Two-degree-of-freedom decoupling reducing mechanism

A technology of deceleration mechanism and degree of freedom, applied in the direction of elastic suspension, control device, vehicle components, etc., can solve the problems of suspension limitation, large tire cornering stiffness, vertical acceleration and wheel dynamic load increase, and achieve convenient layout and installation , reduce the inertial force, the effect of small overall size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with the implementation described in the accompanying drawings, further illustrate the specific content of the present invention and specific embodiments thereof:

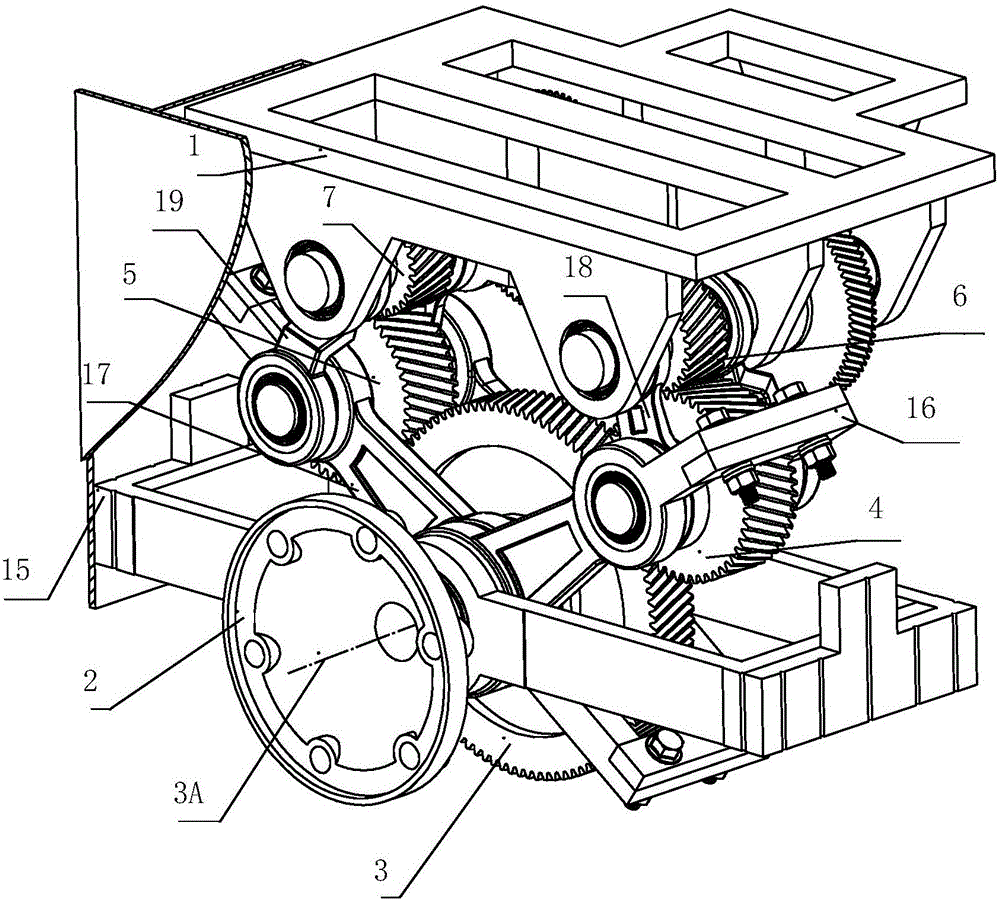

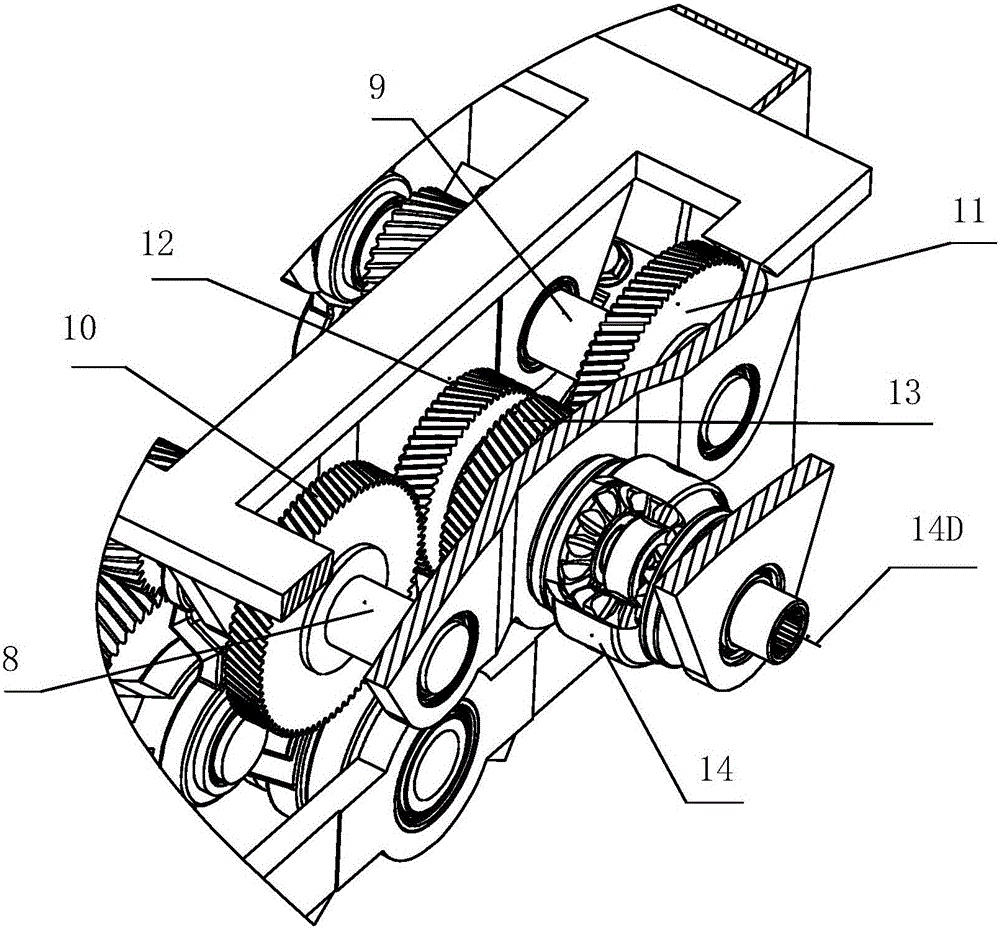

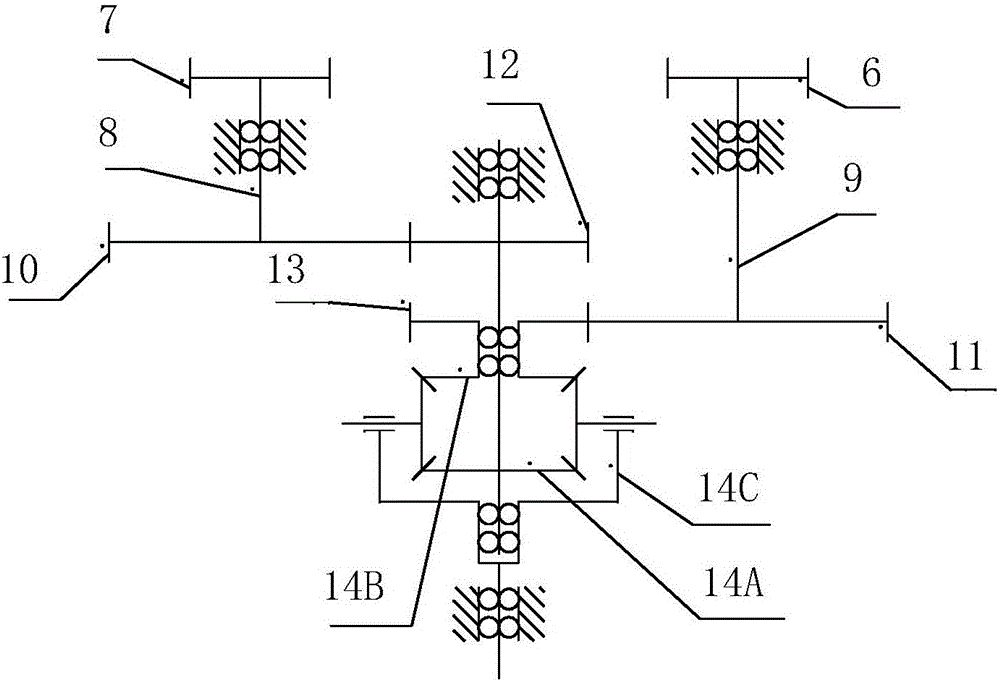

[0019] The realization of the decoupling function of the device provided by the present invention mainly depends on the connecting rod slider mechanism, the gear transmission mechanism and the differential mechanism, and mainly includes: the frame 1, the power output shaft 2, the power output wheel 3, the first idler wheel 4, II idler gear 5, I secondary reduction gear 6, II secondary reduction gear 7, I shaft 8, II shaft 9, I primary reduction gear 10, II primary reduction gear 11, I transfer wheel 12, Second transfer wheel 13, differential assembly 14, linear guide mechanism 15, first connecting rod bearing assembly 16, second connecting rod bearing assembly 17, third connecting rod bearing assembly 18, fourth connecting rod bearing assembly19.

[0020] The linear guide mechanism 15 c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com