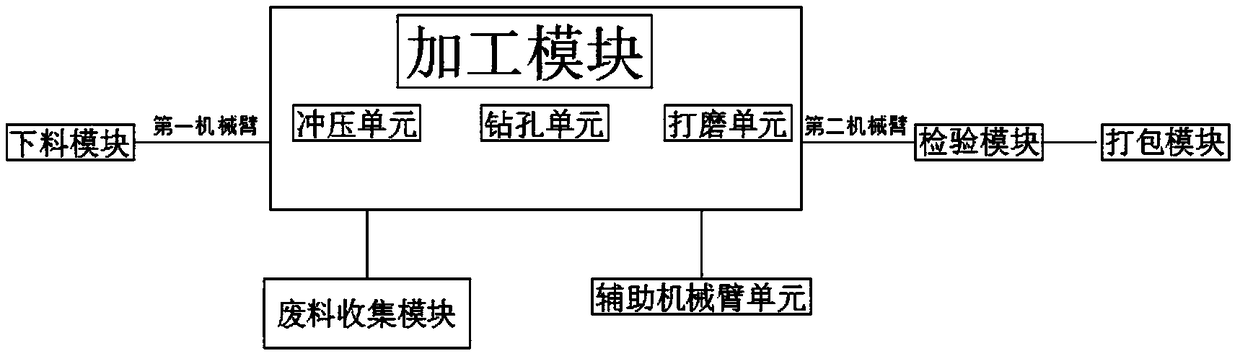

Platformization intelligent manufacturing system

An intelligent manufacturing and platform-based technology, applied in the direction of manufacturing tools and other manufacturing equipment/tools, etc., can solve problems such as low integration rate, troublesome operation, complex processing, etc., to improve processing efficiency, reduce processing steps, and reduce processing steps Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

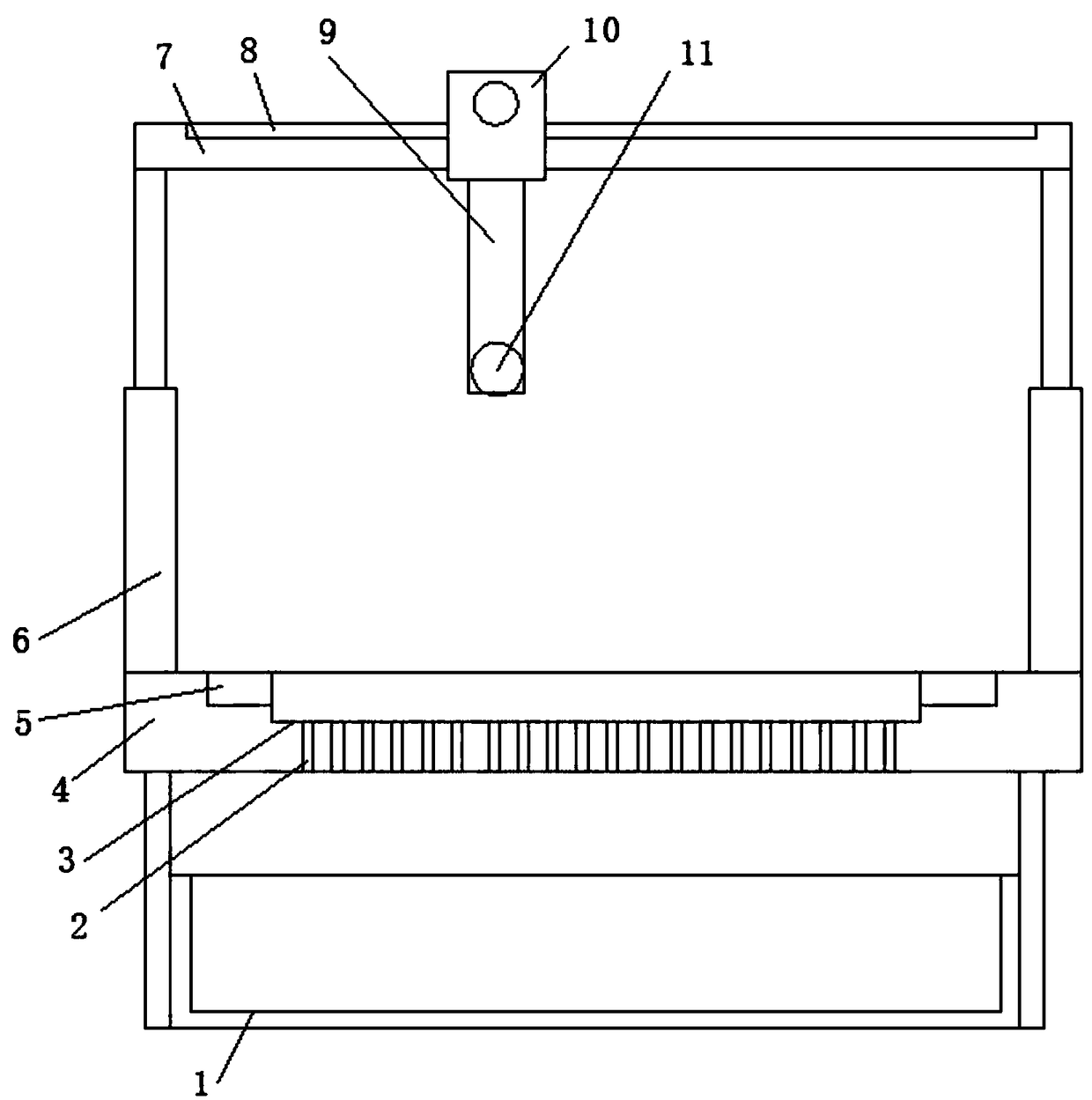

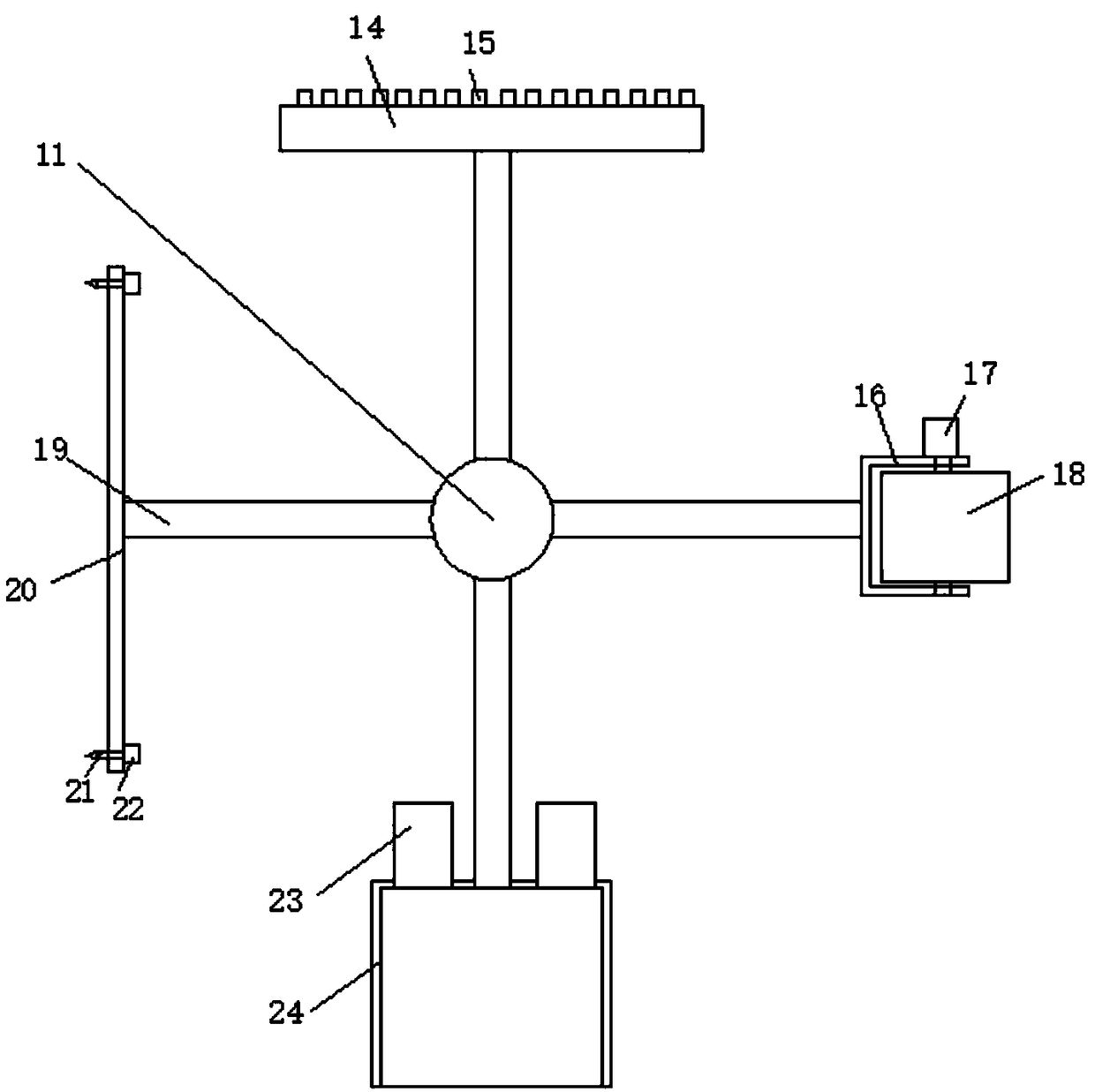

[0021] Embodiment: Put the cut metal plate on the blanking module, and move it to the vicinity of the processing module through the conveying movement of the blanking module. Under the action of the first mechanical arm, the metal plate is introduced into the processing module, and the metal plate is placed on the working module. In the placement slot 5 on the table 4, the first motor 13 drives the gear 12 to rotate, the gear 12 meshes with the rack 8, drives the movable frame 10 to slide on the cross bar 7, and the fourth motor drives the rotating column 11 to rotate, so that the first stamping The block 14 and the second stamping block 15 are vertically downward, and the telescopic column 6 drives the cross bar 7 to move downward. The first stamping block 14 is slidably connected in the stamping groove 3, and the second stamping block 15 is slidably connected in the stamping hole 2. The metal plate is stamped and then punched, and the waste produced during punching falls into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com