Carboxymethylation modification method and applications of semi-cellulose in waste liquor from viscose fiber production

A technology of hemicellulose and viscose fiber, which is used in fiber raw material treatment, coating, paper coating and other directions to achieve the effect of good dispersion performance, easy operation, good adsorption and water solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Use the alkali-containing hemicellulose extracted from viscose fiber production waste liquid as raw material, add monochloroacetic acid, react at 70°C for 120 minutes, cool, let stand, the supernatant is washed with 90% ethanol, precipitated, and the crude product is obtained by suction filtration ; The crude product was dissolved in water and centrifuged; the supernatant was washed with 90% ethanol, precipitated, filtered, and vacuum-dried for 24 hours to obtain carboxymethyl hemicellulose products.

[0027] The raw material is alkali-containing hemicellulose extracted from viscose production waste liquid, wherein the alkali content is 10% of the hemicellulose mass percentage;

[0028] The etherifying agent is monochloroacetic acid;

[0029] The molar ratio of the material containing alkali hemicellulose and monochloroacetic acid is 1:1.5;

[0030] The carboxymethyl hemicellulose has a degree of substitution of 0.47.

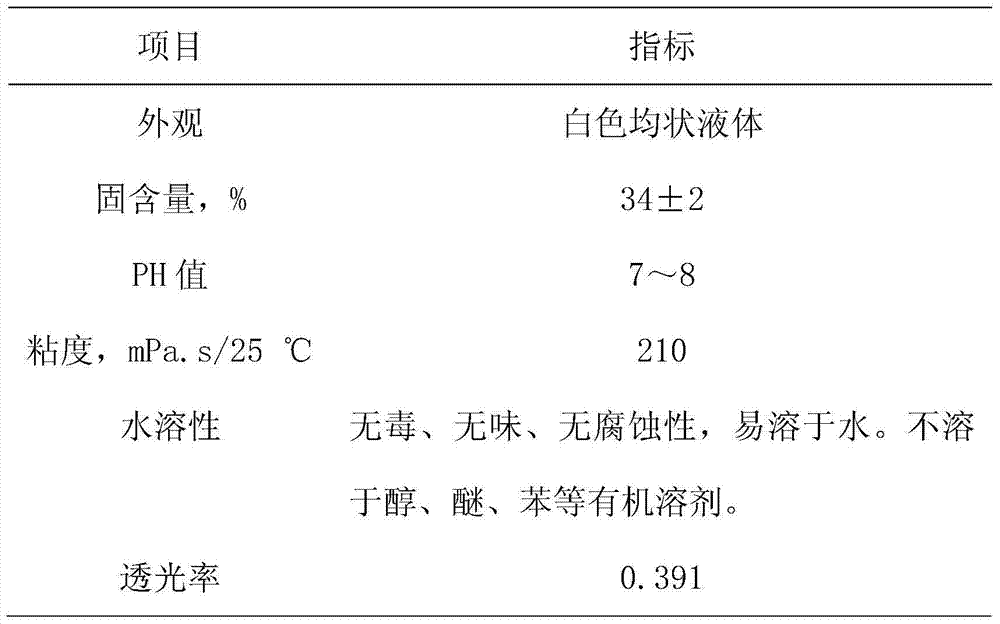

[0031] The carboxymethyl hemicellulose dispersan...

Embodiment 2

[0036] Use alkali-containing hemicellulose extracted from viscose fiber production waste liquid as raw material, add monochloroacetic acid, react at 80°C for 150 minutes, cool, let stand, wash the supernatant with 90% ethanol, precipitate, and suction filter to obtain the crude product ; The crude product was dissolved in water and centrifuged; the supernatant was washed with 90% ethanol, precipitated, filtered, and vacuum-dried for 24 hours to obtain carboxymethyl hemicellulose products.

[0037] The raw material is alkali-containing hemicellulose extracted from viscose production waste liquid, wherein the alkali content is 15% of the hemicellulose mass percentage;

[0038] The etherifying agent is monochloroacetic acid;

[0039] The molar ratio of the material containing alkali hemicellulose and monochloroacetic acid is 1:2;

[0040] The carboxymethyl hemicellulose has a degree of substitution of 0.68.

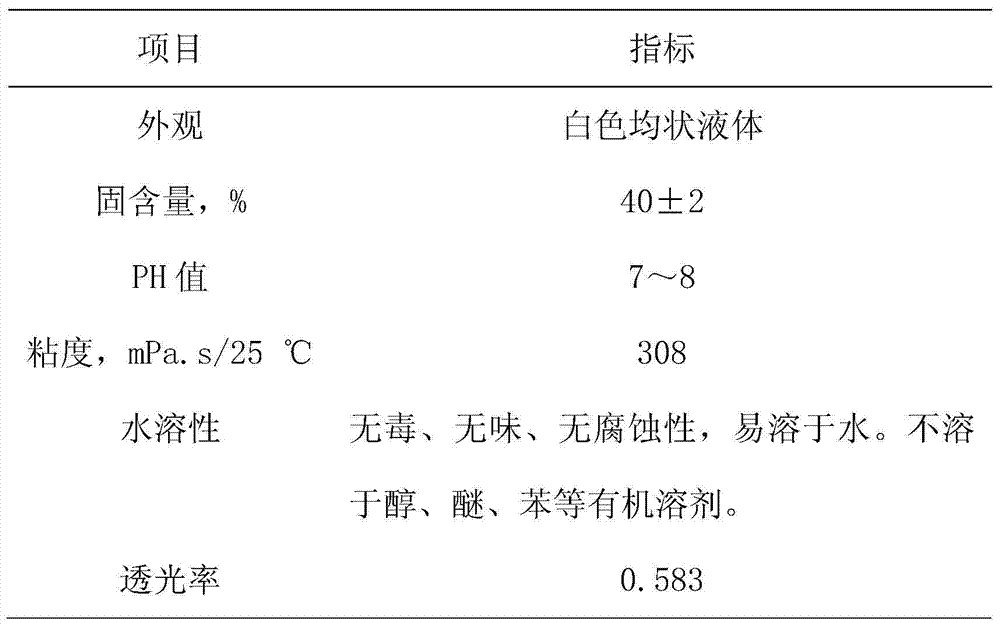

[0041] The carboxymethyl hemicellulose dispersant obtained in the pre...

Embodiment 3

[0046] Use alkali-containing hemicellulose extracted from viscose fiber production waste liquid as raw material, add monochloroacetic acid, react at 80°C for 150 minutes, cool, let stand, the supernatant is washed with 90% ethanol, precipitated, and the crude product is obtained by suction filtration ; The crude product was dissolved in water and centrifuged; the supernatant was washed with 90% ethanol, precipitated, filtered, and vacuum-dried for 24 hours to obtain carboxymethyl hemicellulose products.

[0047] The raw material is alkali-containing hemicellulose extracted from viscose production waste liquid, wherein the alkali content is 20% of the hemicellulose mass percentage;

[0048] The etherifying agent is monochloroacetic acid;

[0049] The molar ratio of the material containing alkali hemicellulose and monochloroacetic acid is 1:2.5;

[0050] The carboxymethyl hemicellulose has a degree of substitution of 0.91.

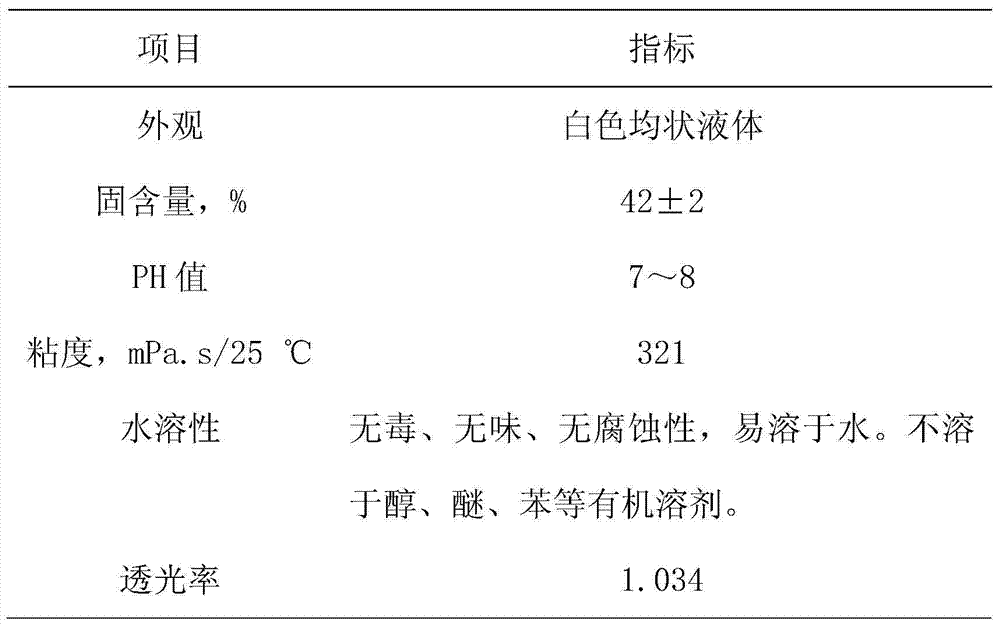

[0051] The carboxymethyl hemicellulose dispersant ob...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com