Method for producing acetone-butanol by co-fermentation of pentoses and hexose

An acetone-butanol and co-fermentation technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, fermentation, etc., to achieve the effects of ensuring the safety of liquid fuels, improving innovation capabilities and R&D capabilities, and being conducive to environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

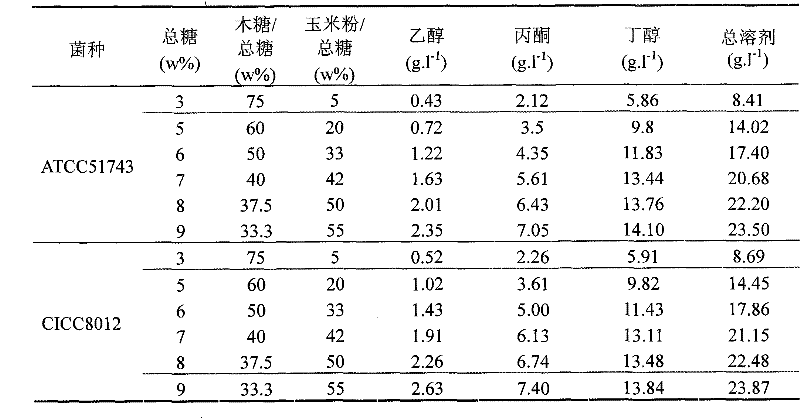

[0028] Embodiment 1: Add corn flour co-fermentation in xylose and glucose mixed sugar

[0029] The total sugar content is controlled to be 3w%, 5w%, 6w%, 7w%, 8w%, 9w%, and xylose accounts for 75w%, 60w%, 50w%, 42.8w%, 37.5w% and 33.3% of the total sugar respectively w%, the rest is glucose. Wherein corn flour accounts for 5w%, 20w%, 33w%, 42w%, 50w% and 55w% of total sugar respectively.

[0030] Add 1000ml of water to corn flour, gelatinize at 100°C for 1 hour, add xylose and glucose in proportion, mix well, and divide into 250ml Erlenmeyer flasks, each with 150ml. Sterilize at 121°C for 120 minutes in a sterilizer.

[0031] After sterilization, the culture medium was taken out and cooled to room temperature, and ATCC 51743 and CICC8012 strains were inserted into the culture medium with an inoculum size of 5%, and fermented in an anaerobic incubator at 35°C for 72 hours.

[0032] After the fermentation is complete, get 1ml of fermented liquid and place it in a centrifuge t...

Embodiment 2

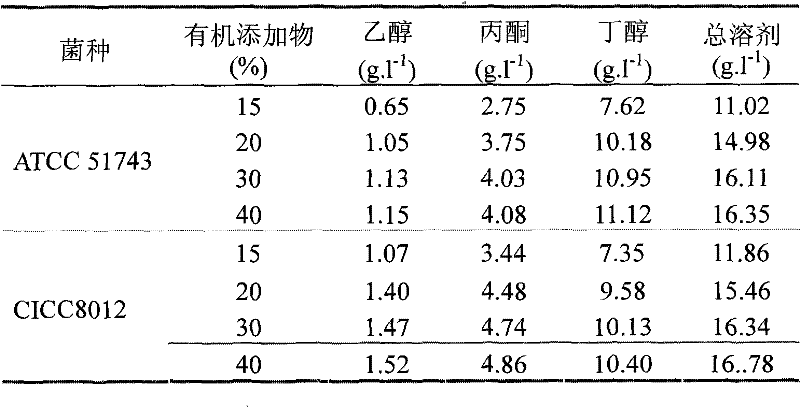

[0035] Embodiment 2: Co-fermentation of adding organic additives in xylose and glucose mixed sugar

[0036] Take 35g of xylose, 35g of glucose and add 1000ml of water to form a sugar content of 7% by weight, organic additives (mixed preparation of various agricultural and sideline products, rich in phosphorus and nitrogen, including bran, rice bran, bean cake powder and bean cake, etc.) Respectively 15w%, 20w%, 25w%, 30w% and 40w% of the amount of total sugar, mixed evenly, and distributed to 250ml Erlenmeyer flasks, each Erlenmeyer flask is filled with 150ml. Sterilize at 121°C for 120 minutes in a sterilizer.

[0037] After sterilization, the culture medium was taken out and cooled to room temperature, and ATCC 51743 and CICC8012 strains were inserted into the culture medium with an inoculum size of 5%, and fermented in an anaerobic incubator at 35°C for 72 hours.

[0038]After the fermentation is complete, get 1ml of fermented liquid and place it in a centrifuge tube, cent...

Embodiment 3

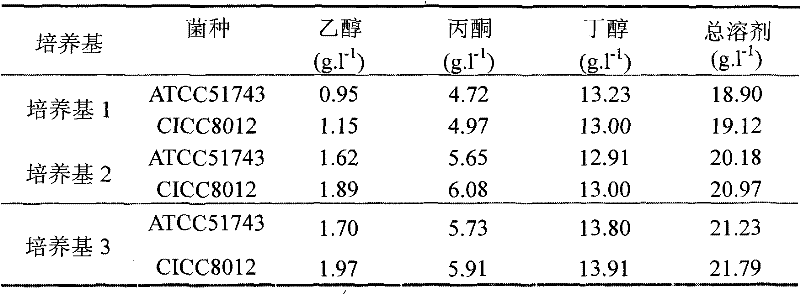

[0041] Example 3: Adding corn flour and organic additives to co-fermentation in xylose and glucose mixed sugar

[0042] Medium 1: Take 3g of corn flour and add 1000ml of water, gelatinize the corn at 100°C for 1 hour, add 30g of xylose to control the total sugar content to 7%, the rest is glucose, and 0.5g of organic additives, of which corn flour and organic additives are 5% of the total sugar, mix well, put into 250ml Erlenmeyer flask, each Erlenmeyer flask is filled with 150ml, and sterilized at 121℃ for 120 minutes in a sterilizing pot;

[0043] Medium 2: Take 15g of corn flour and add 1000ml of water, add 30g of xylose after corn gelatinization at 100°C for 1 hour, control the total sugar content to 7%, and the rest are glucose and 7g of organic additives, of which corn flour and organic additives are the total 31.4% of sugar, mix evenly, dispense into 250ml Erlenmeyer flasks, each Erlenmeyer flask is filled with 150ml, and sterilize in a sterilizing pot at 121°C for 120 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com