MES electrode intelligent manufacturing and detecting system, mould intelligent manufacturing system and mould manufacturing method

An intelligent manufacturing and detection system technology, applied in the field of automation, can solve problems such as poor quality, slow efficiency, and slow down the mold manufacturing process, so as to improve processing accuracy and processing efficiency, realize automatic deviation correction processing, and reduce personnel costs dependent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

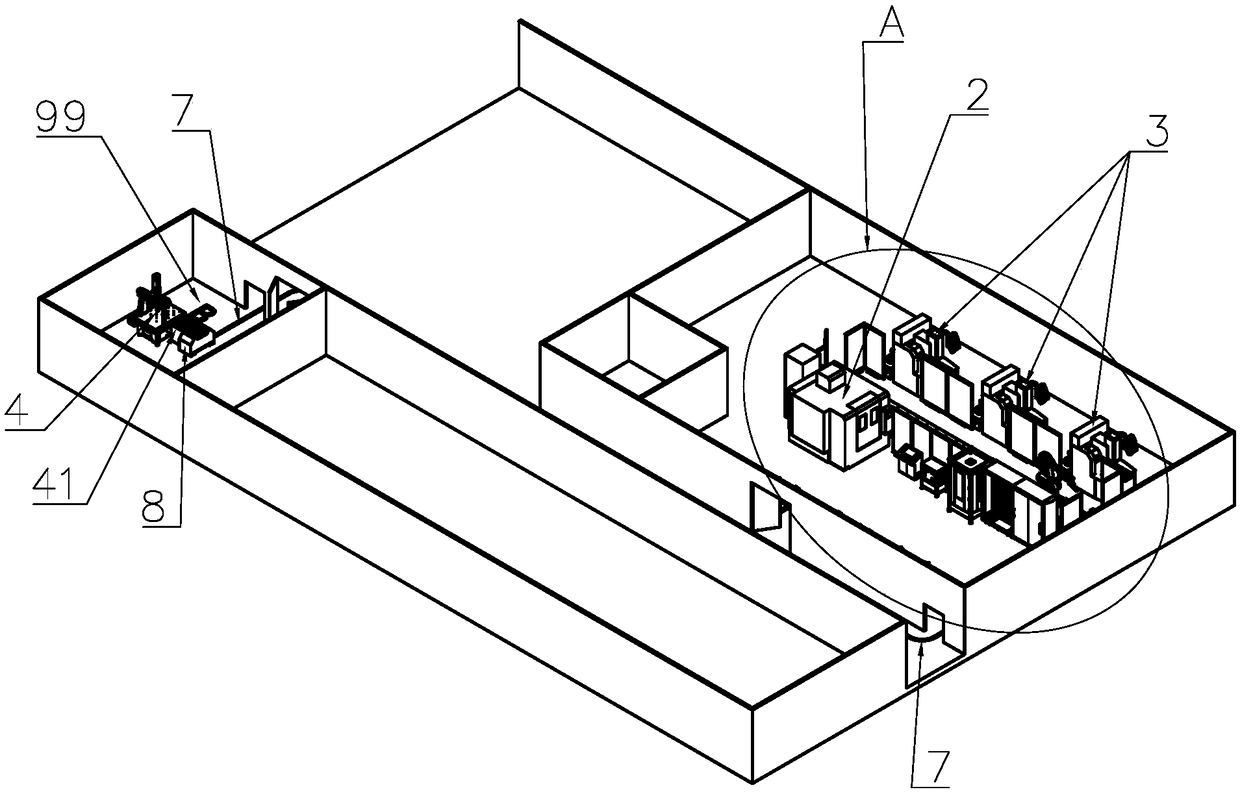

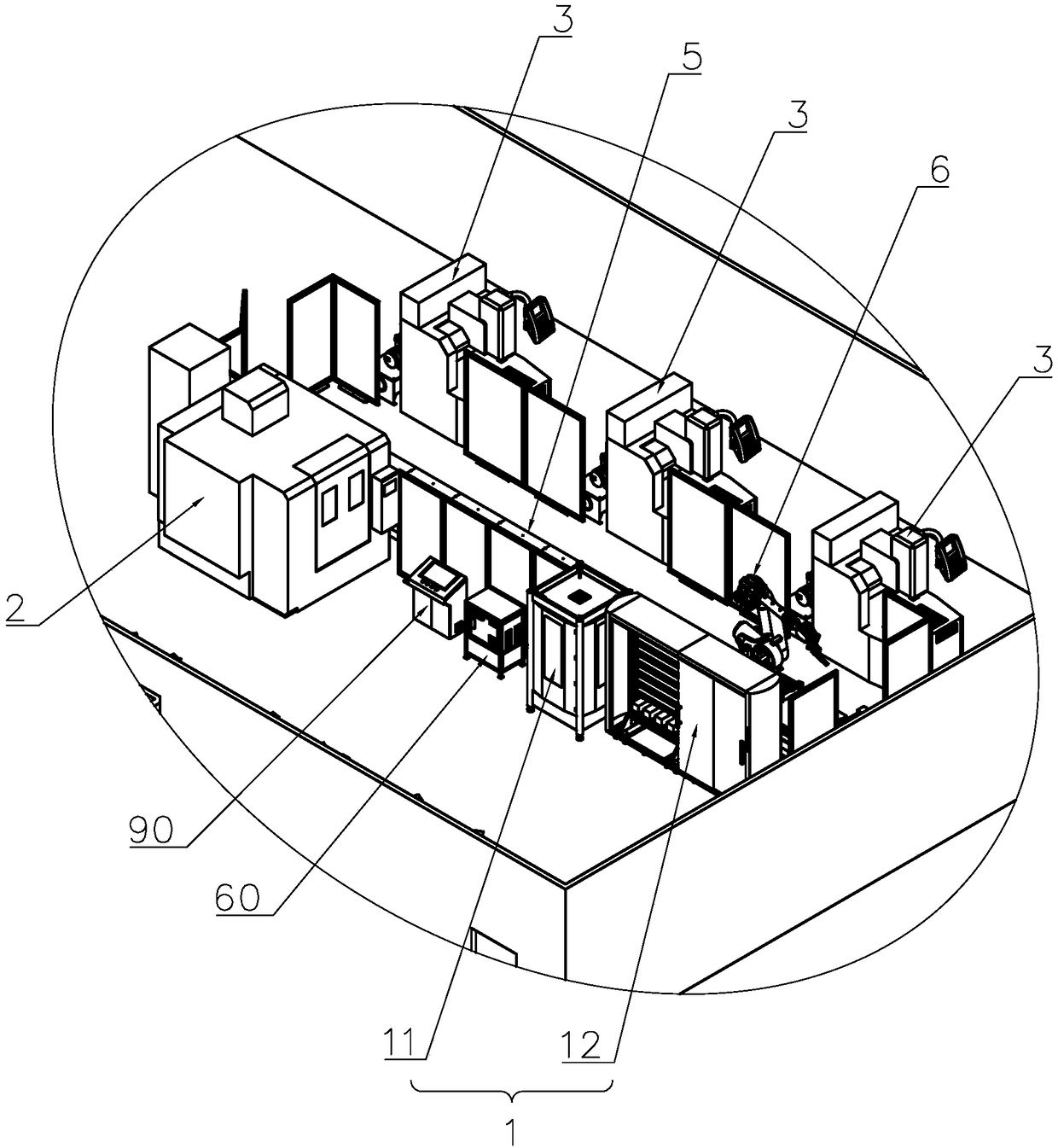

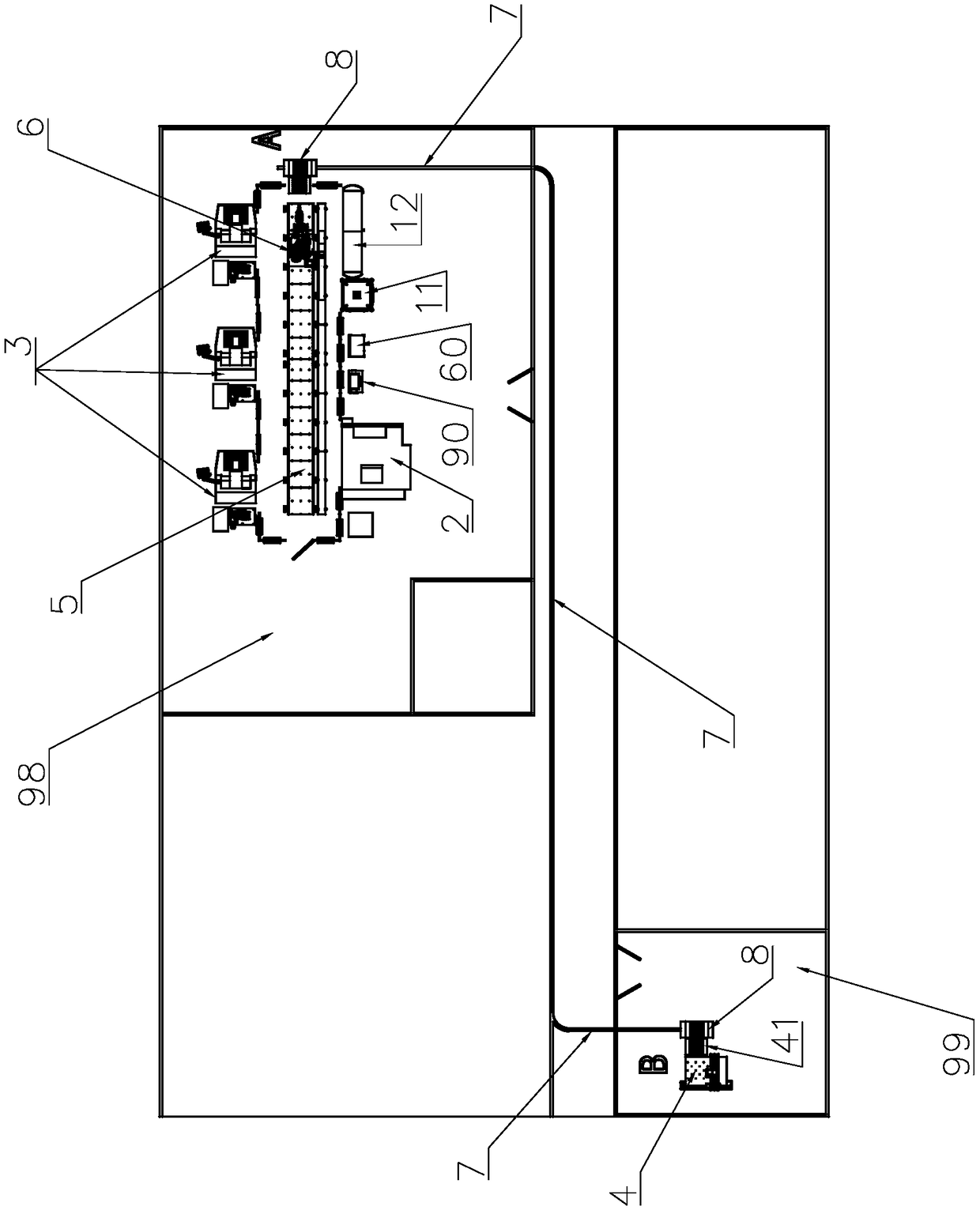

[0037] The following embodiments are mainly aimed at the mold intelligent manufacturing system and the mold manufacturing method of the present invention. Since the mold intelligent manufacturing system in the present invention includes the MES electrode intelligent manufacturing and detection system, the description of the embodiment of the mold intelligent manufacturing system has included the description of the embodiment of the MES electrode intelligent manufacturing and detection system.

[0038] Embodiment of mold intelligent manufacturing system

[0039] The mold intelligent manufacturing system of the present invention is a flexible processing automation system, which integrates data acquisition, analysis, management and display system software based on PC and Window system, which is convenient for managers to monitor remotely, can receive plans from the production management system, and automatically report to the management The system reports the processing results. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com