Method for producing aluminum oxide

A technology of alumina and aluminum salts, applied in the field of metallurgy, can solve problems that need to be improved, achieve good economic benefits, reduce energy consumption, and reduce costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

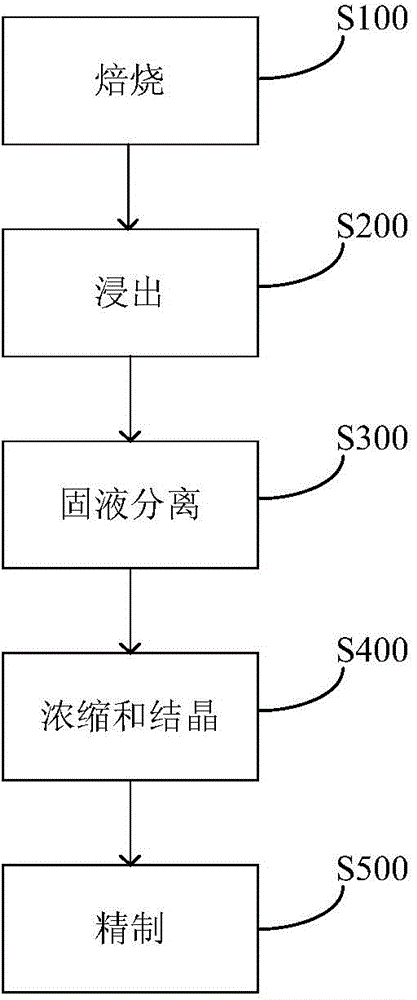

Method used

Image

Examples

Embodiment 1

[0063] Embodiment 1: Recover alumina from high alumina fly ash

[0064] The composition of high-aluminum fly ash from a thermal power plant in Inner Mongolia is shown in Table 1.

[0065] Table 1 Chemical composition of high alumina fly ash samples

[0066] Element

[0067] Get 20 grams of the above-mentioned high-alumina fly ash whose particle size is below 200 orders, add 34.5 grams of ammonium sulfate, 26 grams of 98% sulfuric acid (equal moles of sulfuric acid and ammonium sulfate generate 60 grams of ammonium bisulfate), and the resulting mixture is heated to 180°C (the melting point of ammonium bisulfate is 147°C) and stir evenly, then place it in a muffle furnace and roast at 280°C for 6 hours. , heated to keep the temperature above 80°C, stirred and leached for 1h, then filtered while it was hot, collected the filtrate, cooled the obtained filtrate to room temperature and waited for the precipitation process of aluminum ammonium sulfate crystals to stop com...

Embodiment 2

[0068] Example 2: Recovery of alumina from high alumina fly ash

[0069] The source of high aluminum fly ash is the same as in Example 1. Take 40 grams of the above-mentioned high-alumina fly ash with a particle size below 200 mesh, add 320 grams of sodium bisulfate monohydrate, heat to 120°C (the melting point of sodium hydrogensulfate monohydrate is 58°C), stir evenly, and then place it in a muffle furnace Inside, bake at 320°C for 1 hour. After the roasting is completed, transfer the roasted clinker to a 1000mL beaker, add 800mL of boiling water, heat to keep the temperature above 80°C, stir and leach for 0.5h, then filter while it is hot, and collect the filtrate. Then, add ammonium sulfate 100 grams in the filtrate that obtains, after stirring and dissolving completely, solution is cooled to room temperature and after waiting for the precipitation process of aluminum ammonium sulfate crystal to stop completely, filter, the aluminum ammonium sulfate crystal that obtains i...

Embodiment 3

[0070] Example 3: Recovery of alumina from aluminum-containing fly ash

[0071] The composition of aluminum-containing fly ash from a thermal power plant in Taiyuan, Shanxi is shown in Table 2.

[0072] Table 2 Chemical composition of fly ash samples from a thermal power plant in Taiyuan

[0073] Element

[0074] Take 40 grams of the above-mentioned high-alumina fly ash with a particle size below 200 mesh, add 189.3 grams of sodium sulfate, 133.3 grams of 98% sulfuric acid, and 50 grams of water, heat to 120 ° C (the melting point of sodium bisulfate monohydrate is 58 ° C) and stir evenly , and then placed in a muffle furnace and fired at 320°C for 6 hours. After the roasting is completed, transfer the roasted clinker to a 1000mL beaker, add 800mL of boiling water, heat to keep a slight boil (temperature ~ 100°C), stir and leach for 2 hours, then filter while it is hot, collect the filtrate, and then add sulfuric acid to the obtained filtrate 100 grams of ammonium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com