Workshop-grade smart manufacture system based on digital twins and configuration method thereof

A technology of intelligent manufacturing and workshop, applied in the field of workshop-level intelligent manufacturing system based on digital twin and its configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below in conjunction with the accompanying drawings.

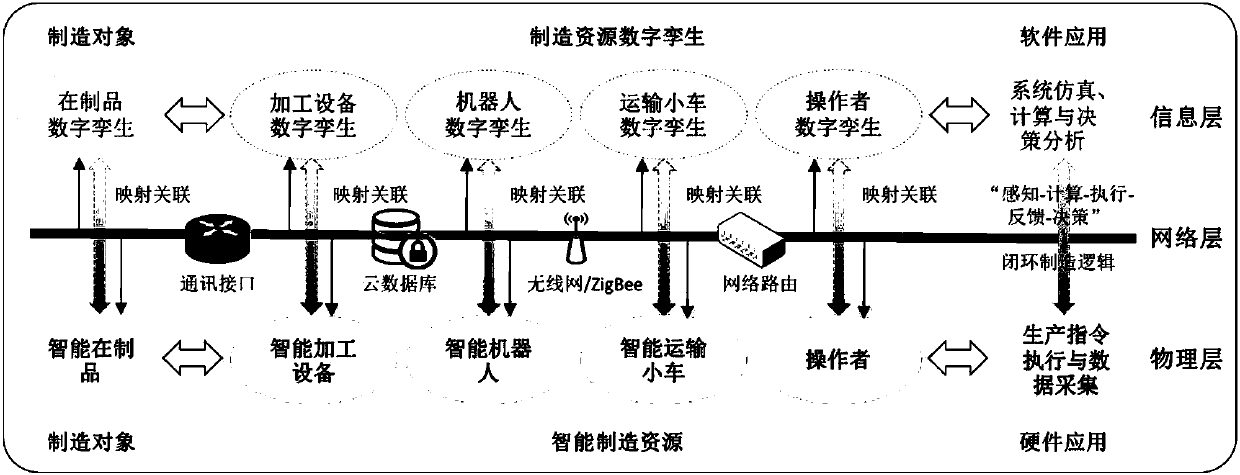

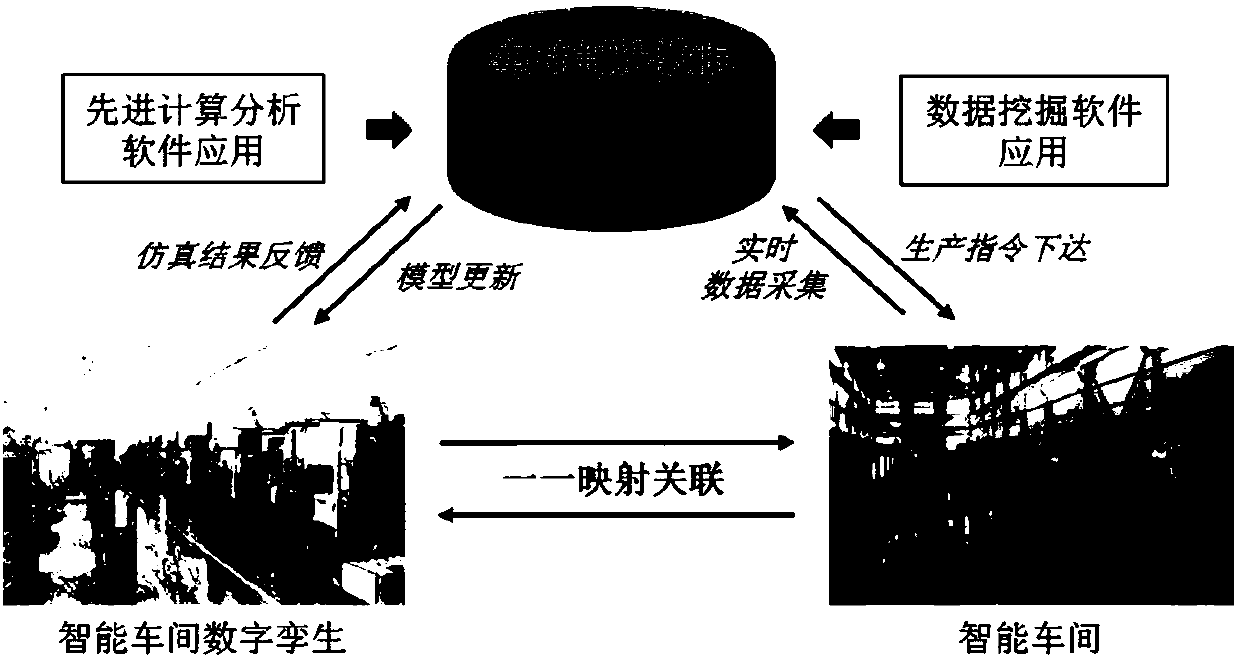

[0041] see figure 1 , the present invention is based on a digital twin workshop-level intelligent manufacturing system. The system architecture is divided into a physical layer, a network layer and an information layer, wherein the network layer serves as a bridge connecting the physical layer and the information layer.

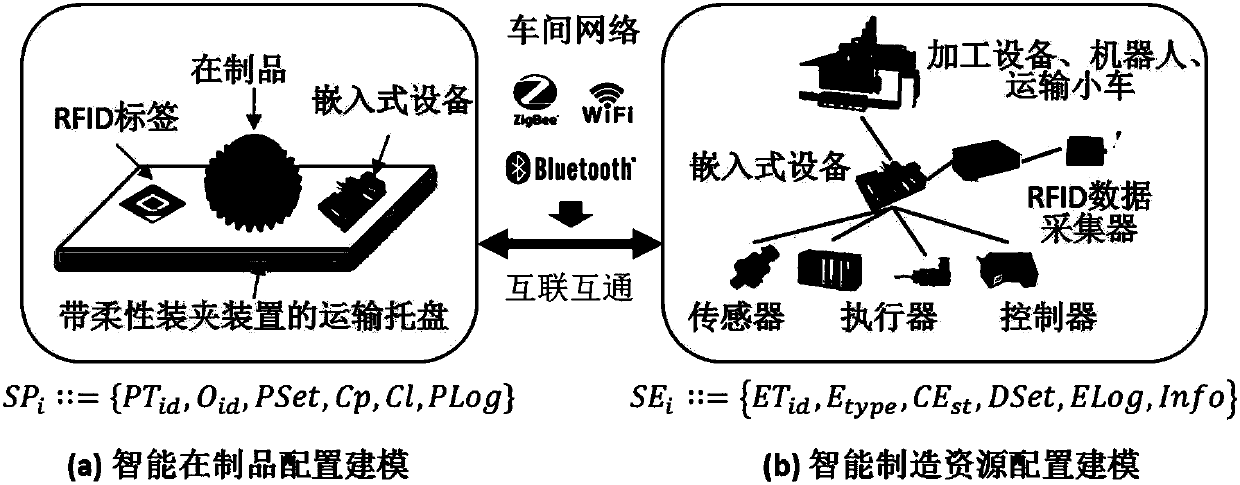

[0042] The physical layer includes work-in-progress and manufacturing resources. Manufacturing resources include processing equipment, robots, transport vehicles, and operators. Each work-in-progress in the workshop is configured with an RFID tag and an embedded system using precise matching criteria. Equipment, a transport pallet with a flexible clamping device to form a work-in-progress that can actively interact and flexibly clamp to different CNC machining machines; use a one-to-one mapping rule to configure an RFID data collector for ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com