Intelligent manufacturing system based on industrial robot

An industrial robot, intelligent manufacturing technology, applied in the direction of manufacturing tools, other manufacturing equipment/tools, stacking of objects, etc., can solve problems such as affecting the health of employees, high labor costs, affecting work efficiency, etc., to achieve flexible and unmanned The effect of high production, high degree of automation, convenient and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

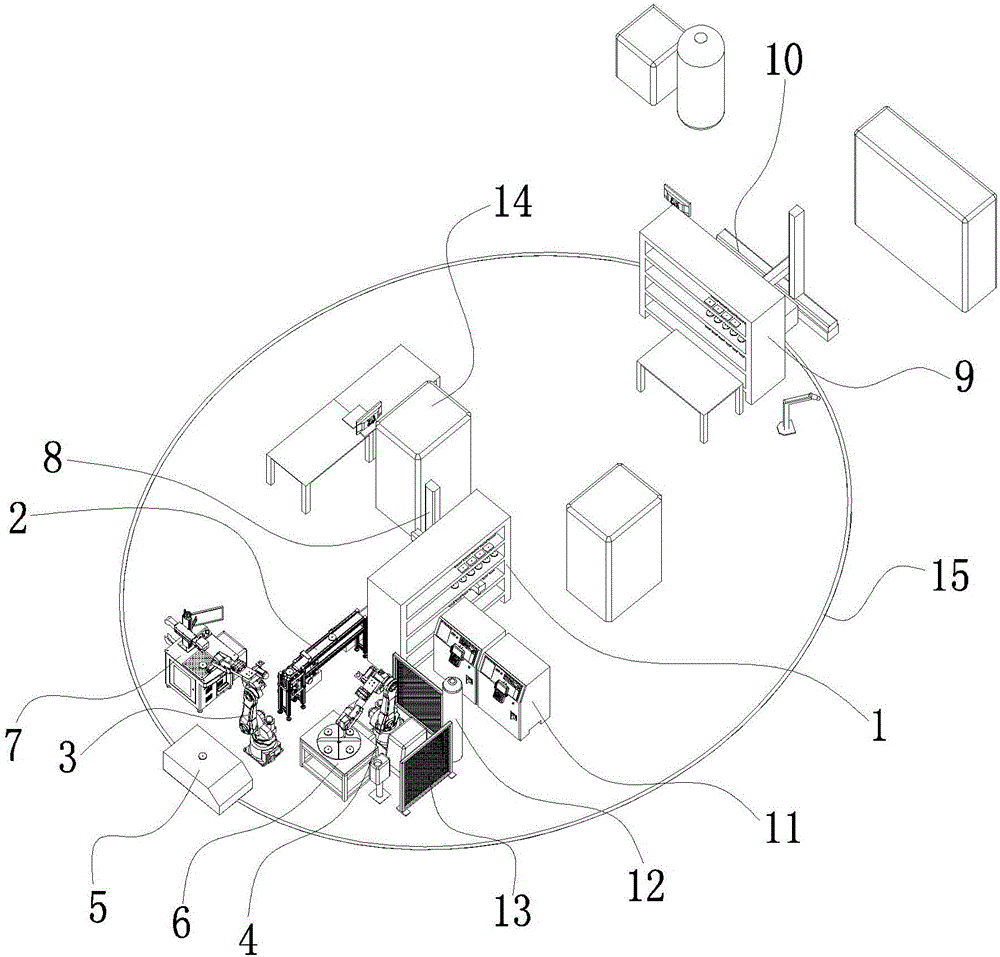

[0021] Such as figure 1 As shown, an intelligent manufacturing system based on industrial robots is a training workshop in the field of robotics and industrial automation. It aims to concentrate and Intuitively teach college students the basics of automation and get a real feel for it.

[0022] This system includes the palletizing and handling robot 3 and the welding and palletizing manipulator 4, together with the machine vision system, the robots will work in coordination to complete the most common applications of parts handling and welding. It includes the automatic warehouse with palletizing and handling robot 3, welding and palletizing manipulator 4 and barcode recognition as the core, as well as the automatic logistics system composed of automatic conveyor belt and AGV trolley 5, the automatic warehouse with automatic input function and automat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com