Method for decomposing potassium feldspar to extract soluble potassium

A potassium feldspar and soluble technology, applied in the field of comprehensive utilization of resources, can solve the problems of high energy consumption, high roasting temperature, and long roasting time, and achieve the effects of lower roasting temperature, wide sources, and shortened roasting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

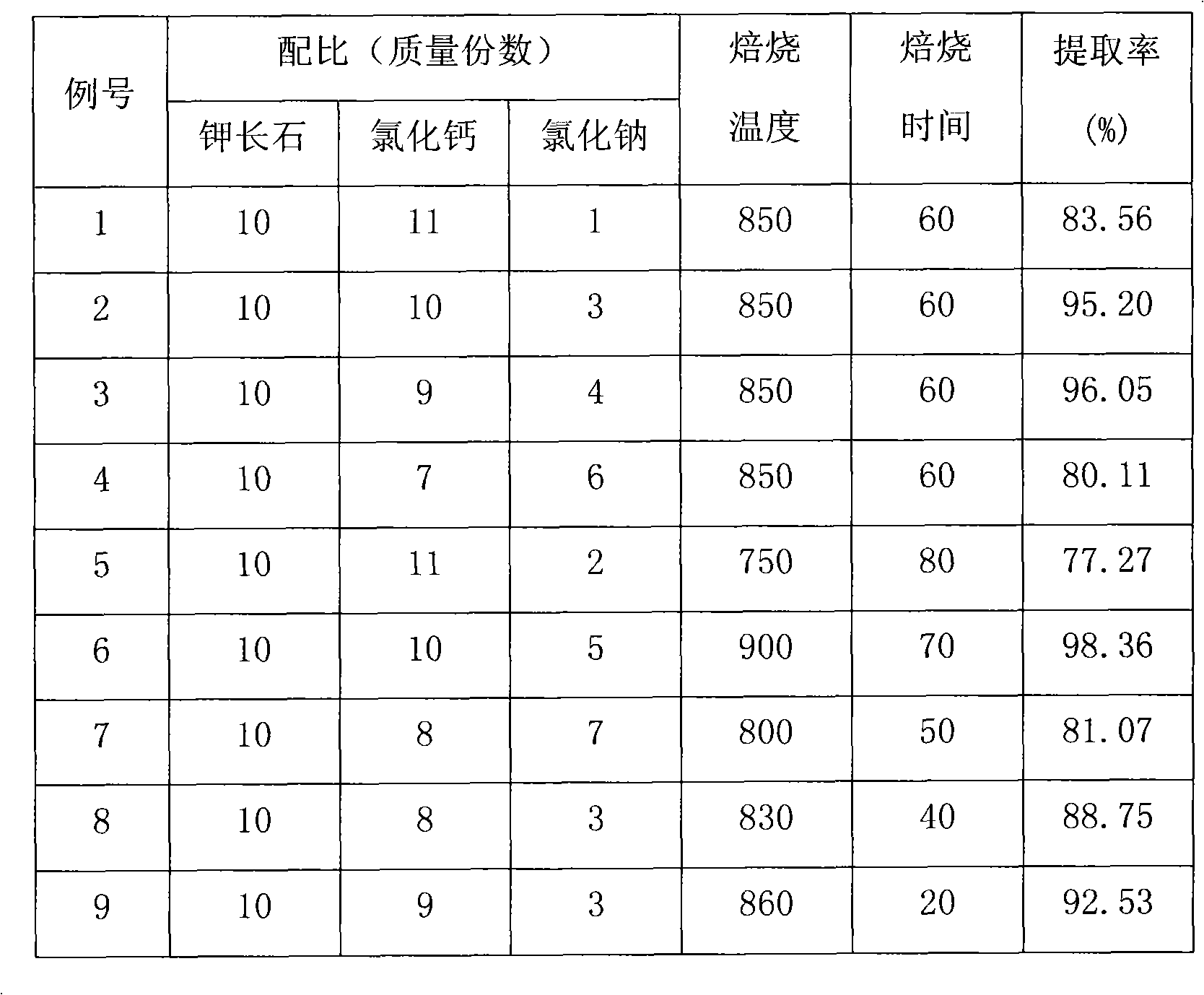

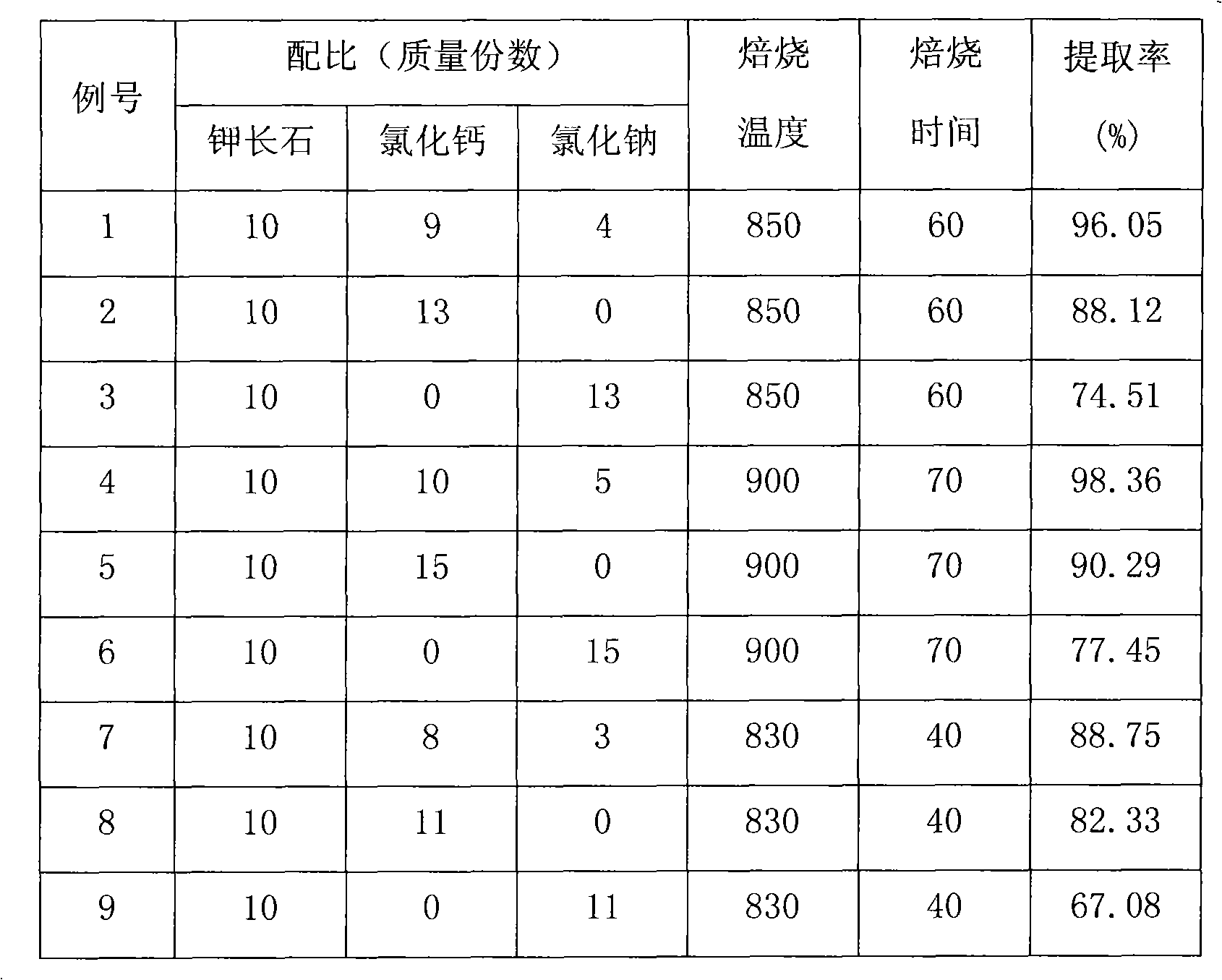

[0016] Grinding the potassium feldspar to below 100 mesh, mixing and stirring with calcium chloride and sodium chloride evenly, roasting, leaching the product with water, and filtering to obtain soluble potassium. In Examples 1-9, see Table 1 for the mixing ratio of potassium feldspar, calcium chloride and sodium chloride, the parameters of the roasting process and the extraction rate of soluble potassium.

[0017] The proportioning, parameter and result of table 1 embodiment 1~9

[0018]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com