Compressor

A compressor and anechoic cavity technology, applied in the field of compressors, can solve the problems of limited muffler muffler capacity, poor muffler muffler effect, and small muffler volume, achieving small increase in design cost and processing cost, simple structure, and reduced noise volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

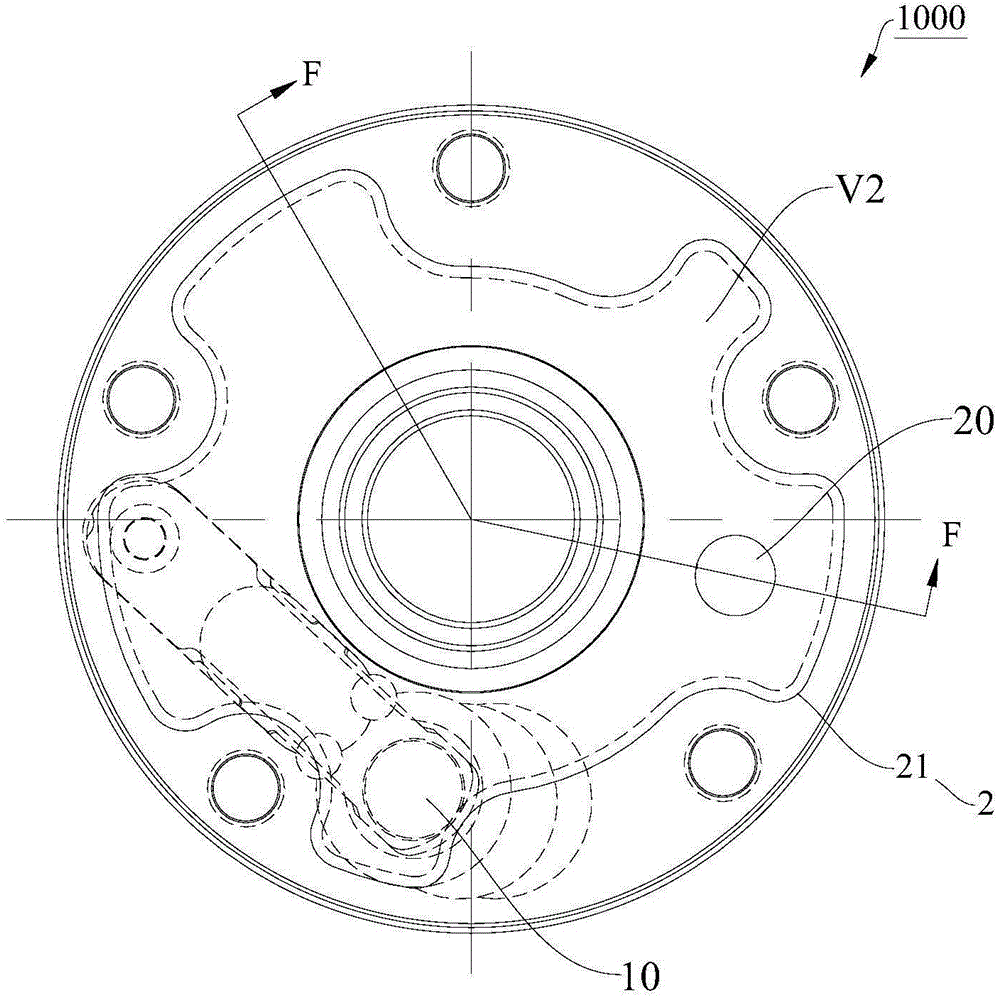

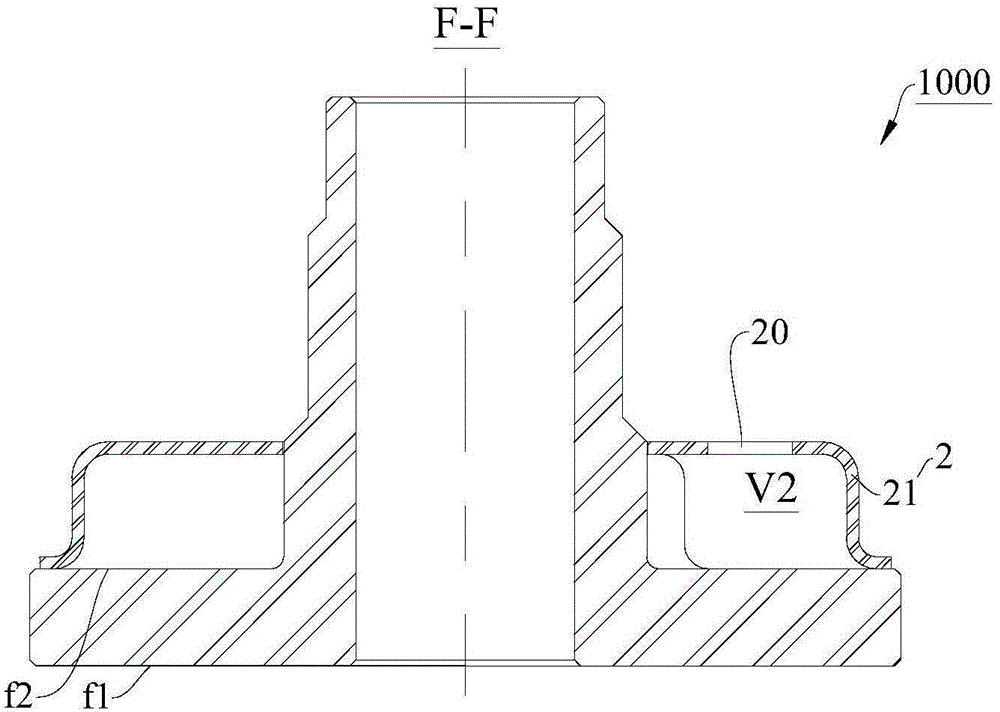

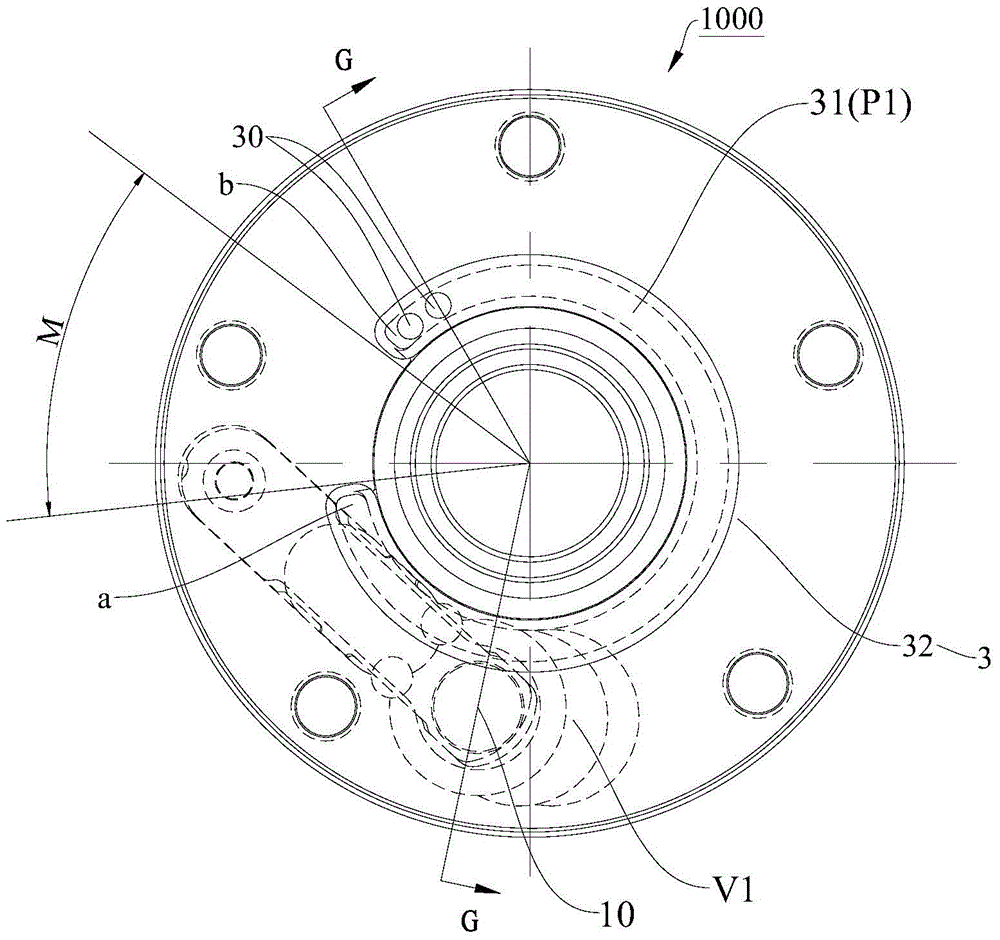

[0071] In the first embodiment, if Figure 1-Figure 6 As shown, the compressor 1000 is in the figure 1 with figure 2 The conventional structure shown adds the image 3 with Figure 4 The first sound-absorbing partition 32 shown, the combined structure is as follows Figure 5 with Image 6 shown.

[0072]Wherein, the first noise-absorbing baffle 32 is formed in an annular shape and is sheathed on the hub 12 of the bearing 1, and a part of the first silencing baffle 32 is recessed toward a direction away from the bearing 1 to form a groove 31, and the groove 31 is in contact with the bearing. The second end surface f2 of 1 cooperates to define the first sub-muffling cavity P1. The first sub-muffling chamber P1 is formed in an arc shape extending around the center of the first sound-absorbing partition 32 , and two second exhaust holes 30 are provided at the ends of the first sub-muffling chamber P1 . The first muffler 21 is arranged on the first muffler baffle 32 , and a...

Embodiment 2

[0075] In the second embodiment, if Figure 8-Figure 11 As shown, the compressor 1000 is in the Figure 8 with Figure 9 In the traditional structure shown, the first sound-absorbing partition 32 is added, and the combined structure is as follows Figure 10 with Figure 11 shown.

[0076] Wherein, the second muffler 22 is disposed on the first muffler baffle 32 , and the second muffler 22 is provided with two third exhaust holes 20 . Moreover, compared with the first muffler 21 in the first embodiment, the shape of the second muffler 22 is also changed.

[0077] Figure 14 Shown is the inventor's comparative study of compressors without the first noise-absorbing partition 32 and with the first noise-absorbing partition 32, and the curve C in the figure shows that the second muffler 22 combines the first noise-absorbing partition The transmission loss distribution diagram behind the plate 32, the D curve in the figure represents the transmission loss distribution diagram ...

Embodiment 3

[0079] In the third embodiment, the compressor 1000 is Figure 8 with Figure 9 The conventional structure shown adds the Figure 12 The second sound-absorbing partition 33 is shown.

[0080] Wherein, the second noise-absorbing partition 33 is formed in an annular shape and is sheathed on the hub 12 of the bearing 1, and a part of the second noise-absorbing partition 33 is recessed toward a direction away from the bearing 1 to form a groove 31, and the groove 31 is in contact with the bearing. The second end surface f2 of 1 cooperates to define the first sub-muffling cavity P1. The first sub-muffling chamber P1 is formed as a connected circular ring extending around the center of the second muffling partition 33 , and two second exhaust holes 30 are arranged on the second muffling partition 33 .

[0081] Figure 14 It also shows the comparative research conducted by the inventor on the compressors without the second noise-absorbing partition 33 and with the second noise-ab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com