Portable digital display automotive suspension clearance test stand calibrating apparatus

A technology of automobile suspension and verification device, which is applied in the direction of measuring device, vehicle test, and electric device, and can solve the problems that there is no verification device for automobile suspension gap test bench, so as to shorten the clamping time and avoid mechanical clamping. The effect of compact structure and low processing precision requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

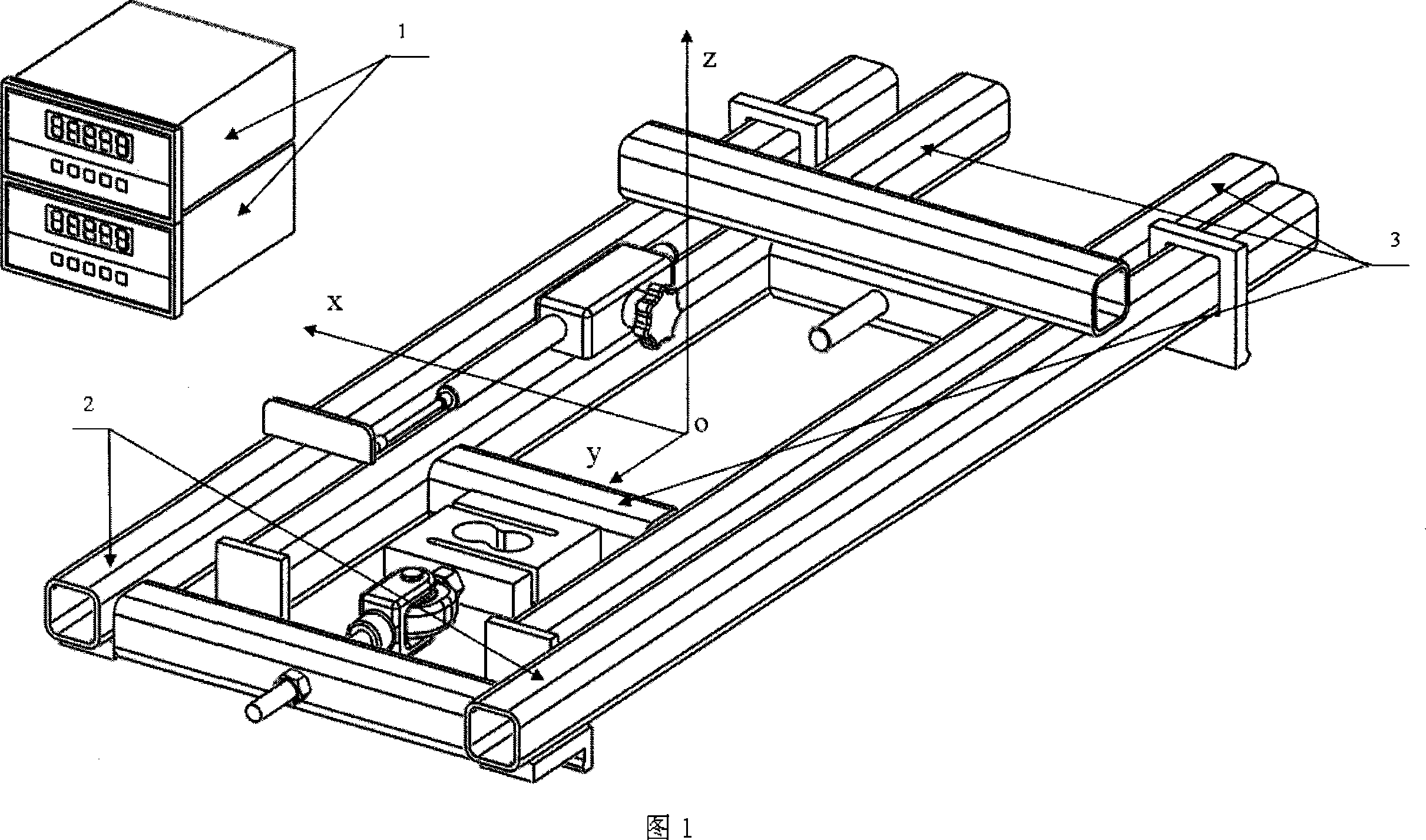

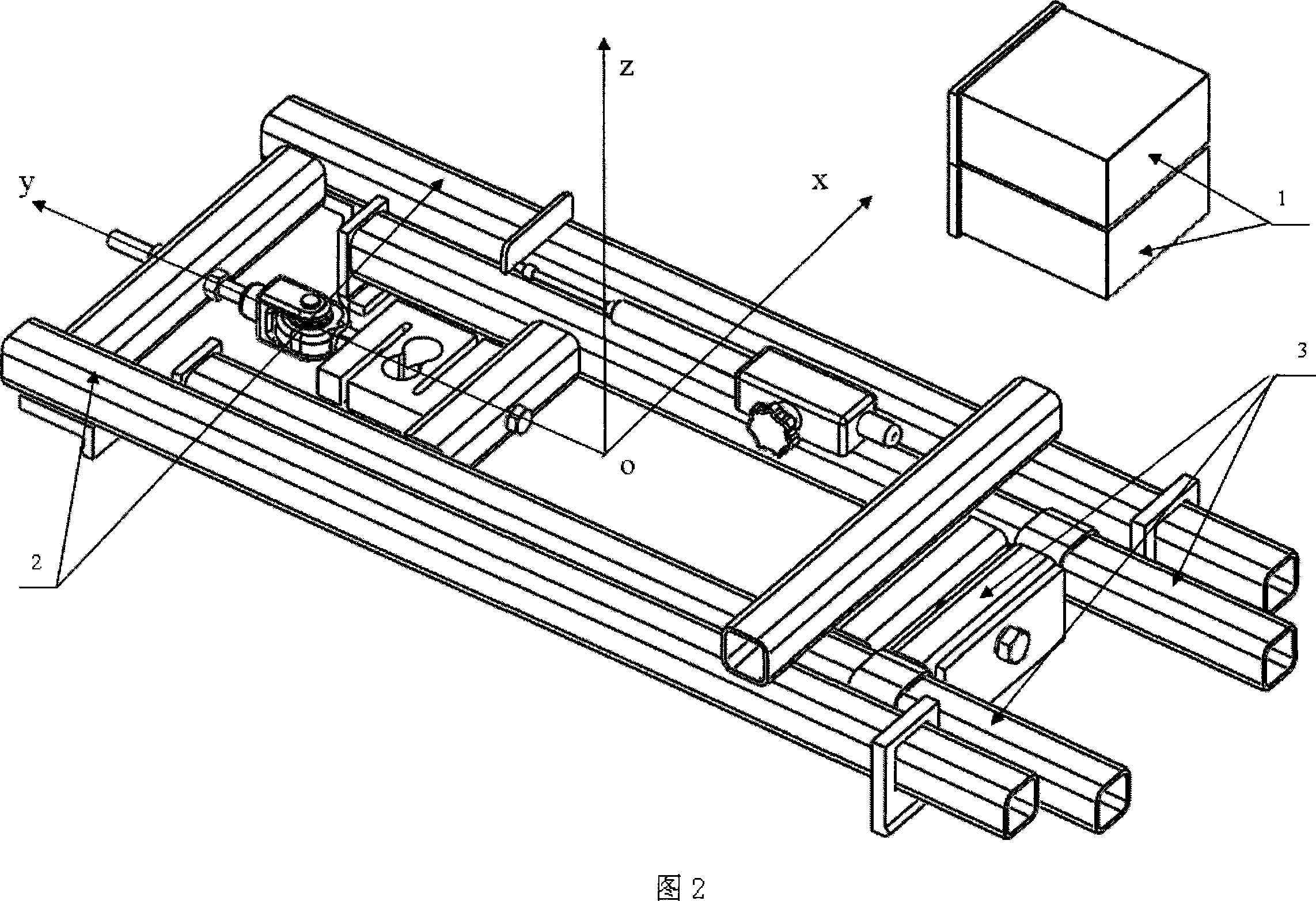

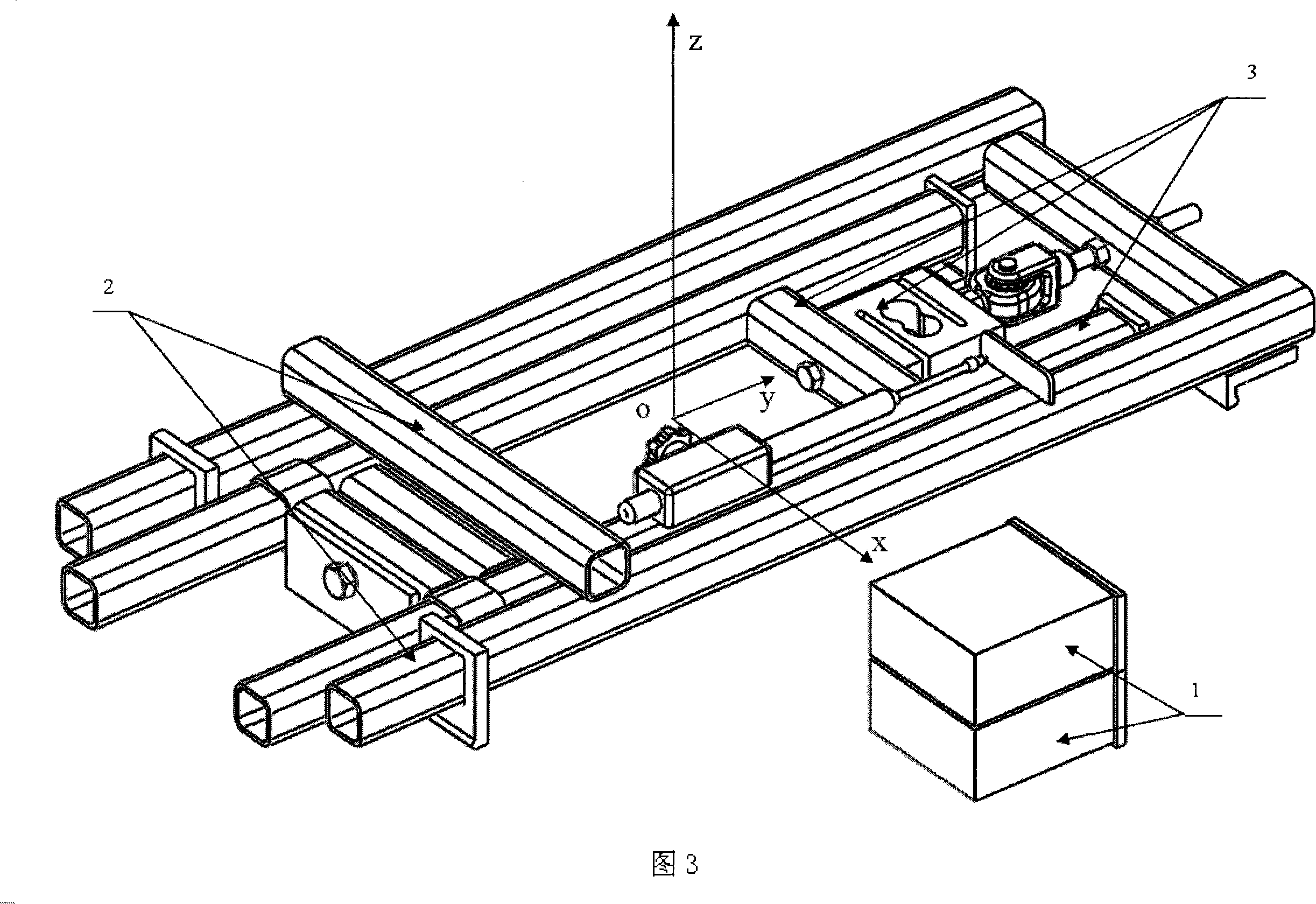

[0026] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0027] The invention is a special equipment for verifying the automobile suspension clearance test bench. It can quickly and simultaneously detect the lateral force and displacement of the automobile suspension clearance test bench. The accuracy of the verification device of the present invention is higher than that of the automobile suspension clearance test bench. Through the serial port and the computer network, the measured The data of the automobile suspension clearance test bench is compared with the data measured by the automobile suspension clearance test bench to realize the verification of the automobile suspension clearance test bench.

[0028] The invention adopts a digital intelligent display instrument, which has the characteristics of simple operation, stable performance, accurate measurement result and high precision. It can be applied to automob...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com