Patents

Literature

172 results about "Intelligent manufacturing system" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

User interface for reporting event-based production information in product manufacturing

ActiveUS7380213B2Quality improvementDrawing from basic elementsCopying process control systemsTimestampDisplay device

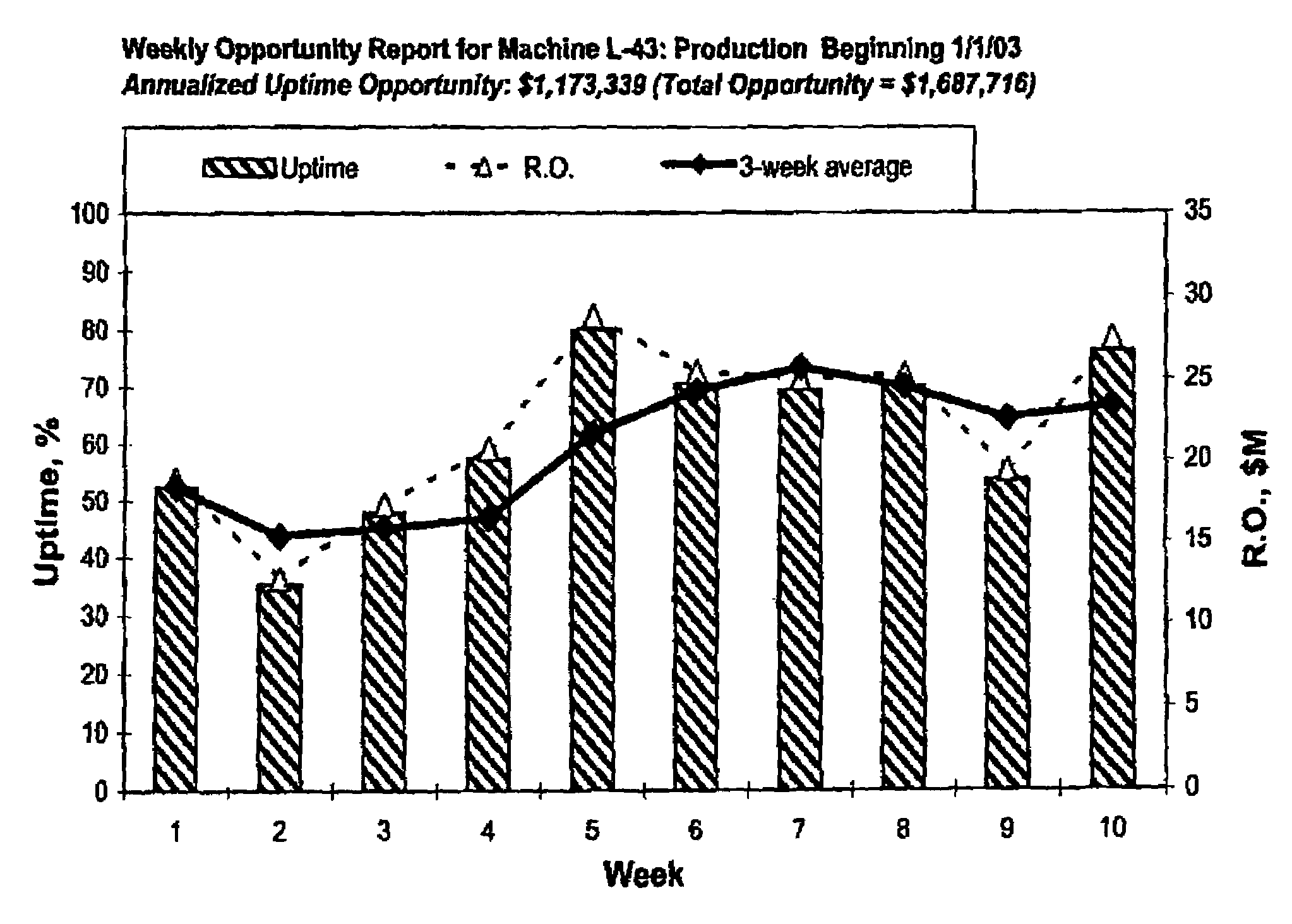

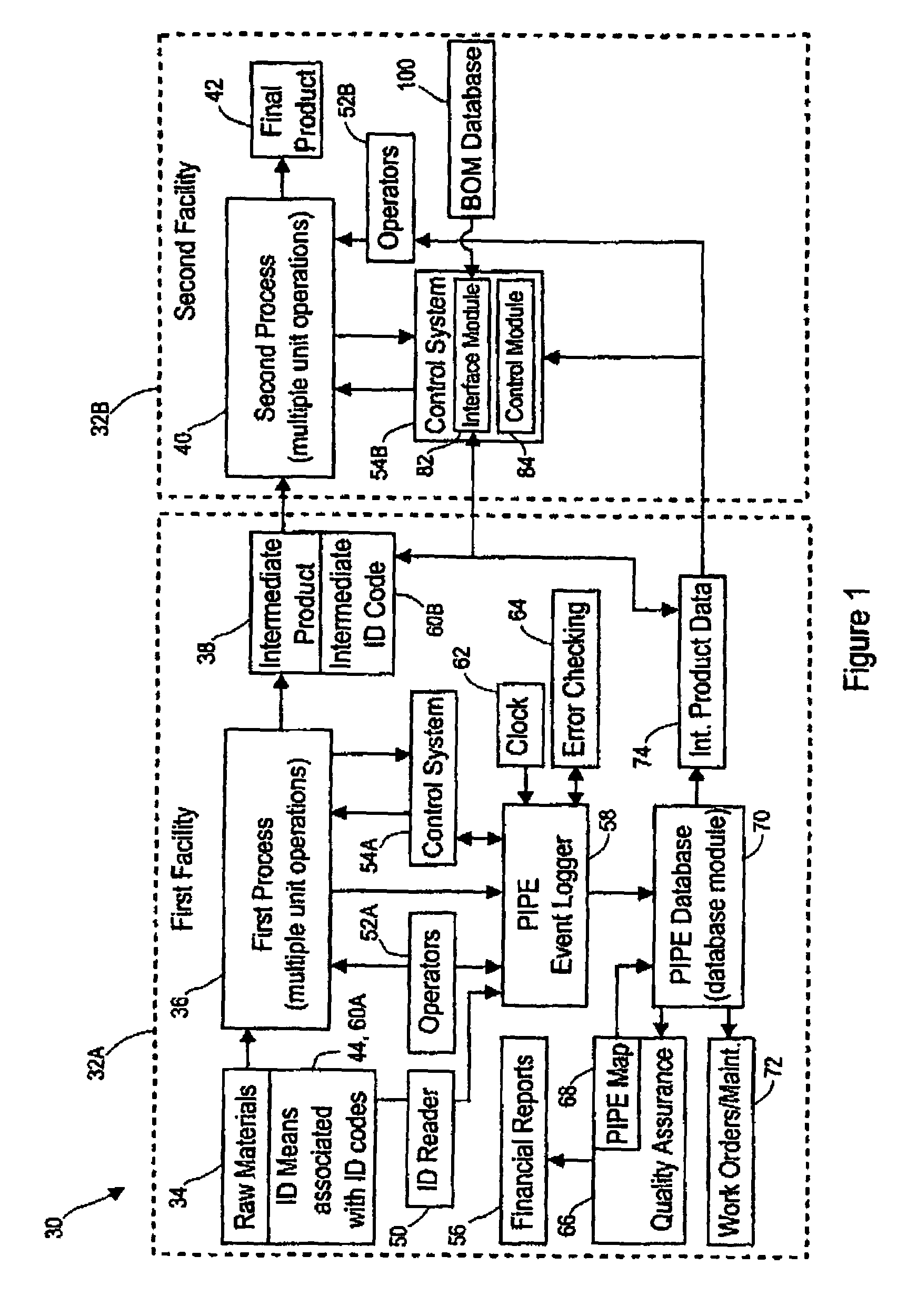

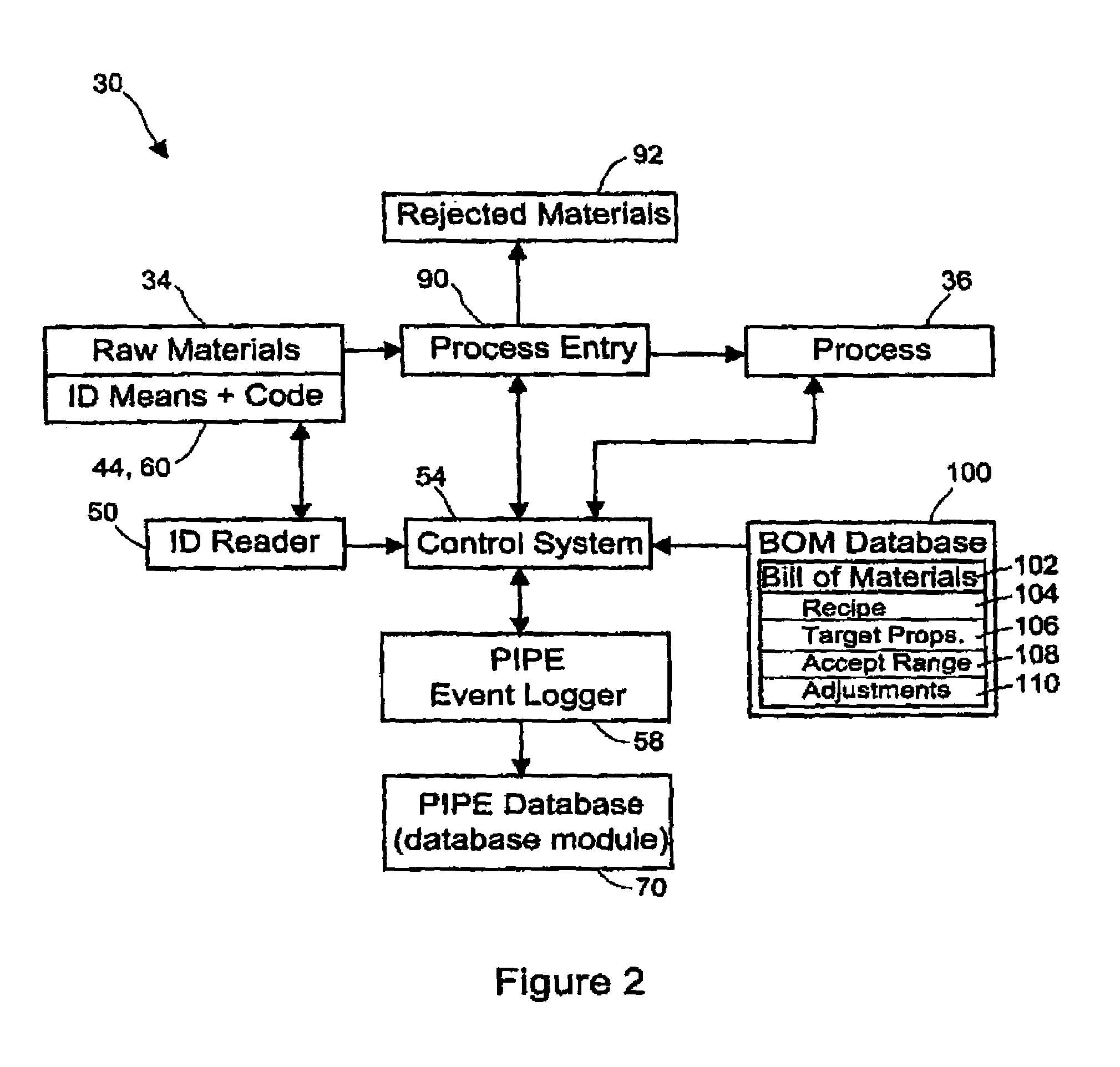

User interface for reporting event-based production information in product manufacturing. Some of the disclosed embodiments include a system, method, computer-readable medium, and display device for processing data stored in a database. The data includes automatically collected event-based production information records in a manufacturing system wherein each record represents an event and includes a timestamp, an event code, and a measure of cost or production loss associated with the event. The embodiments are operable in an intelligent manufacturing system including a process for converting raw materials to a product, a process control system including one or more sensors capable of generating an alarm in response to an event that results in one of waste, machine delay, or decrease product quality, a data logger associated with the process control system for obtaining event parameters associated with the event, a database on a server for recording event parameters obtained by the data logger, and a reporting system cooperatively associated with the database for reporting productivity parameters regarding the process derived at least in part from the event parameters.

Owner:CALLAHAN CELLULAR L L C

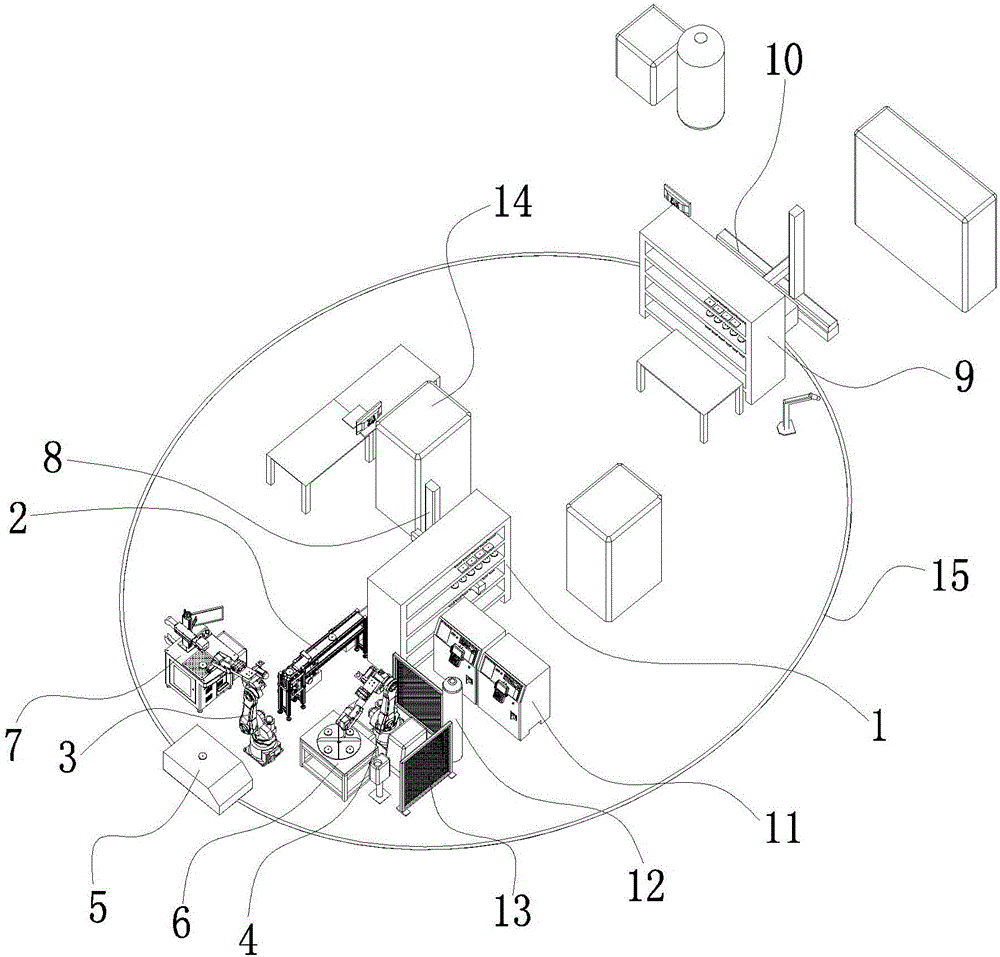

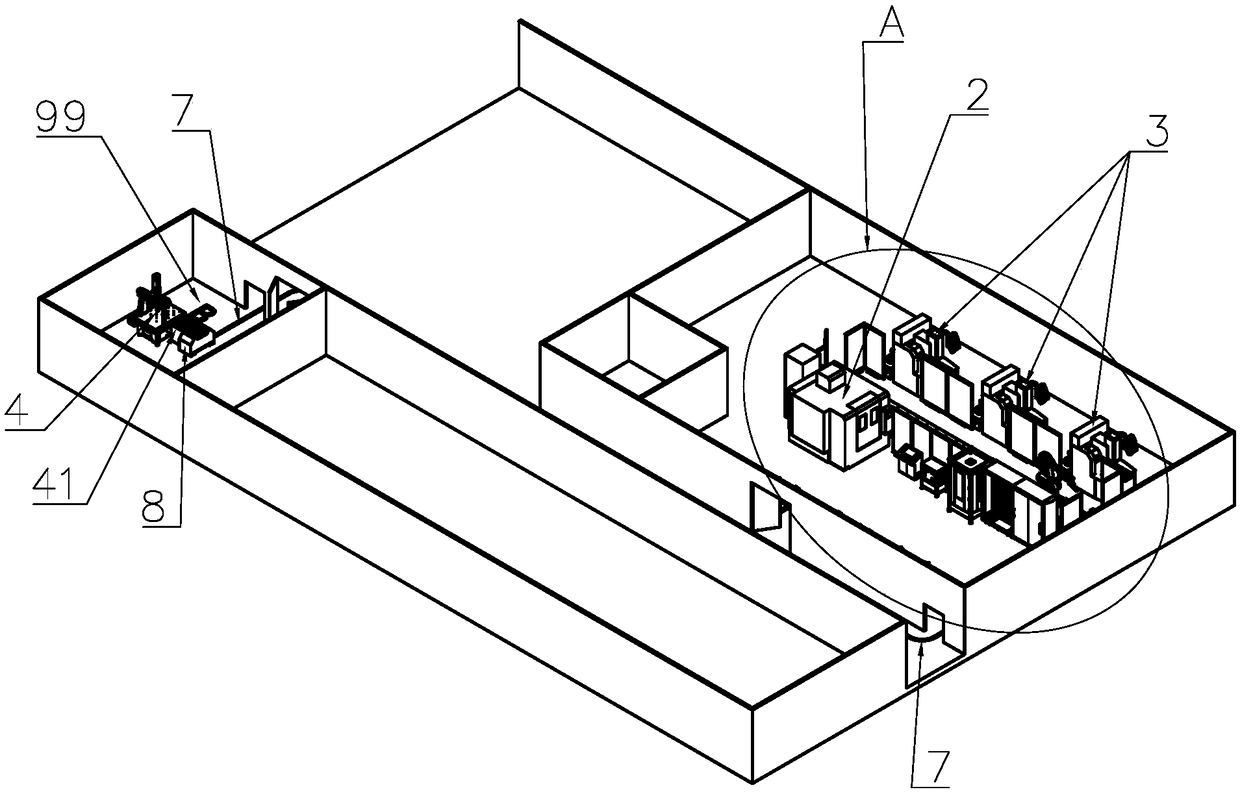

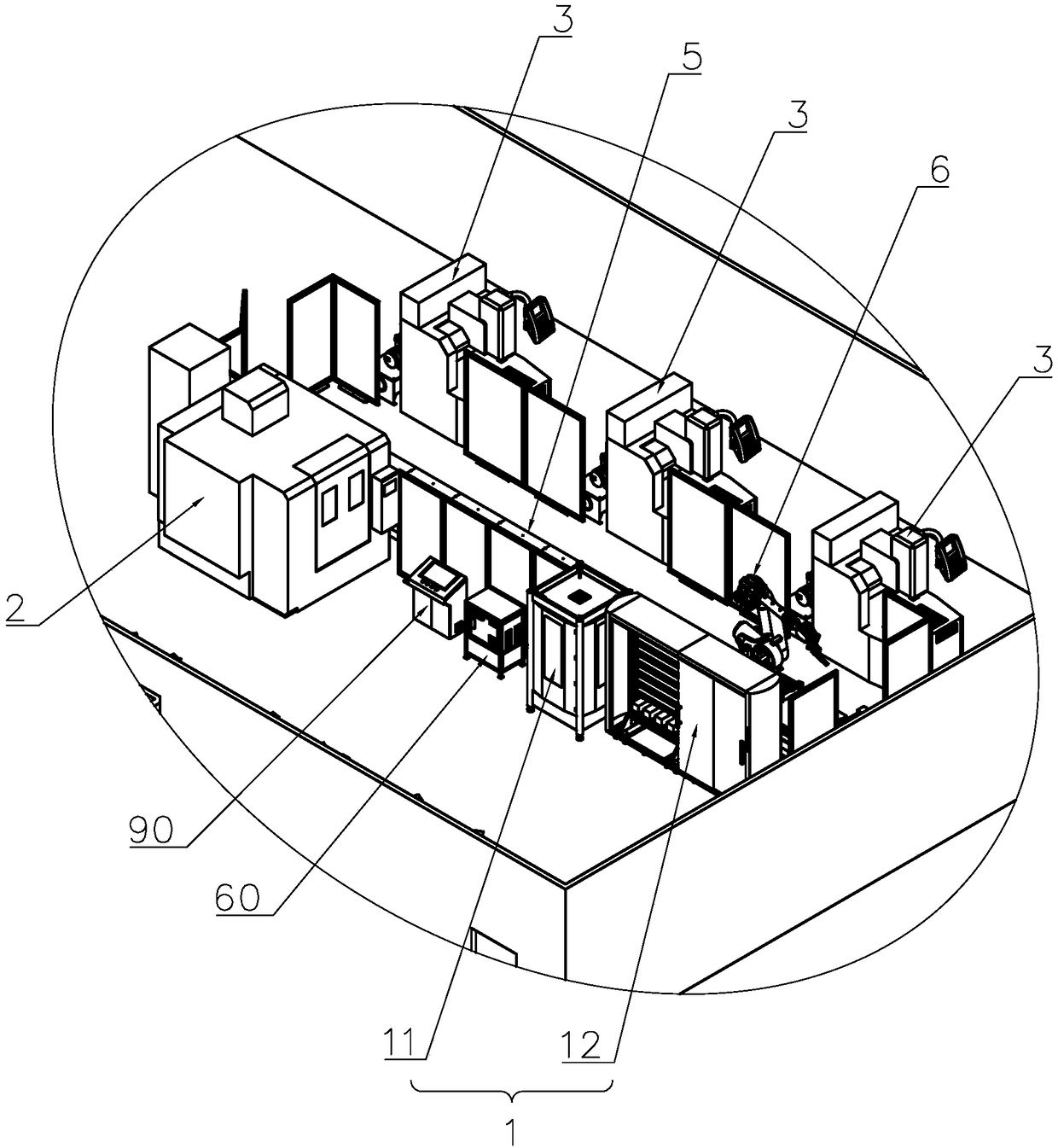

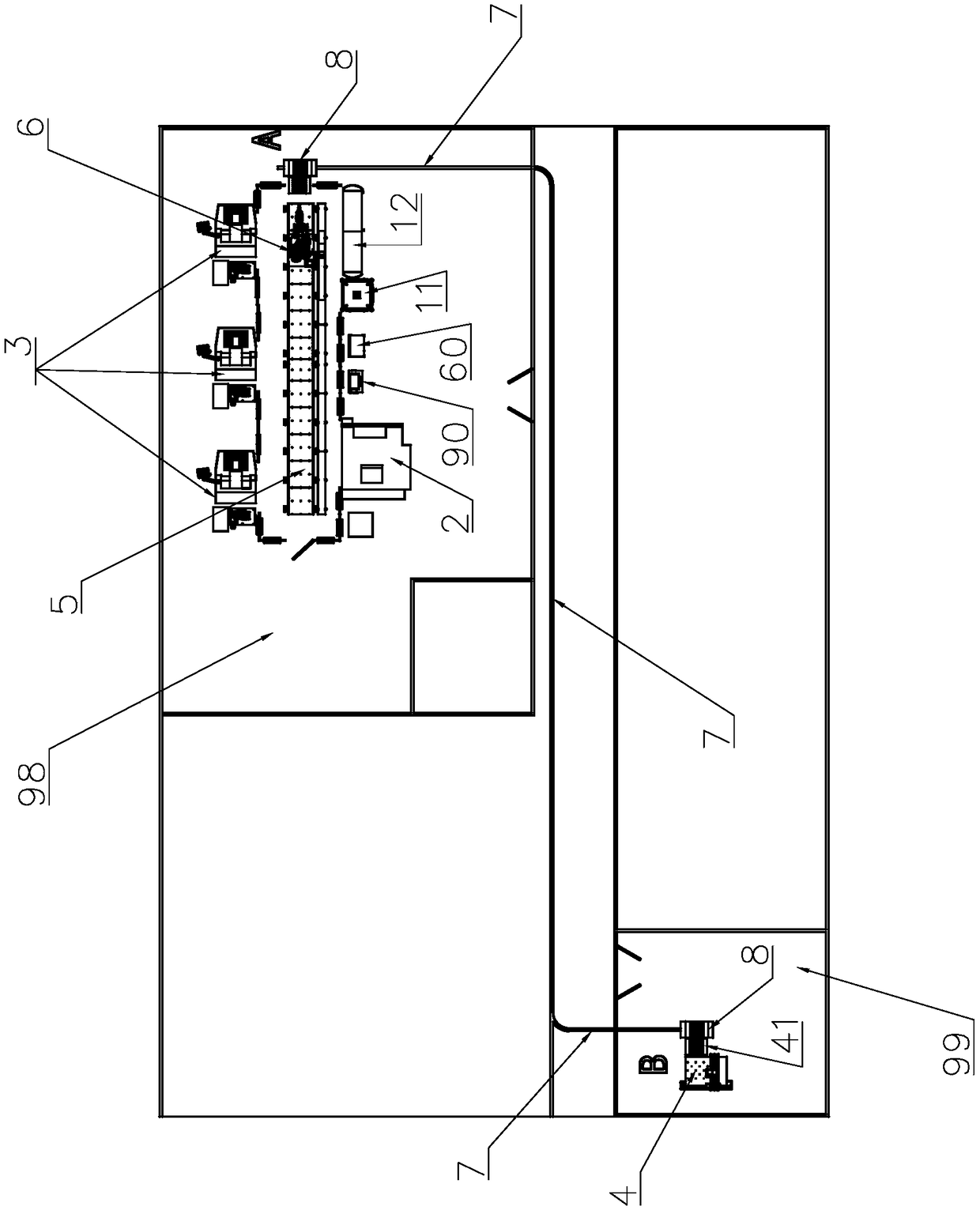

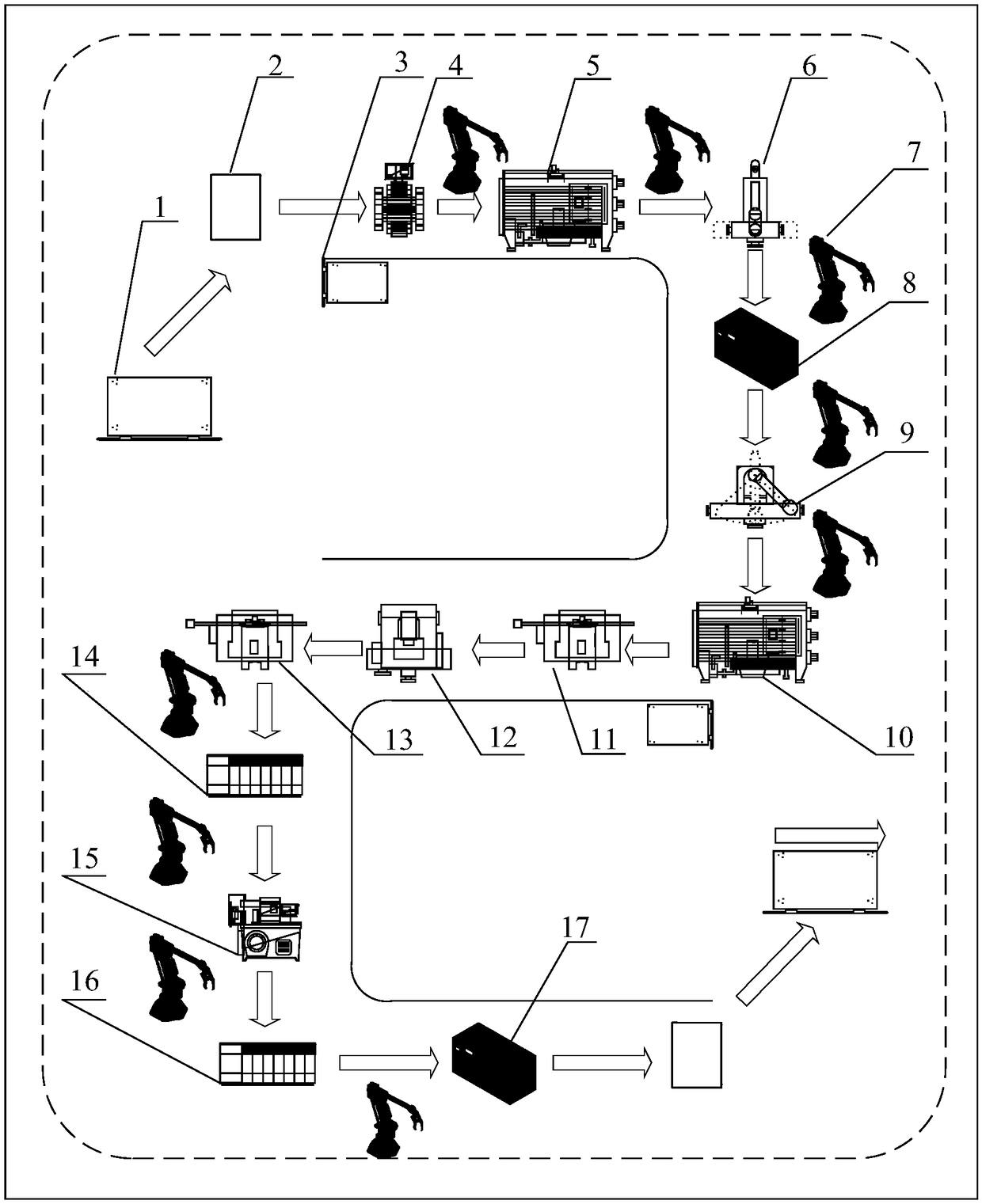

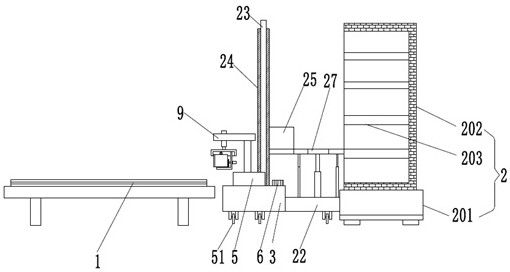

Intelligent manufacturing system based on industrial robot

InactiveCN106078208ALow design costSimple structureOther manufacturing equipments/toolsStacking articlesRemote controlManipulator

The invention relates to an intelligent manufacturing system based on an industrial robot. The system comprises a welding delivery frame for placing workpieces, a welding finished product delivery and storage shelf, a stacking visual manipulator, a stack carrying manipulator and an automatic stack lifting device; and the stack carrying manipulator is positioned on one side of the welding delivery frame, and is corresponding to one end of the automatic stack lifting device. The system is characterized by further comprising a stack carrying robot, a welding stacking manipulator, a multi-station welding automatic tool table, a laser marking machine, an AGV automatic remote control guide car device and a central control cabinet. Compared with the prior art, the system is low in design and manufacturing costs and simple in structure, is provided with the AGV automatic remote control guide car device, has no need to lay such fixing devices as rails and bracket frames in a moving area of an AGV car in material conveying, is not limited by places, roads and space, and is high in automation degree and convenient and simple in operation.

Owner:马鞍山市申海智能装备科技有限公司

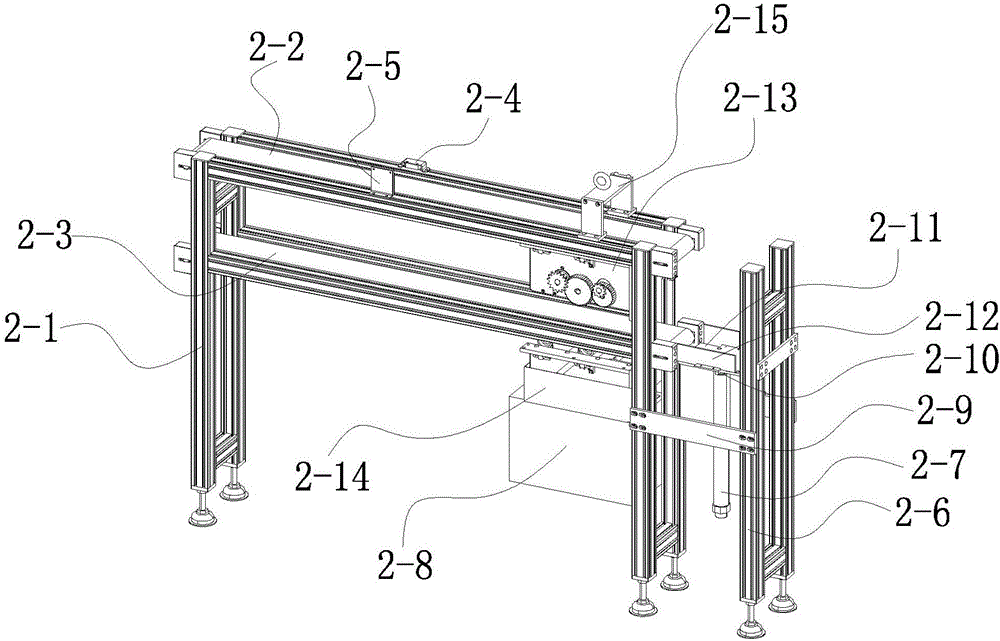

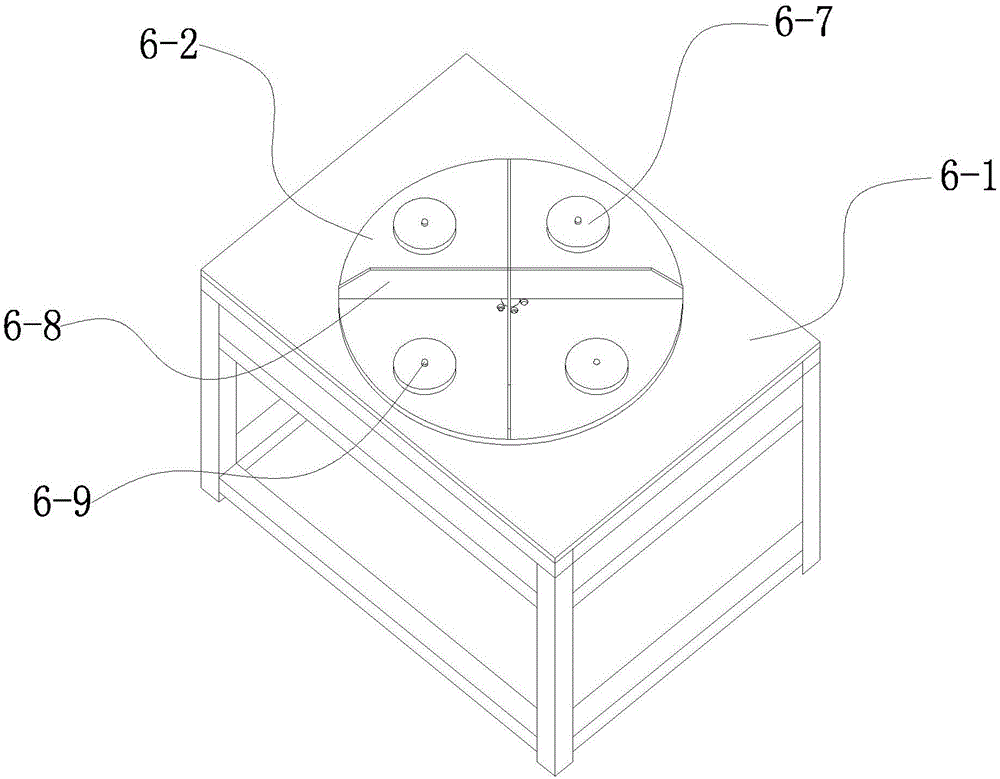

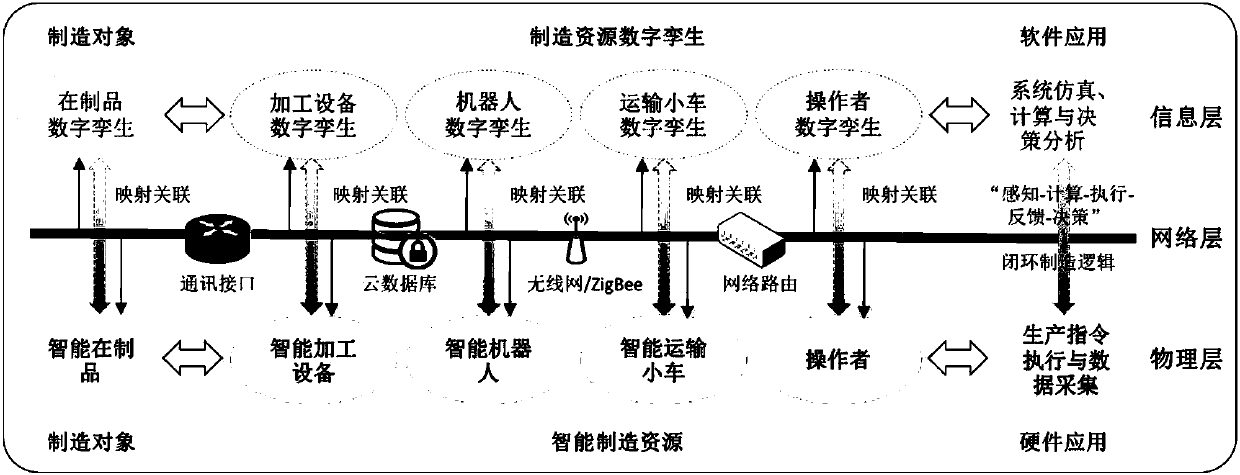

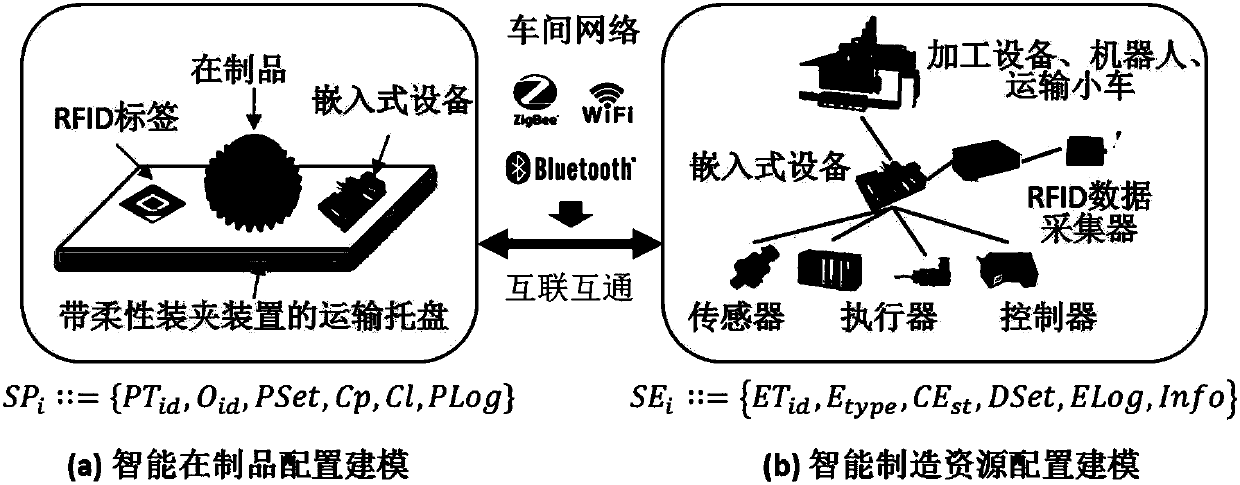

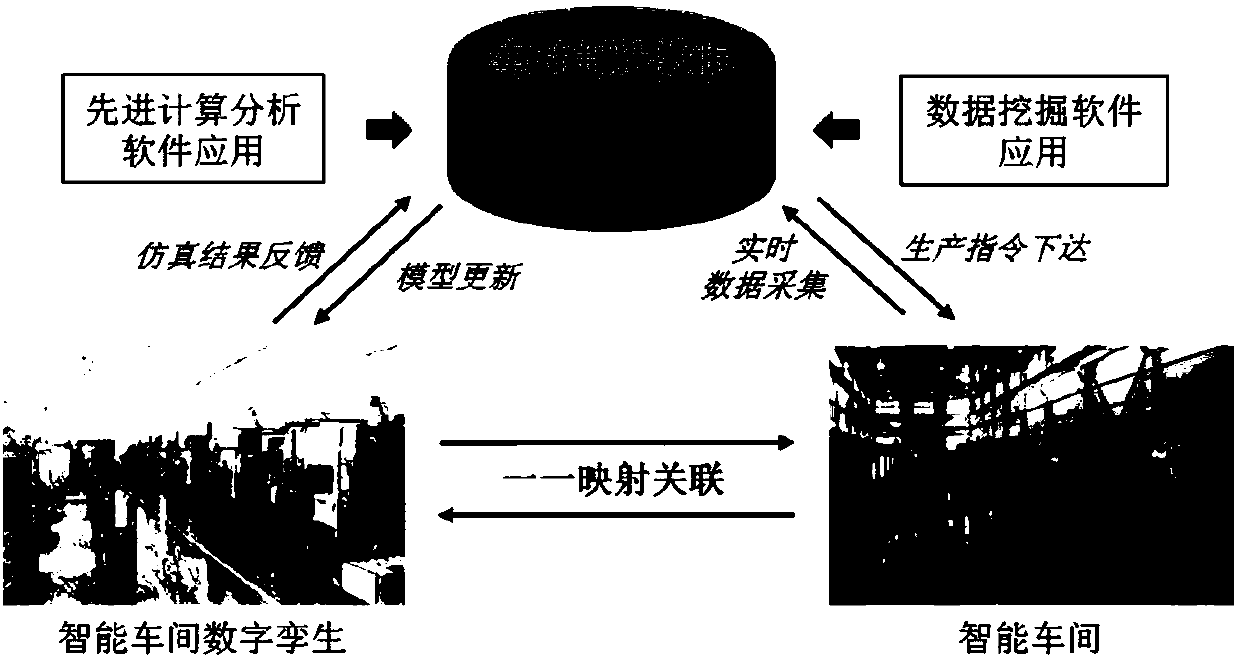

Workshop-grade smart manufacture system based on digital twins and configuration method thereof

InactiveCN108427390AImprove production flexibilityIncrease autonomyTotal factory controlProgramme total factory controlInformation layerPhysical layer

Provided are a workshop-grade smart manufacture system based on digital twins and a configuration method thereof. According to the workshop-grade smart manufacture system, a system architecture composed of a physical layer, a network layer and an information layer is adopted. According to the configuration method of the workshop-grade smart manufacture system, digital twins of an article in process and a manufacture source are built, mapping relations between the digital twins and the article in process and between the digital twins and the manufacture source are also built, in this way, a workshop human-machine-article self-government interaction mechanism is formed, and workshop perception-calculation-execution-feedback-decision closed-loop manufacture logic is achieved. By the adoptionof the workshop-grade smart manufacture system based on the digital twins and the configuration method thereof, a digital twin technology is applied to workshop-grade smart manufacture system modelingand simulating, an optimized smart workshop production operation scheme is given, support is provided for improving the production flexibility, self-government capacity and dynamic response capacityof industry workshops, and certain references are provided for transforming and upgrading traditional manufacture workshops into smart manufacture workshops.

Owner:CHANGAN UNIV

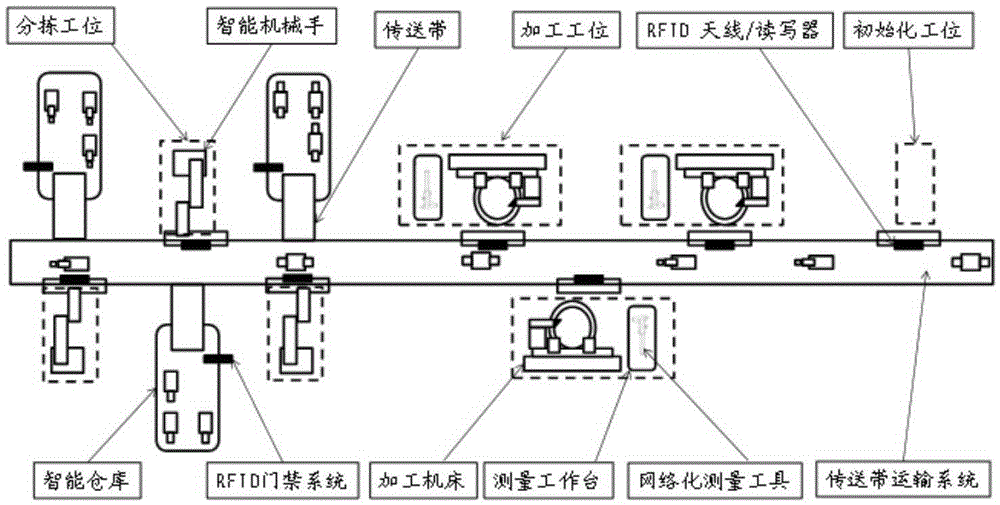

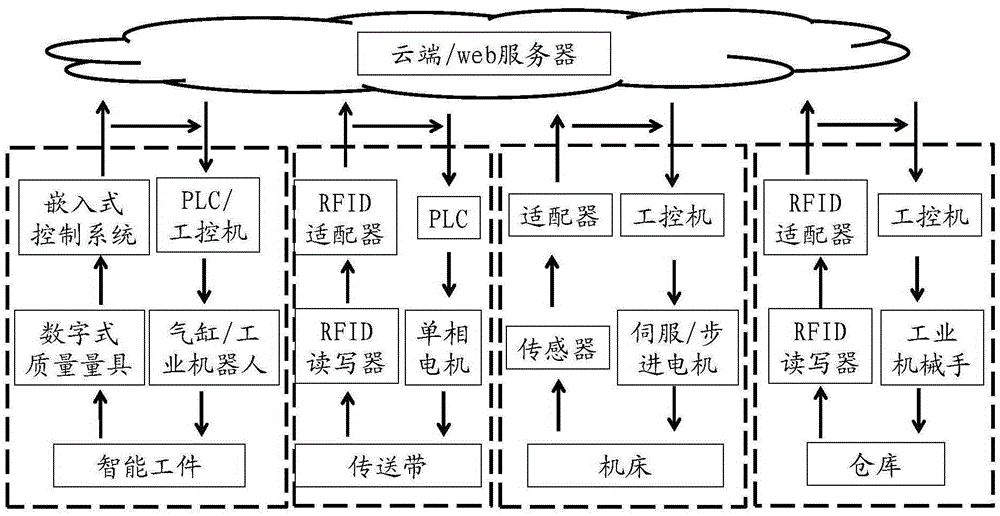

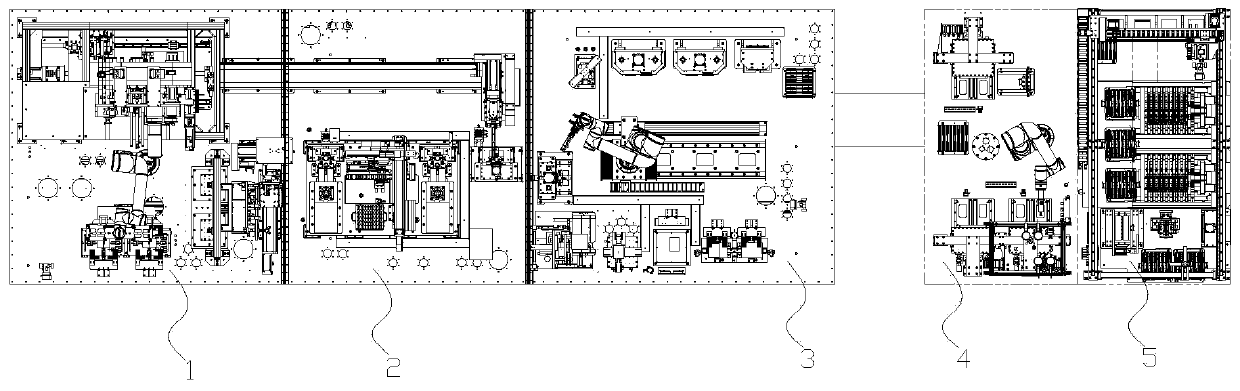

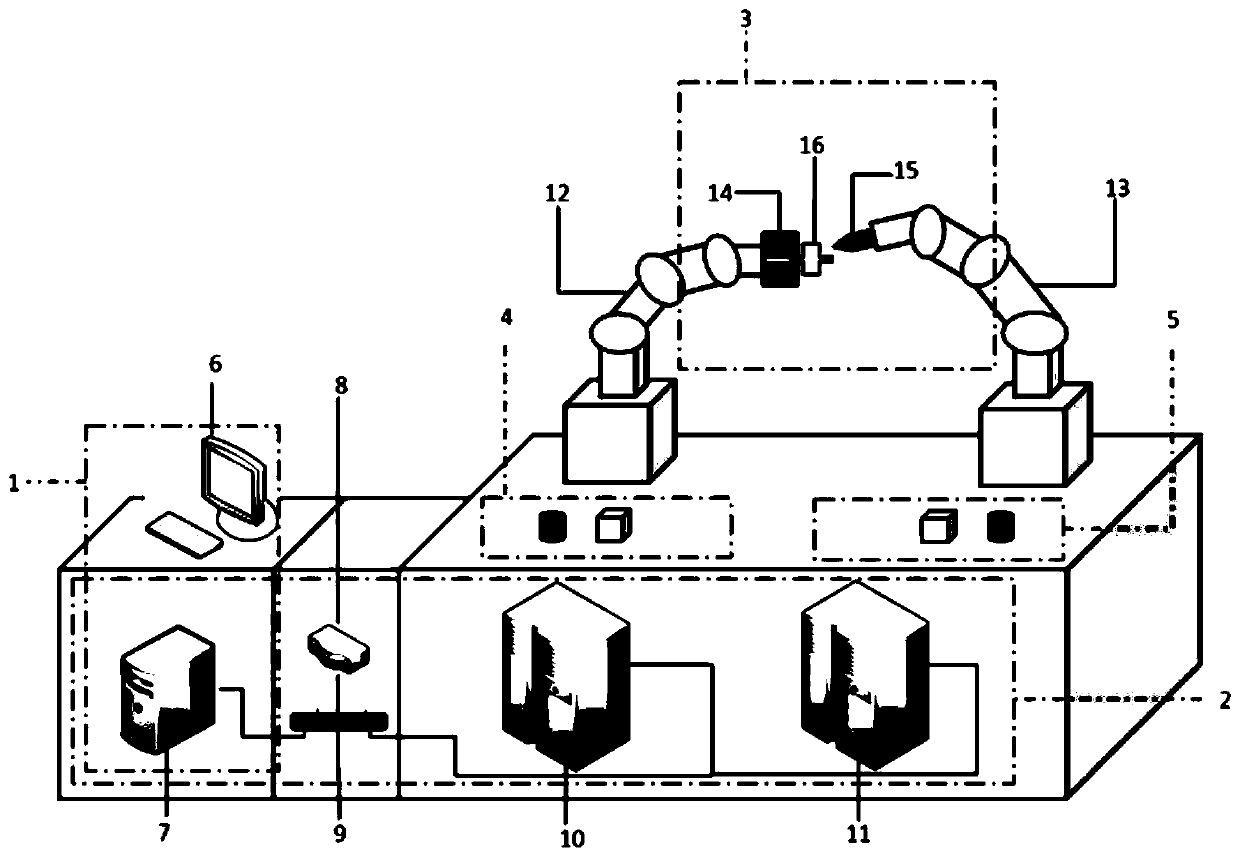

Robot-contained multi-unit intelligent manufacturing system based on smart-RFID tags

ActiveCN105388860AHave the ability to controlIncrease flexibilityTotal factory controlProgramme total factory controlWeb serviceWorkstation

A robot-contained multi-unit intelligent manufacturing system based on smart-RFID tags includes intelligent work pieces, an initialization workstation, processing workstations, sorting workstations, intelligent warehouses, and a conveyer belt conveying system, wherein each processing workstation includes a processing machine tool and a measuring workbench; and each intelligent work piece is provided with a smart-RFID tag, and production process information of the work pieces is written in the tag on the initialization workstation through RFID reading-writing devices. In a production process, the intelligent work pieces and the processing devices can perform production information interaction through radio-frequency signals, the sorting workstations can achieve on-line sorting of different types of the work pieces through smart-RFID tag information of the intelligent work pieces, and the intelligent warehouses can perform automatic statistics on work piece storage information according to the smart-RFID tag information. The intelligent manufacturing system includes independent control modules, each control module can automatically perform relevant operations and can receive control instructions sent by a cloud / web server; and distributed control of the intelligent manufacturing system can be achieved, and each module has the control ability, so that the flexibility of the intelligent manufacturing system can be improved, and the response time of the intelligent manufacturing system can be shortened.

Owner:XI AN JIAOTONG UNIV

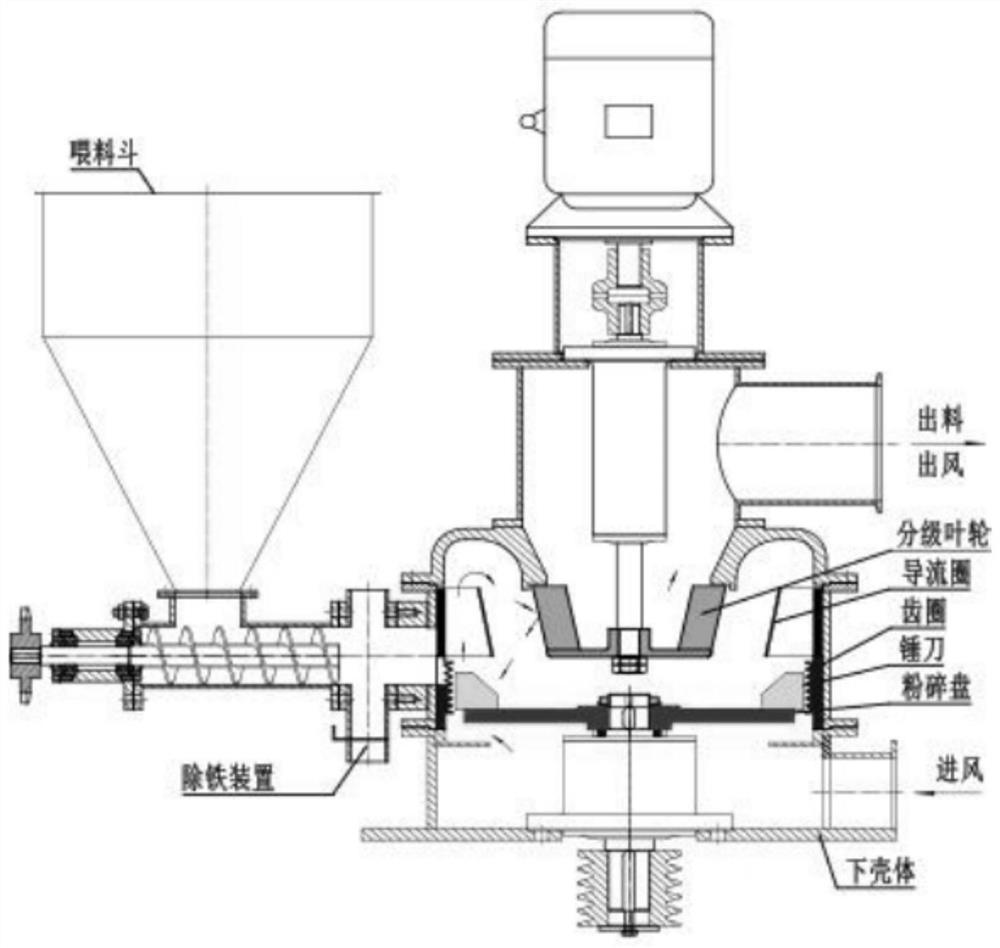

Multi-dosage-form Chinese and western medicine product full-process intelligent manufacturing system and construction method

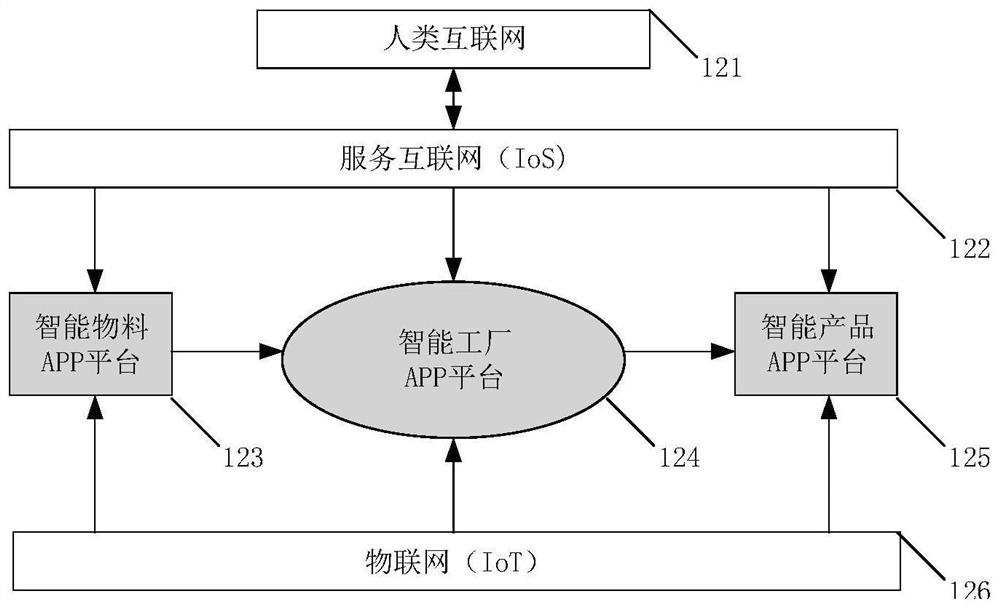

PendingCN112163688AIncrease productivityReduce operating costsForecastingResourcesInformation interoperabilitySmart factory

The invention provides a multi-dosage-form Chinese and western medicine product full-process intelligent manufacturing system and a construction method. The invention breaks through a multi-dosage-form Chinese and western medicine product manufacturing process and a digital equipment technology. Advanced intelligent equipment such as intelligent equipment facilities, intelligent sensors, intelligent instruments and meters, industrial robots and the like are applied to implementation, and an advanced industrial control system, industrial control software and the like are integrated through technologies such as the Internet of Things technology, the big data technology, cloud computing, artificial intelligence, information security and the like. The information intercommunication between people and equipment, the information intercommunication between equipment and equipment, the information intercommunication between equipment and systems and the information intercommunication between systems are achieved. The full-life-cycle information integration of products from research and development design, planned purchasing, production and manufacturing, quality inspection, sales delivery,product tracing, after-sales service and the like is achieved.

Owner:CHONGQING PHARSCIN PHARM CO LTD

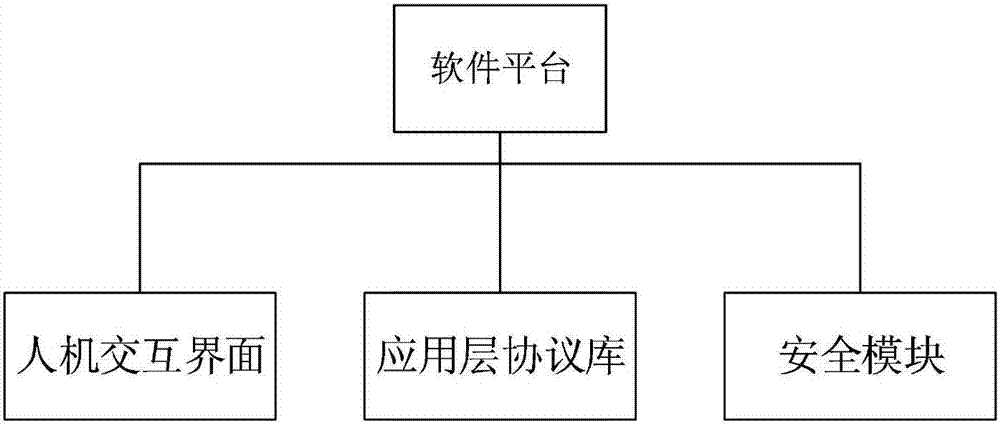

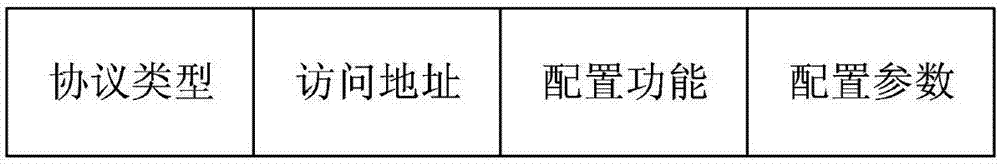

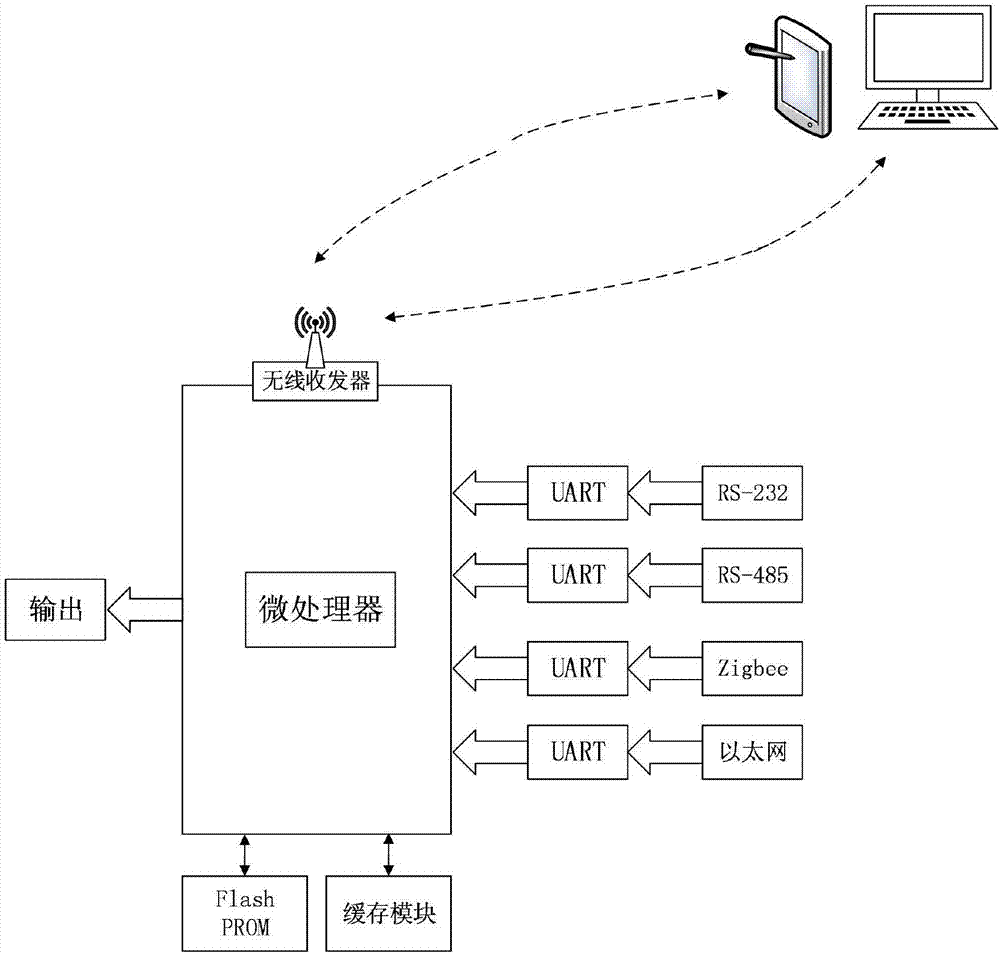

Configurable multi-protocol data access method and device under industrial 4.0 environment

The invention discloses a configurable multi-protocol data access method and device under an industrial 4.0 environment. The device comprises a terminal for remote protocol configuration, an industrial wireless network, and a data access card supporting the multi-protocol; the device function comprises a manufacturing equipment communication protocol base, a configurable communication protocol format parameter, and a newly added manufacturing equipment convenient access intelligent manufacturing system; the method comprises the following steps: establishing an editable application layer protocol base on a computer or a mobile phone according to different manufacturing equipment communication protocol format requirements; configuring an application layer communication protocol on the computer or an intelligent mobile phone according to a new equipment communication requirement when the new manufacturing equipment is accessed into the manufacturing system; downloading the configured application layer communication protocol data to the data access card, storing and updating the communication protocol, and accessing the newly added equipment into the manufacturing system. The device adopts the configurable multi-protocol data access device aiming at the manufacturing equipment access problem under the industrial 4.0 background, so that the manufacturing equipment can be conveniently accessed into the manufacturing system.

Owner:SOUTH CHINA UNIV OF TECH

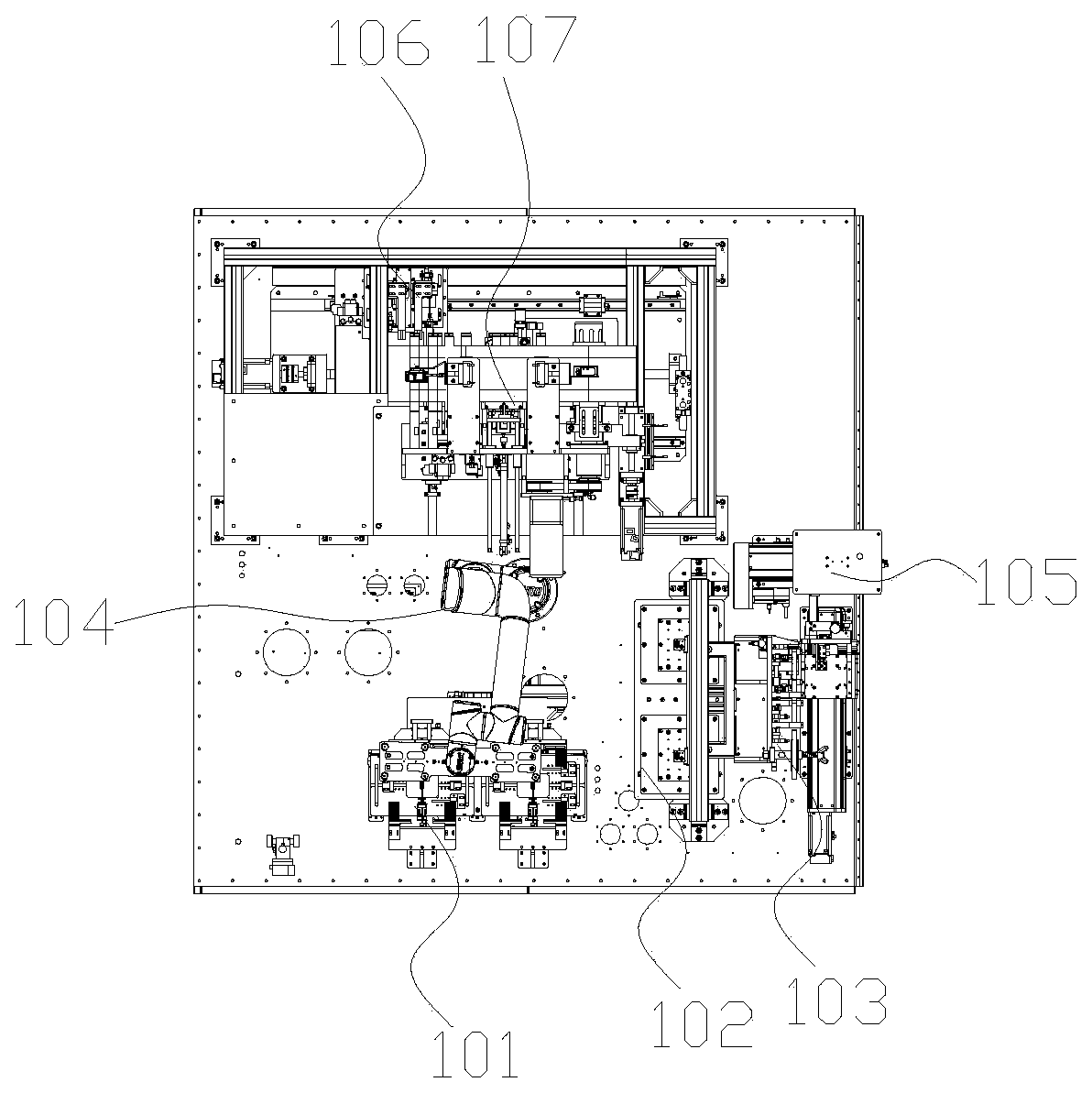

MES electrode intelligent manufacturing and detecting system, mould intelligent manufacturing system and mould manufacturing method

ActiveCN108526622AReduce dependenceRealize automatic fault alarmElectrical-based machining electrodesElectric dischargeLogistics management

The invention provides an MES electrode intelligent manufacturing and detecting system, a mould manufacturing system and a mould manufacturing method. The MES electrode intelligent manufacturing and detecting system comprises a feeding frame, a CNC electrode machining center, a coordinate measuring machine (CMM), a robot travelling guide rail, a robot and a central control system. Each electrode workpiece is provided with an RFID chip, a mechanical claw of the robot is provided with an RFID reading and writing device, and the robot is mounted on the robot travelling guide rail. An AGV magneticstripe navigation line is arranged between the CMM and the robot travelling guide rail, and an AGV logistics vehicle is arranged on the AGV magnetic stripe navigation line. A CNC system, a CMM control system, a robot control system and an AGV control system are all connected to the central control system. The mould manufacturing system comprises the MES electrode intelligent manufacturing and detecting system and an electric discharge machine (EDM). The invention further provides the method for manufacturing a mould through the mould manufacturing system. The manufacturing efficiency of the electrode workpieces and the mould is effectively improved, and the product passing rates of the electrode workpieces and the mould are effectively increased.

Owner:珠海汉迪自动化设备有限公司

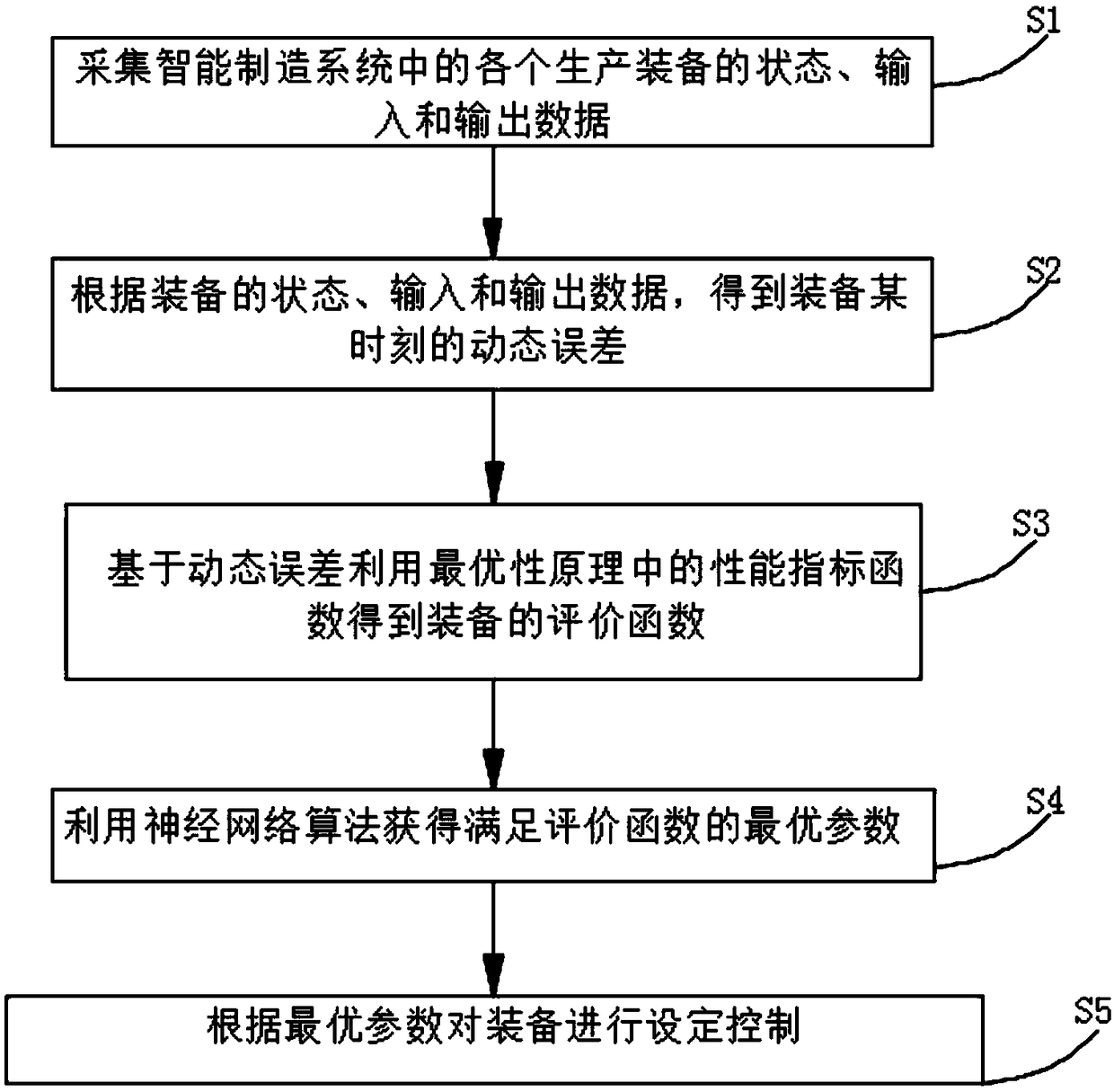

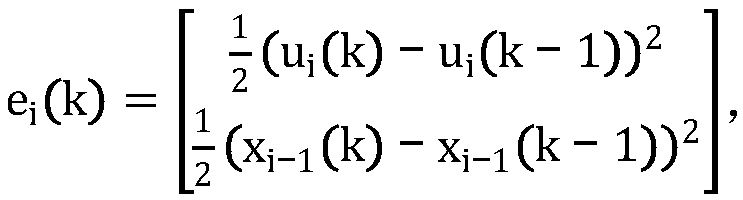

Cooperative control method for intelligent manufacturing system

ActiveCN109031949AReduce information trafficReduce the amount of calculationTotal factory controlAdaptive controlPerformance indexIntelligent manufacturing system

The invention discloses a cooperative control method for an intelligent manufacturing system, which comprises the steps as follows: acquiring state, input and output data of each production equipmentin the intelligent manufacturing system; according to the state, input and output data of the equipment, obtaining a dynamic error of the equipment at a certain moment; based on the dynamic error, obtaining an evaluation function of the equipment by utilizing a performance index function in an optimality principle; obtaining an optimal parameter which meets the evaluation function by utilizing a neural network algorithm; and according to the optimal parameter, carrying out setting control on the equipment. According to the invention, based on knowledgeability and automation, each intelligent equipment has a reinforcement signal determined by all adjacent production equipment, and influence of outside interference and equipment condition changes on the intelligent manufacturing system can be adaptively eliminated, so that the intelligent manufacturing system has good robustness.

Owner:GUANGDONG UNIV OF TECH

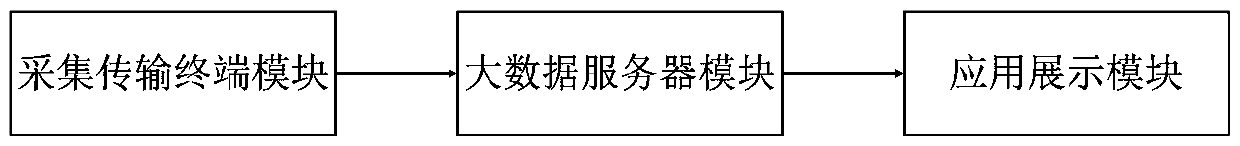

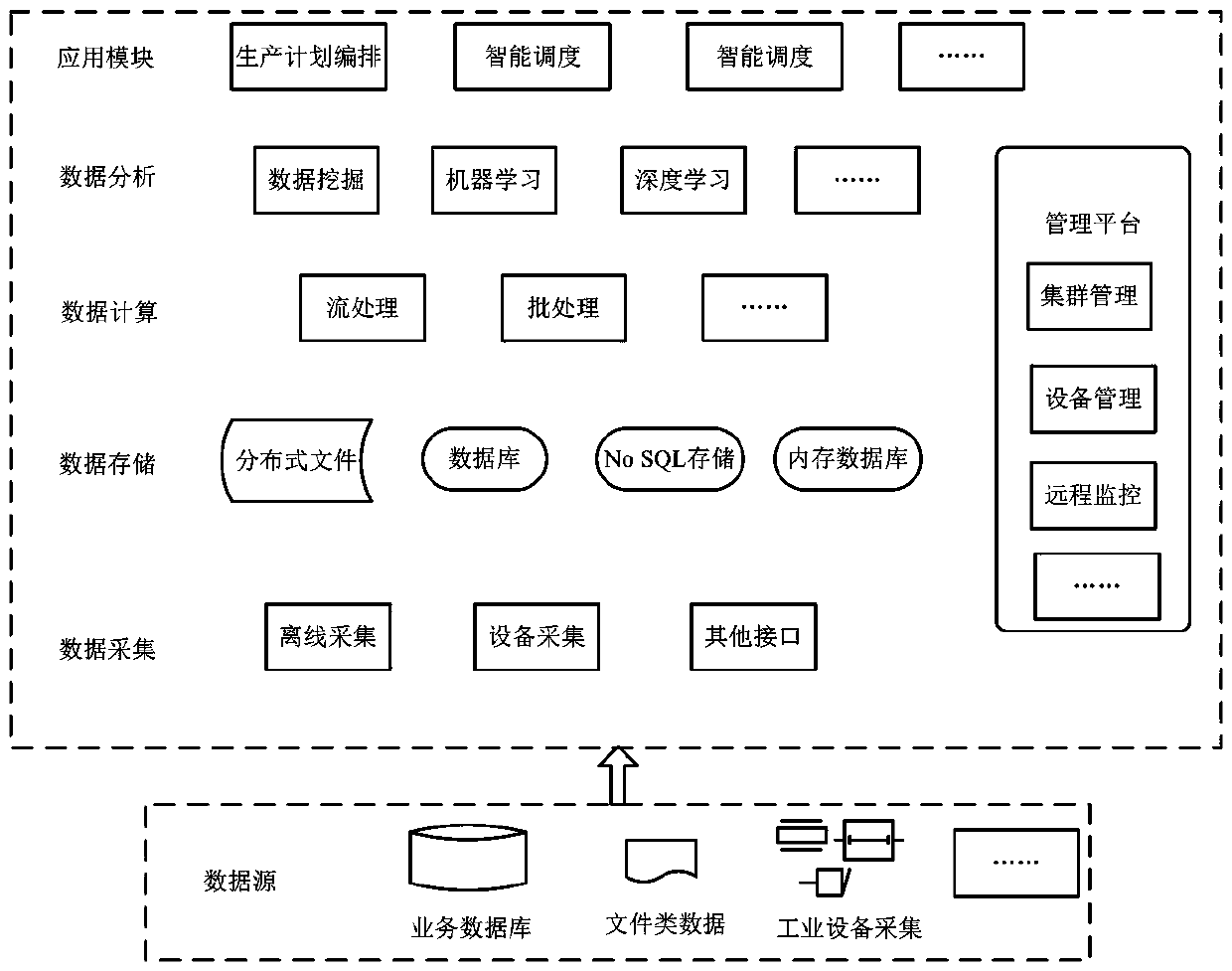

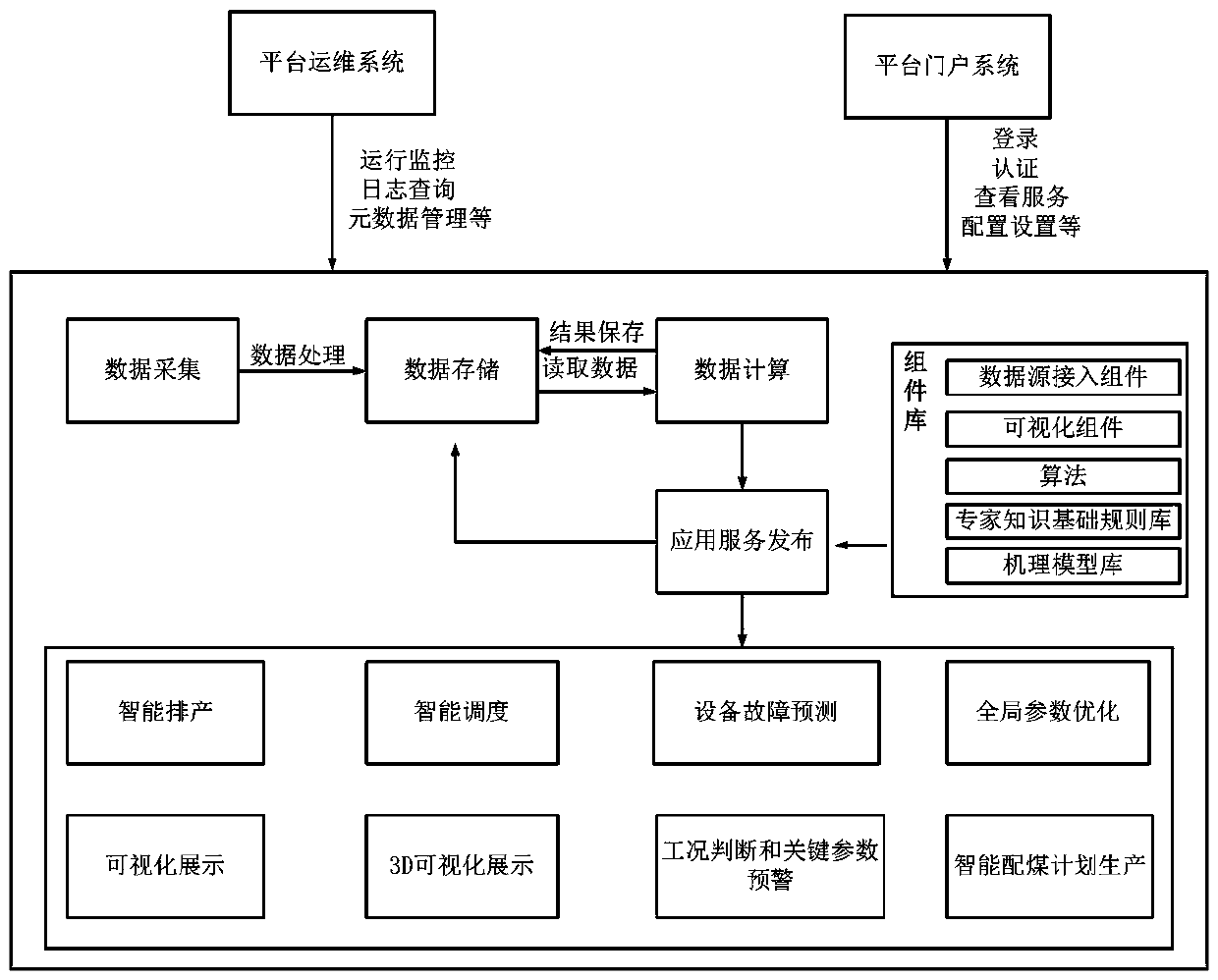

Coking intelligent manufacturing system based on big data

InactiveCN110161999ARealize monitoringRealize data collectionTotal factory controlProgramme total factory controlOptimal controlData acquisition

The invention discloses a coking intelligent manufacturing system based on big data. The system comprises a collection and transmission terminal module, a big data server module and an application display module, wherein the collection and transmission terminal module collects whole-plant data of an existing coking plant and uploads the whole-plant data to the big data server module; the big dataserver module stores, analyzes and calculates the uploaded data and uploads the result to the application display module; and the application display module controls and displays whole-plant production of the coking plant according to the uploaded result. Through setup of the intelligent big data system, monitoring, data collection, control and centralized display on the whole coking plant and each section are realized; overall parameters and control parameters of the system can be optimized in real time according to the monitoring data of each section, and optimal control over each section isrealized; and meanwhile, optimal and intelligent control is performed on the whole plant, so that reliability is high, cost is low, and efficiency is high.

Owner:HUNAN QIANMENG INTELLIGENT INFORMATION TECHCO LTD

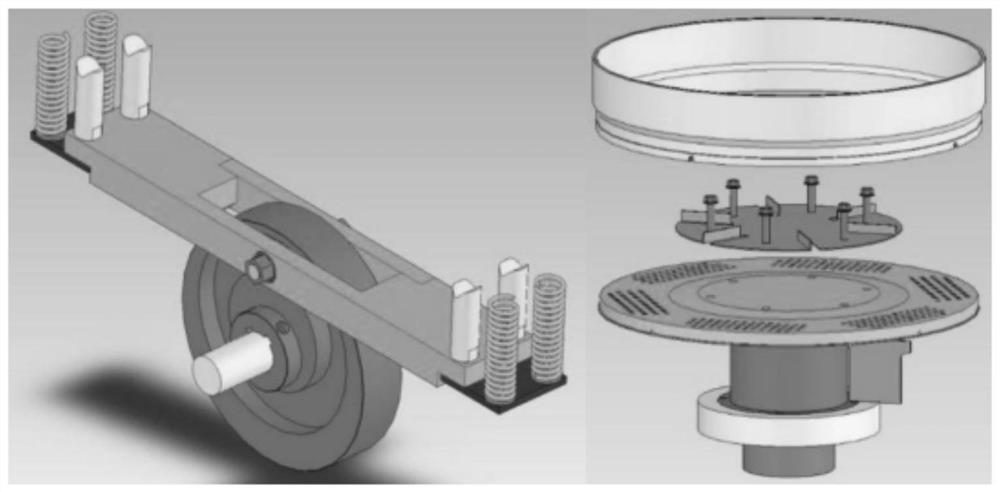

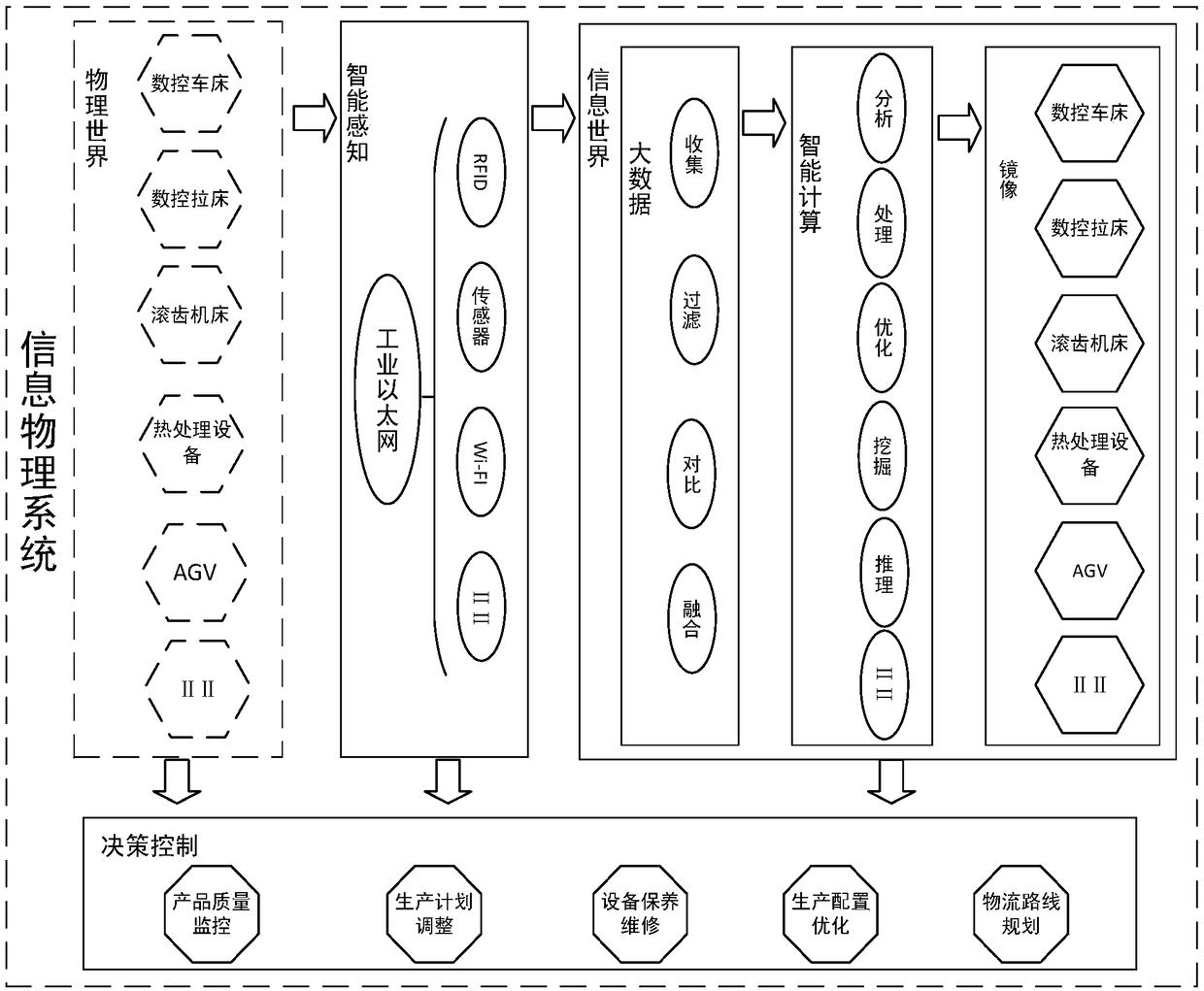

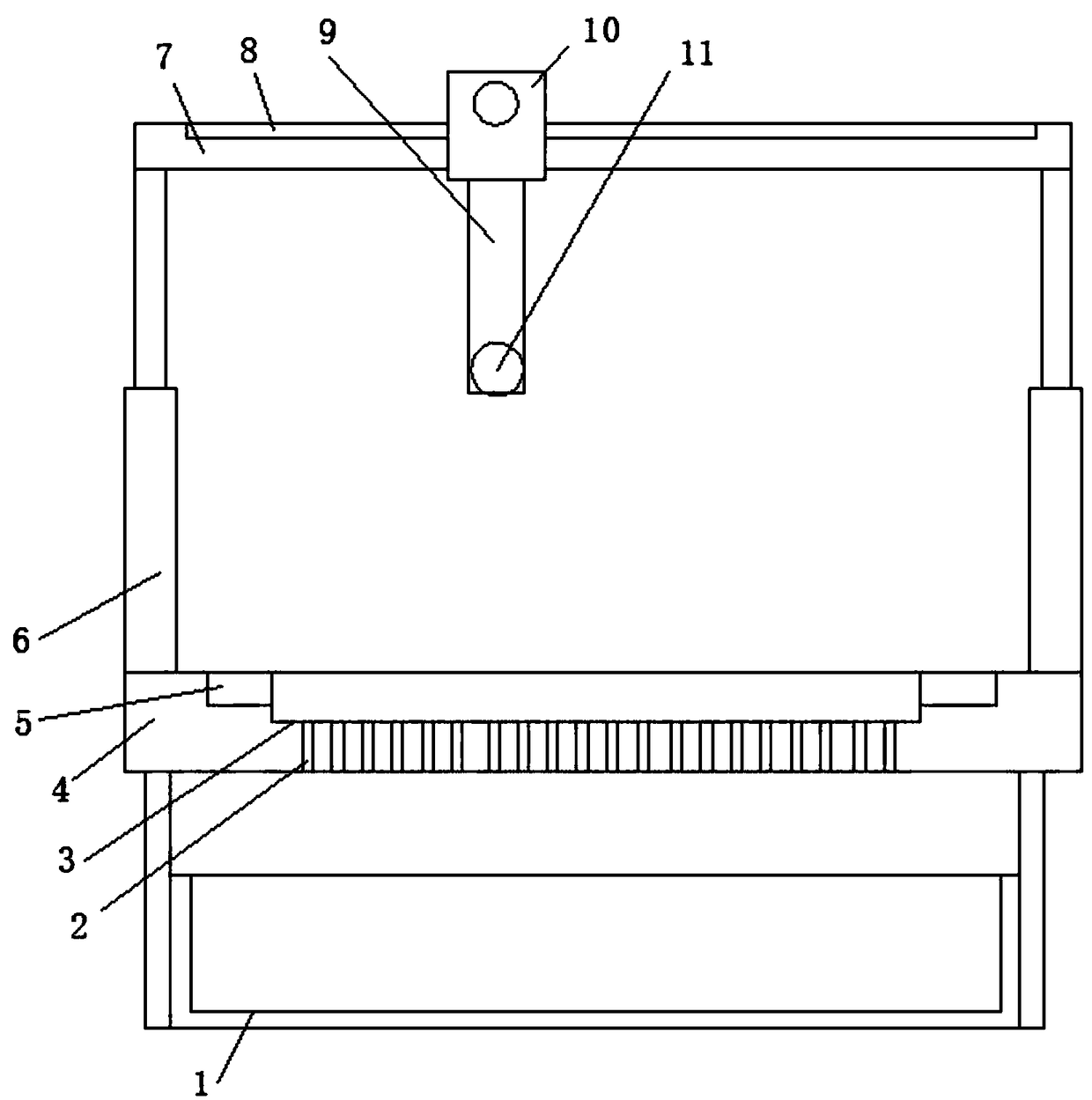

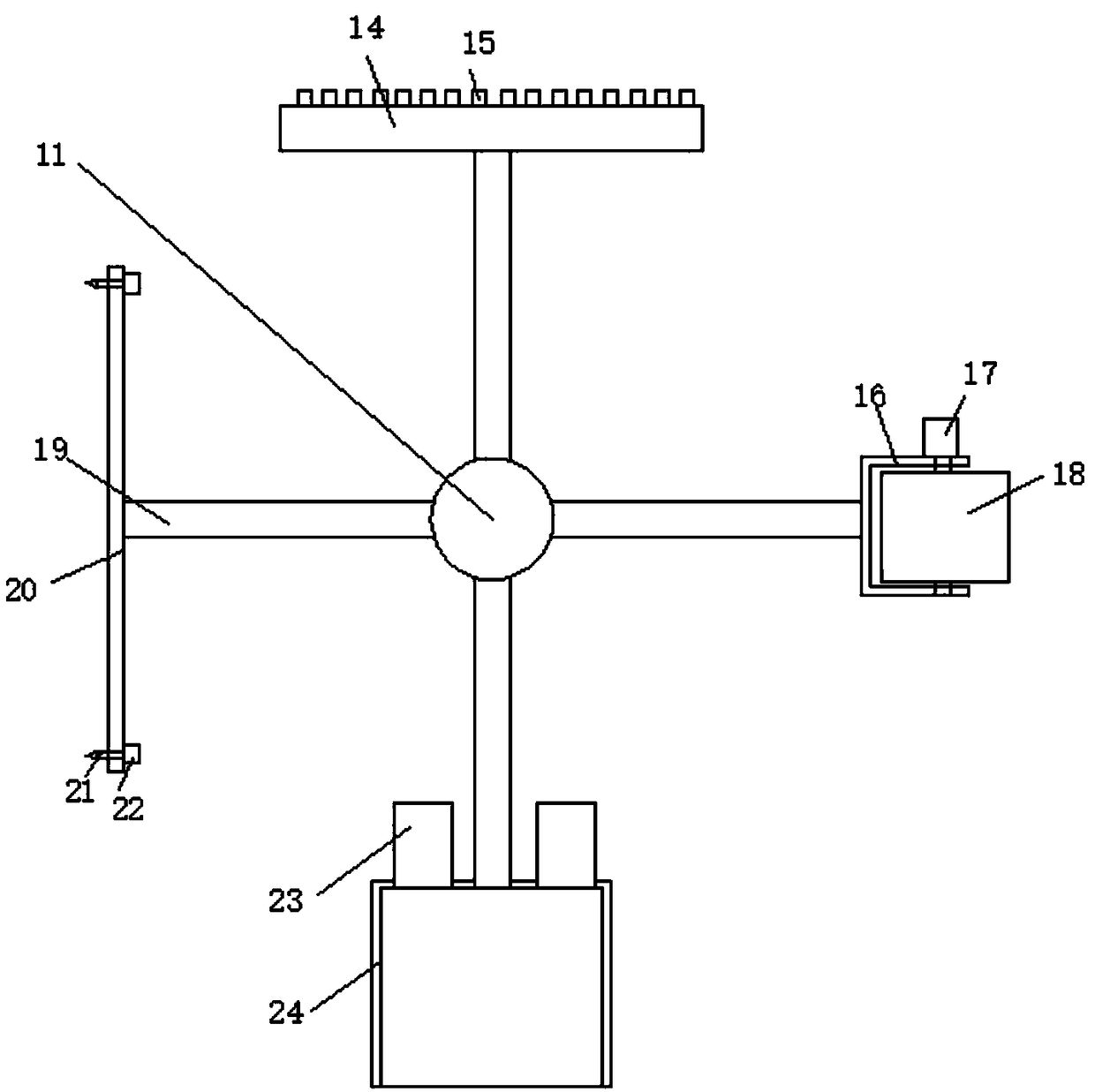

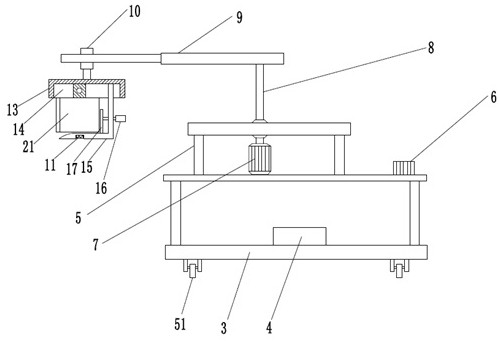

Intelligent manufacturing system for precise speed reducer planetary gears

InactiveCN109249186ARealize intelligent manufacturingImprove product qualityReduction drivePhysical system

The invention relates to an intelligent manufacturing system for precise speed reducer planetary gears, and belongs to the field of machining. The system comprises planetary gear machining equipment,an information physical system and a material system. The planetary gear machining equipment is used for completing a machining process of the planetary gears from blanks to production of finished workpieces; the information physical system is used for optimizing, analyzing and intelligently controlling the planetary gears in the machining process; and the material system is used for completing automatic supply, loading and unloading of workpieces and tool clamps in a planetary gear production process. The production process of the planetary gears is optimized and analyzed, waste of resourcesis relieved, the amount of labor of operators is reduced, the production quality and efficiency of the planetary gears are improved, and thus, intelligent manufacturing of the precise speed reducer planetary gears is realized.

Owner:CHONGQING UNIV

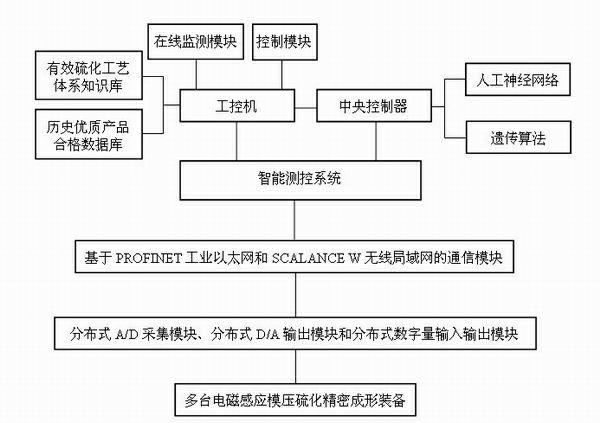

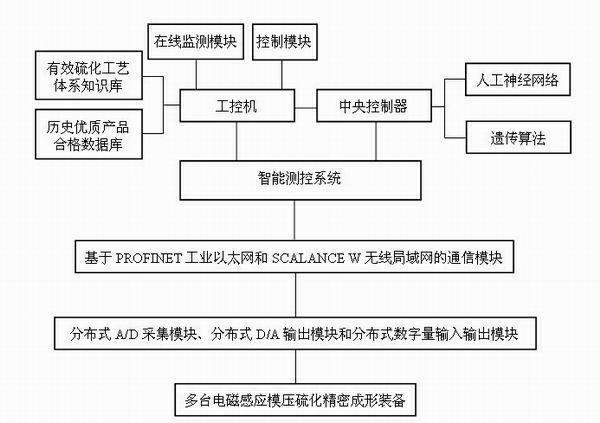

Intelligent manufacturing system for precisely forming high-precision mechanical basic part

ActiveCN102495606ASupport extensionEasy to shareTotal factory controlProgramme total factory controlProcess systemsVulcanization

The invention provides an intelligent manufacturing system for precisely forming a high-precision mechanical basic part, comprising a plurality of electromagnetic induction moulding curing and precise forming devices, an intelligent monitoring system and the like. The intelligent manufacturing system is used for carrying out moulding curing and precise forming as well as automatic de-moulding on the mechanical basic part, and carrying out distribution type online monitoring, display and intelligent optimized control on the technological parameters and state information of each device, including temperature, pressure, time, displacement and the like. According to comprehensive performance requirements on product structure, material, size, working condition, load, application environment and the like, and a product quality condition in the production process, distribution type intelligent monitoring and control can be carried out on the plurality of the electromagnetic induction moulding curing and precise forming devices through wired and wireless communication modules by utilizing a neural network and a genetic algorithm and combining an effective vulcanization process system knowledge base with a historical top-quality product qualification database, thereby improving the qualification rate and the production efficiency of top-quality products; and therefore, the system can not only meet the significant requirement on industrialization of various high-precision mechanical basic parts, but also realize efficient, energy-saving, green and intelligent manufacturing.

Owner:重庆奔腾科技发展有限公司

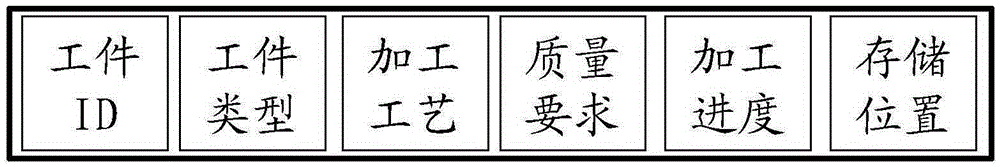

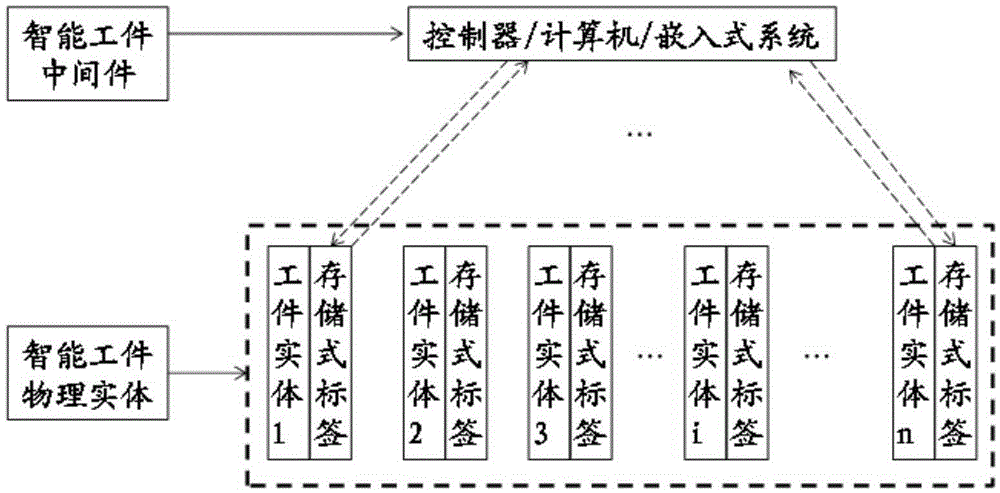

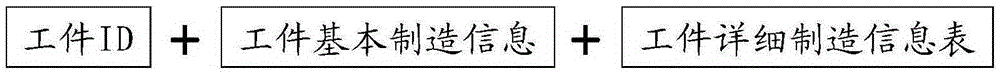

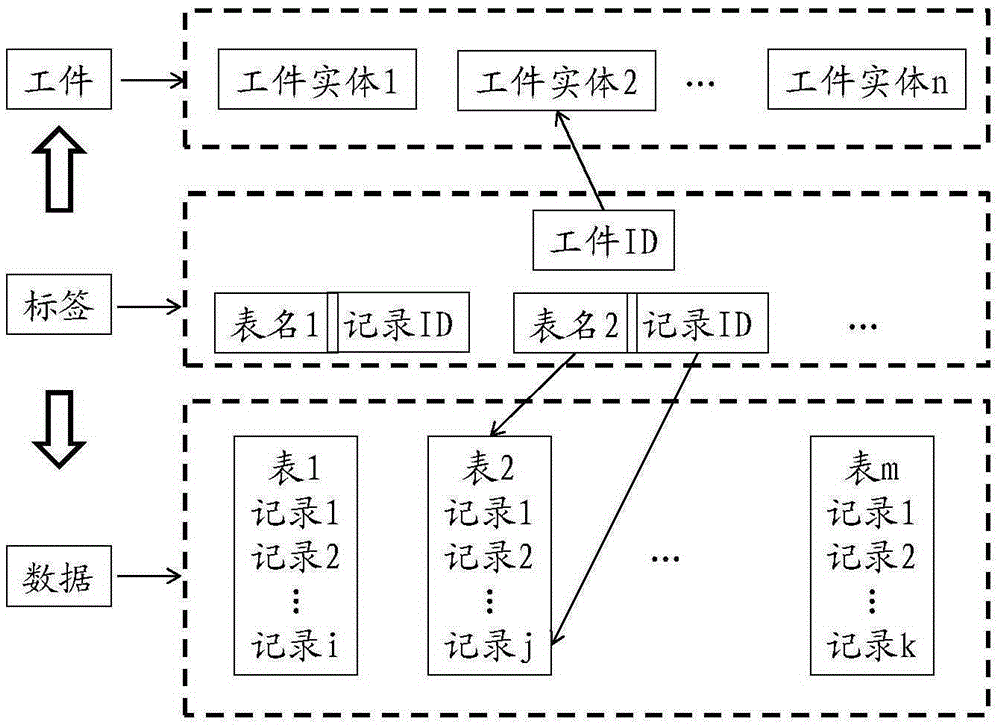

Method for realizing intelligent manufacturing system by using memory type RFID tags

InactiveCN105389610ASmooth preparation processShorten access timeRecord carriers used with machinesMemory typeIntelligent manufacturing system

A method for realizing an intelligent manufacturing system by using memory type RFID tags includes the following steps of: storing an ID code of a work piece, basic manufacturing information of the work piece, and detailed manufacturing information of the work piece into each memory type RFID tag; establishing a dynamic mapping relationship between each intelligent work piece and an intelligent manufacturing system data base through each memory type RFID tag; physically binding the memory unit memory type RFID tag of each intelligent work piece and a corresponding work piece entity to realize that each intelligent work piece has an independent memory unit; and finally realizing intellectualization of a manufacturing unit and intellectualization of a conveying device. According to the invention, intellectualization of the work pieces can be realized through the memory type RFID tags, and a work piece manufacturing process can be smooth in a manufacturing environment without network; and meanwhile, in the manufacturing process, the work pieces and the manufacturing system can perform a negotiation and dynamically adjust the manufacturing process.

Owner:XI AN JIAOTONG UNIV

Multi-module composite complete machine linkage soft package lithium battery intelligent manufacturing control system and method

ActiveCN111258286AAvoid motion interferenceImprove product qualityAssembling battery machinesFinal product manufactureControl signalEngineering

The invention discloses a multi-module composite complete machine linkage soft package lithium battery intelligent manufacturing control system and method, and relates to the technical field of lithium battery intelligent manufacturing. The method is used for controlling the soft package lithium battery intelligent manufacturing system. The soft package lithium battery intelligent manufacturing system comprises a lamination device, a welding device, a heat sealing device, a liquid injection device and a formation device, and comprises a cloud network, an upper computer and a PLC main station which are in control connection, and the PLC main station is in control signal connection with a battery cell manufacturing control module, an aluminum plastic film heat sealing control module and a liquid injection formation control module. According to the control system, mechanical overall linkage and multi-channel information interaction, data analysis and intelligent process parameter optimization in electrical control are achieved, all the modules achieve whole-line linkage in the mechanical aspect and the control aspect, and all the modules and an intelligent system of an execution layerachieve information data interaction through a switch.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

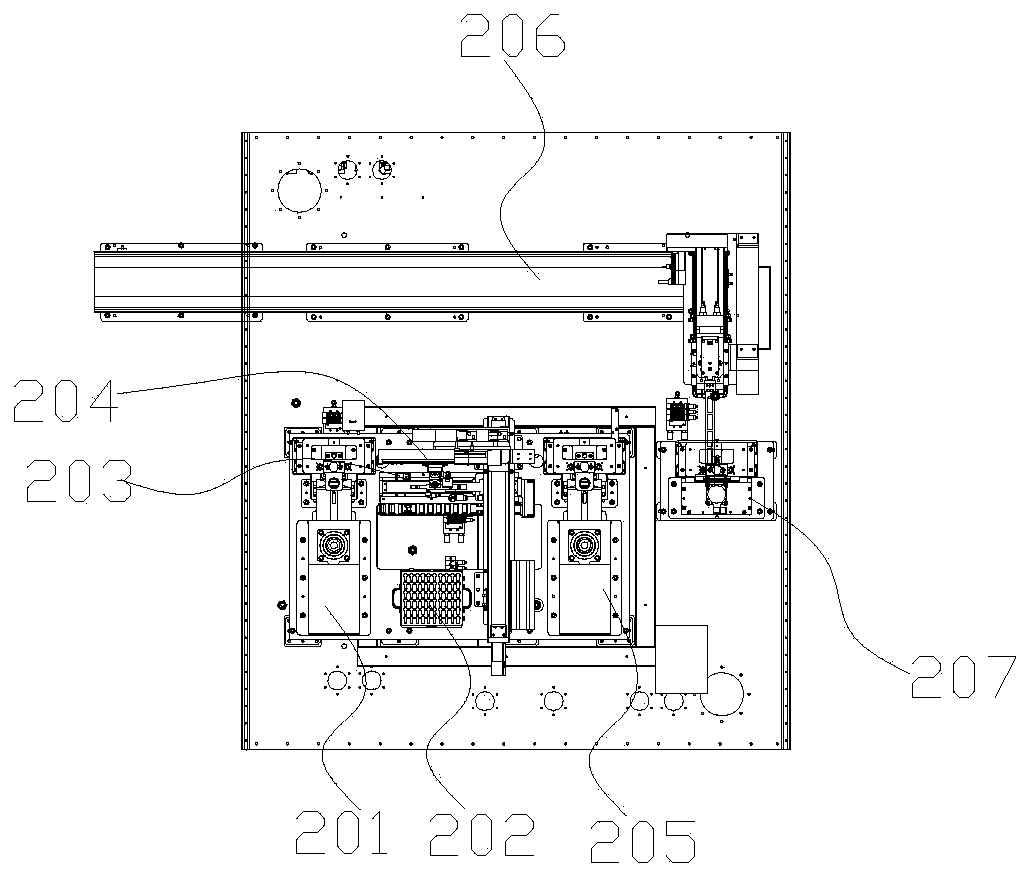

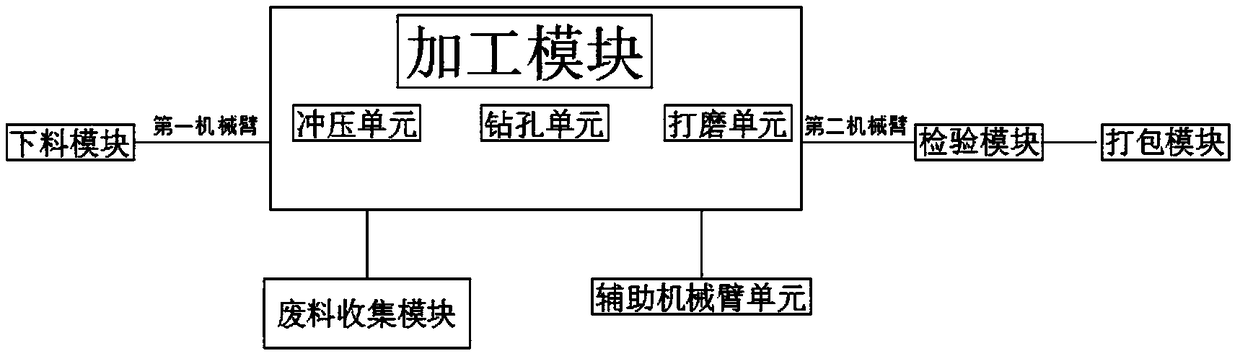

Platformization intelligent manufacturing system

InactiveCN108620875ALow costReduce processing stepsOther manufacturing equipments/toolsIntelligent manufacturing systemEmbedded system

The invention discloses a platformization intelligent manufacturing system. The platformization intelligent manufacturing system comprises a blanking module, a processing module, an inspection moduleand a packing module; the output end of the blanking module is connected with the processing module through a first mechanical arm; the output end of the processing module is connected with the inspection module through a second mechanical arm; the output end of the inspection module is connected with the packing module; the processing module comprises a stamping unit, a drilling unit and a polishing unit, and the stamping unit, the drilling unit and the polishing unit are positioned at the same working station; and the output end of the processing module is connected with a scrap collecting module, and the processing module is connected with an auxiliary mechanical arm unit. According to the platformization intelligent manufacturing system, the processing procedure is fewer, the stampingunit, the drilling unit and the polishing unit are integrated in one working station and made into one device, a workpiece does not need to be operated repeatedly, the equipment cost is low, and the processing efficiency is high.

Owner:JINGDE COUNTY HANHAI NEBULA INTELLIGENTIZE TECH RES & DEV CO LTD

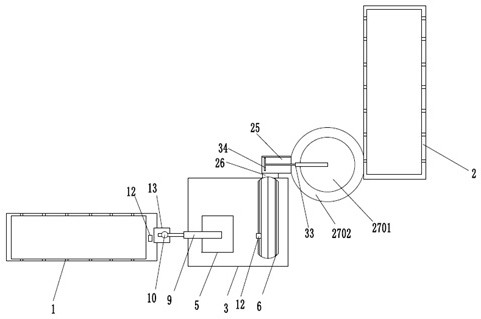

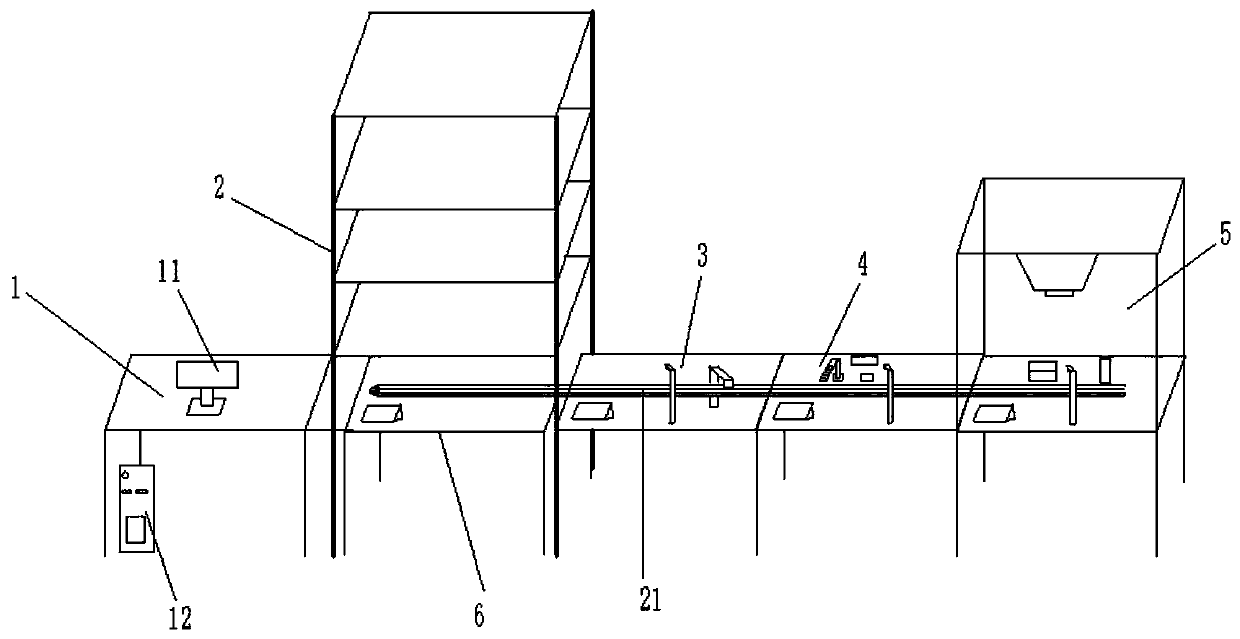

Intelligent manufacturing system based on industrial robot

ActiveCN112693927AHigh degree of intelligenceImprove palletizing efficiencyProgramme-controlled manipulatorConveyorsIndustrial roboticsIntelligent manufacturing system

The invention discloses an intelligent manufacturing system based on an industrial robot. The intelligent manufacturing system comprises a first conveying belt, a middle transferring module and a stacking frame, wherein the middle transferring module transfers goods on the first conveying belt to the stacking frame; the middle transferring module comprises an intelligent grabbing device and a lifting transferring device; and the intelligent grabbing device is located on the front side of the lifting transferring device, and the intelligent grabbing device and the lifting transferring device are detachably connected. According to the intelligent manufacturing system, the goods can be conveniently, rapidly and safely transferred to the stacking frame, the goods are automatically stacked in order, the intelligent degree is high, the system cost is low, and the stacking efficiency is greatly improved; and the middle transferring module serves as an independent module and can move, and the intelligent manufacturing system is not limited to use places and can be repeatedly used in different places.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

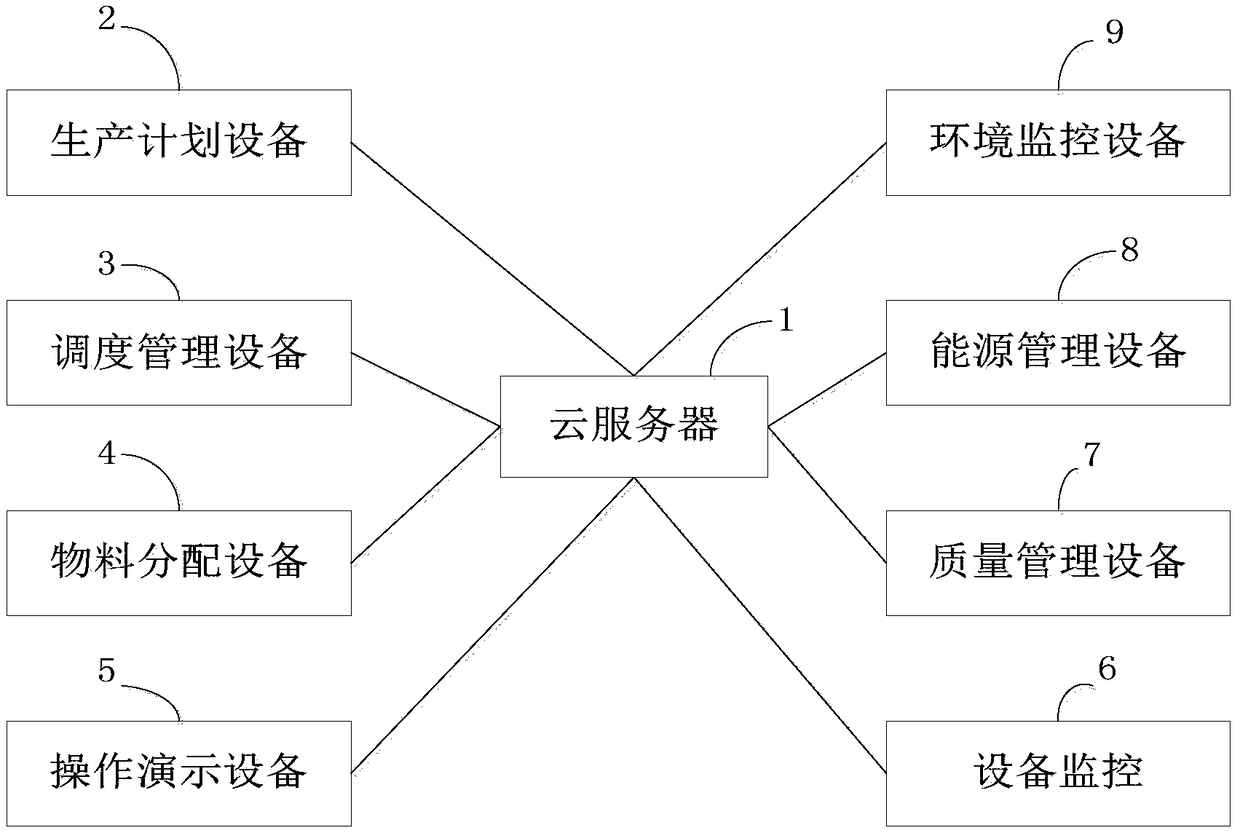

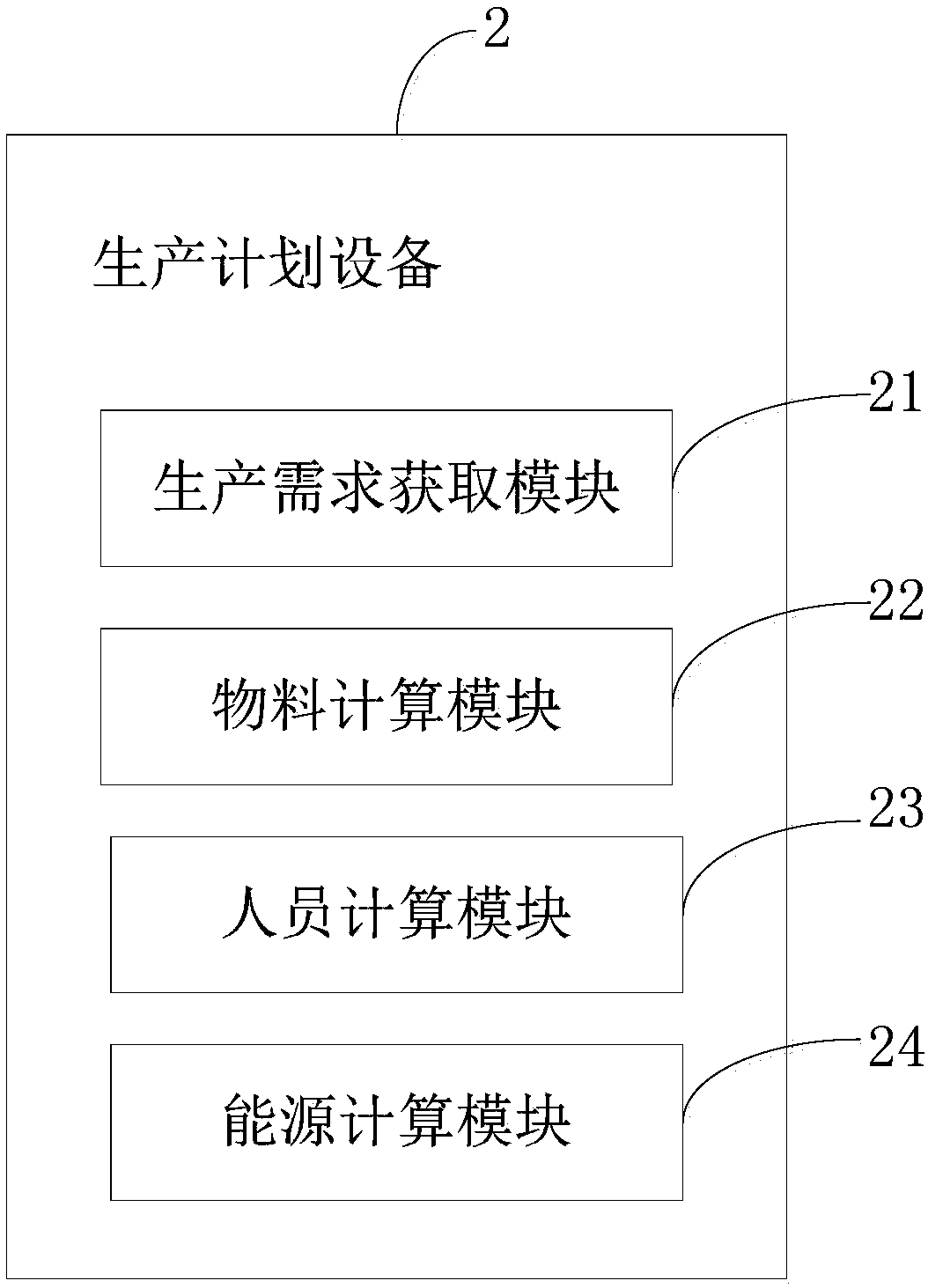

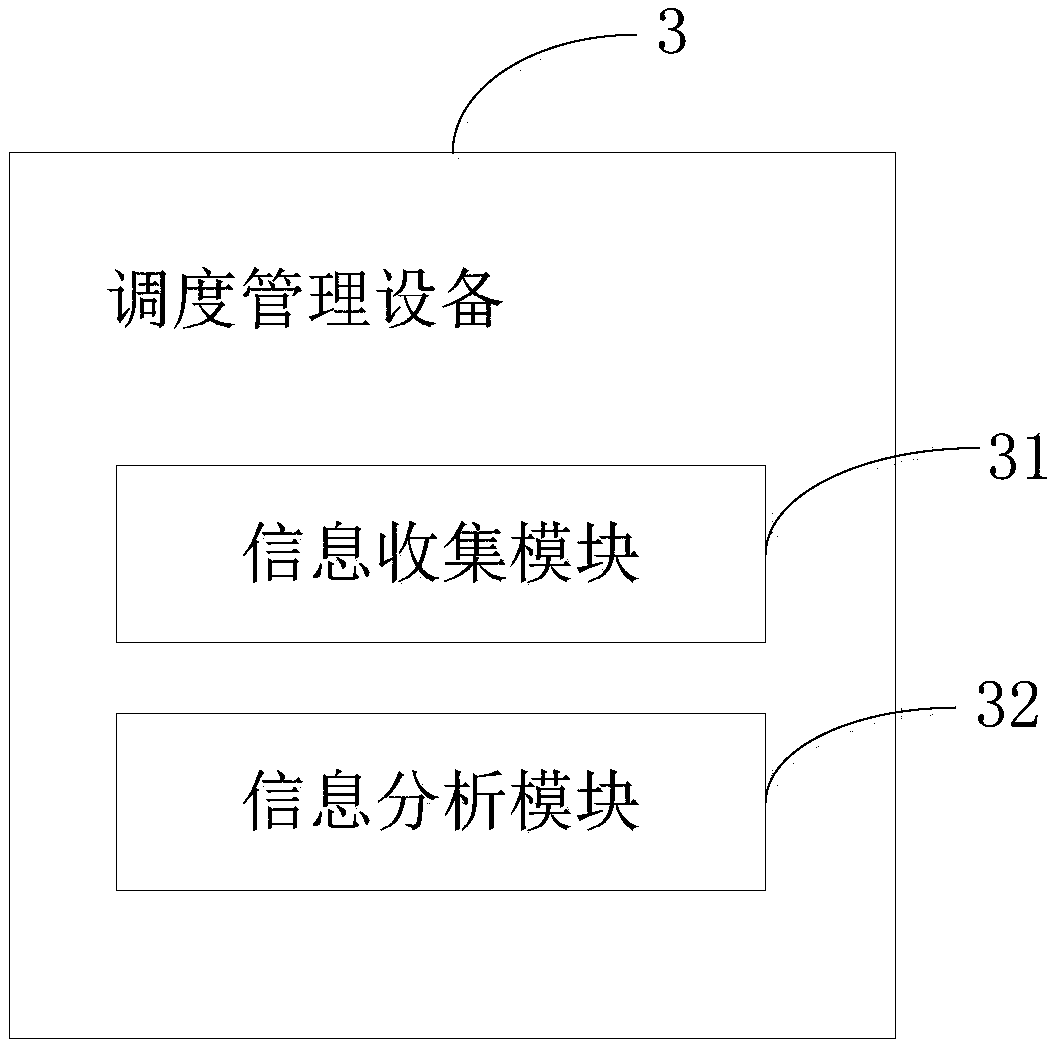

Cloud-platform-based integrated intelligent manufacturing system

InactiveCN109507960AKeep healthyQuality assuranceEnergy industryTotal factory controlProcess qualityDevice Monitor

The invention provides a cloud-platform-based integrated intelligent manufacturing system, comprising a cloud server, a production planning device, a scheduling management device, a material allocation device, an operating presentation device, a device monitor, a quality management device, an energy management device and an environment monitoring device; the production planning device, the scheduling management device, the material allocation device, the operating presentation device, the device monitor, the quality management device, the energy management device and the environment monitoringdevice are in communicated connection with the cloud server through internet. The cloud-platform-based integrated intelligent manufacturing system can provide integrated intelligent manufacturing, production cost is reduced, labor intensity is reduced, production process quality is guaranteed, and production safety is guaranteed.

Owner:广西华磊新材料有限公司

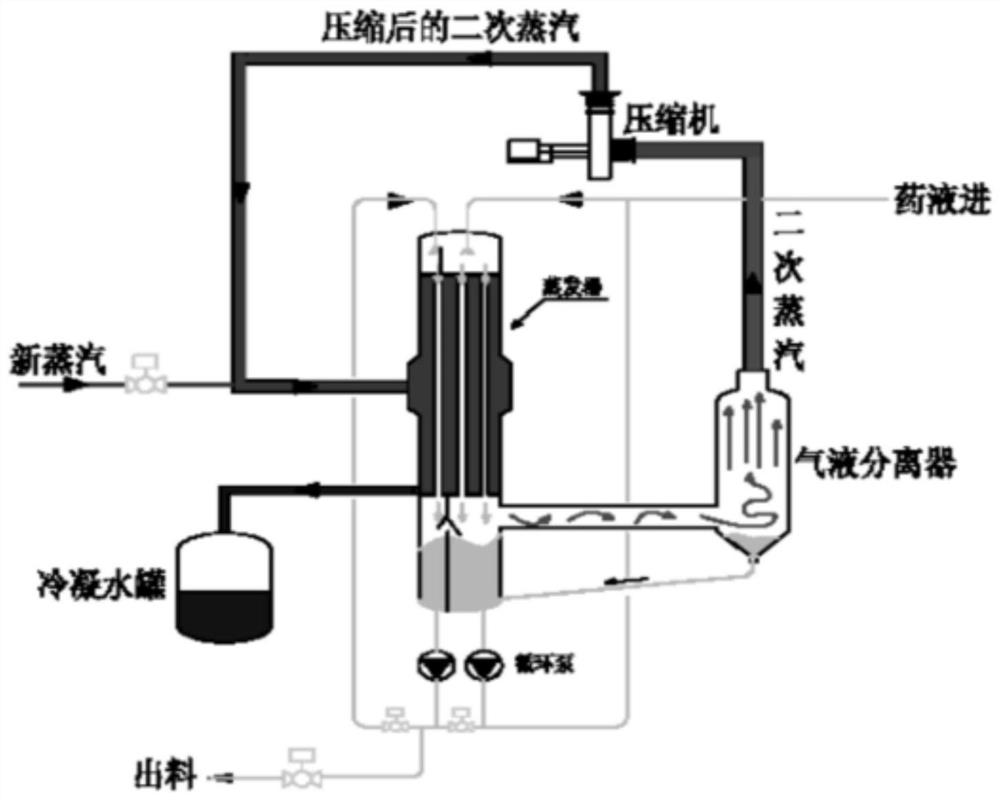

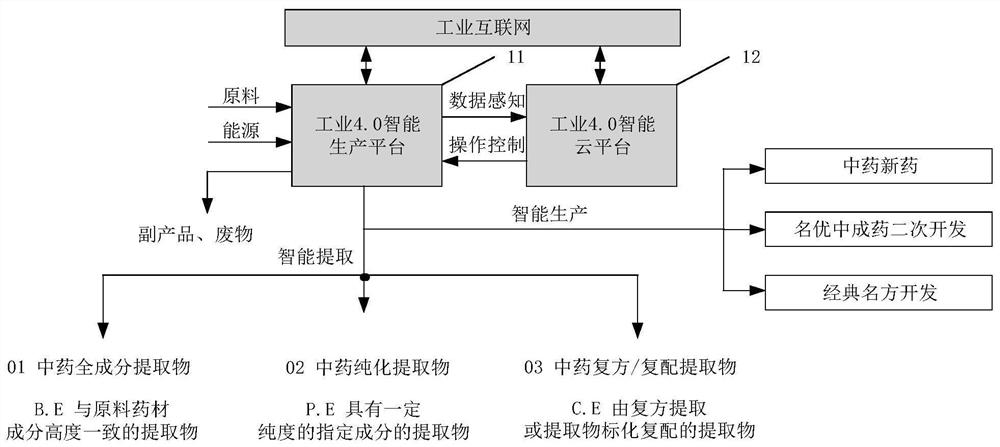

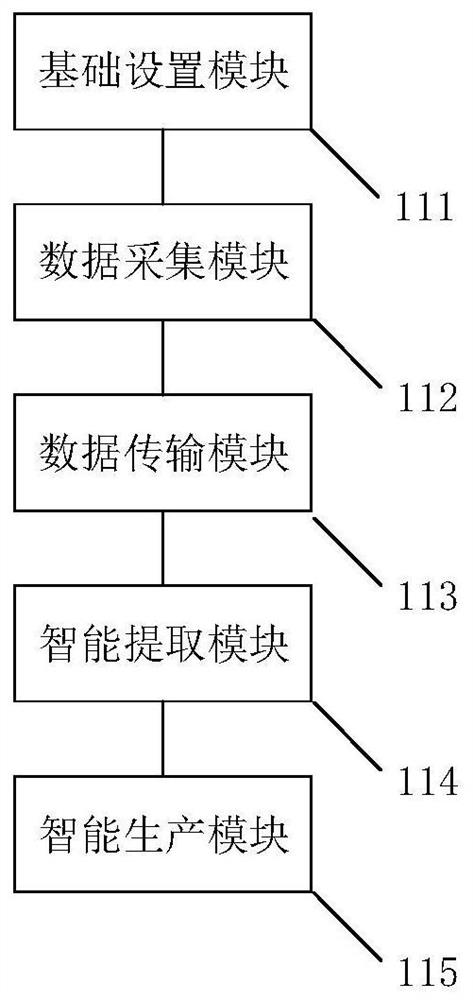

Traditional Chinese medicine or natural plant extraction intelligent manufacturing system based on industrial internet

PendingCN111667162AAccelerate the digitization processImprove management efficiencyOffice automationResourcesManufacturing intelligenceThe Internet

The invention discloses a traditional Chinese medicine or natural plant extraction intelligent manufacturing system based on an industrial Internet. The traditional Chinese medicine or natural plant extraction intelligent manufacturing system comprises an intelligent production platform and an intelligent cloud platform, wherein the intelligent production platform is connected with the industrialInternet and the intelligent cloud platform; and the intelligent cloud platform is connected with the industrial Internet and the intelligent production platform. Through cross-equipment, cross-system, cross-factory and cross-region interconnection and intercommunication, the traditional Chinese medicine or natural plant extraction intelligent manufacturing system realizes resource optimization, cooperative cooperation and service extension of industrial production, improves the resource utilization efficiency, and promotes new modes such as large-scale personalized customization, network cooperative manufacturing, service-oriented manufacturing and intelligent production. The traditional Chinese medicine or natural plant extraction intelligent manufacturing system promotes sufficient flowof industrial data through internal and external networks of a factory, enhances the data analysis capability, realizes the wide convergence and deep mining of diversified data, promotes the global optimization of an industrial production system, accelerates the industrial digitization process, improves the enterprise management efficiency, reduces the investment cost, and constructs a brand-newindustrial automatic manufacturing and service system for traditional Chinese medicine extraction and production.

Owner:GUANGDONG UNIV OF TECH

Intelligent manufacturing system consisting of 3D printing device and mechanical arms

ActiveCN105150537AImprove efficiencyImprove manufacturing efficiencyAdditive manufacturing apparatusRobot controlIntelligent manufacturing system

The invention provides an intelligent manufacturing system consisting of a 3D printing device and mechanical arms. The intelligent manufacturing system comprises a printer placement table, a plurality of 3D printing equipment, the mechanical arms, a conveying belt, plastic cutting equipment, plastic grinding equipment, a large conveying belt, an assembly center and a task allocation center host machine, wherein the conveying belt is divided into a conveying belt front section and a conveying belt rear section; at least one mechanical arm is mounted on one side surface of the conveying belt front section; the printer placement table is mounted on the other side surface of the conveying belt front section along a mounting path of the conveying belt front section; and the 3D printing equipment is mounted on the printer placement table along the mounting path of the conveying belt front section. The intelligent manufacturing system combines methods for manufacturing plastic products in a 3D printing technology and a robot control technology. The products can be manufactured in a shorter time regardless of the complexity of product structures and processes, so that the innovative design of the products is facilitated greatly.

Owner:HANKAISI INTELLIGENT TECH CO LTD GUIZHOU

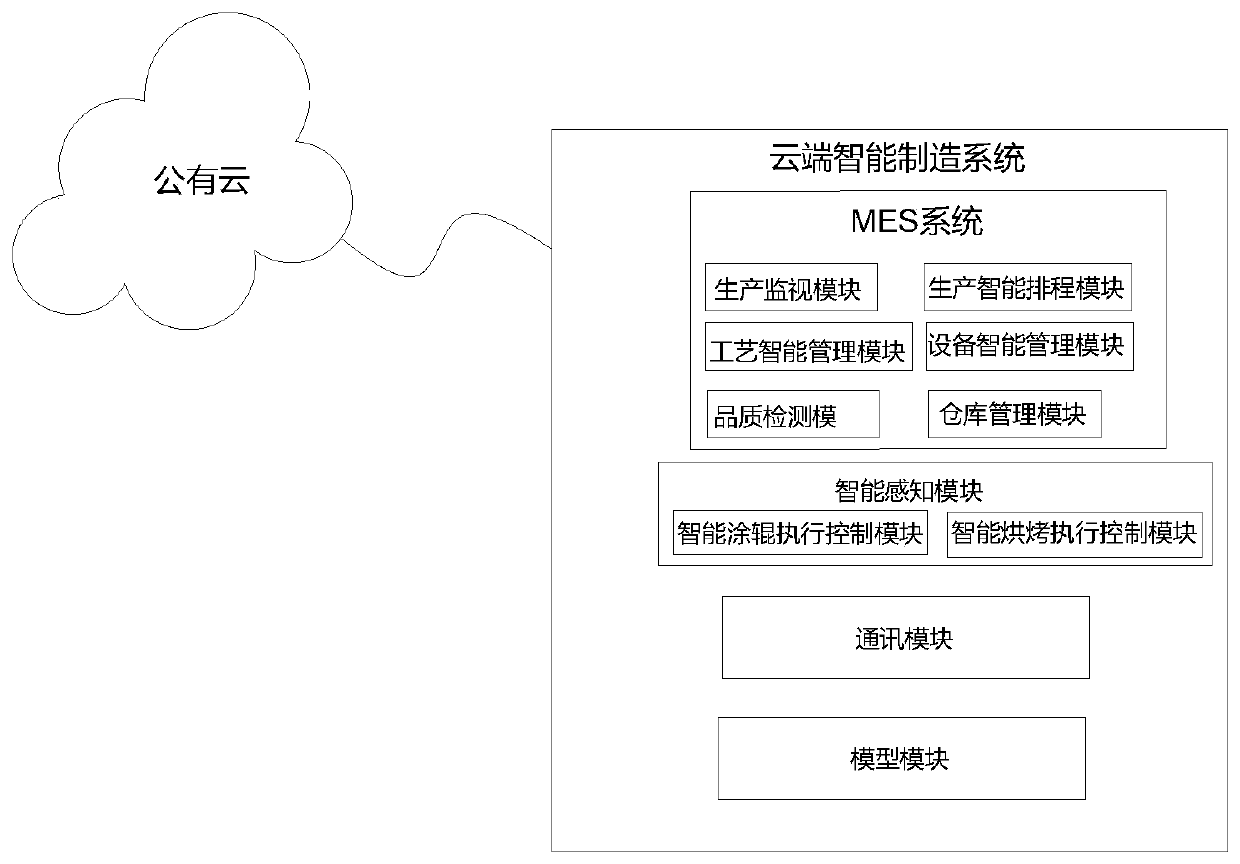

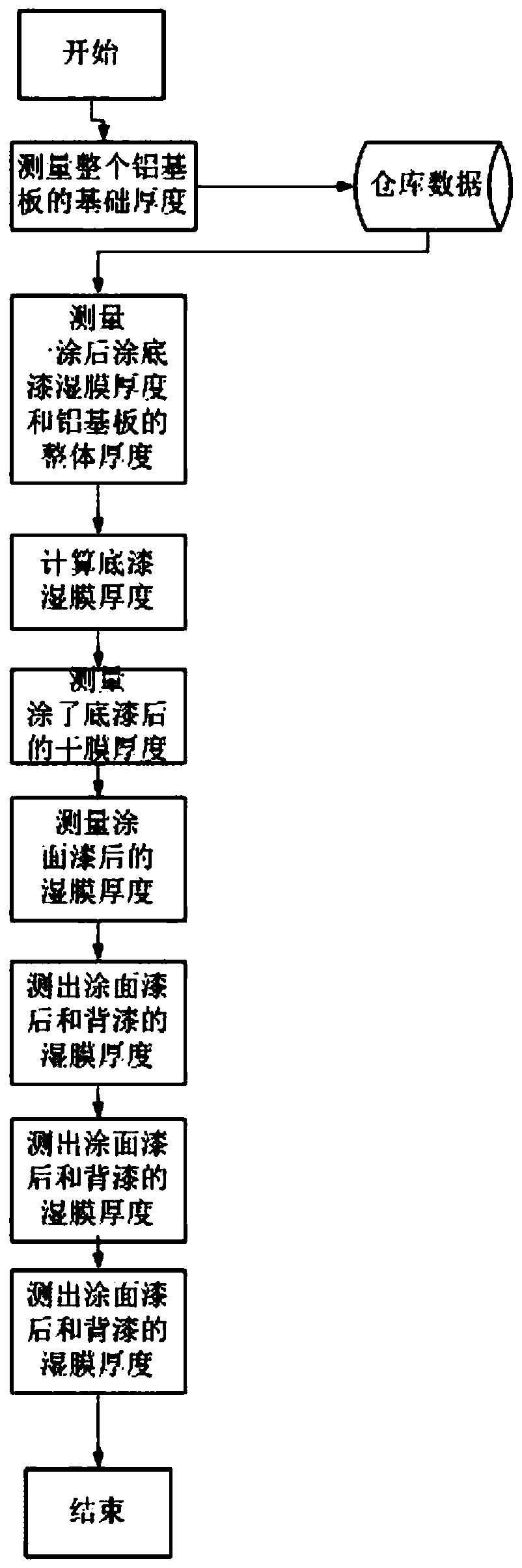

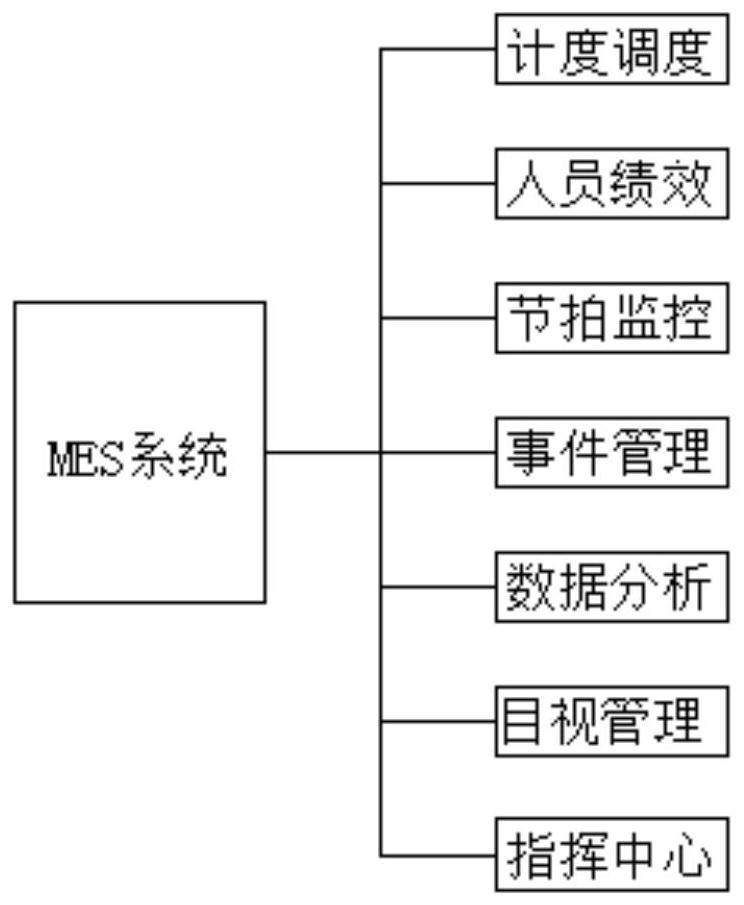

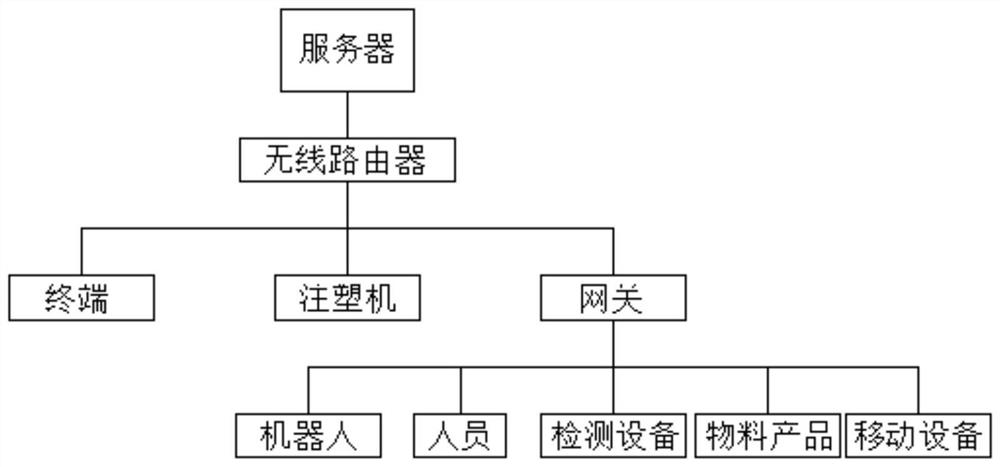

Cloud intelligent manufacturing system based on public cloud

InactiveCN110647126AAvoid job hazardsRealize data interactionTotal factory controlProgramme total factory controlThe InternetData profiling

The invention relates to the technical field of intelligent manufacturing, and specifically relates to a cloud intelligent manufacturing system based on a public cloud. The cloud intelligent manufacturing system includes a MES system that achieves interaction of cloud production data collected by a public cloud with a production system through production modeling and industrial big data analysis,and achieves intelligent control of cloud production; an intelligent perception module that exchanges data with an application module and the MES system through an ethernet communication module of a PLC, receives data instructions transmitted by an OPC for automatic production control and process adjustment while feeding back a status of each device; a communication module that is used to provideinternet services for the intelligent perception module, the application module and a model module to achieve data interaction; and a model module that is used for data interaction with the intelligent perception module, thereby achieving intelligent production.

Owner:任羲

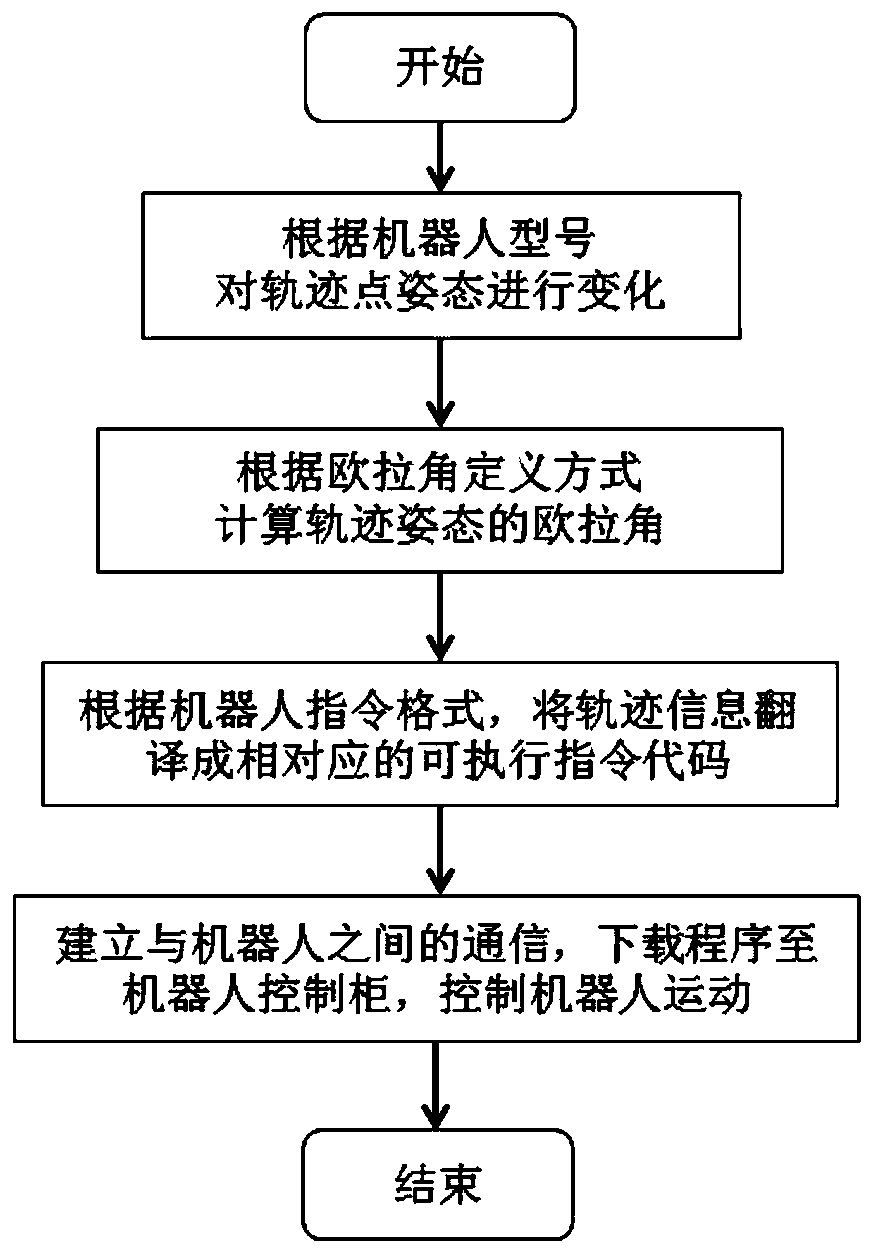

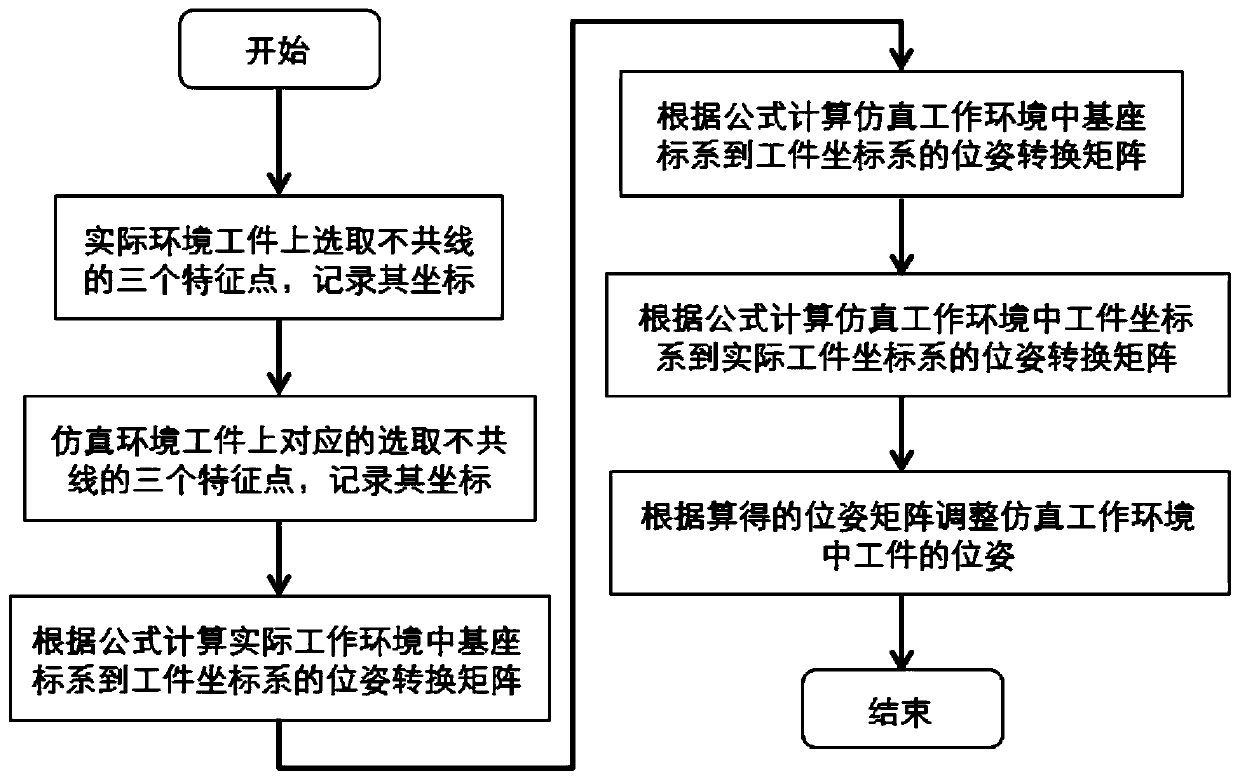

Offline programming postposition code conversion method and double-robot collaborative intelligent manufacturing system and method based on offline programming postposition code conversion same

ActiveCN111381815AImprove work efficiencyImprove scalabilityProgramme-controlled manipulatorNeural learning methodsMachineIntelligent manufacturing system

The invention discloses an offline programming postposition code conversion method, and a double-robot collaborative intelligent manufacturing system and a double-robot collaborative intelligent manufacturing method based on the offline programming postposition code conversion method. The offline programming postposition code conversion method comprises the steps of: importing entity models of a simulation robot, a machining tool and a part into a simulation system, carrying out reasonable layout and calibration of the system according to the machining demands, and generating a machining track; detecting whether track points are reachable or not through simulation, and adjusting abnormal track points such as unreachable and axis overrun track points; and converting the adjusted track points into operation codes of entity robots of the corresponding models through adopting a track points code conversion algorithm, and completing single-machine machining, double-machine synchronous independent machining and double-machine cooperative machining through utilizing the operation codes under the condition that the two entity robots meet mutual communication. The whole system is safe, reliable, high in precision and high in robustness, meets the machining requirements of robots of various different brands and models and various types, and can meet the application of double-robot collaborative intelligent manufacturing.

Owner:XI AN JIAOTONG UNIV

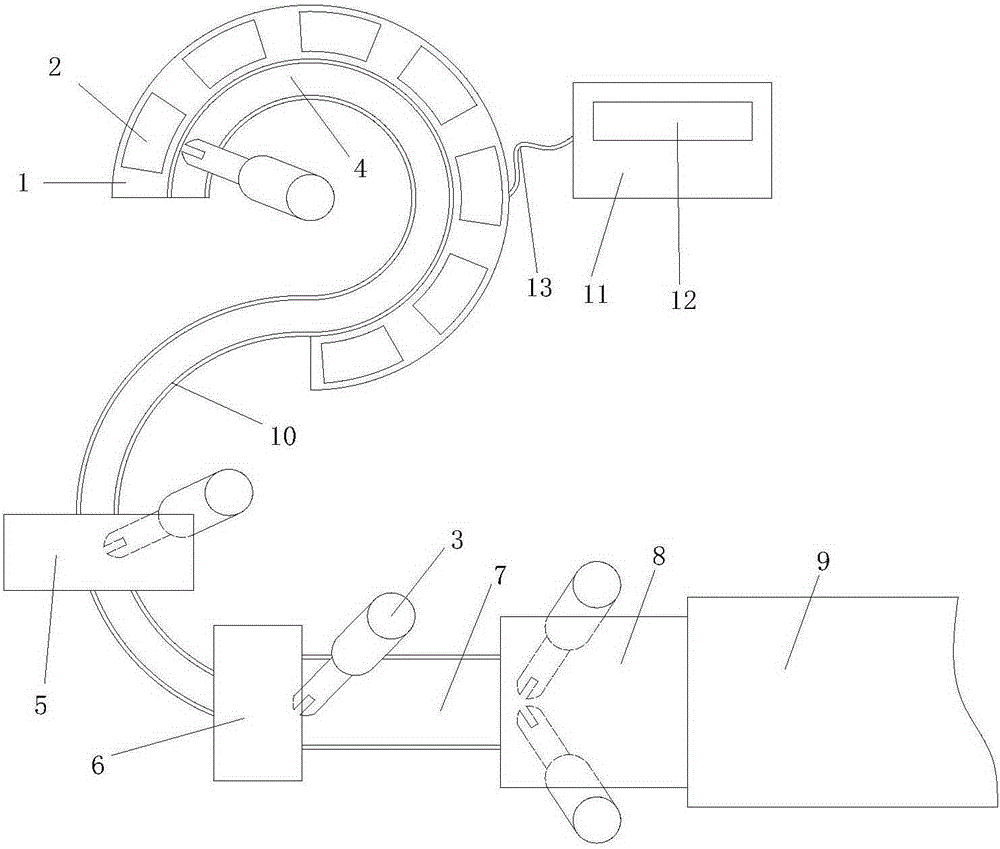

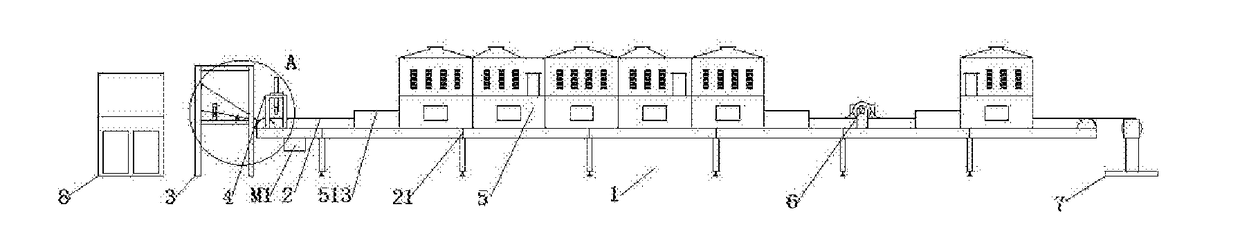

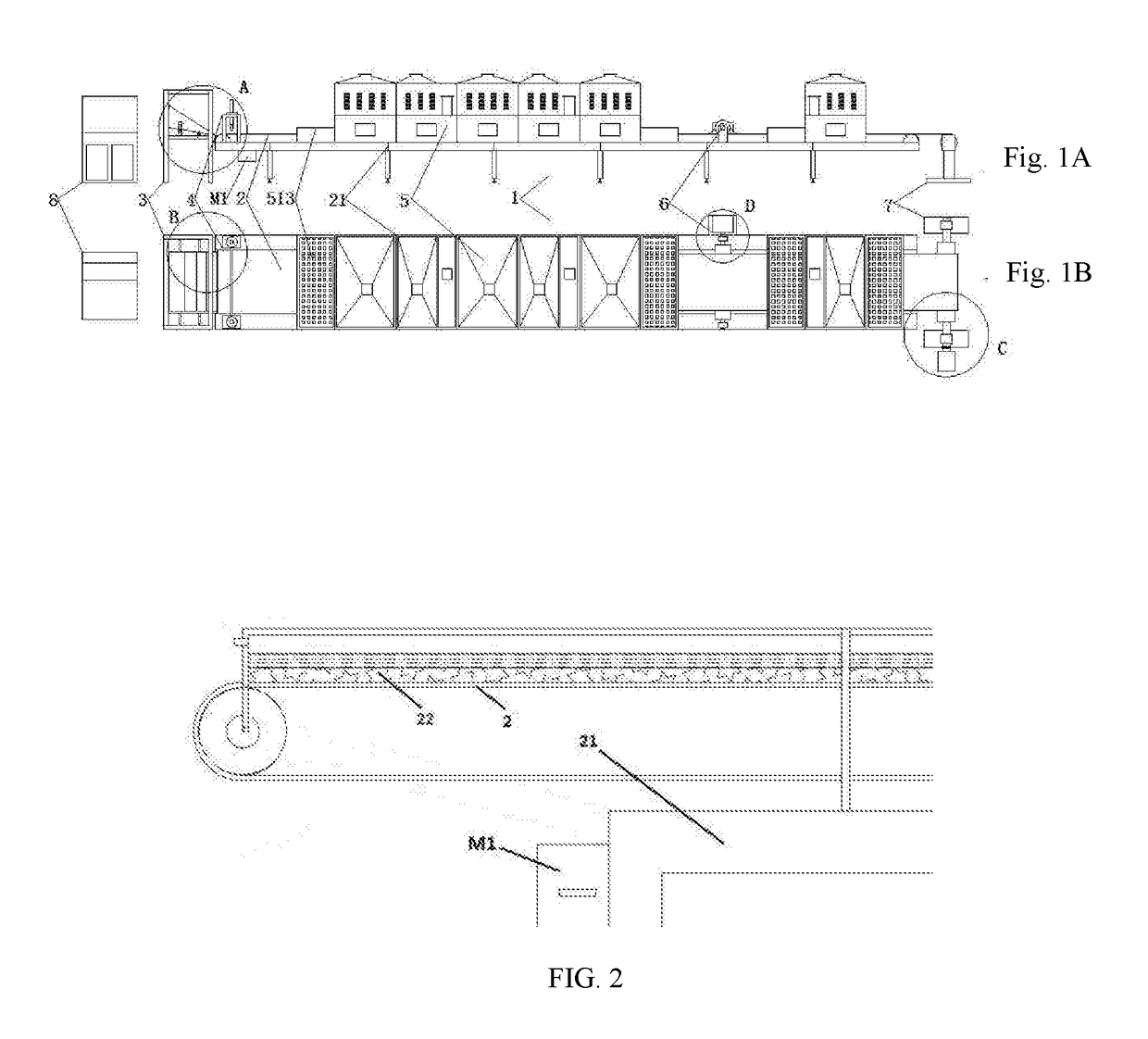

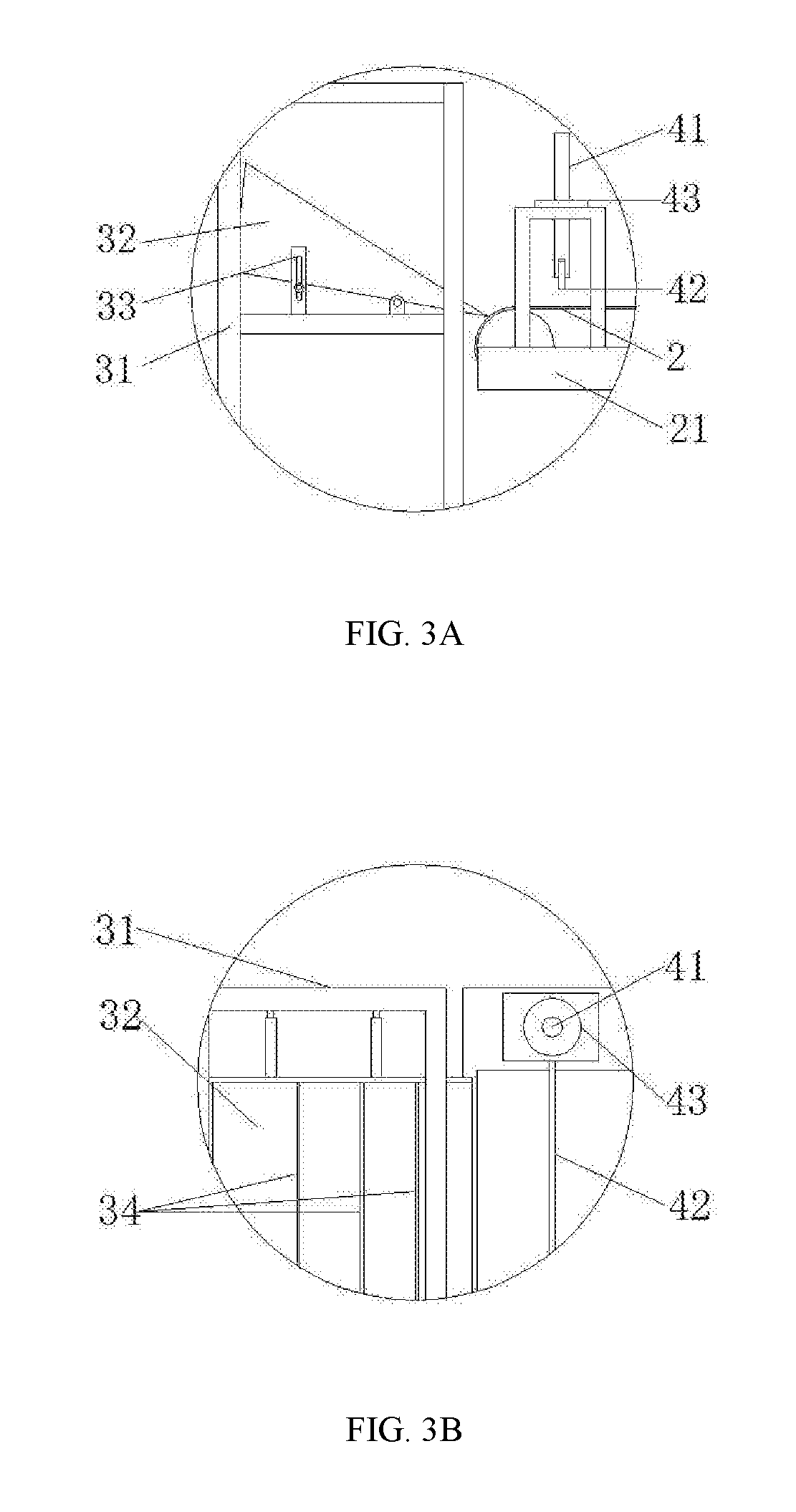

Intelligent Manufacturing System for Making Cleaning Sheet

InactiveUS20170234618A1Avoid stickingEfficient retentionMechanical working/deformationDrying solid materials with heatIntelligent manufacturing systemMechanical engineering

An intelligent manufacturing system for making cleaning sheet includes a multi-stage drying apparatus and a continuous track with non-stick coating. The drying apparatus has at least two stages and a lifting roller arranged between the two stages of the drying apparatus. The continuous track is at its exterior surface coated with the non-stick coating or covered by a medium having the non-stick coating, so that the manufactured cleaning sheet can have active cleaning ingredients therein protected and be easily removed from the continuous track after being dried. The lifting roller between the two stages of the drying apparatus prevents the adhesion between adjacent layers in the rolled cleaning sheet. The intelligent manufacturing system also has an enzyme-adding apparatus for spraying active enzyme that increases cleaning capacity onto the dried cleaning sheet so as to ensure the enzyme to retain good activity.

Owner:MINGYAN BIOTECH SHANGHAI CO LTD

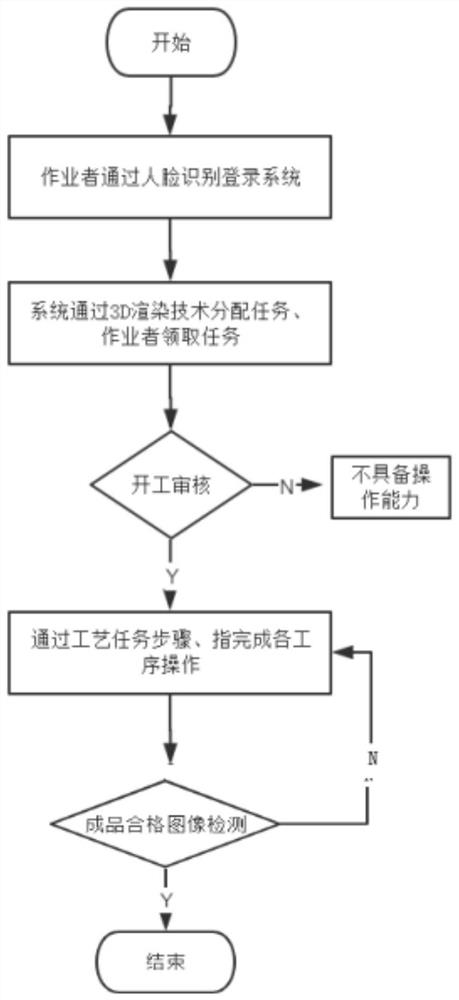

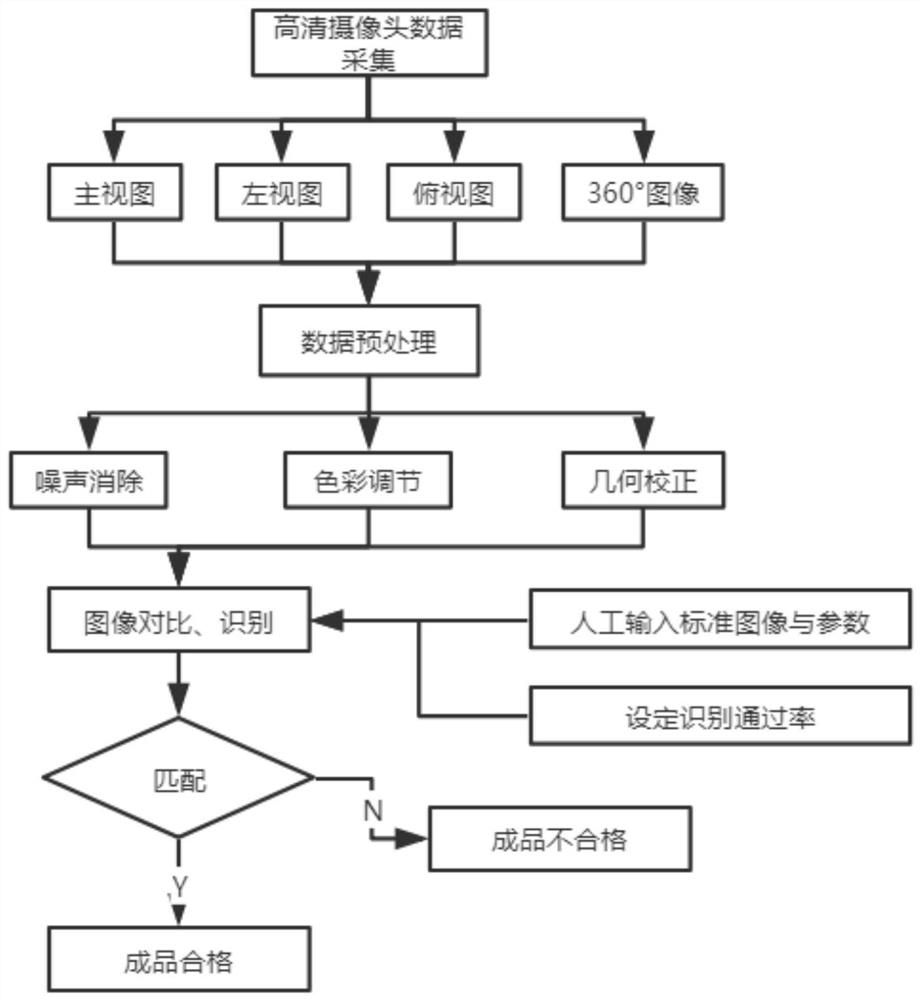

Implementation method of intelligent manufacturing system platform

PendingCN111626234AEasy to understandMeet job requirementsImage analysisCharacter and pattern recognitionProduction lineProcess engineering

The invention provides an implementation method of an intelligent manufacturing system platform. The implementation method comprises the following steps that an operator logs in through a face recognition system; after an operator enters the system, the system allocates tasks through 3D rendering to complete receiving tasks; the system carries out startup auditing, and if auditing is passed, the next step is carried out; an operator completes each process according to the indication of the 3D rendering video in each process task step; whether a product is qualified or not is automatically detected through a picture recognition technology, and a result is displayed. The system divides operation tasks; operation authority management is achieved through face recognition. Technicians make product decomposition and installation videos through rendering view angles and structure view angles according to data such as product characteristics, product structures and various standard parameters,production line operator training is completed, production line operators complete product production according to video guidance, terminal camera shooting is carried out to collect product shapes completed, and process intelligent detection is achieved.

Owner:江苏中车数字科技有限公司

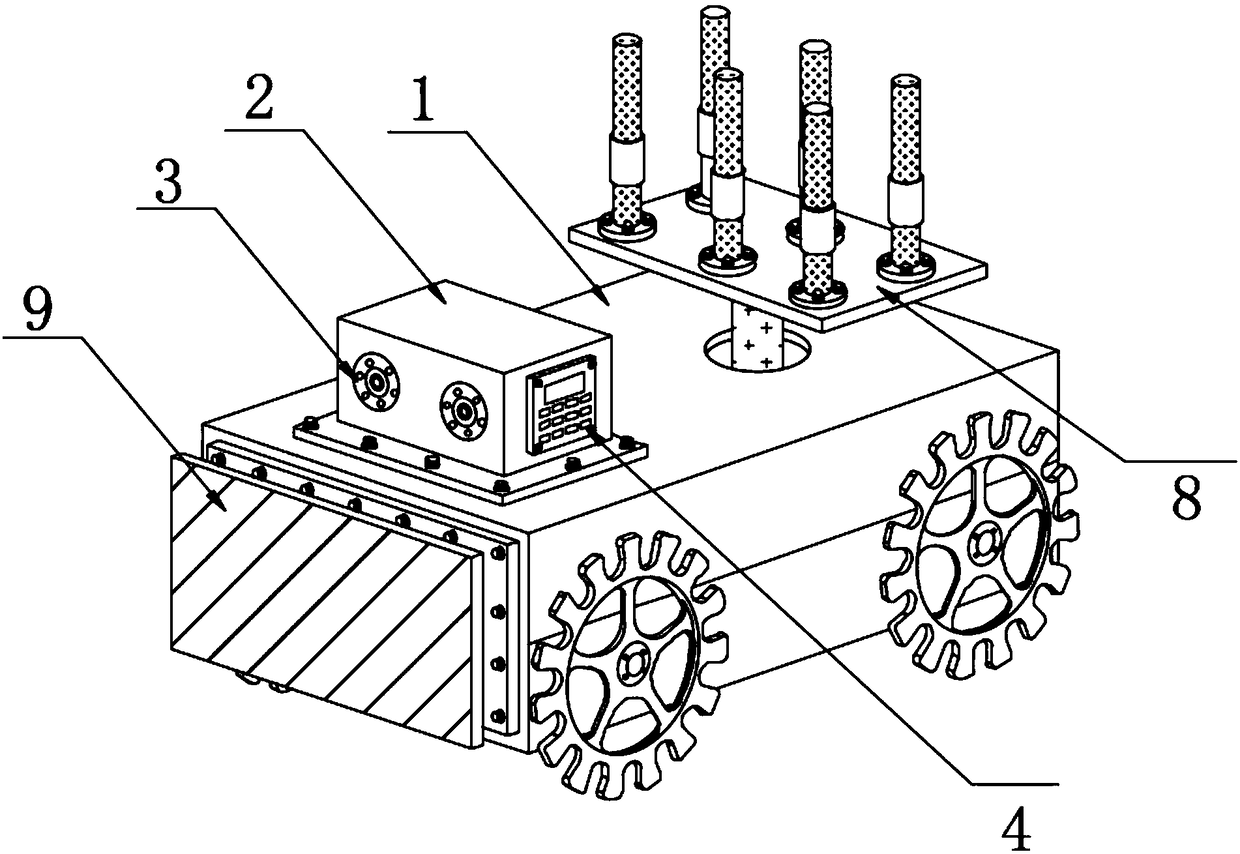

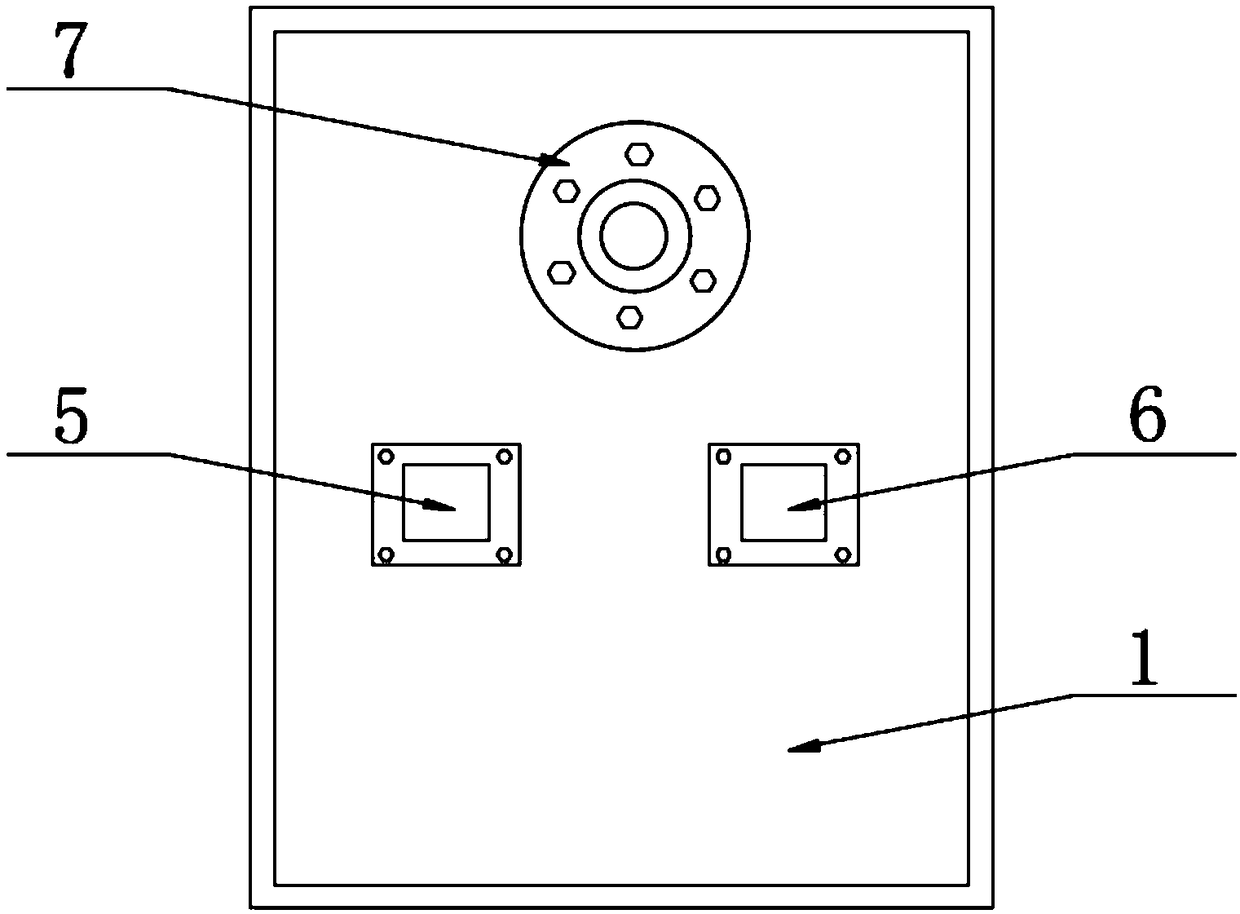

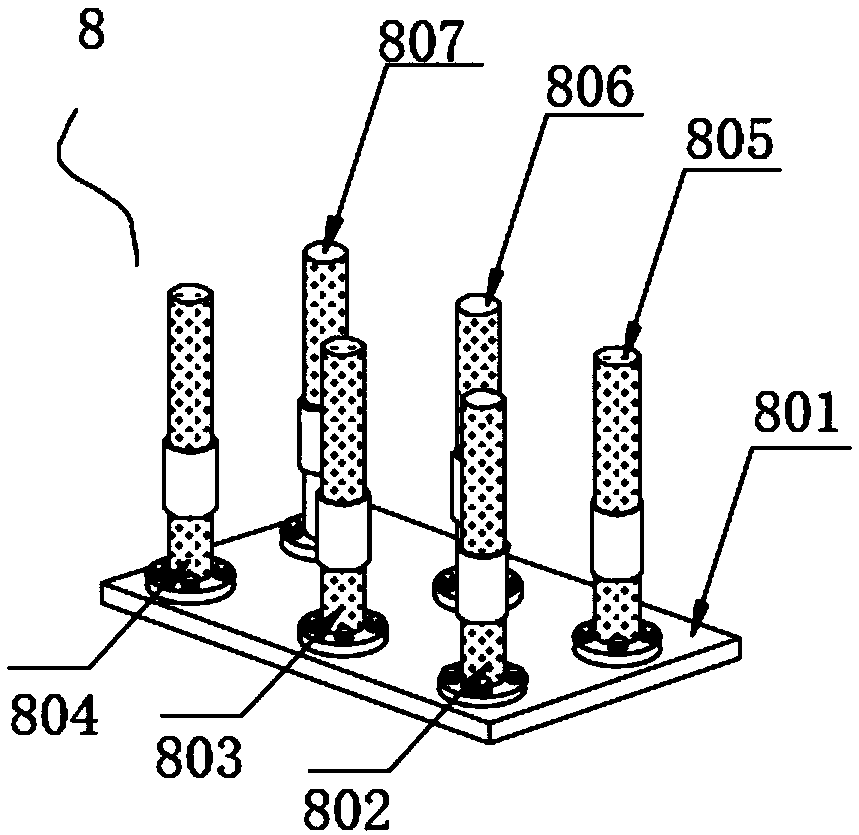

Data acquisition device of intelligent manufacturing system

ActiveCN109032011AScientific and reasonable structureEasy to useProgramme controlComputer controlData acquisitionEngineering

The invention discloses a data acquisition device of an intelligent manufacturing system. The data acquisition device comprises a robot carrier; a protection box is fixedly mounted on the upper surface of the robot carrier; two industrial cameras same in structure and size are symmetrically arranged in the protection box by taking a transverse central axis of the protection box as a base line; anda control switch is fixedly mounted on one side surface of the protection box. The data acquisition device is a data acquisition device improved according to the situations of workshops of the intelligent manufacturing system; the temperature and humidity, the PM2.5, the carbon dioxide concentration and smoke in the intelligent manufacturing system and even the methane content in part of the workshops can be collected; and the collected data can be sent to a mobile communication terminal by a wireless signal through a wireless network module, so that a user can timely know specific numericalvalues or change curvatures of parameters in the workshops, and the user can timely make effective measures for collected objects corresponding to the parameters not in a normal range.

Owner:青岛恒星仪表有限公司

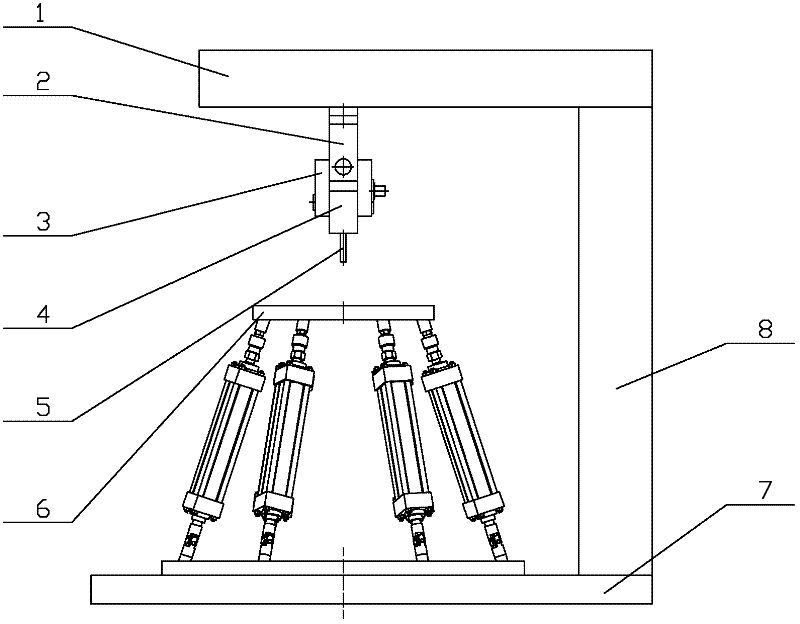

High melting point metal electric arc spraying intelligent manufacturing system

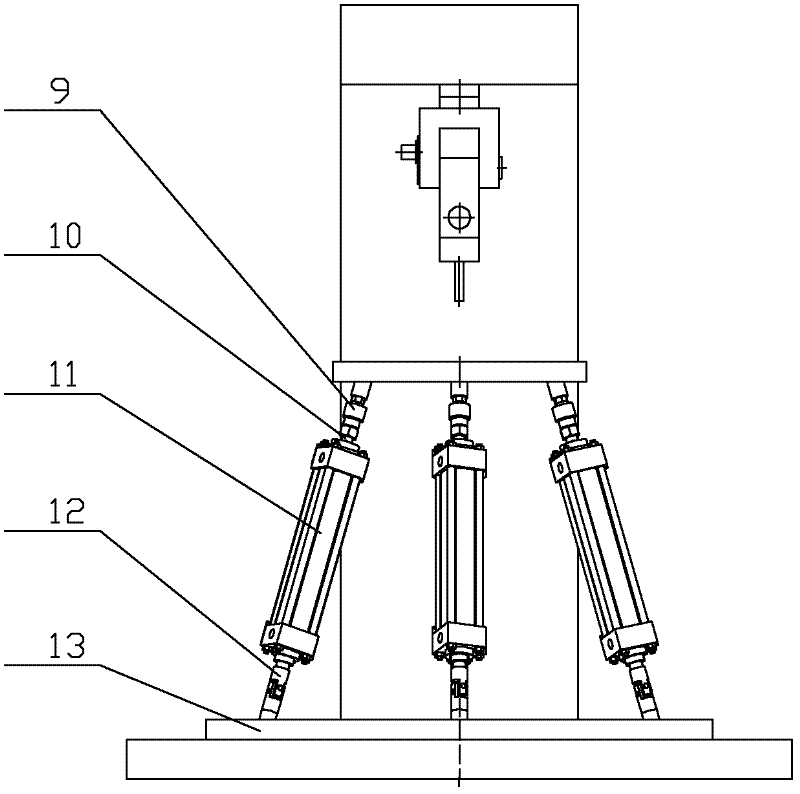

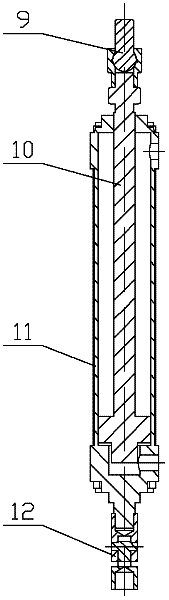

ActiveCN102443755AHigh movement precisionHigh degree of modularityMolten spray coatingDegrees of freedomSocial effects

The invention discloses a high melting point metal electric arc spraying intelligent manufacturing system which has the advantages of reasonable structure, convenient use, high modularization degree and low cost. The system which comprises an equipment body, a 6-DOF (degree of freedom) parallel platform, a 3-DOF head, a master mold heating device and a control computer is characterized in that: the pedestal of the equipment body is provided with the 6-DOF parallel platform chucked with a master mold; the crossbeam of the equipment body is provided with the 3-DOF head; the 3-DOF head which is provided with a nozzle is opposite to a movable platform of the 6-DOF parallel platform and cooperates with the movable platform to work; the movable platform of the 6-DOF parallel platform is provided with the master mold heating device; the 3-DOF head has a feed movement in a Z-axial direction with the crossbeam along a vertical column; and the 6-DOF parallel platform, the 3-DOF head, the mastermold heating device are all connected with the control computer. The system which allows the spraying on any complex curved surface master mold matrix to be realized, and the spray processing of large master mold substrates, especially large automobile cover member substrates, to be realized, has obvious economic and social effects.

Owner:南通通途机电制造有限公司

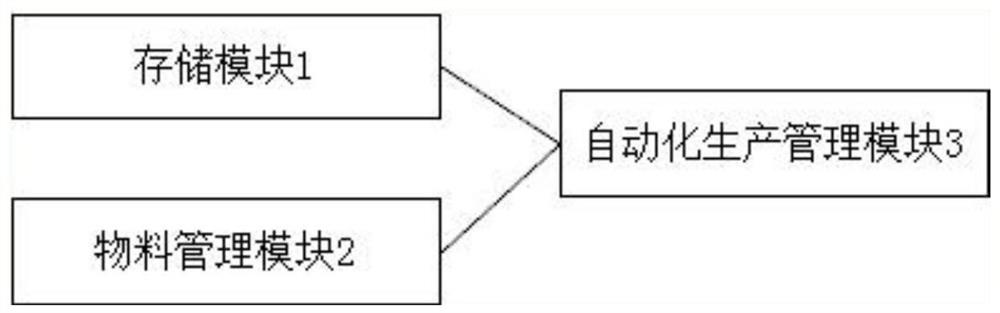

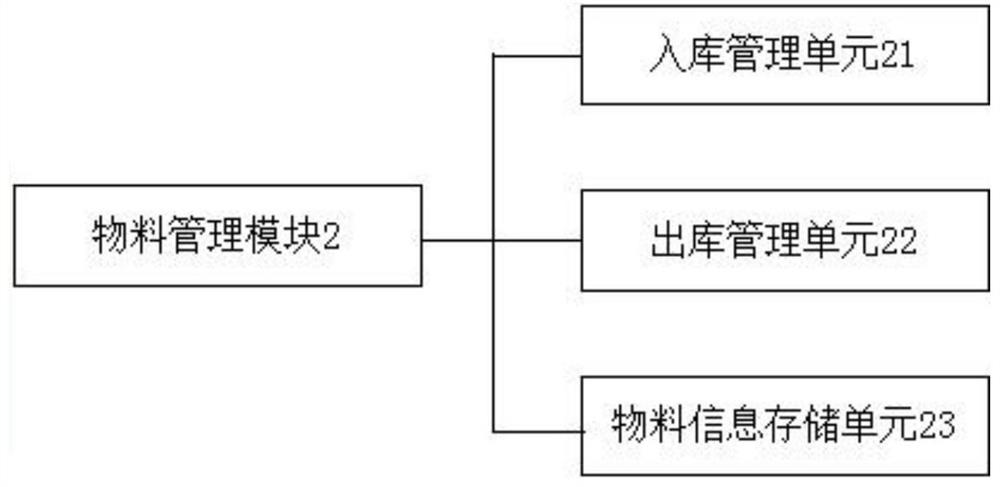

Industrial automatic intelligent manufacturing system based on block chain technology

PendingCN111984981APrevent tamperingEnsure safe productionDatabase distribution/replicationCharacter and pattern recognitionProduction lineIntelligent manufacturing system

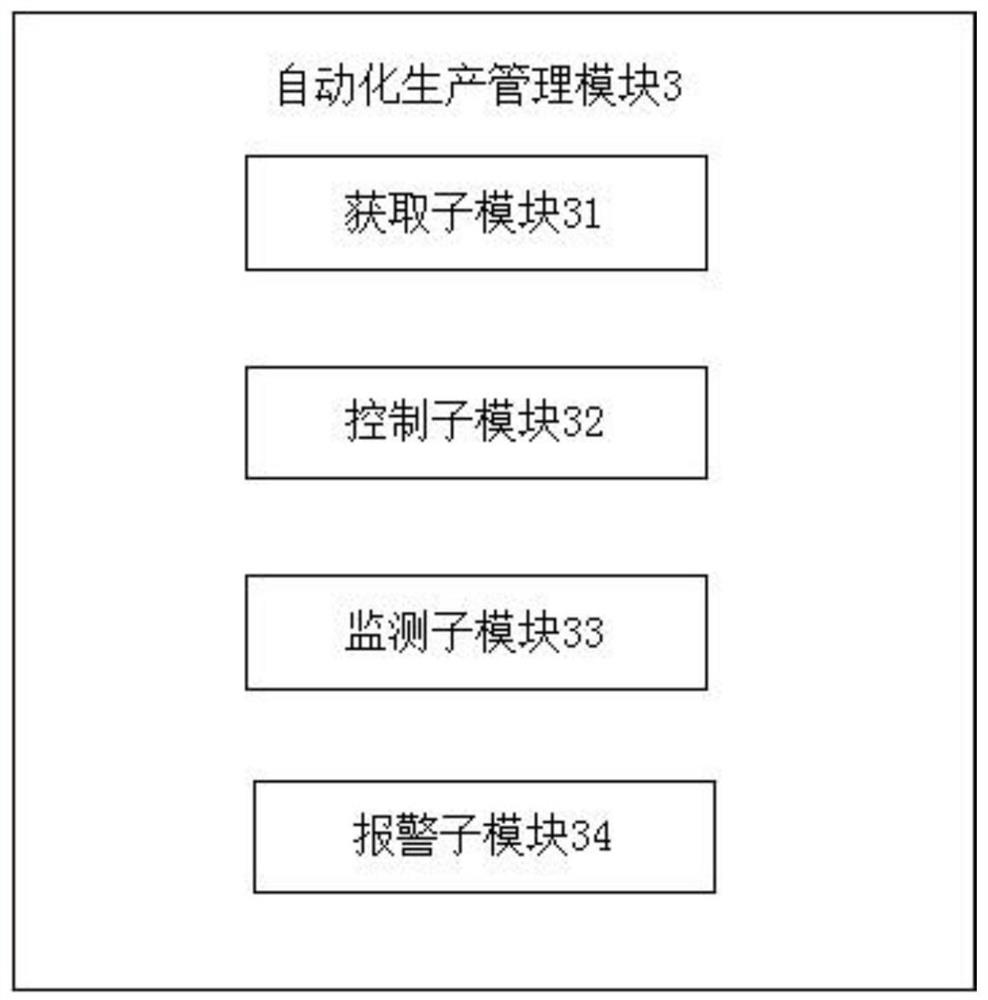

The invention provides an industrial automatic intelligent manufacturing system based on a block chain technology. The industrial automatic intelligent manufacturing system comprises a storage module,a material management module and an automatic production management module; the storage module is used for storing an automatic production control program into a block chain storage node which is arranged in a distributed manner; the material management module is used for carrying out warehouse-in management and warehouse-out management on the materials; and the automatic production management module is used for obtaining the automatic production control program from the block chain storage node and controlling a production line to automatically process the materials subjected to ex-warehousemanagement according to the automatic production control program to obtain a finished product. According to the invention, the automatic production control program is stored through the block chain storage node, so that the automatic production control program is effectively prevented from being tampered, and the safety production of the industrial automatic intelligent manufacturing system is ensured.

Owner:安徽游川网络科技有限公司

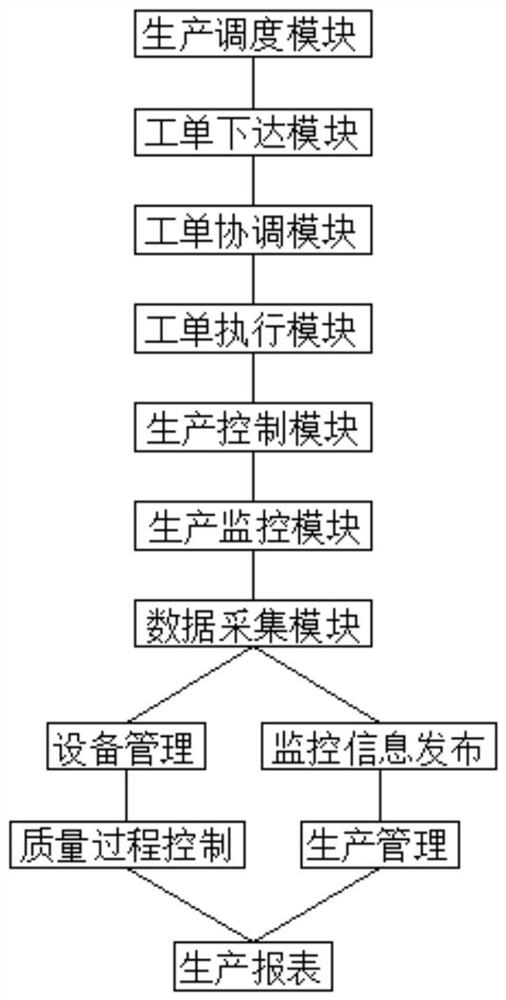

Intelligent manufacturing MES system

PendingCN112488446AImprove applicabilityPersonalizedTransmission systemsOffice automationPersonalizationIntelligent manufacturing system

The invention discloses an intelligent manufacturing MES system, and the system comprises a production scheduling module, a work order issuing module, a work order coordination module, a work order execution module, a production control module, a production monitoring module, a data collection module, equipment management, quality process control, monitoring information publishing, production management, and a production report. The intelligent manufacturing MES system has the advantages of individuation, high applicability, low cost and quick delivery, has the characteristics of easiness in learning, easiness in use and quickness in starting, and can be used for quickly entering an application interface of each operator to find a required function menu and clarify a full-service process related to each operator after each operator enters the system in an actual application process. Meanwhile, a large number of dragging and linking modes similar to Win7 and Win10 operation modes are adopted to achieve rapid and convenient combination, disassembly, enlargement, reduction and hiding operation.

Owner:JANDA ELECTRIC CO LTD

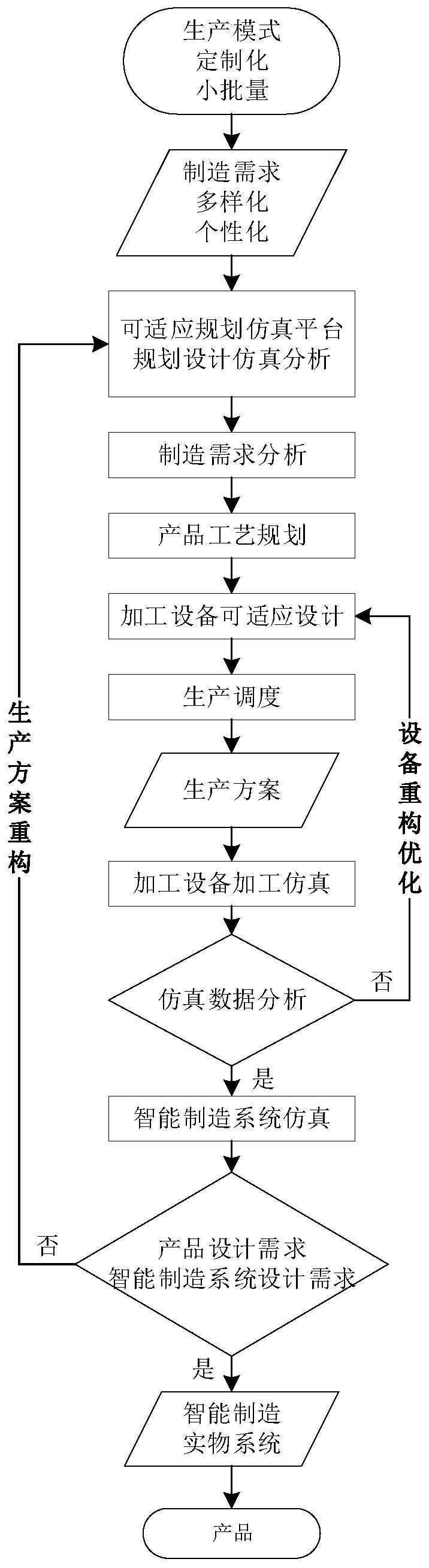

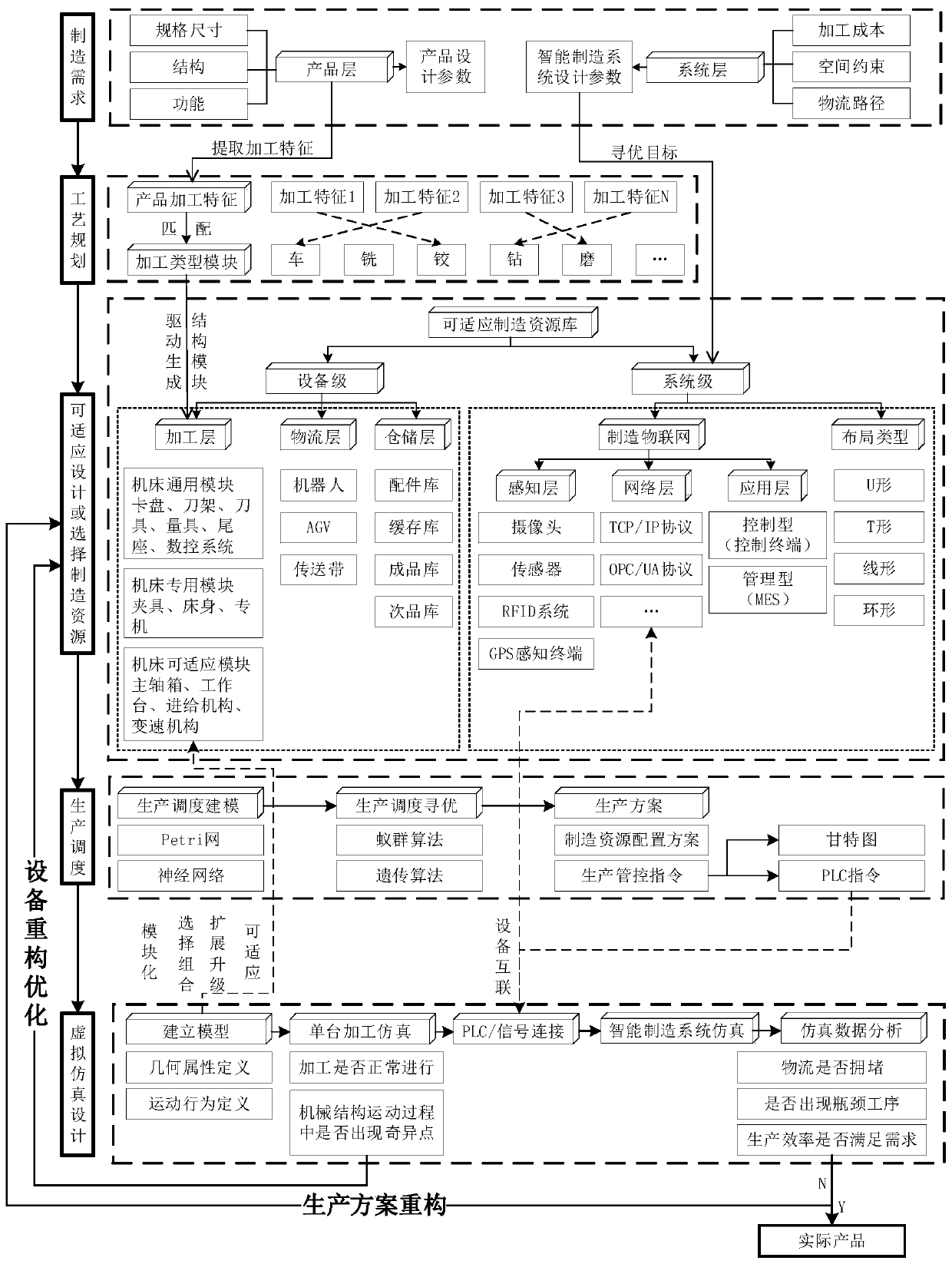

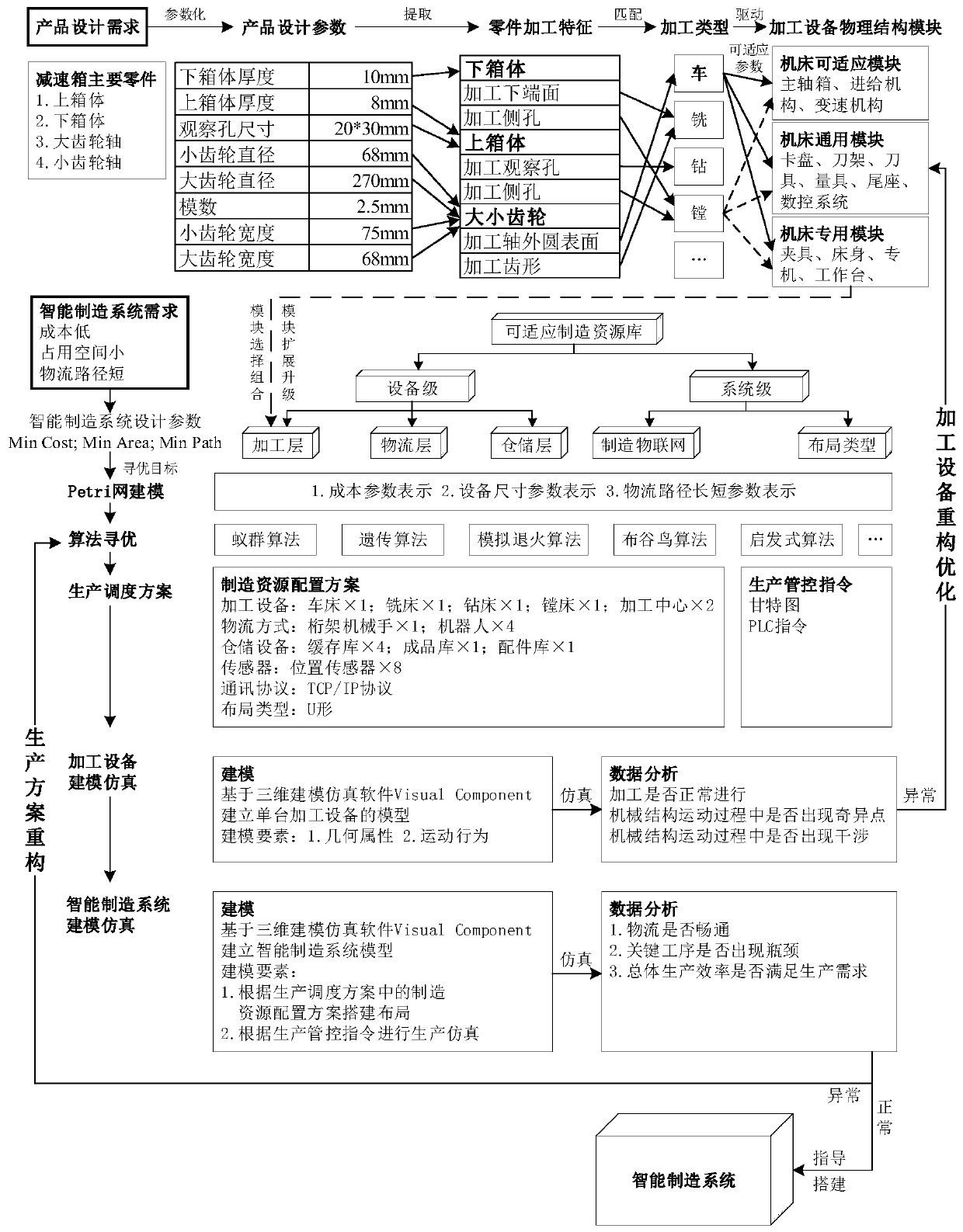

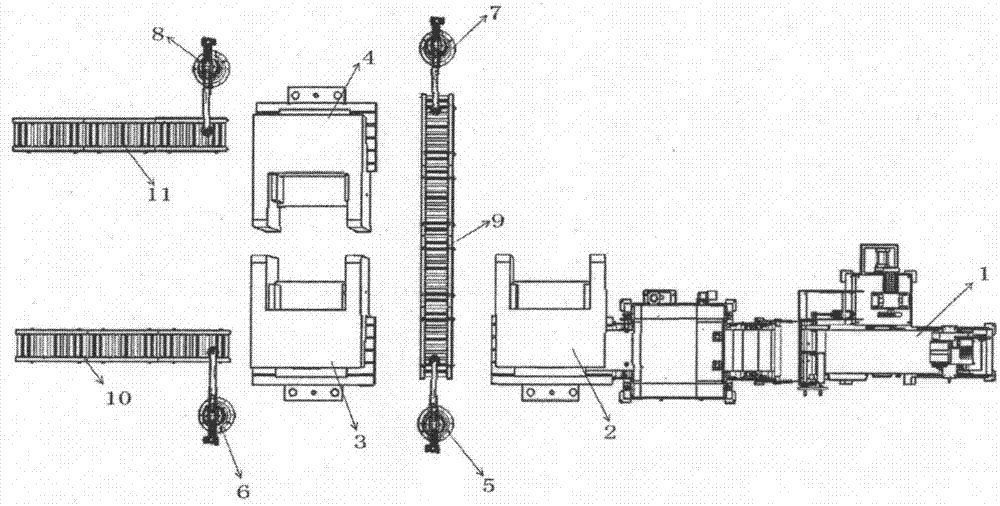

Adaptable planning design simulation platform construction method for intelligent manufacturing system

ActiveCN111240283AImprove adaptabilityImprove response speedTotal factory controlProgramme total factory controlProcessing typeIntelligent manufacturing system

The invention discloses an adaptable planning design simulation platform construction method for an intelligent manufacturing system. The method comprises the following steps: establishing a mapping relationship between manufacturing requirements and product design parameters and a mapping relationship between the manufacturing requirements and the intelligent manufacturing system design parameters; extracting the processing characteristics of the part, performing process planning design on the part, matching a processing type module corresponding to the product design parameters and generating a process route; establishing an adaptable manufacturing resource library; carrying out production scheduling and generating a production scheme comprising a manufacturing resource configuration scheme and a production process management and control instruction; performing processing simulation on adaptable processing equipment, and performing simulation verification on the manufacturing resource configuration scheme and the production process management and control instruction; and deciding whether adaptive processing equipment reconstruction optimization is carried out or not according tothe processing simulation result of the adaptive processing equipment, and deciding whether production scheme reconstruction is carried out or not according to the manufacturing resource configurationscheme and the result of production process control instruction simulation verification.

Owner:TIANJIN UNIV

Intelligent manufacturing system and method of motor punching and shearing workshop

PendingCN107537912ARealize unmannedAvoid the Risk of Work InjuryMetal-working feeding devicesManufacturing stator/rotor bodiesPunchingWorkload

The invention relates to an intelligent manufacturing system and method of a motor punching and shearing workshop. The intelligent manufacturing system comprises a servo deflection feeding machine, wherein a discharging hole of the servo deflection feeding machine is connected with a feeding hole of a punching machine tool 1; a material positioned at the discharging hole of the punching machine tool 1 is grabbed to a conveying line 1 or a punching machine tool 2 by a mechanical hand 1; a material positioned at a discharging hole of the punching machine tool 2 is grabbed to a conveying line 2 by a mechanical hand 2; a mechanical hand 3 is arranged near the conveying line 1; the material positioned on the conveying line 1 is grabbed to a punching machine tool 3 by the mechanical hand 3; a mechanical hand 4 is arranged near a discharging hole of the punching machine tool 3; and the material positioned at the discharging hole of the punching machine tool 3 is grabbed to a conveying line 3by the mechanical hand 4. According to the intelligent manufacturing system and method of the motor punching and shearing workshop disclosed by the invention, an unmanned punching operation of an ironcore of a motor can be realized, and the workload is reduced while the risk is reduced at the same time; and meanwhile, through interaction of a PCS (Process Control System) and an upper-layer system, intelligent distribution of operations, automatic issuing of procedures, and real-time acquisition and interaction of data are realized, and intelligent manufacturing of the motor punching and shearing workshop is realized.

Owner:SHANGHAI MOTOR SYST ENERGY SAVING ENG TECH RES CENT +2

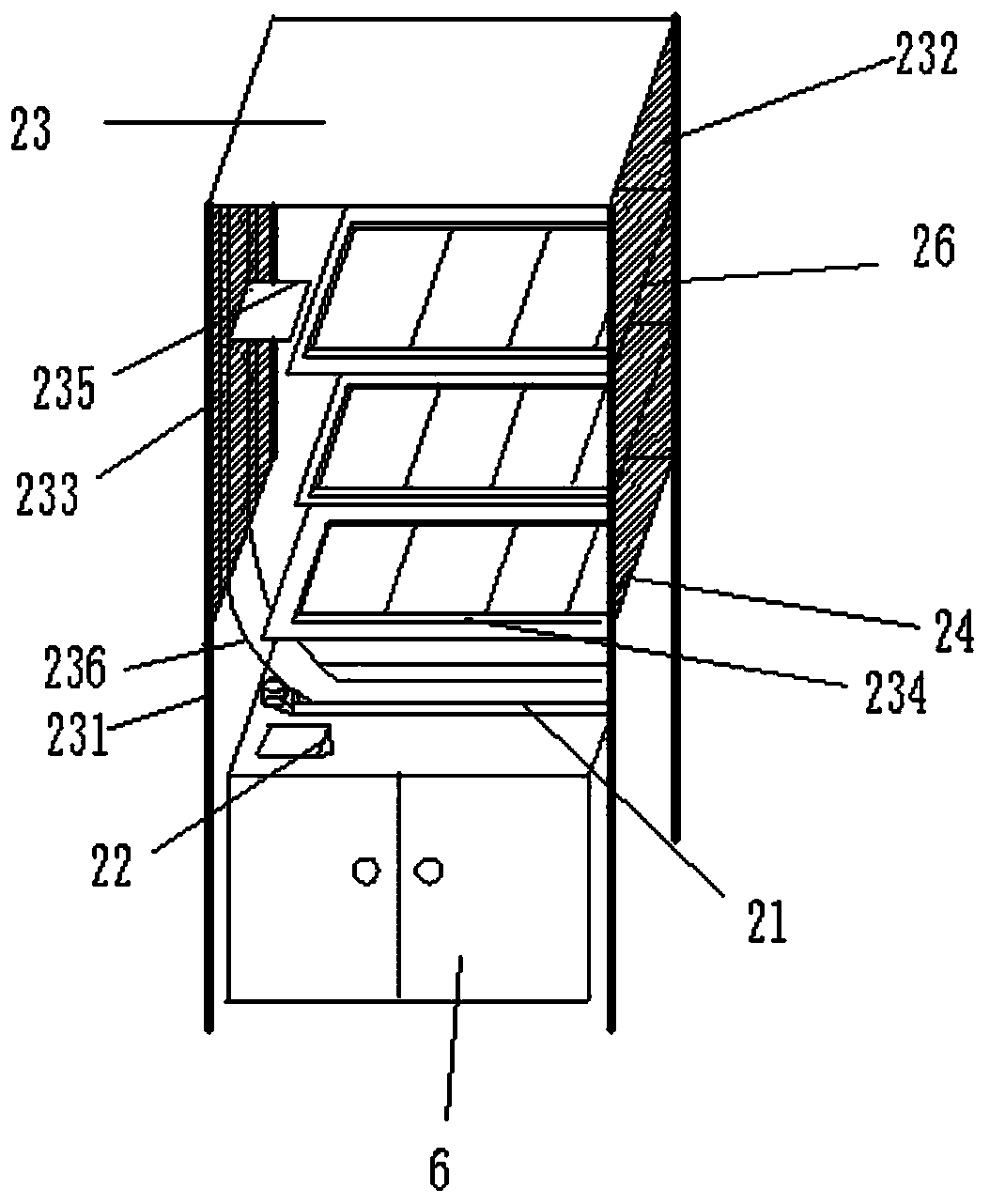

Intelligent manufacturing system of multifunctional industrial robot and manufacturing method

ActiveCN110687879ARealize the operationQuick assemblyTotal factory controlProgramme total factory controlCode moduleMachine

The invention discloses an intelligent manufacturing system of a multifunctional industrial robot and a manufacturing method. The intelligent manufacturing system comprises a main console, a feeding module, a laser coding module, an intelligent assembling and packaging module and an automatic sorting module which are arranged on a base rack. According to the manufacturing system, the manufacturingmodules are scientifically and reasonably arranged from the perspective of intelligentization. Meanwhile, the step of manual operation is canceled, and cooling and curing treatment is further effectively carried out on the laser coding system and the coding identification area, so that the service life of the machine is prolonged, the laser coding quality is improved, the later packaging qualityis guaranteed, the whole system saves the time by one time compared with an existing manufacturing production line in operation, the manufacturing quality is remarkably improved at the same time, thefinished product rate and the defective rate are classified accurately, and the finished product rate is close to 100%.

Owner:HUAIAN COLLEGE OF INFORMATION TECH

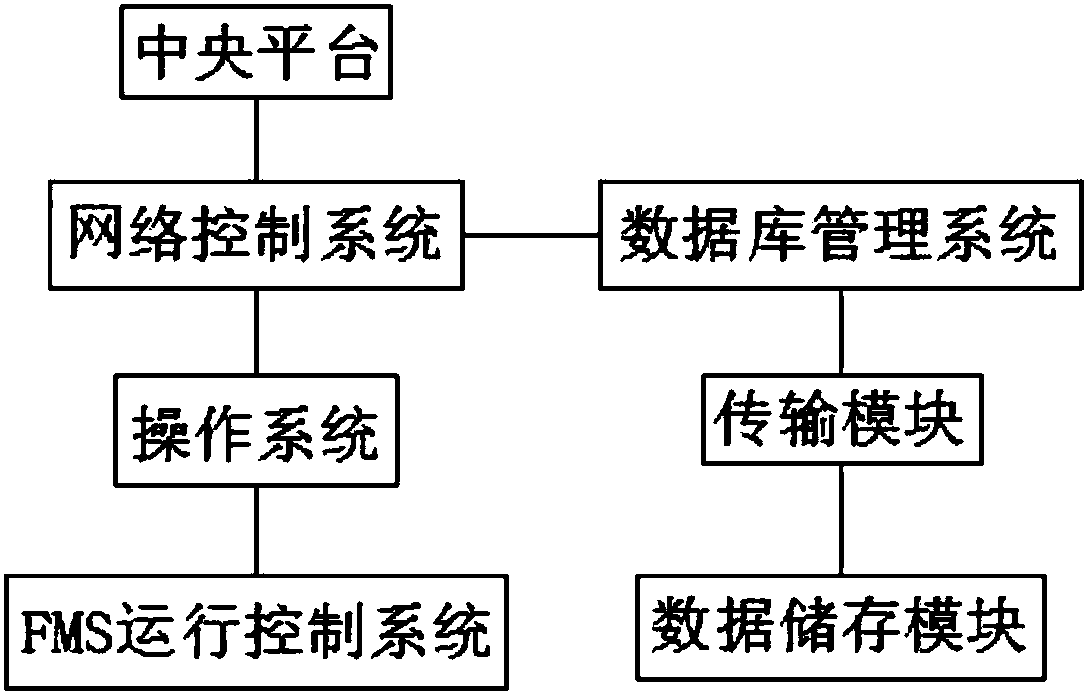

Flexible intelligent manufacturing system for hybrid multi-workpiece processing

InactiveCN108549342AImprove efficiencyLow costTotal factory controlProgramme total factory controlOperational systemEngineering

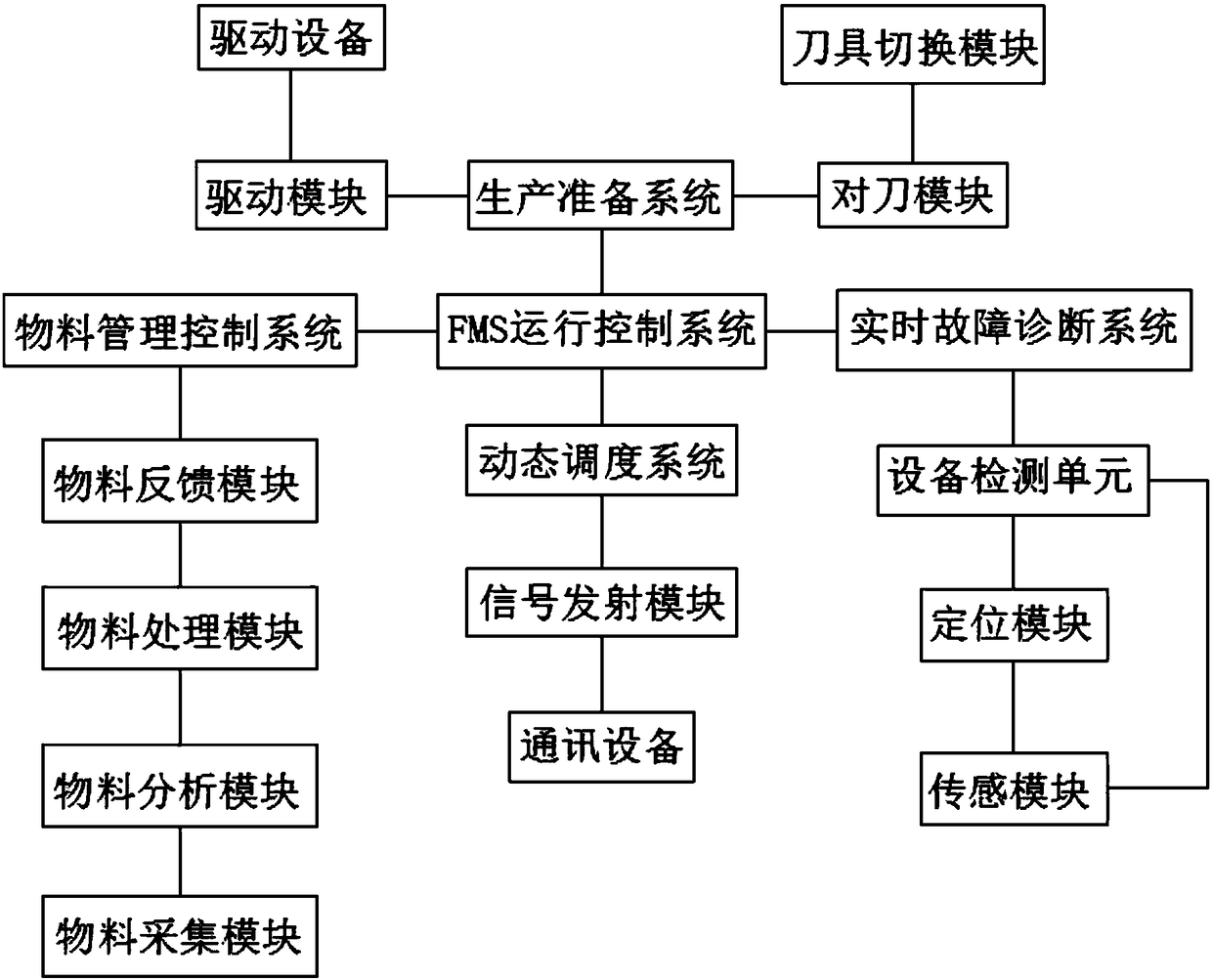

The invention discloses a flexible intelligent manufacturing system for hybrid multi-workpiece processing. The system comprises a central platform, wherein the central platform is connected with a network control system through a power supply wire, the network control system comprises an operation system and a database management system, the operation system is connected with an FMS operation control system through a power supply wire, the database management system is connected with a transmission module through a power supply wire, the transmission module is connected with a data storage module through a power supply wire, and the FMS operation control system comprises a production preparation system, a material management control system, a dynamic scheduling system and a real-time faultdiagnosis system. The flexible intelligent manufacturing system is advantaged in that productivity is high, the equipment is fixed, the equipment utilization rate for flexible manufacturing is further high, cost of single products is low, one or several similar parts can be processed, production of many varieties of small and medium batches can be carried out, efficiency of hybrid workpiece processing is improved, and labor intensity of operators is reduced.

Owner:佛山聚晨知识产权运营有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com