants and complex densifiers are added to produce the beverage, which not only improves the added value of resources, but also increases the income of fruit growers and has remarkable economic benefits and social benefits. Fallen loquat leaves are usually taken as waste and burnt in loquat orchards, which not only wastes resources, but also pollutes the environment. The processing method takes the fallen loquat leaves as raw material, thereby utilizing waste effectively.

Owner:FUJIAN AGRI & FORESTRY UNIV

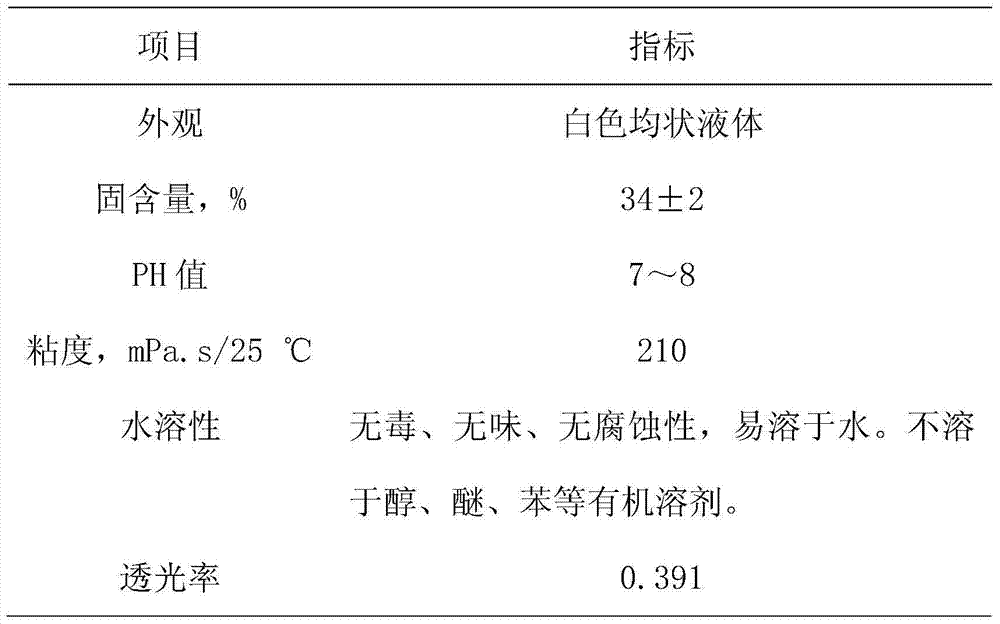

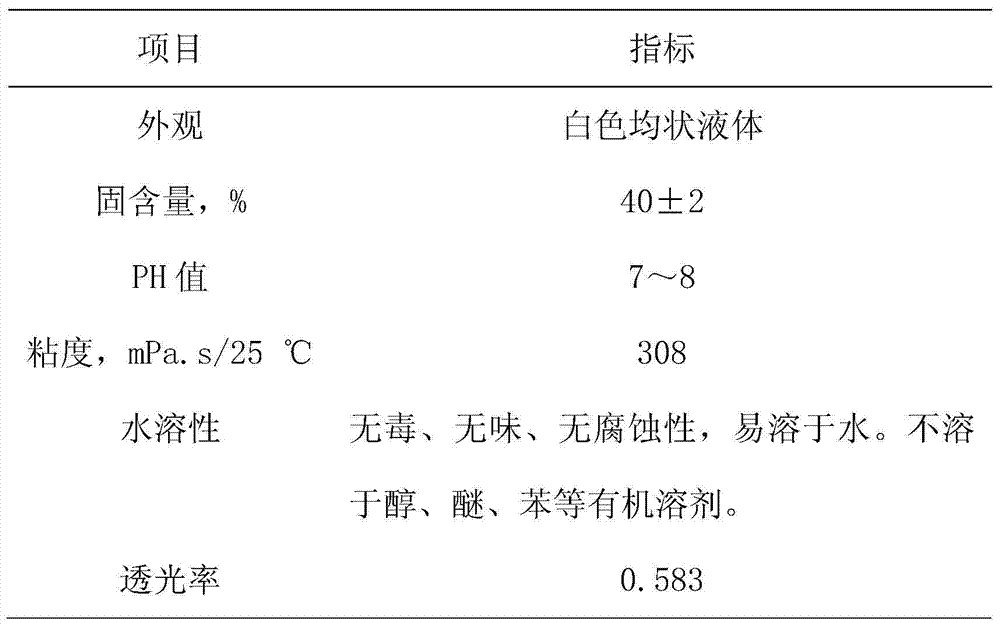

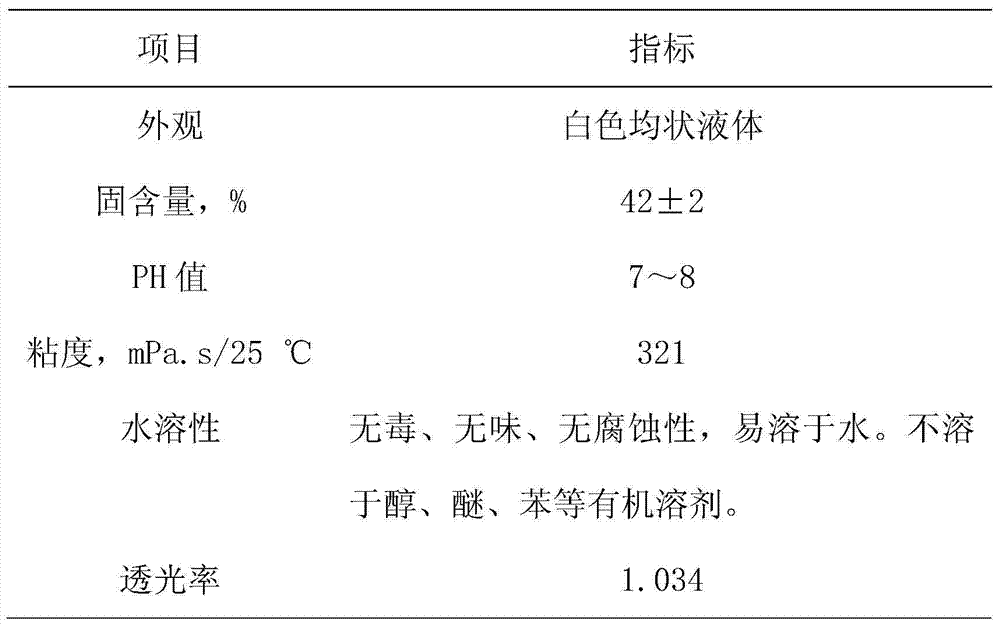

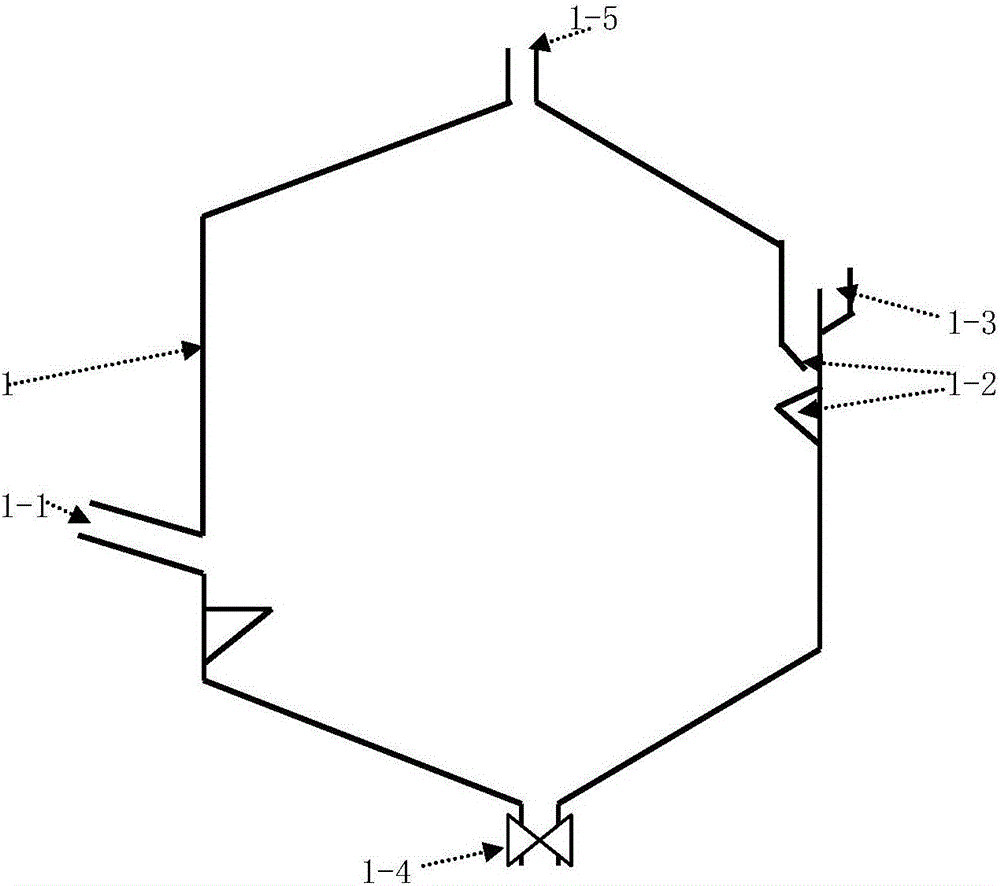

Carboxymethylation modification method and applications of semi-cellulose in waste liquor from viscose fiber production

The invention relates to a carboxymethylation modification method and applications of semi-cellulose in waste liquor from viscose fiber production. The modification method comprises the steps of: adding monochloroacetic acid in a raw material which is alkaliferous semi-cellulose extracted from the waste liquor from viscose fiber production, reacting for 120-180min at 70-90DEG C, cooling, standing, washing supernated liquor with 90% ethanol, precipitating, and performing suction filtration to obtain a crude product; dissolving the crude product into water, and performing centrifugal separation; washing supernated liquor with 90% ethanol, precipitating, filtering, performing vacuum drying for 24h to obtain a carboxymethyl semi-cellulose product. After being applied to dispersing agents of coating, printing and dyeing, industrial water treatment and the like, the modified carboxymethyl semi-cellulose product has good adsorportion property, is low in usage amount and good in dispersity. The alkaliferous semi-cellulose extracted from the waste viscose fiber production liquor is subjected to carboxymethylation modification, the carboxymethylation modification method is simple in technology, easy to operate and low in production cost, the hydrophilicity of the modified semi-cellulose is greatly improved, the application performance is good, and the waste liquor pollution and the semi-cellulose plant resource reutilization problems can be reasonably solved.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

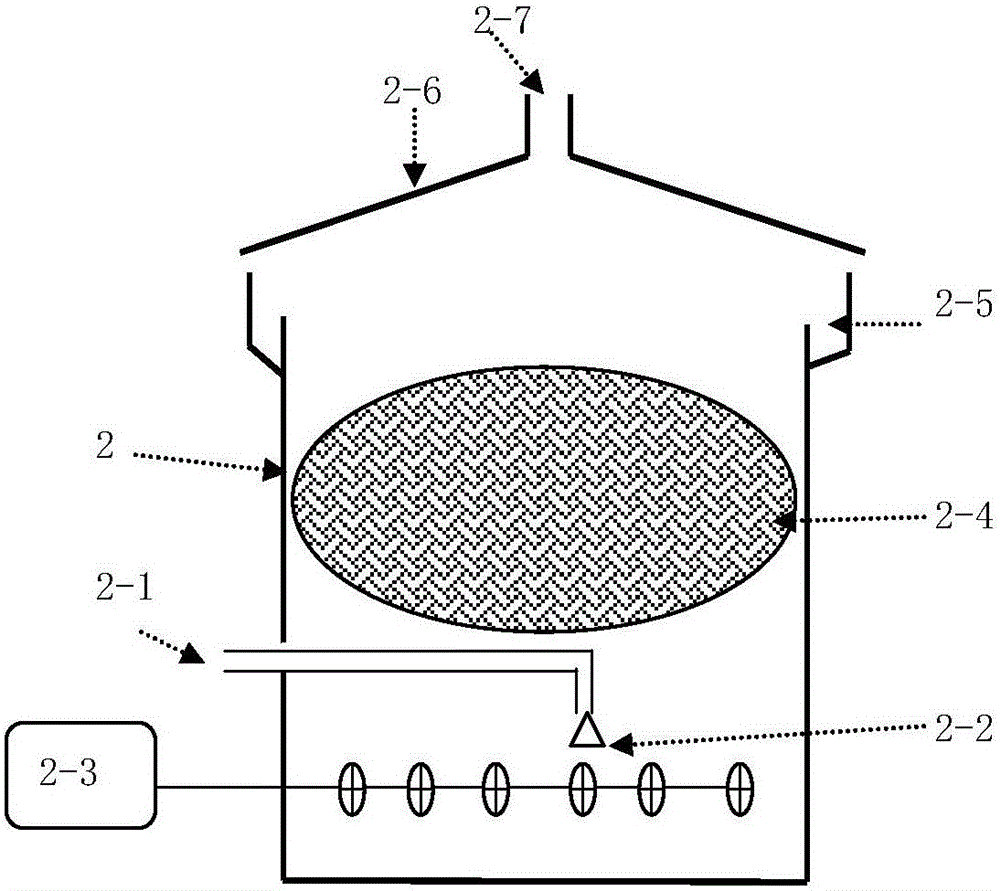

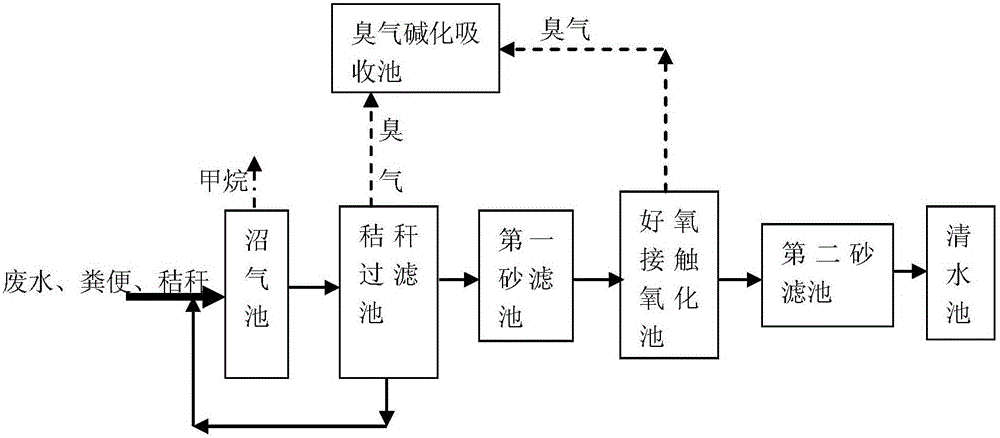

Large breeding farm waste treatment device and method

InactiveCN105753263ASolve pollutionSolve effective useTreatment using aerobic processesTreatment involving filtrationChemical reactionCatalytic oxidation

The invention relates to a large breeding farm waste treatment device which comprises a solid and liquid treatment system and a smelly gas treatment system.The solid and liquid treatment system comprises a methane tank, a straw filter tank, a first sand filter tank, an aerobiotic catalytic oxidation tank, a second sand filter tank and a clean water tank.The methane tank is of a cylindrical structure and is provided with a methane tank feeding port used for waste water, excrement and treated straw to enter.The straw filter tank is of a cuboid structure, and a straw filter tank water inlet pipe is arranged on the upper portion of the straw filter tank and is communicated with a straw filter tank water distribution pipe.Outlet water of the second sand filter tank enters the clean water tank to be recycled.The smelly gas treatment system comprises a draught fan and a smelly gas alkalization absorption tank; after smelly gas enters the smelly gas alkalization absorption tank, pollution substances in the gas are subjected to a chemical reaction with an alkali solution, and the smelly gas is treated into clean gas which is emitted with the standard met.

Owner:CHANGZHOU UNIV

Saw Band and Method for the Production of a Saw Band

InactiveUS20120017742A1Convenient coatingLess loadExhaust apparatusVacuum evaporation coatingBorideNitrite

Owner:OERLIKON TRADING AG TRUEBBACH

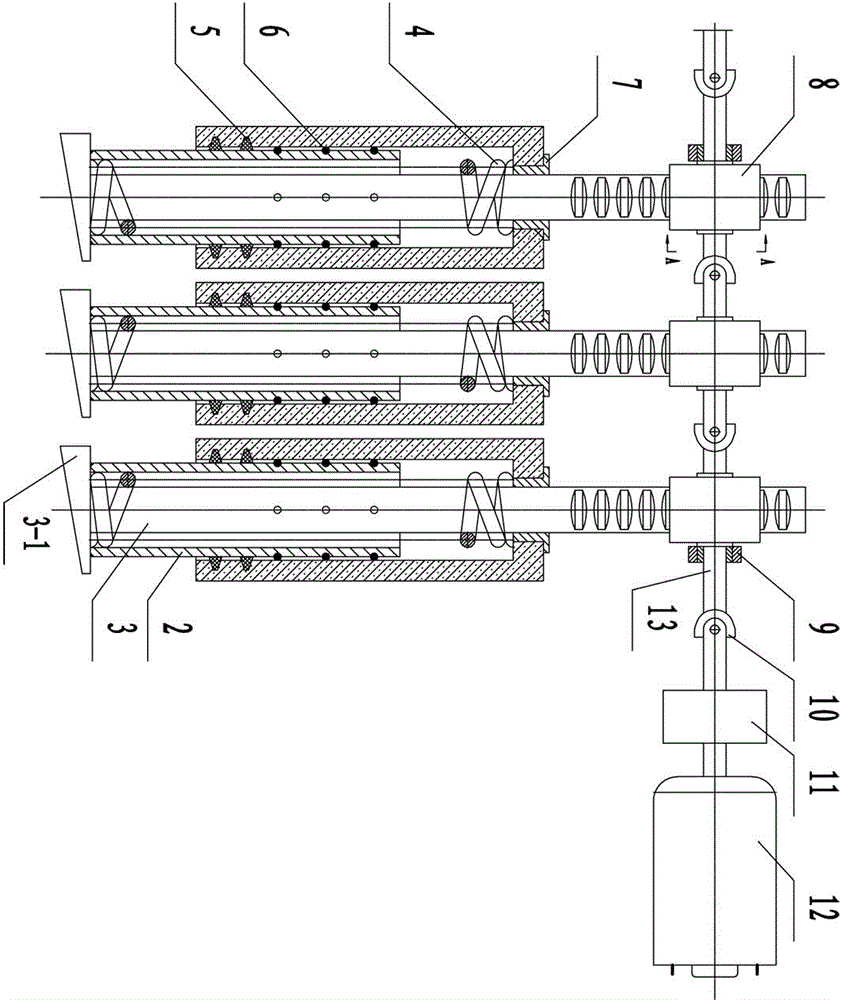

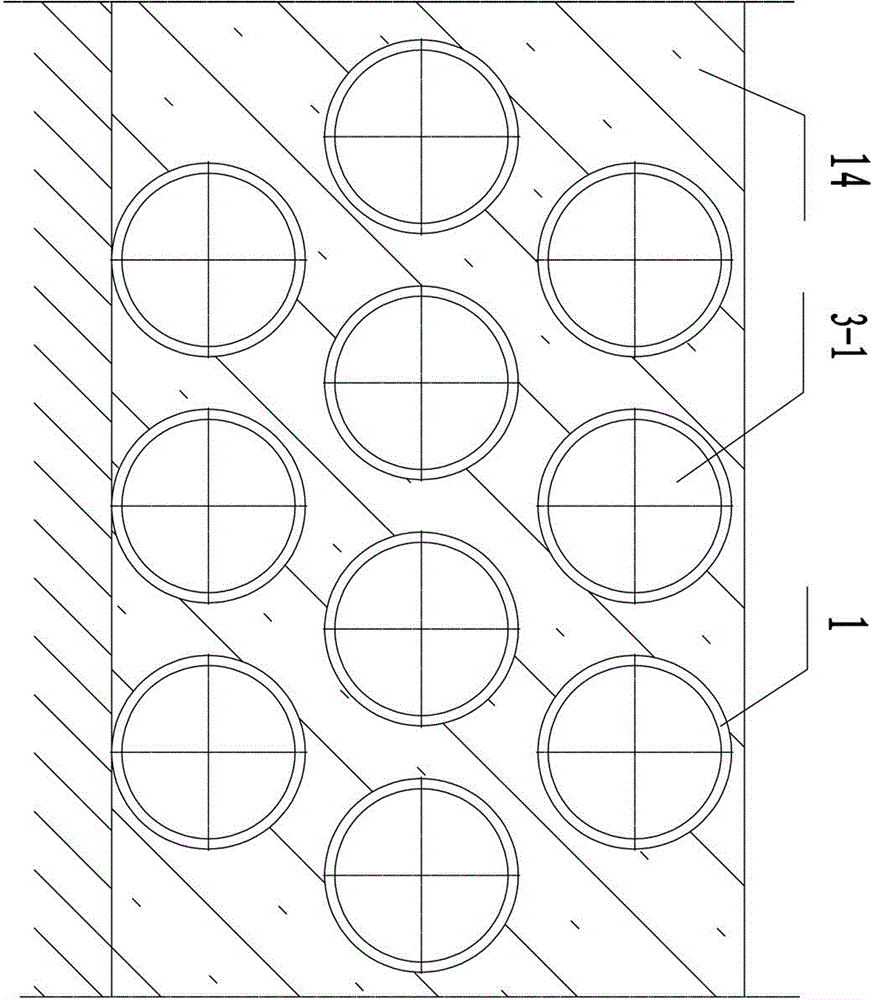

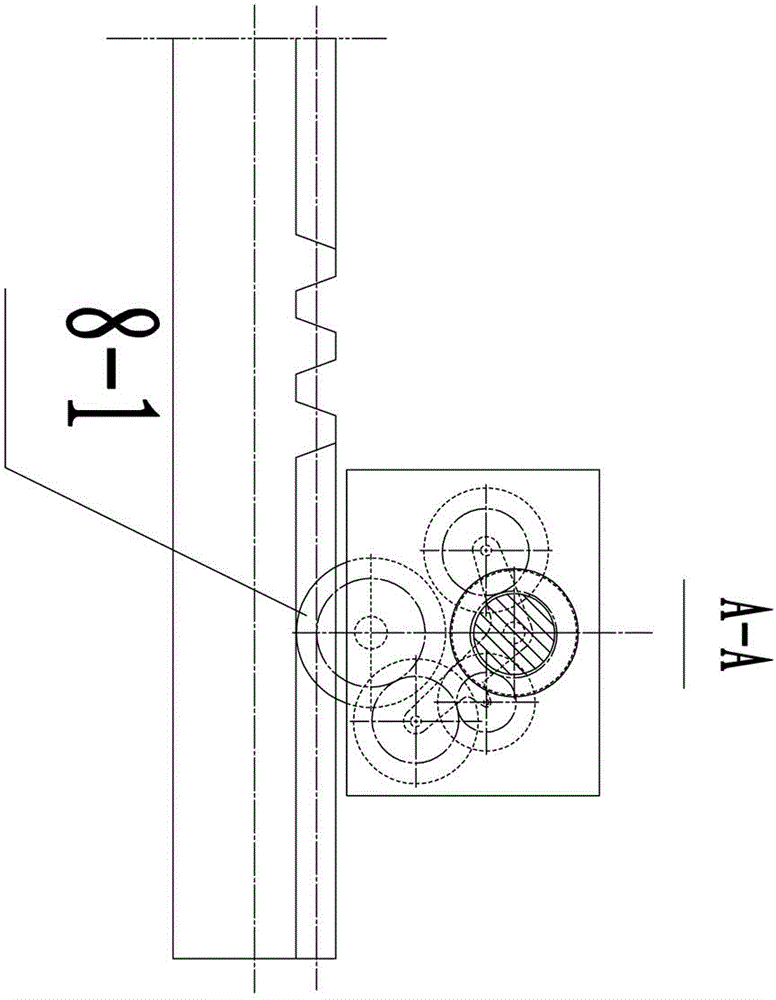

Device for generating electricity by tide

ActiveCN104405573ASolve effective useTo achieve reinforcementMachines/enginesEngine componentsElectricityGear wheel

A device for generating electricity by tide solves the problem of electricity generation by marine resources. The device comprises culvert pipes, piston sleeves, rack type piston rods, piston rod heads, compression springs, sealing strips, steel balls, guide sleeves, gearboxes, a set of transmission gears, a supporting base, universal couplers, a flywheel, an electricity generator and an output shaft. Piston bushes are arranged in the culvert pipes; the outer diameter of the piston sleeves is matched with inner holes of the culvert pipes, and the piston sleeves are sealed by the sealing strips; a set of ball sockets are arranged on the outer diameter surfaces of the piston sleeves; the steel balls are embedded into the ball sockets; one end of each rack type piston rod is connected with the corresponding piston sleeve through the corresponding piston rod head, and the other ends of the rack type piston rods are matched with inner holes of the guide sleeves; the compression springs are arranged between the inner holes of the piston sleeves and the rack type piston rods; the rack portions of the rack type piston rods are meshed with the transmission gears in the gearboxes; output of reciprocating motion of the rack type piston rods is in one-way rotation, and the gearboxes are fixed to the supporting base; and the output shaft of the gearboxes is in shaft connection with the electricity generator through the universal couplers and the flywheel, and therefore electric energy is output. According to the device, resources are effectively utilized, and benefits are giant.

Owner:SHENZHEN PUFANG ENVIRONMENTAL PROTECTION DEV

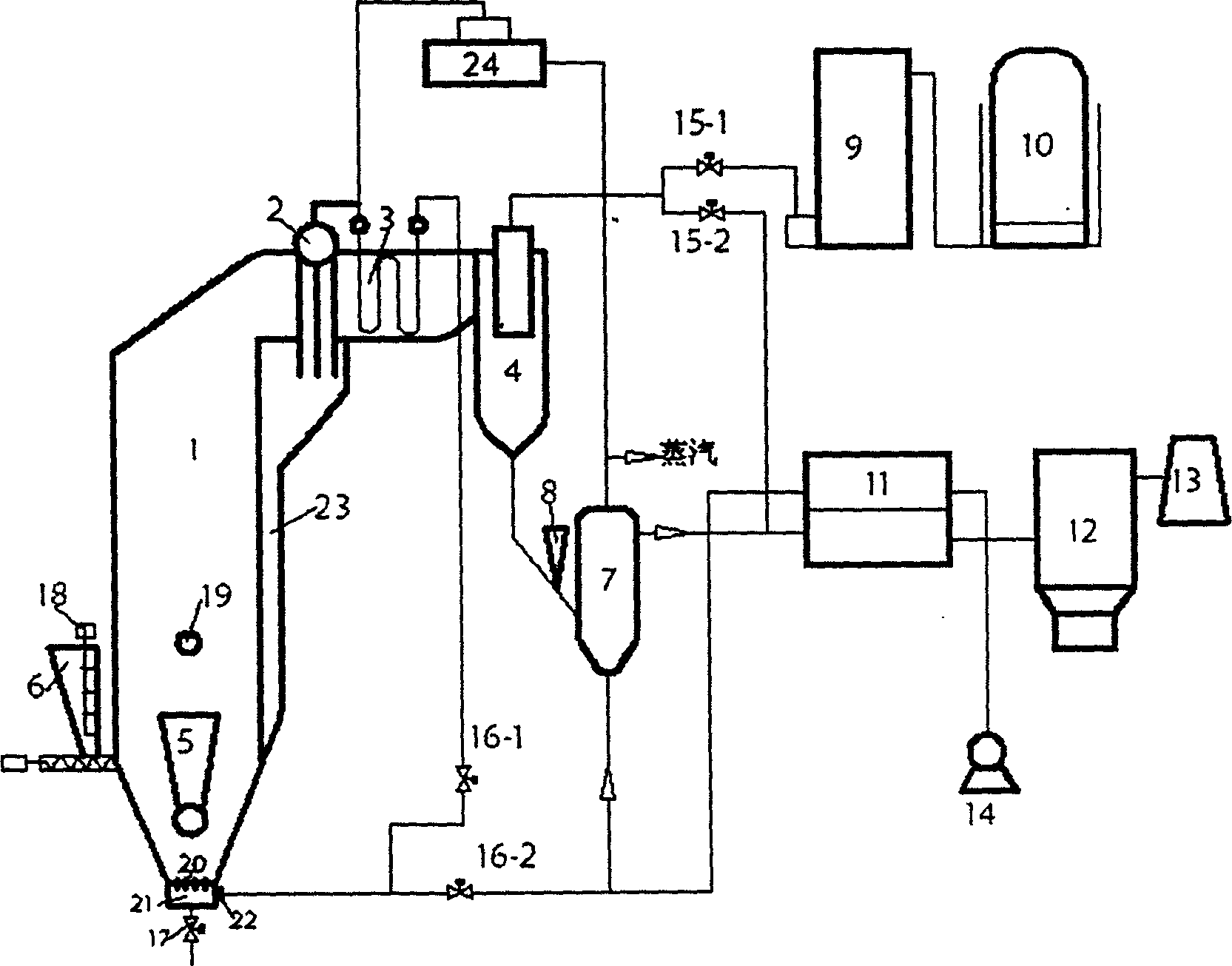

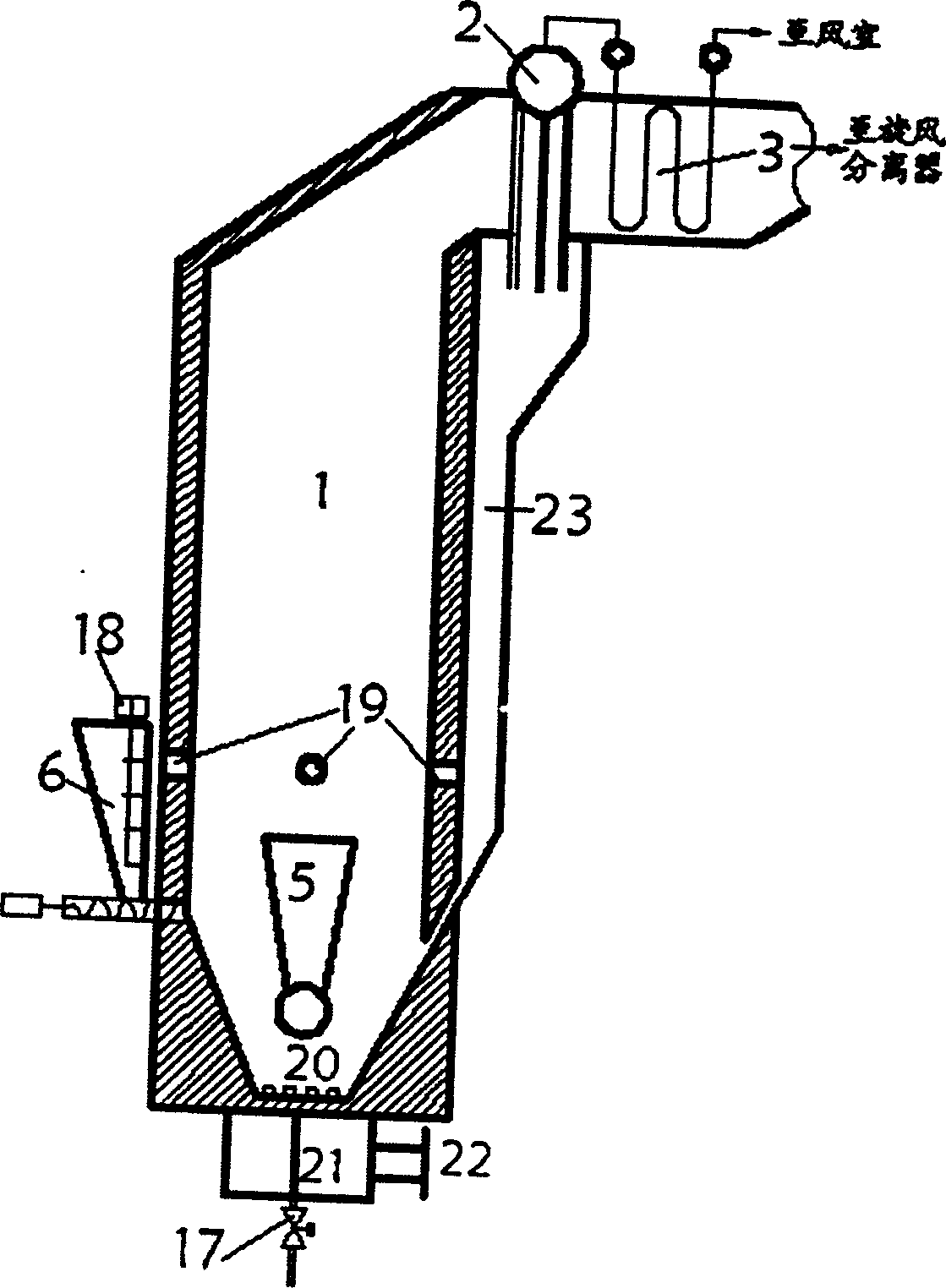

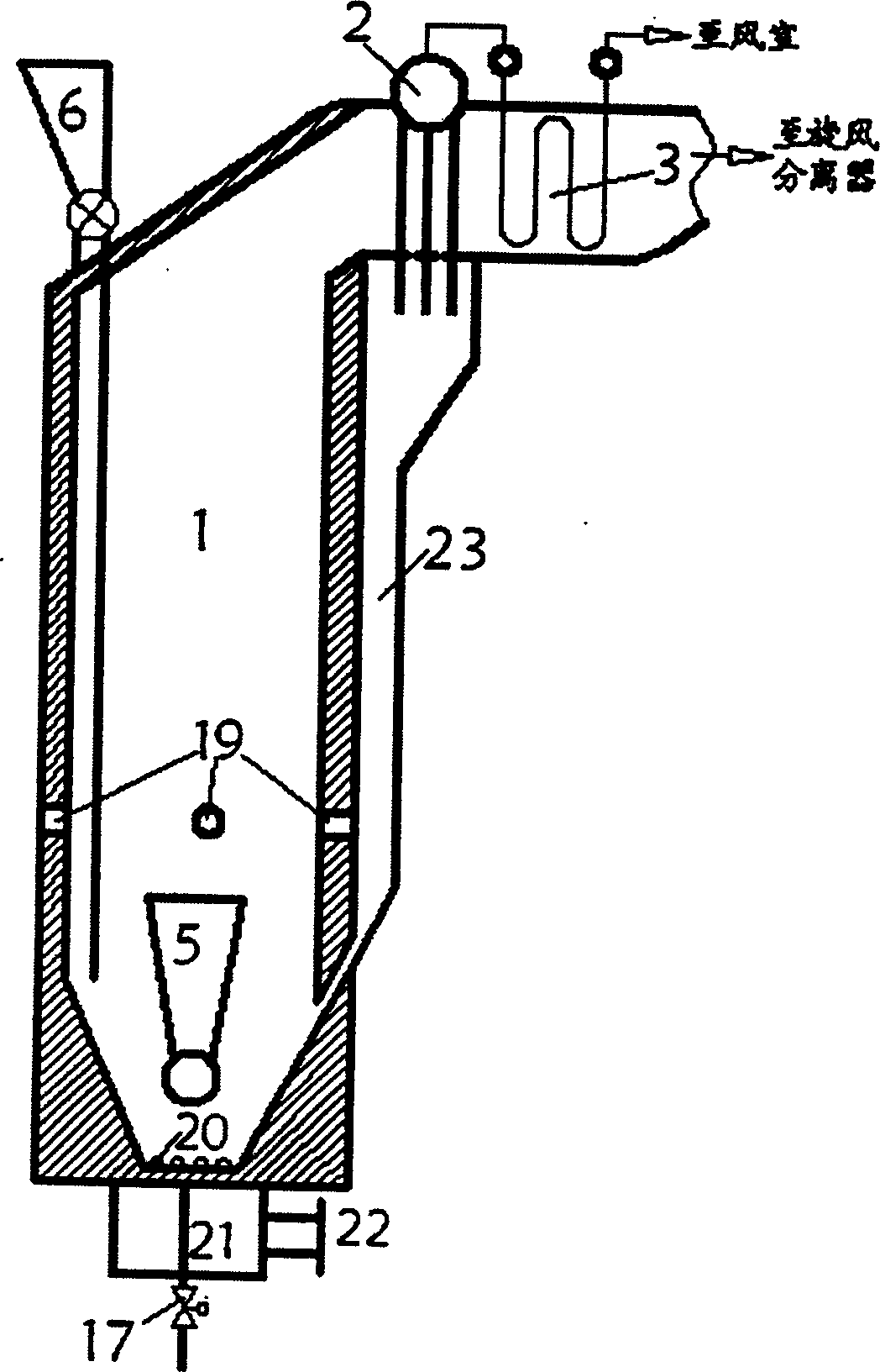

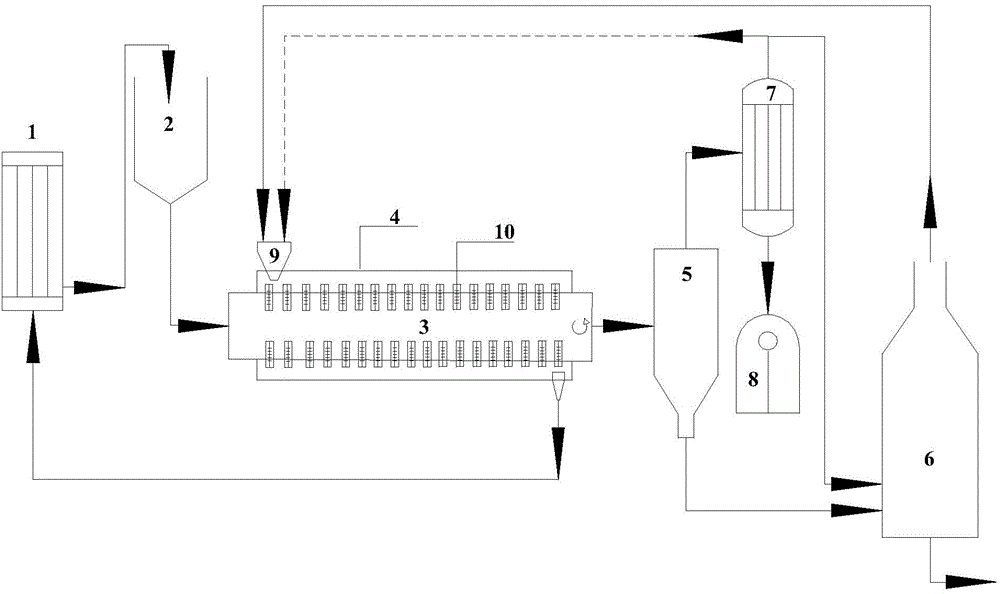

Biomass and coal mixed fluidized-bed gasification method and device

ActiveCN1230498CHigh volatile contentLess fixed carbonCombined combustion mitigationGranular/pulverulent flues gasificationWater vaporProduced water

The present invention relates to energy source apparatus, and is one kind of simple biomass-coal mixture gasifying method and apparatus capable of producing high heat value gas and no tar. Inside fluidized bed gasifying furnace, biomass and coal as gasified material is burnt and gasified intermittently. In the burning stage, coal and blast are supplied to the furnace, so that coal is burnt in fluidizing state to produce heat; in the gasifying stage, vapor and biomass are supplied to the furnace, so that the high temperature carbon material layer produces water gas reaction in fluidizing state and biomass is dry distilled and pyrolyzed at high temperature to produce high heat value gas, which is cooled and made to enter the gas purifying system. By combining of biomass and coal with different advantages, the present invention produces high heat value fuel gas without tar.

Owner:JIANGSU UNIV

Externally heated oil shale destructive distillation process

ActiveCN104531195ASolve effective useQuality improvementLiquid hydrocarbon mixture productionIndirect heating destructive distillationCombustionFlue gas

An externally heated oil shale destructive distillation process is characterized by comprising the steps that oil shale which is dried and allows external water to be removed enters an externally heated horizontal rotating destructive distillation furnace from a destructive distillation storage hopper for heat exchange with a heat pipe, destructive distillation product semicoke and destructive distillation gas are fed into a gas-solid separation chamber simultaneously, solid semicoke is fed into a combustion furnace to be combusted, generated shale ash is discharged from the bottom of the combustion furnace, generated high-temperature flue gas is fed to the exterior of the externally heated horizontal rotating destructive distillation furnace for heat exchange with the heat pipe, and drying and dewatering are conducted on oil shale raw ore fed from the tail of the externally heated horizontal rotating destructive distillation furnace to a drying chamber under residual temperature of flue gas; gas in the gas-solid separation chamber is fed into a cooling recovery system for condensate recovery of shale oil, uncondensed gas is fed into the combustion furnace to be combusted, and generated flue gas is fed to the exterior of the externally heated horizontal rotating destructive distillation furnace for heat exchange or is fed into a nozzle located outside the externally heated horizontal rotating destructive distillation furnace to be combusted to generate high-temperature flue gas for heat exchange with the heat pipe.

Owner:NORTHEAST DIANLI UNIVERSITY

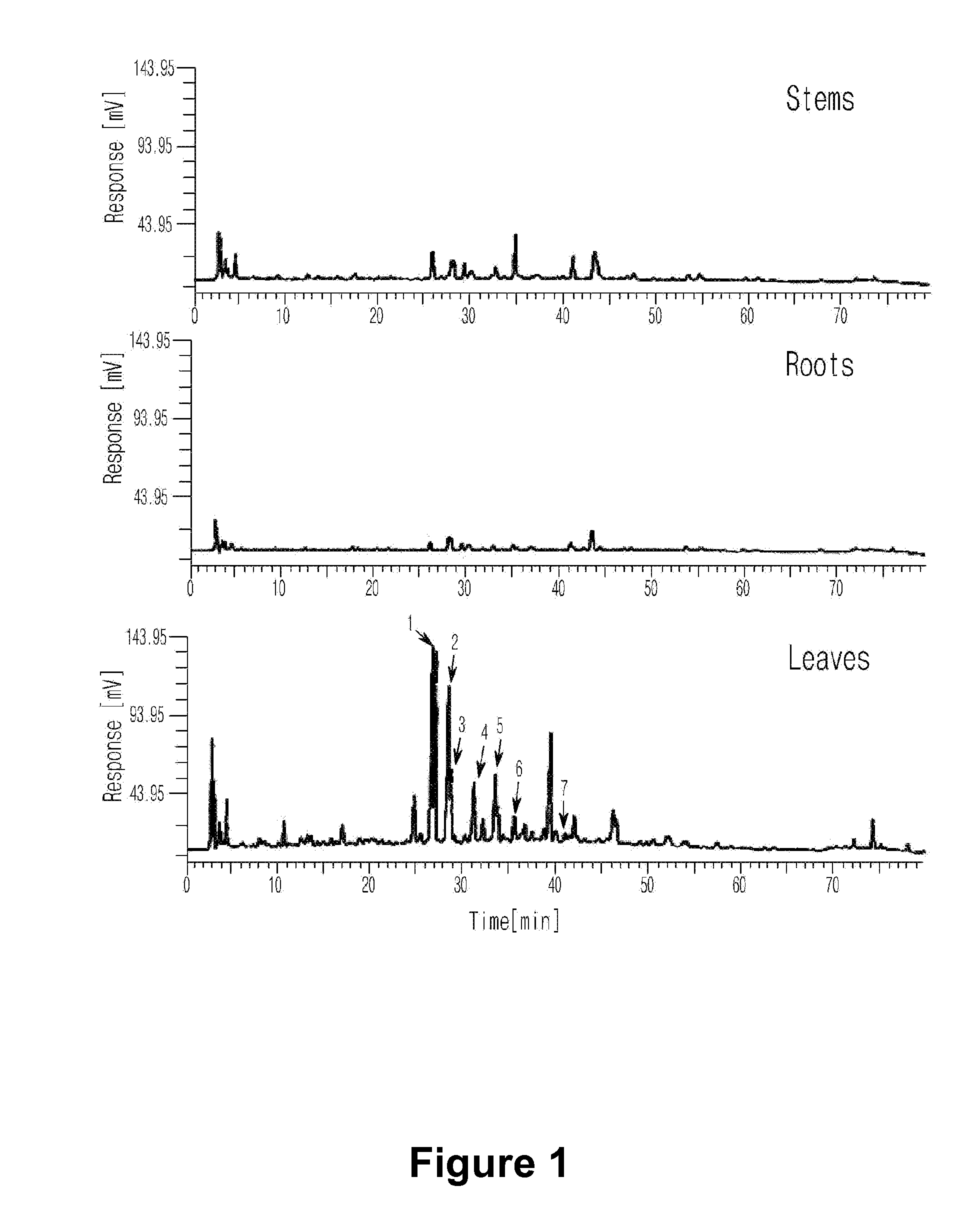

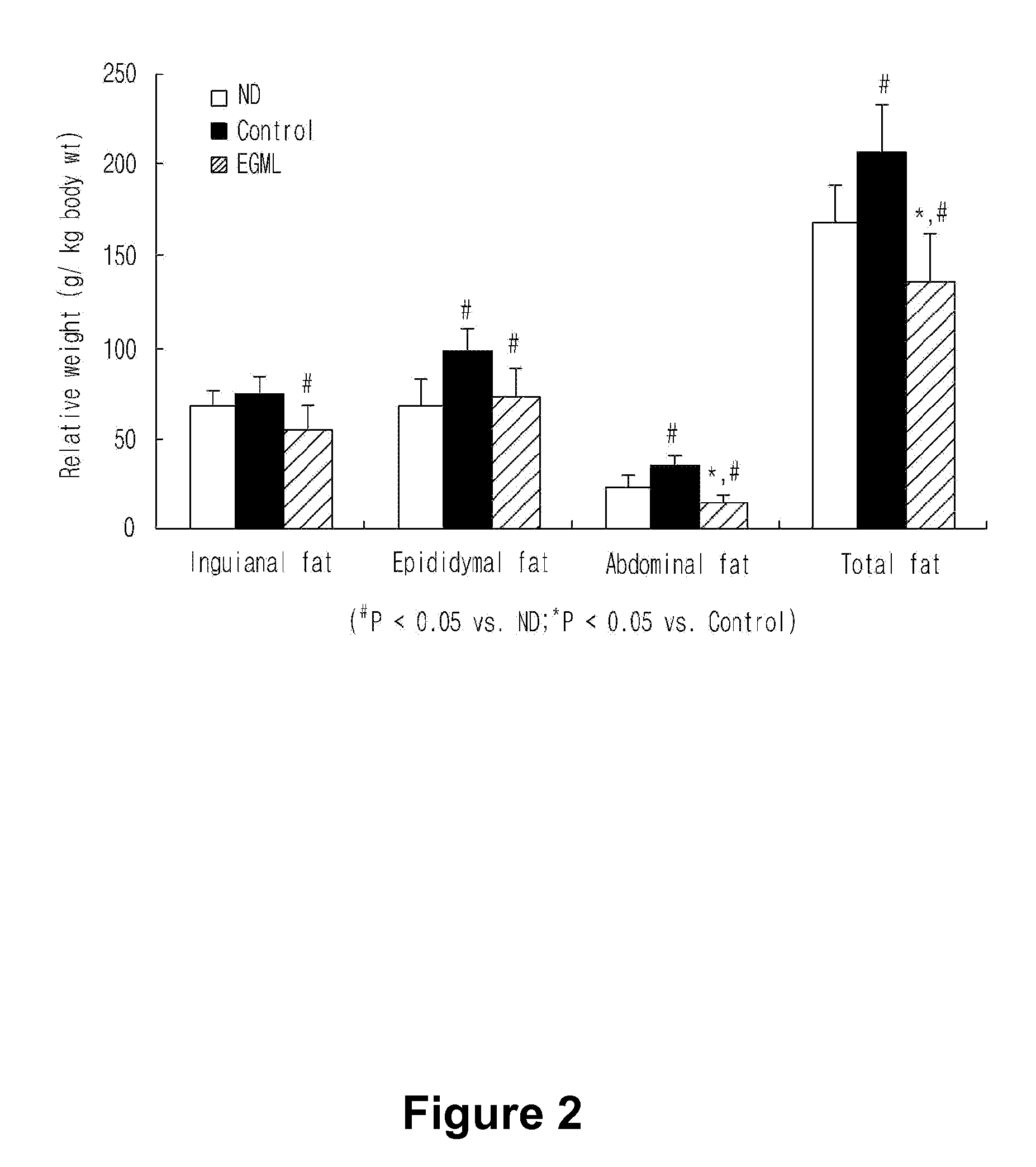

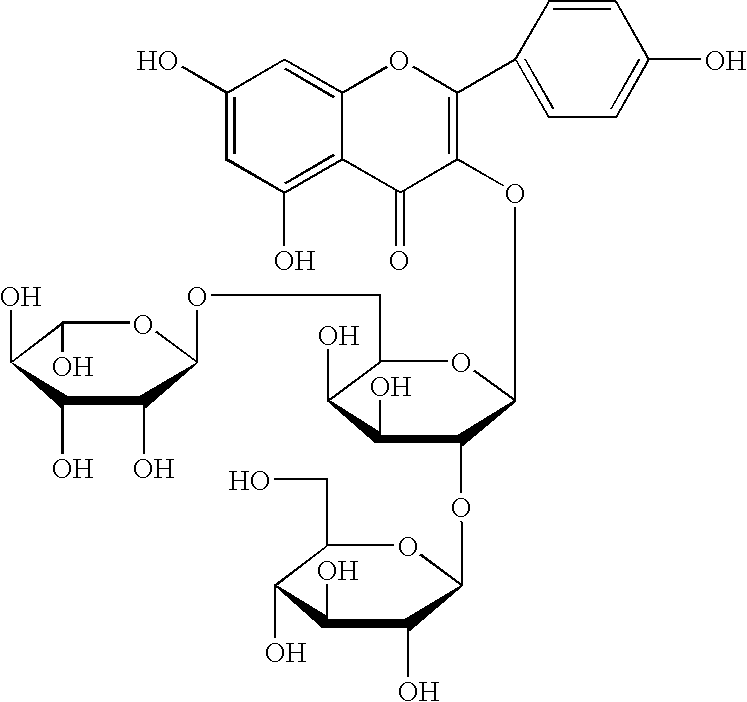

Compositions for Preventing and Treating Obesity, Hyperlipidemia, Atherosclerosis, Fatty Liver, Diabetes or Metabolic Syndrome Containing Extracts of Glycine Max Leaves or Fractions Isolated from the Same as an Active Ingredient

ActiveUS20100291248A1Effectively of obesitySolve effective useBiocideMetabolism disorderGlycineFatty liver

The present invention relates to compositions for preventing and treating obesity, hyperlipidemia, atherosclerosis, fatty liver, diabetes or metabolic syndrome containing extracts of Glycine max leaves or fractions isolated from the same.

Owner:KOREA RES INST OF BIOSCI & BIOTECH

Method for producing acetone-butanol by co-fermentation of pentoses and hexose

ActiveCN101440381BEnsure safetyRealize comprehensive utilizationMicroorganism based processesFermentationCelluloseLiquid fuel

The invention provides a method for producing acetone butanol by jointly fermenting pentose and hexose. The method comprises the following steps: the pentose and the hexose are mixed, the weight of the pentose against the total weight of the mixture is between 5 and 75 percent, the mixture is added with a nitrogen source or a phosphorus source to obtain a raw material, and the raw material is subjected to cooking sterilization to obtain cooking mash; the cooking mash is cooled to a temperature of below 42 DEG C and injected with strains and fermented; and the fermented solution is filtered, distilled and rectified to obtain final acetone, butanol and ethanol products. By the invention, the method which effectively utilizes the joint fermentation of the pentose and the hexose to produce the acetone butanol is obtained. According to local conditions, lignocellulose is utilized to hydrolyze pentose and the hexose for joint fermentation to produce the acetone butanol, thereby realizing waste reutilization, facilitating environmental protection, promoting diversification of energy structure in China, ensuring safety of liquid fuel in China and having positive significance on improving creativity and research capability in the field of preparing biomass liquid fuel in China.

Owner:GUANGZHOU INST OF ENERGY CONVERSION - CHINESE ACAD OF SCI

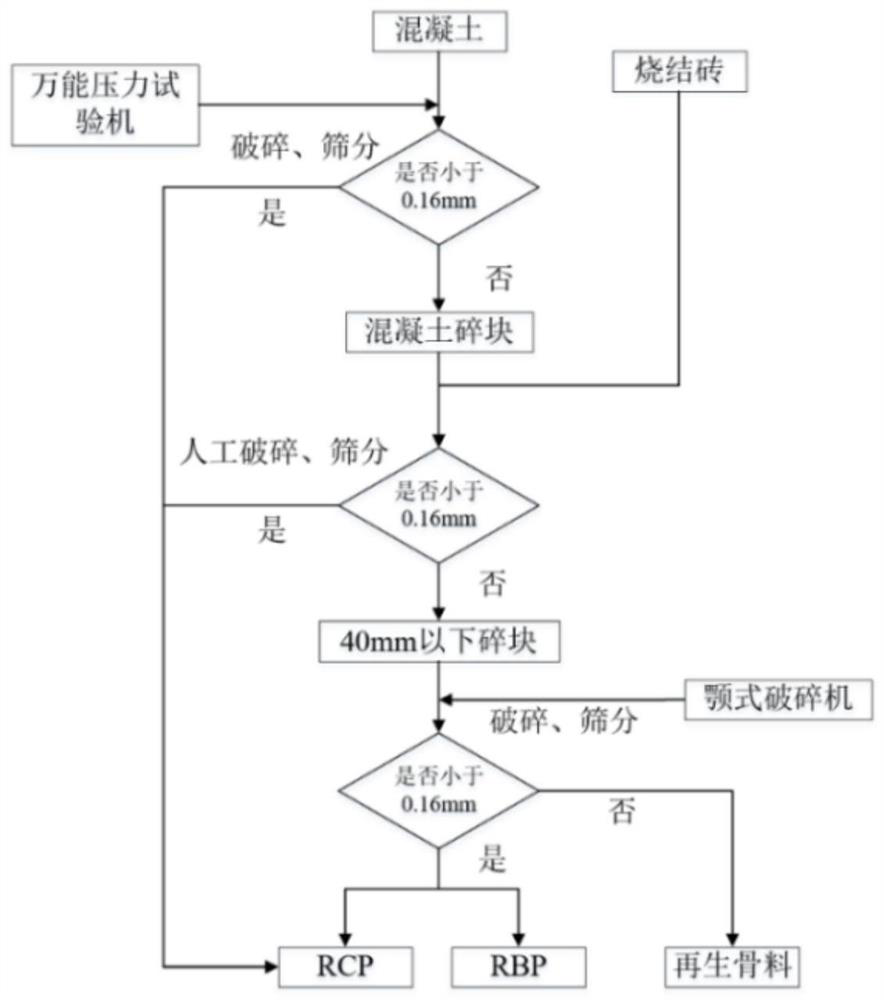

Regenerated micro-powder activation method

The invention discloses a regenerated micro-powder activation method. The method comprises the following steps: (1) selecting materials: selecting waste concrete and waste sintered bricks recovered from a construction site as regenerated micro-powder raw materials, wherein the waste concrete and the waste sintered bricks being processed separately; (2) creating an isolation area: selecting a construction area, erecting an isolation plate to seal the construction area, and installing a dust removal facility to create a construction environment; (3) performing primary crushing: performing primary crushing on the regenerated micro-powder raw material through a universal crusher; and (4) screening: screening the crushed regenerated micro-powder raw material to separate small fragments with the diameter of less than 40 mm, and taking powder with the diameter of less than 0.16 mm as initial regenerated micro-powder. The regenerated micro-powder can be collected to the maximum extent, the regenerated micro-powder is prevented from diffusing in air to form haze to pollute the atmosphere, and recycling is achieved; and the regenerated micro powder can be activated through the exciting agent and can be prepared into regenerated micro powder concrete and set cement, so the building waste is effectively and comprehensively utilized, and environmental hazards are relieved.

Owner:JINHUA VOCATIONAL TECH COLLEGE

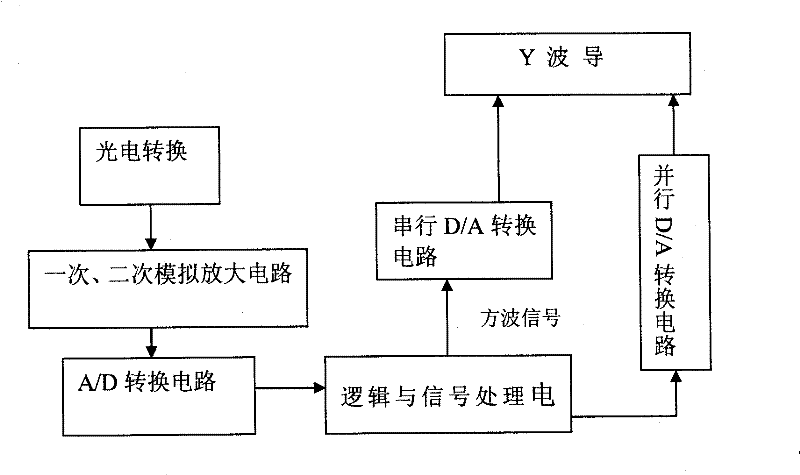

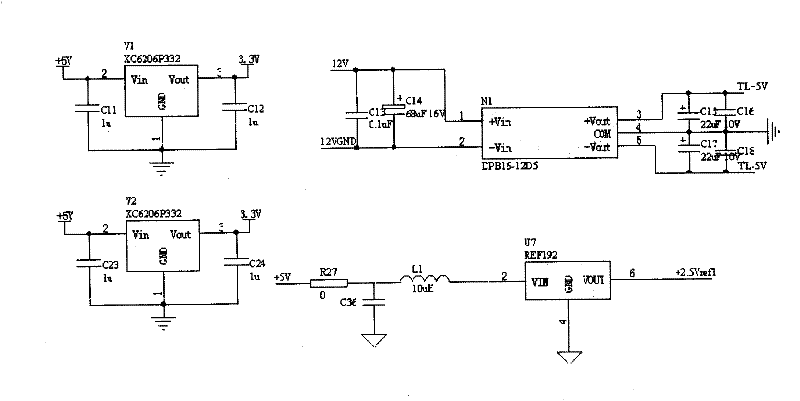

Two dimensional space running orbit tester based on double-shaft optical fiber gyroscope

InactiveCN101475018BSolve the high and low controlSolve solving problemsRailway auxillary equipmentRailway profile gaugesGyroscopeEngineering

The invention discloses a two dimensional space track tester based on a double-axis optical fiber gyro, and belongs to the field of moving track engineering test. The tester comprises a host computer, an interface system connected with the host computer, a trochometer, an upper computer and an optical fiber gyro connected with the interface system, wherein the optical fiber gyro is a double-axis optical fiber gyro formed by integrating two single-axis optical fiber gyros into a gyro body; and sensitive axes of the double-axis optical fiber gyro are mutually perpendicular and can simultaneously measure running tracks in two directions on the same plane. The tester integrates the two single-axis optical fiber gyros into one gyro body, and sensor information is provided for the space runningtrack tester through the one double-axis optical fiber gyro. At the same time, only one set of interface equipment needs to be matched so as to solve the problems of large volume and lower integration of the prior track tester, and simplify the electric design simultaneously.

Owner:HUBEI SANJIANG AEROSPACE HONGFENG CONTROL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com