Externally heated oil shale destructive distillation process

An oil shale, external heat technology, applied in the field of oil shale dry distillation, can solve the problems of high dust content in dry distillation gas, low heat transfer efficiency, short residence time, etc., to improve quality and efficiency, reduce production energy consumption, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below using the accompanying drawings and examples.

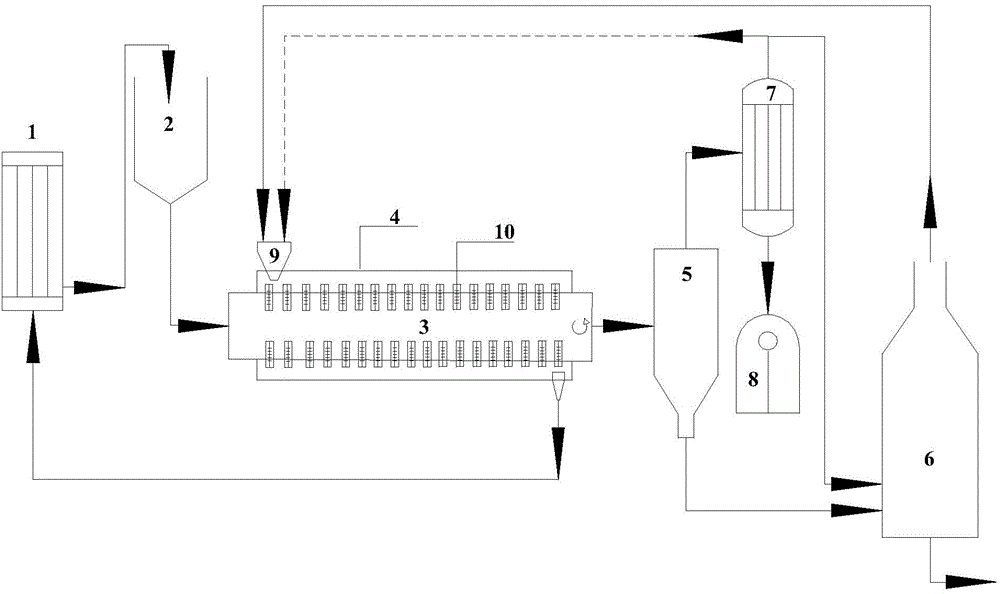

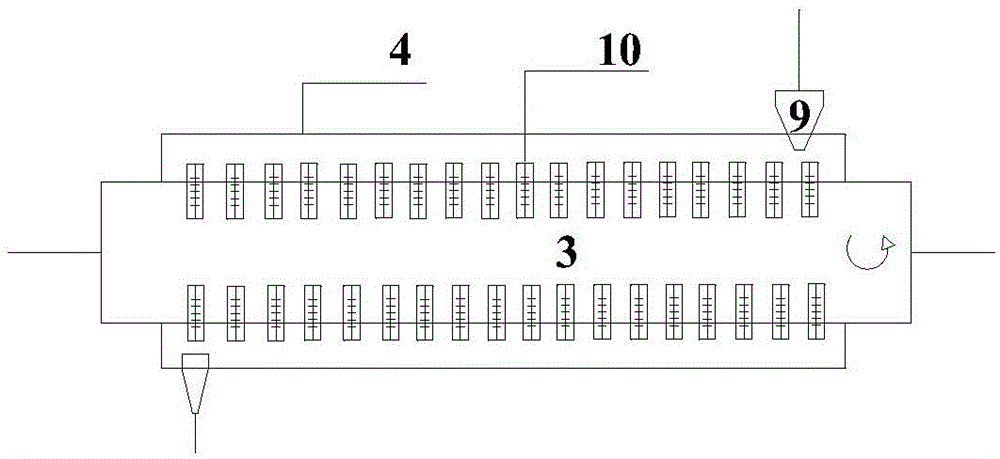

[0022] Such as figure 1 As shown, an externally heated oil shale carbonization process of the present invention includes the following steps: sending the oil shale raw ore at ambient temperature into the drying chamber 1, and sending it to the carbonization storage hopper 2 after drying to remove the external water In the process, the oil shale in the retort storage hopper has a temperature of 150°C-200°C, enters the externally heated horizontal rotary retort furnace 3 by its own gravity, and exchanges heat with the heat pipe 10 in the externally heated horizontal rotary retort furnace 3, and the temperature ranges from 400°C to 200°C. The dry distillation product semi-coke at 500°C and dry distillation gas are sent to the gas-solid separation chamber 5 at the same time, and the semi-coke with a solid part at 400°C-500°C is sent to the combustion furnace 6 for combustio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com