Intelligent manufacturing system for precisely forming high-precision mechanical basic part

A high-performance mechanical and precision forming technology, applied in the directions of comprehensive factory control, electrical program control, and comprehensive factory control, etc., it can solve the problems such as the inability to centrally monitor the operation change curve online, the inability to respond quickly to user needs, and the low manufacturing efficiency. , to achieve the effect of easy information resource sharing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with drawings and embodiments.

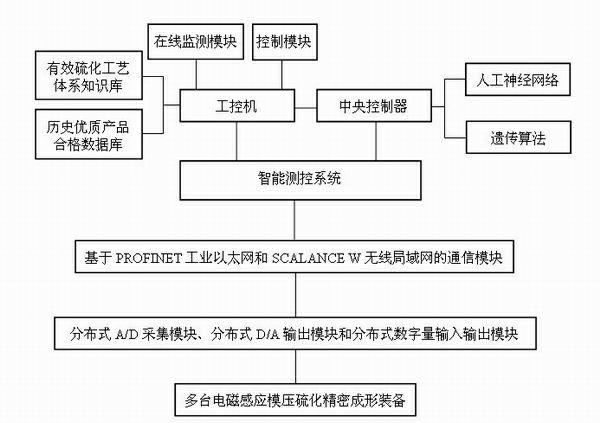

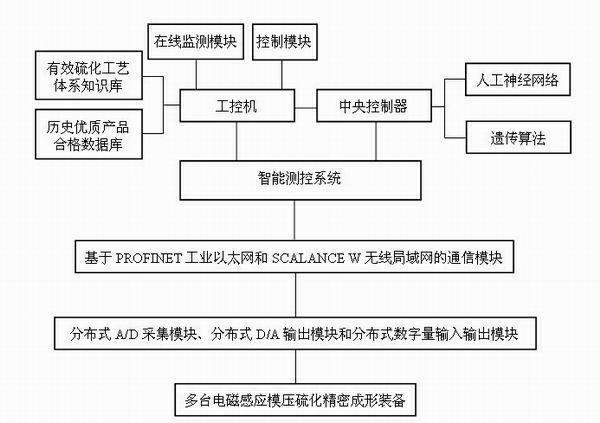

[0040] Intelligent manufacturing system for precision forming of high-performance mechanical basic parts, the system includes an intelligent measurement and control system and multiple electromagnetic induction molding vulcanization precision forming equipment,

[0041] Electromagnetic induction molding vulcanization precision forming equipment, complete the electromagnetic induction molding vulcanization precision forming and automatic demoulding of mechanical basic parts, collect real-time pressure data, temperature data and displacement data during the processing of mechanical basic parts, and feed the data back to intelligent measurement and control system;

[0042]The intelligent measurement and control system collects the pressure data, temperature data and displacement data of multiple electromagnetic induction molding vulcanization precision forming equipment in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com