Differential-speed dynamic coupling device

A power coupling and differential technology, applied in the direction of differential transmission, transmission, transmission parts, etc., can solve problems such as affecting the normal power transmission of the vehicle, reducing the life of the differential, and difficult to assemble needle rollers, and achieve a simplified new Design and trial production, prevent breakage, and run well

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

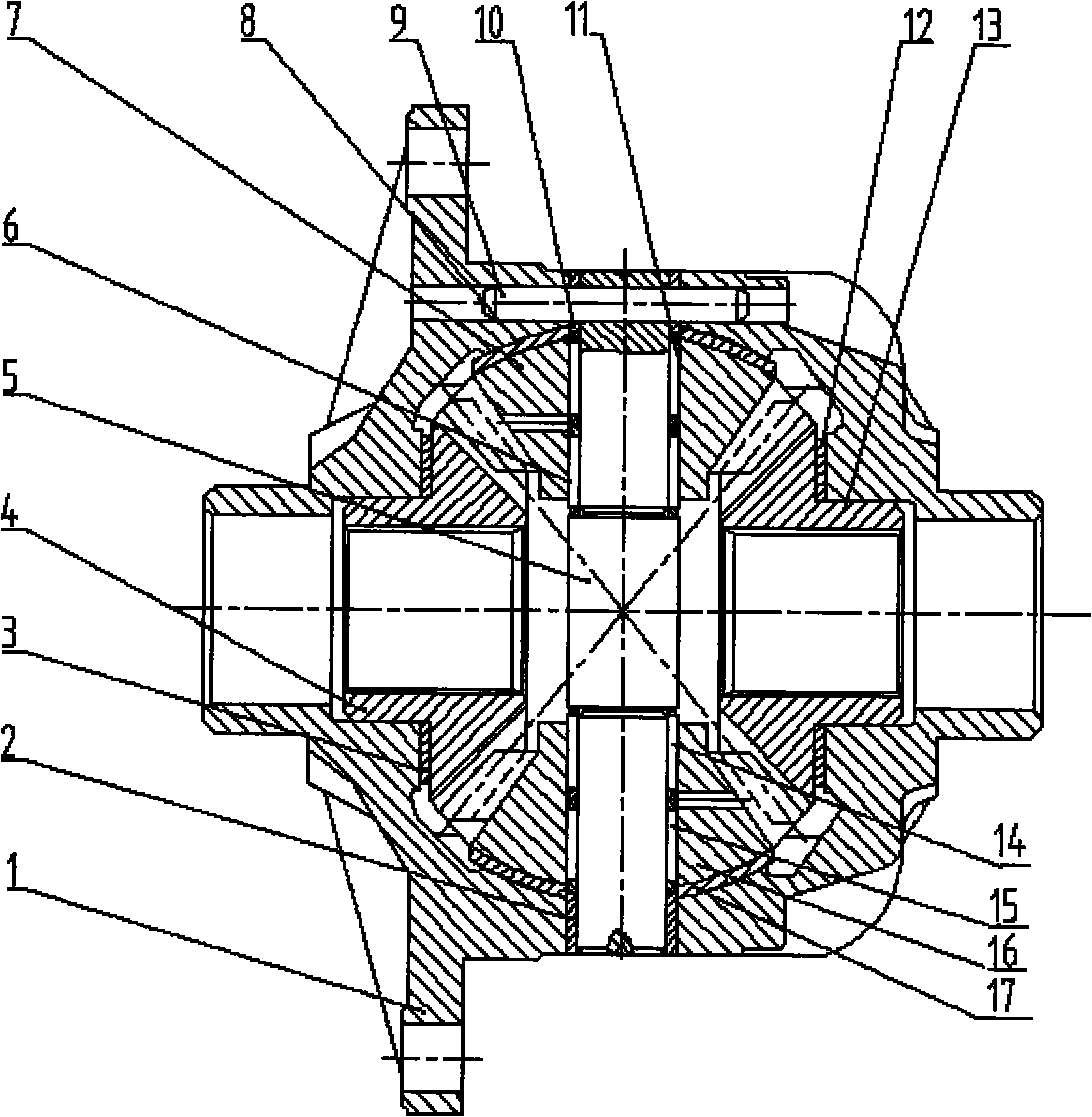

[0020] The present invention is described in detail below in conjunction with accompanying drawing:

[0021] refer to figure 1 , in order to solve the problem that the "pure needle roller bearing" scheme adopted in the prior art has difficulty in assembling the needle rollers, prone to movement interference between the needle rollers, breaking the planetary gear shaft, and partially bending or breaking the needle rollers, the present invention proposes Differentials using needle roller bearings with cages for use as power coupling devices for series-type hybrid electric vehicles. In other words, the traditional differential can be applied to hybrid electric vehicles as a power coupling device only by partially modifying the internal structure of the traditional differential.

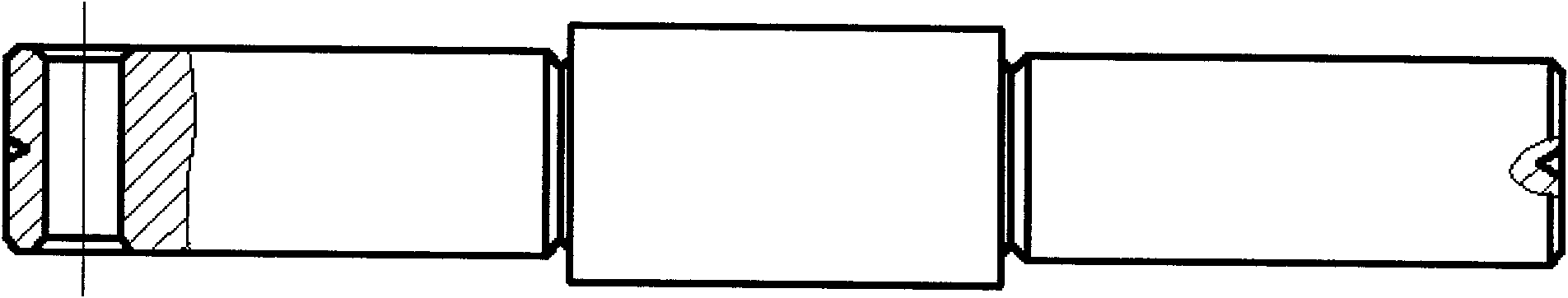

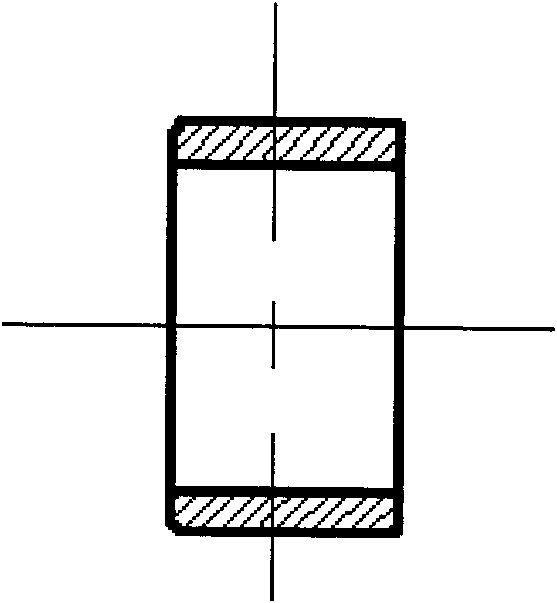

[0022] The differential power coupling device of the present invention includes a differential case 1, a circular sleeve without holes 2, a left side gear spacer 3, a left side gear (bevel gear) 4, a pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com