Multi-module composite complete machine linkage soft package lithium battery intelligent manufacturing control system and method

A soft-pack lithium battery, intelligent manufacturing technology, applied in secondary battery manufacturing, general control system, control/regulation system, etc., can solve problems such as the inability to monitor the operation process and status of battery products in real time, and the difficulty in tracing quality control products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

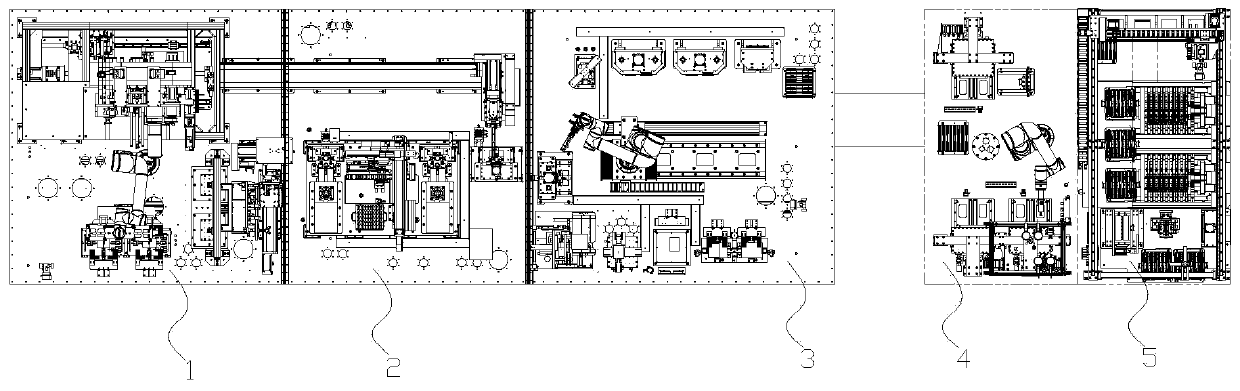

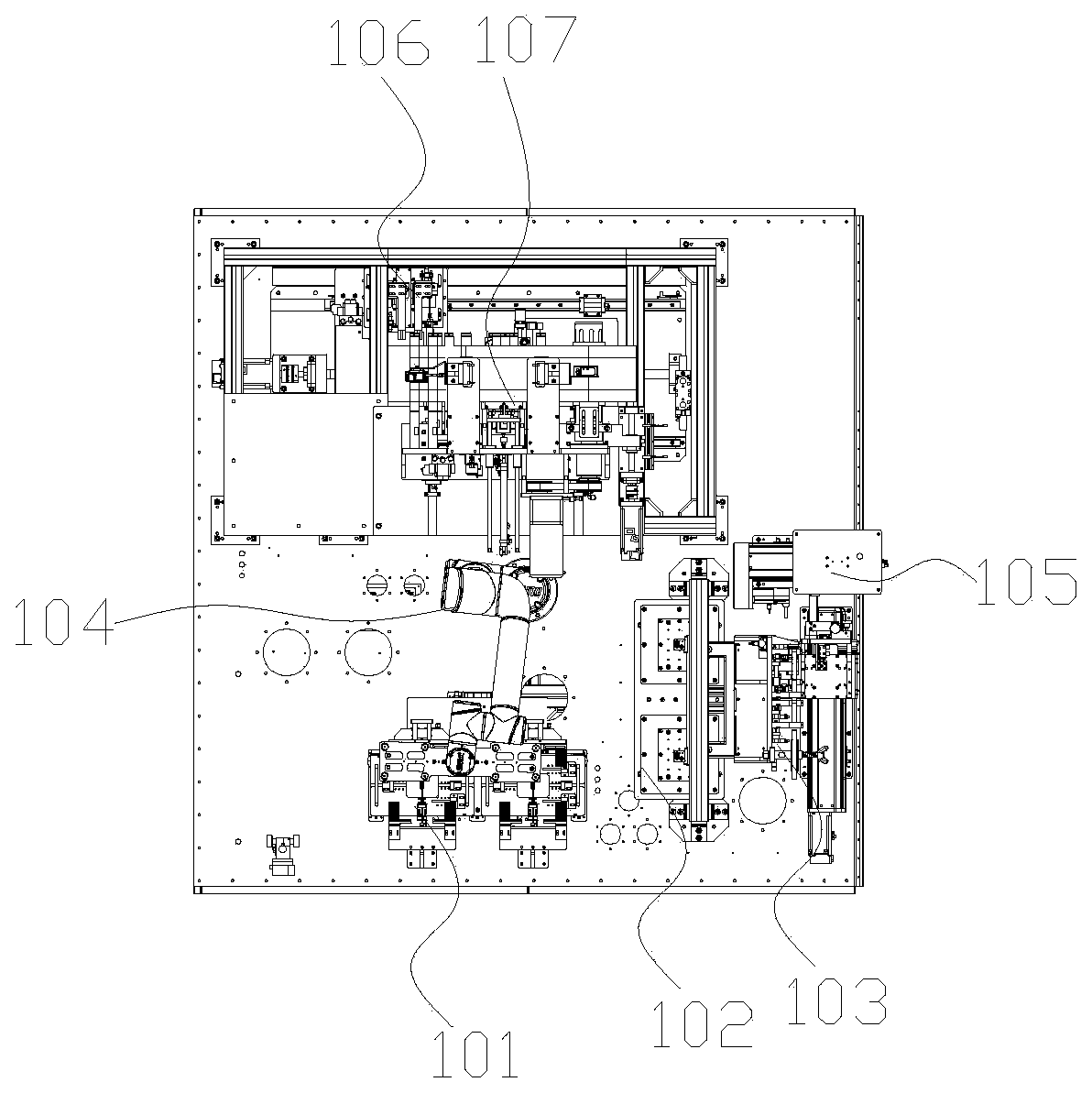

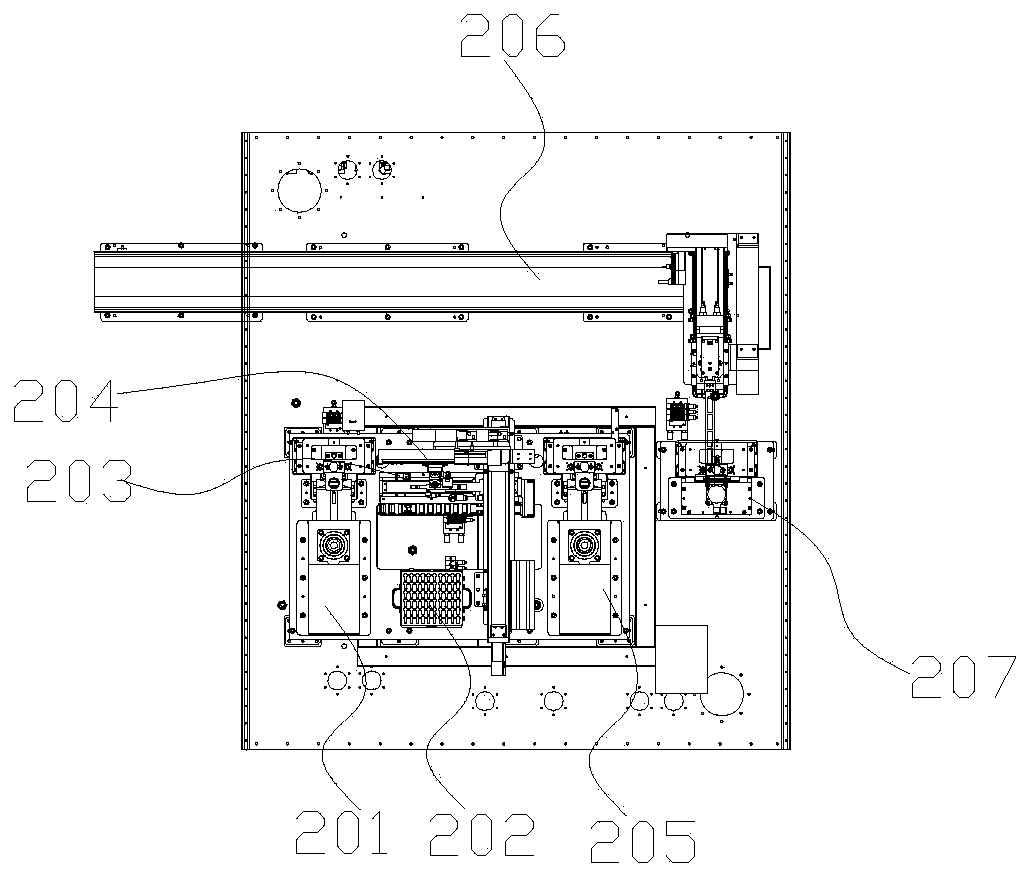

[0042] A multi-module composite whole machine linkage soft-pack lithium battery intelligent manufacturing control system is used to control the soft-pack lithium battery intelligent manufacturing system. The soft-pack lithium battery intelligent manufacturing system includes a stacking device 1, a welding device 2, a heat-sealing device 3, The liquid injection device 4 and the chemical conversion device 5, specifically, the stacking device 1 includes a feeding mechanism 101, a CCD platform 102, a glue feeding mechanism 103, a first manipulator 104, a cell glue sticking mechanism 105, a stacking table 106, and a material roll agency107. The welding device 2 includes a final welding mechanism 201 , an electrode plate 202 , an electrode plate docking arm 203 , a feeding manipulator 204 , a pre-welding mechanism 205 , a first transplanting mechanism 206 , and a cutting mechanism 207 . The heat sealing device 3 includes a top sealing mechanism 301, a side sealing mechanism 302, a s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com