Coking intelligent manufacturing system based on big data

A technology of intelligent manufacturing and big data, applied in general control system, control/adjustment system, program control, etc., can solve the problems of time-consuming, labor-intensive, low reliability, comprehensive control, etc., and achieve high efficiency, low cost, and high reliability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

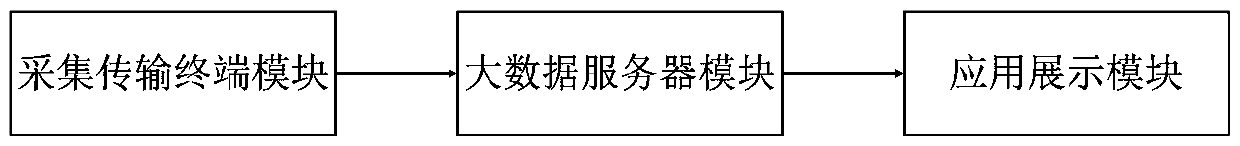

[0014] like figure 1 Shown is a schematic diagram of the hardware structure of the system of the present invention: the coking intelligent manufacturing system based on big data provided by the present invention includes a collection and transmission terminal module, a big data server module and an application display module; a collection and transmission terminal module, a big data server module It is connected in series with the application display module in sequence; the collection and transmission terminal module is used to collect the whole plant data of the existing coking plant, and upload the big data server module; the big data server module is used to store, analyze and calculate the uploaded data, and analyze And the calculated results are uploaded to the application display module; the application display module is used to control and display the whole plant production of the coking plant according to the uploaded results.

[0015] In the actual implementation, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com