Regenerated micro-powder activation method

A technology of regenerated micropowder and activation method, which is applied in the direction of climate sustainability, sustainable waste treatment, solid waste management, etc., to achieve the effects of improving compressive strength and flexural strength, improving utilization value, and solving effective comprehensive utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

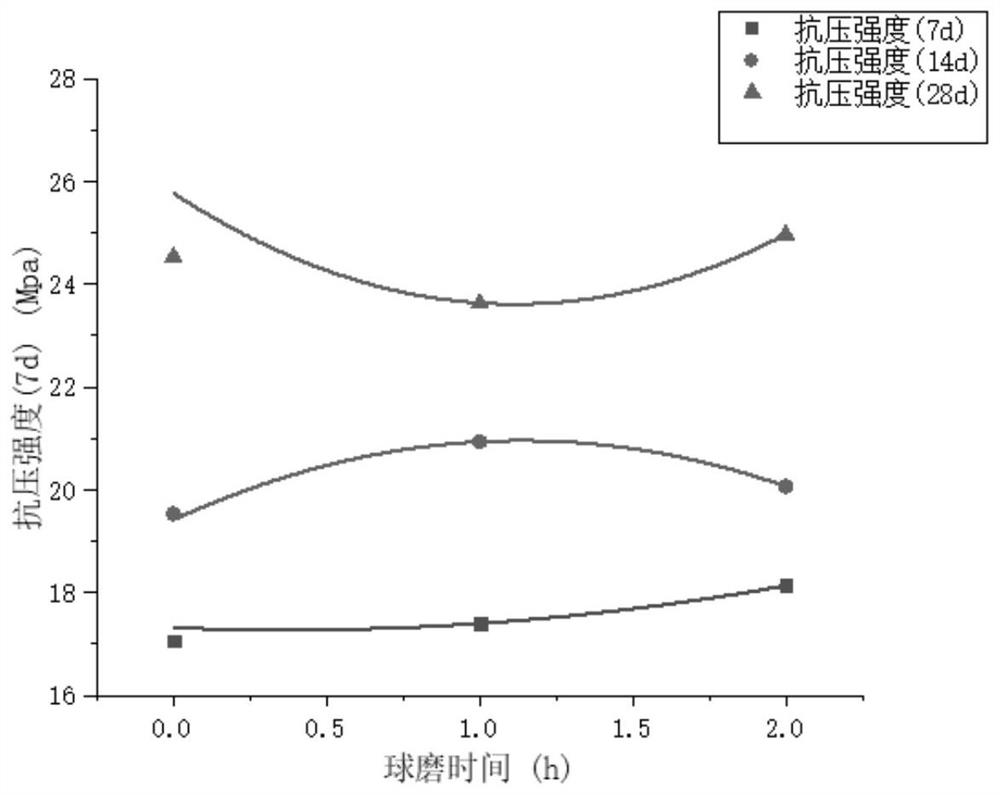

Embodiment 1

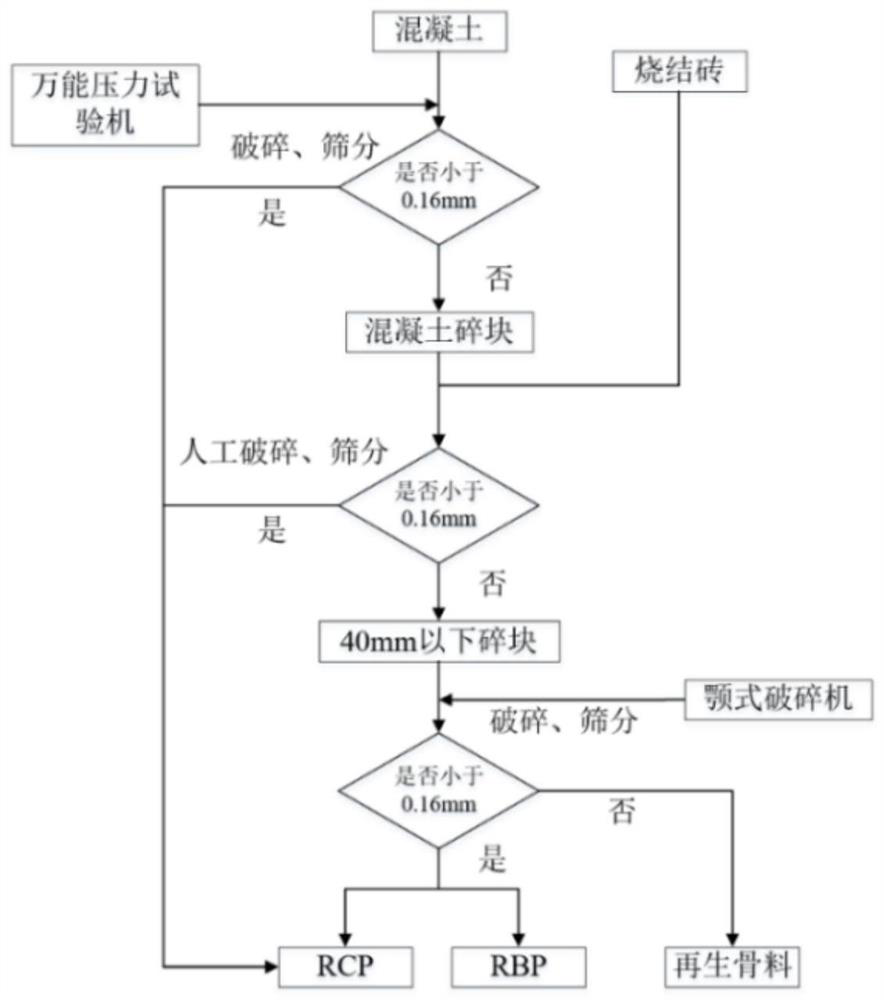

[0027] Embodiment 1: a kind of regeneration micropowder activation method comprises the following steps:

[0028] (1) Material selection: waste concrete and waste fired bricks recovered from construction sites are selected as raw materials for regenerated micropowder, and the waste concrete and waste fired bricks are processed separately;

[0029] The strength of concrete is measured by a universal pressure testing machine, and concrete blocks with a strength grade of C25 or higher and an age of more than one year are selected;

[0030] (2) Create an isolation area: select the construction area, erect an isolation board to close the construction area, and install dust removal facilities to create a construction environment. The isolation board is made of color steel plate, which has strong corrosion resistance and anti-aging ability, which is more conducive to long-term use and prevents dust from being raised Diffusion into the atmosphere to form smog;

[0031] (3) Primary cr...

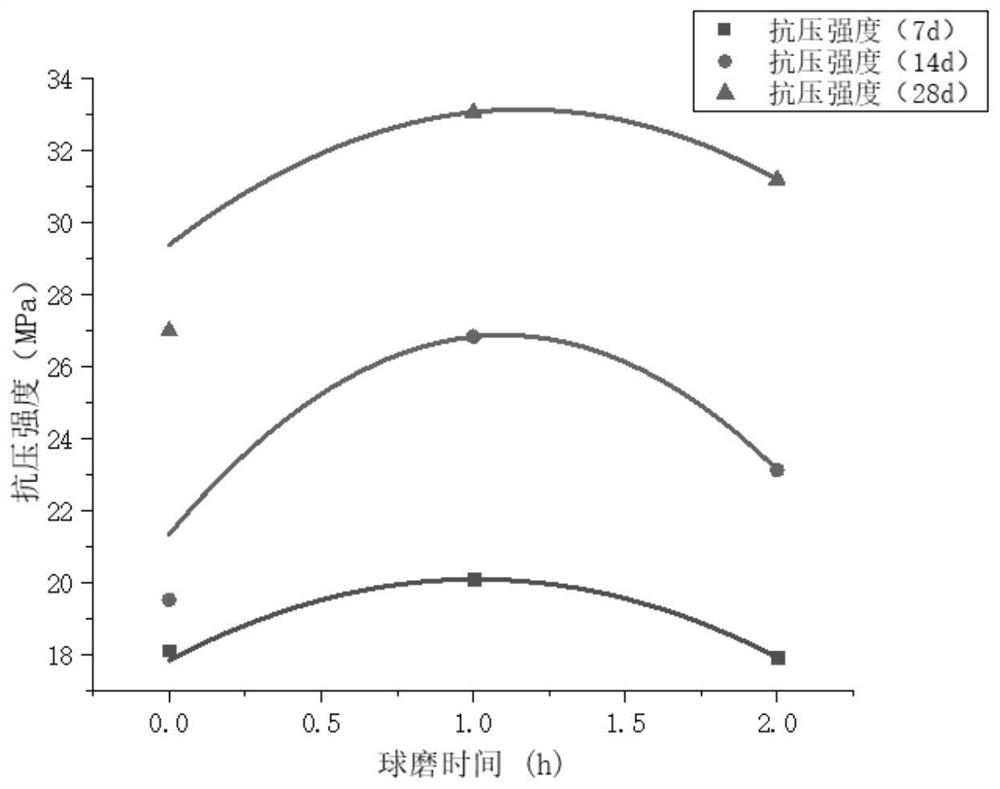

Embodiment 2

[0038] Embodiment 2: a kind of regeneration micropowder activation method comprises the following steps:

[0039] (1) Material selection: waste concrete and waste fired bricks recovered from construction sites are selected as raw materials for regenerated micropowder, and the waste concrete and waste fired bricks are processed separately;

[0040] The strength of concrete is measured by a universal pressure testing machine, and concrete blocks with a strength grade of C25 or higher and an age of more than one year are selected;

[0041] (2) Create an isolation area: select the construction area, erect an isolation board to close the construction area, and install dust removal facilities to create a construction environment. The isolation board is made of color steel plate, which has strong corrosion resistance and anti-aging ability, which is more conducive to long-term use and prevents dust from being raised Diffusion into the atmosphere to form smog;

[0042] (3) Primary cr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com