Intelligent manufacturing system consisting of 3D printing device and mechanical arms

A 3D printing and intelligent manufacturing technology, applied in the direction of additive processing, etc., can solve the problems of speed, low efficiency, and single control of one machine, and achieve the effects of avoiding waste, solving high production costs, and large market development prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the present invention is further described below, but the scope of protection is not limited to the description.

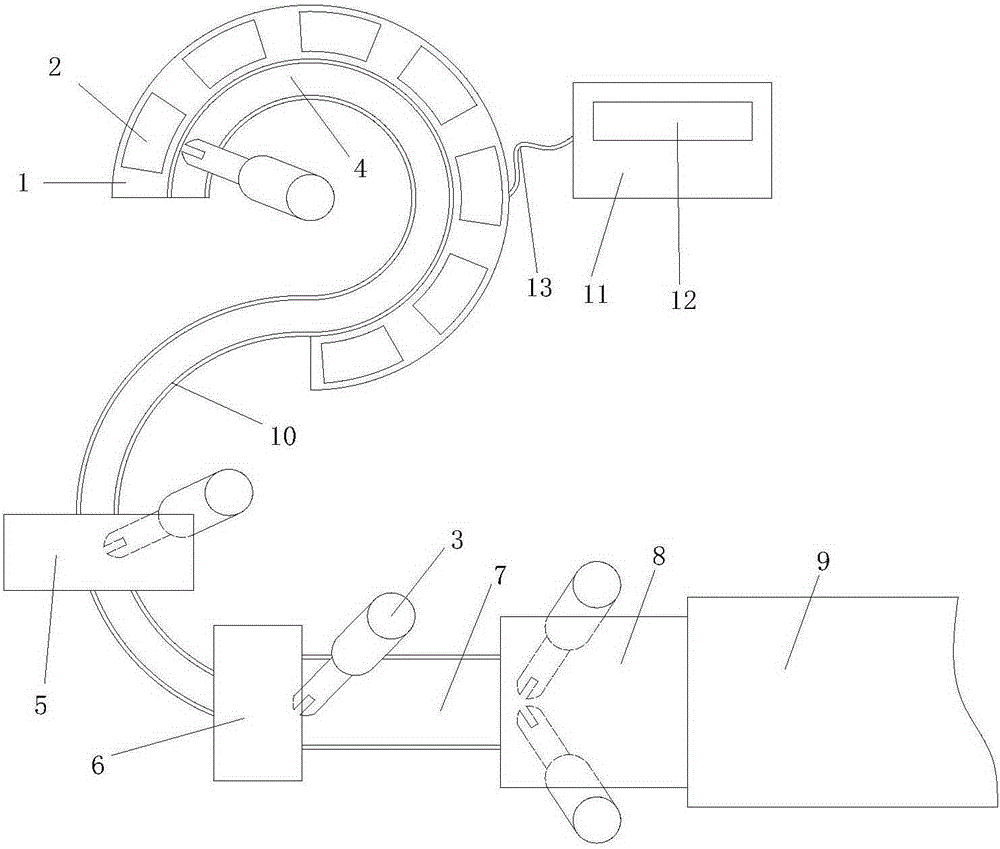

[0018] like figure 1 An intelligent manufacturing system consisting of 3D printing equipment and robotic arms is shown, including printer placement table 1, 3D printing equipment 2, robotic arm 3, conveyor belt, plastic cutting equipment 5, plastic grinding equipment 6, large conveyor belt 7, and assembly center 8. Task distribution center host 12; the conveyor belt is divided into the front section 4 of the conveyor belt and the rear section 10 of the conveyor belt; at least one mechanical arm 3 is installed on one side of the front section 4 of the conveyor belt, and a printer is installed on the other side along the installation path of the front section 4 of the conveyor belt There are multiple 3D printing devices 2 installed on the printer placing table 1 along the installation path of the front section 4 of the conveyor belt;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com