Cooperative control method for intelligent manufacturing system

A technology of intelligent manufacturing and collaborative control, which is applied in the general control system, control/regulation system, adaptive control, etc., can solve problems such as the impact of product stability, reduce the amount of information communication and calculation, enhance scalability, very robust effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

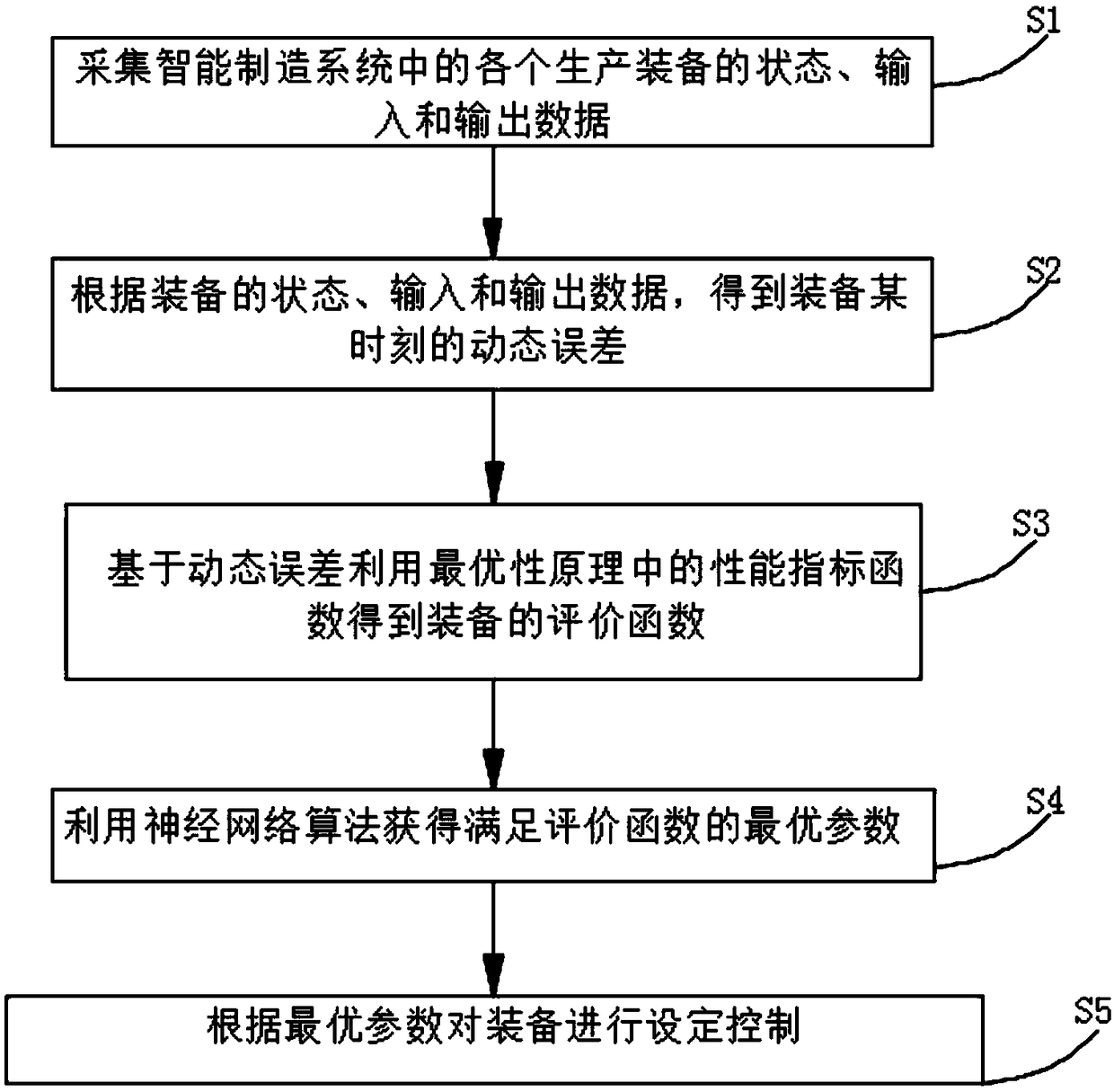

[0039] Please refer to figure 1 , a collaborative control method for an intelligent manufacturing system, comprising the following steps:

[0040] S1. Collect the status, input and output data of each production equipment in the intelligent manufacturing system;

[0041] The collection of various production equipment data in the intelligent manufacturing system includes injection molding intelligent equipment, manipulators (robots), conveyor belts, monitoring devices, grinding devices and other processing, monitoring, transmission equipment input, output, and state data collection, while injection molding intelligence The equipment also includes subsystems such as injection, film lamination, pressure holding, cooling, pre-molding, mold opening, and pick-up. The data collection of each production equipment: we collect the input of each production equipment through sensors or from servo drives (PLC / DSP) , output and state data, assuming that the input of the current equipment i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com