Intelligent manufacturing system for precise speed reducer planetary gears

A precision reducer and planetary gear technology, applied in the field of mechanical processing, can solve problems such as difficulty in guaranteeing processing quality, increased labor costs, and poor environment, and achieve the effects of improving production quality and efficiency, realizing intelligent manufacturing, and realizing intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

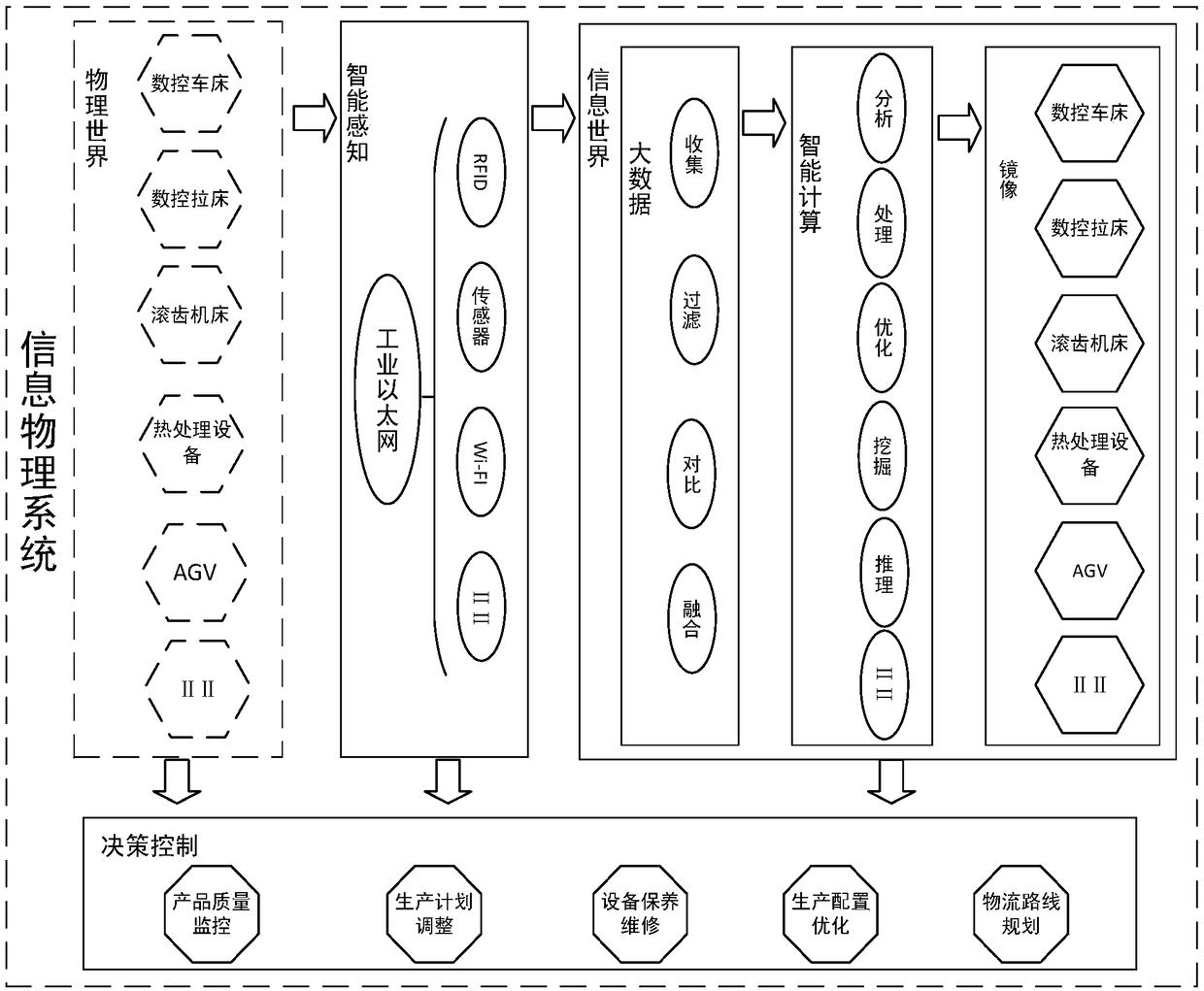

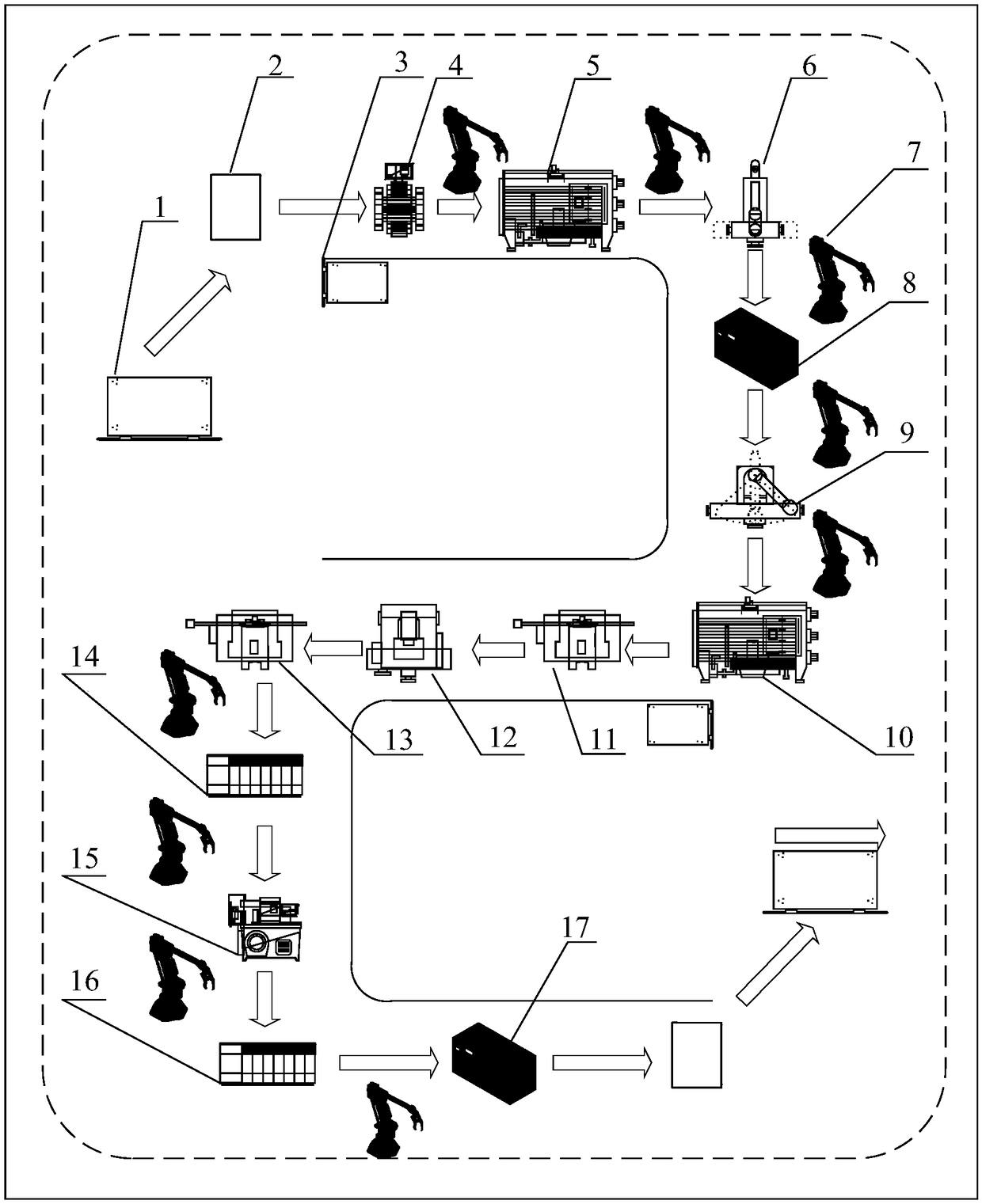

[0031]The intelligent planetary gear manufacturing system of the precision reducer described in the present invention includes a cyber-physical system, planetary gear processing equipment and a material system. Planetary gear processing equipment completes the processing process of planetary gears from blanks to finished workpieces; as a multi-dimensional intelligent technology system, cyber-physical systems rely on big data, networks and massive computing, and through core intelligent perception, analysis, and mining , evaluation, prediction, optimization, collaboration and other technical means, the organic integration and in-depth cooperation of calculation, communication, and control make the processing equipment of the planetary gear production line have the ability of introspection, self-prediction, self-comparison and self-configurati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com