Integral high-pressure small-flow adjuster

A small flow, integrated technology, applied in valve details, sliding valves, engine components, etc., can solve the problems of low accuracy and insufficient stability of the medium flow adjustment system, achieve small structure size, stable output, and prevent movement interference Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

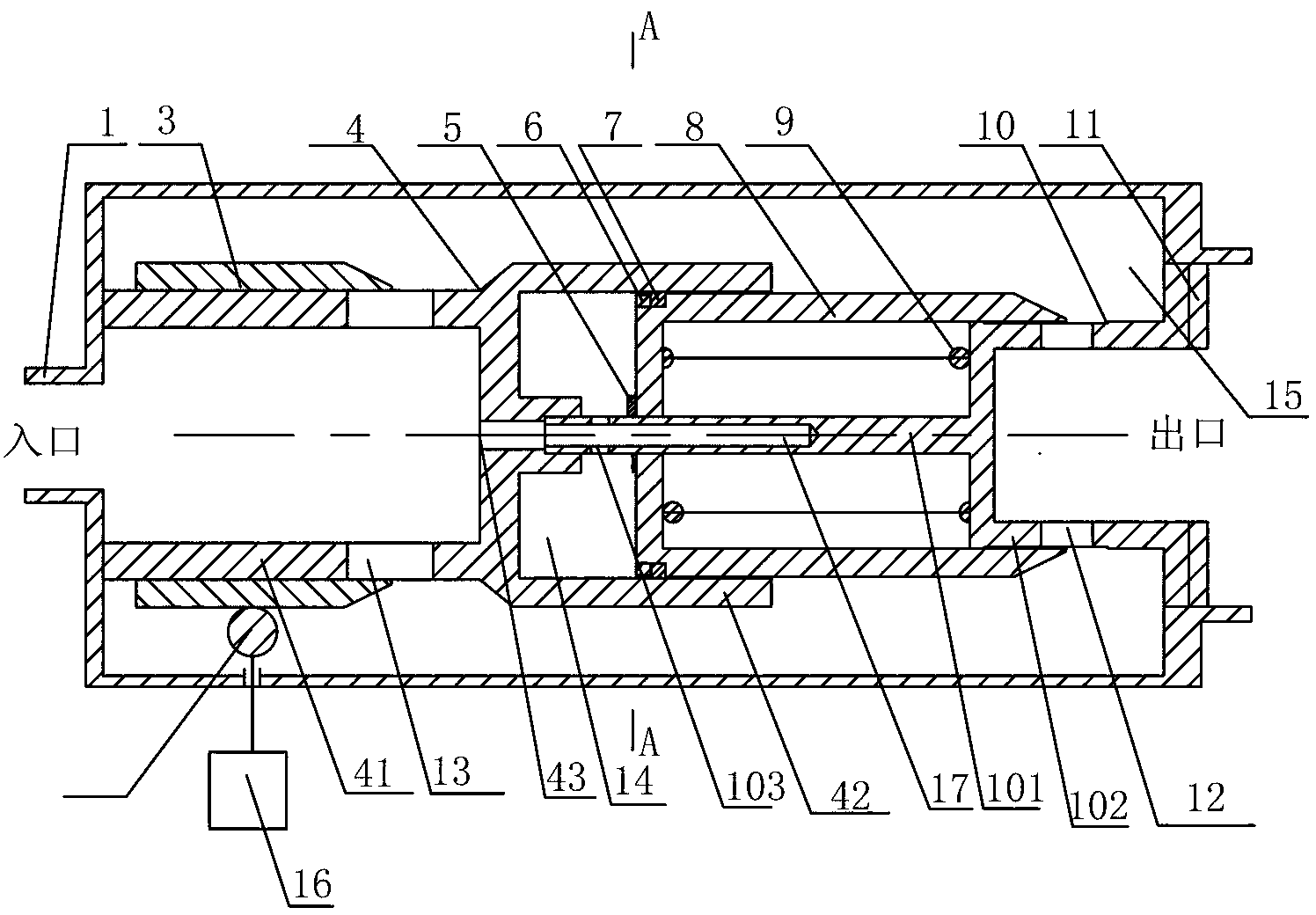

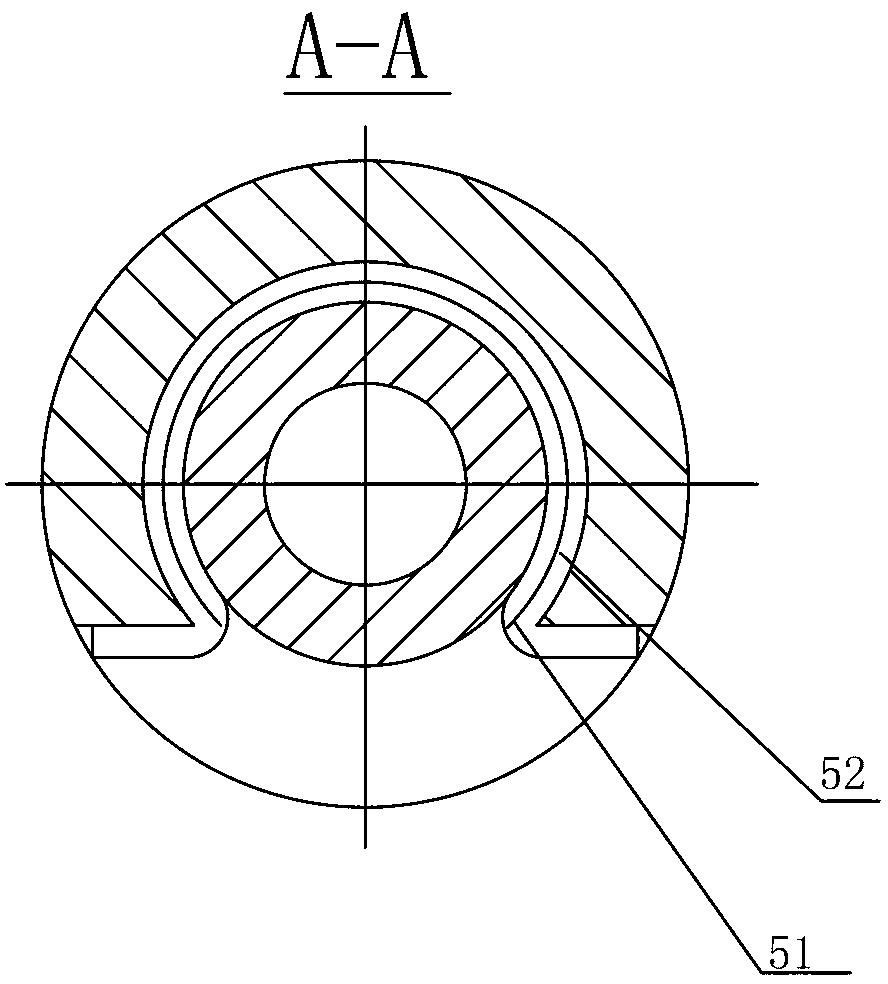

[0025] The composition of the flow regulator: as figure 1 As shown, it consists of housing 1, gear shaft 2, gear sleeve 3, support sleeve 4, limit block 5, limit nut 6, piston ring 7, tapered slide valve 8, adjustment spring 9, slide valve seat 10, nut 11 and so on.

[0026] The support sleeve 4 is arranged at the entrance of the housing. The support sleeve 4 includes an inlet flow guide sleeve 41 and a limit seat 42 fixedly connected in sequence. The inlet flow guide sleeve 41 is provided with an inlet throttle hole 13,

[0027] The slide valve seat 10 includes a fixed cylinder 101 and an outlet guide sleeve 102 connected in sequence, the other end of the fixed cylinder 101 passes through the end face of the slide valve and is fixedly connected with the support sleeve 4, and the other end of the outlet guide sleeve 102 is fixed on the At the outlet of the casing 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com