Process for preparing Mn-Si alloy from slags generated by smelting low-carbon ferromanganese

A technology of manganese-silicon alloy and low-carbon ferromanganese, which is applied in the field of producing manganese-silicon alloy materials and cement raw materials, can solve pollution and other problems, achieve the effects of solving environmental protection, solving effective utilization problems, and reducing the loss of metal manganese

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

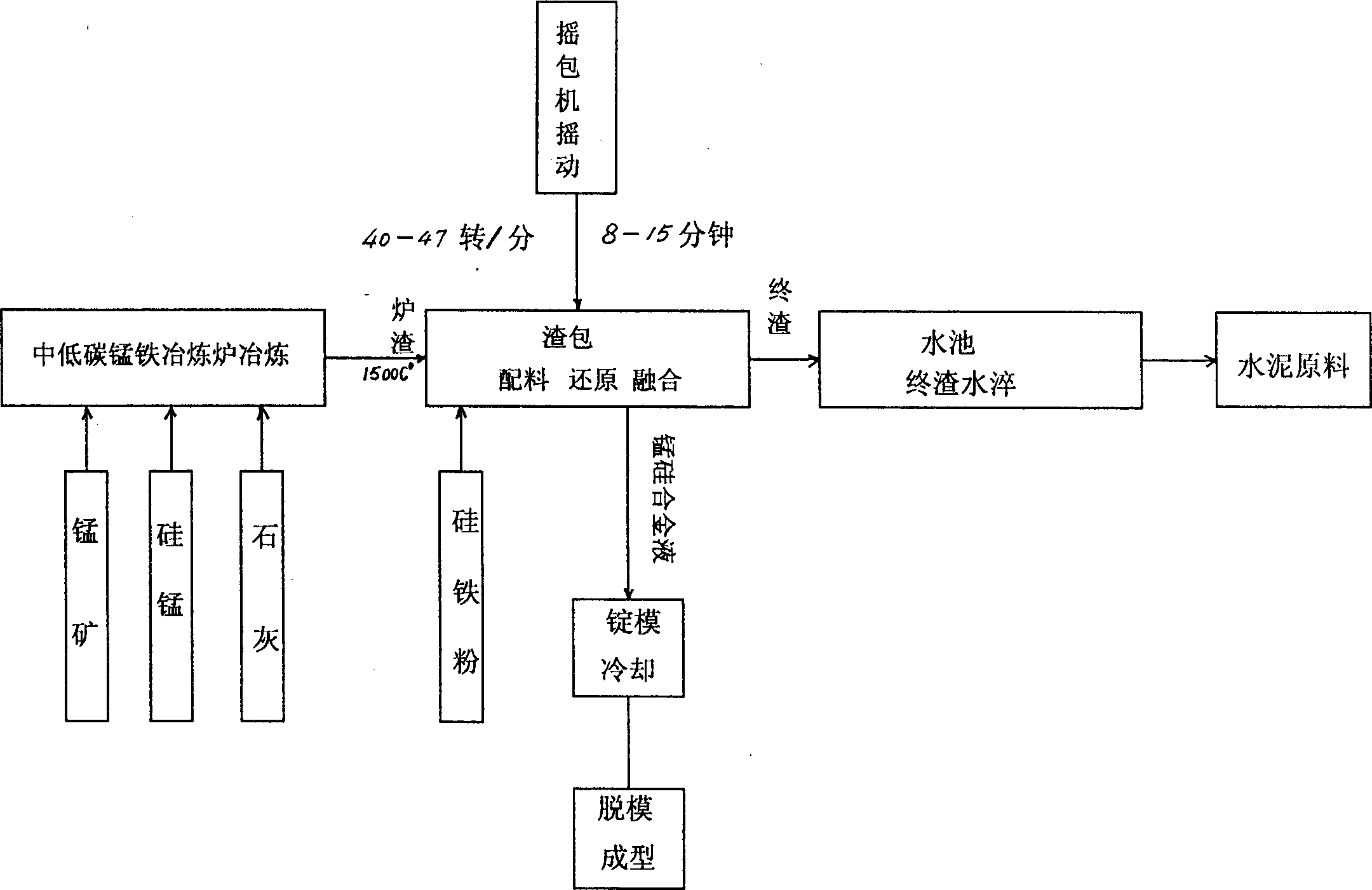

Image

Examples

Embodiment Construction

[0009] The conditions for implementing this process method are:

[0010] Smelting furnace: one 1250kw electric arc furnace

[0011] Lifting equipment: a 12.5-ton crane

[0012] Slag bag: at least one slag bag of 4 tons

[0013] Shaking machine: one 15-ton shaking machine

[0014] pool

[0015] The production process of the ingot mold body is as follows: During the smelting process of medium and low carbon ferromanganese in the electric arc furnace, when the slag comes out of the furnace, the slag at about 1500 ° C is poured into the slag bag, and at the same time, 15-20% of the slag weight is added to the slag bag. Slag fine powder (silicon slag crystallized by ferrosilicon, ferrosilicon powder) is used as a reducing agent, and then the slag bag is hoisted on the shaking bag machine by driving, and the shaking bag machine shakes the slag bag at a speed of 40-47 rpm for 8-15 minutes , so that the slag and silicon slag fine powder are fully contacted at high temperature, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com