High melting point metal electric arc spraying intelligent manufacturing system

A high melting point metal, arc spraying technology, applied in metal material coating process, melt spraying, coating and other directions, can solve the problems of low modularity, low motion precision, complex control mechanism, etc., to achieve obvious economic and Social effect, accurate and reliable control system, simple structure of equipment body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

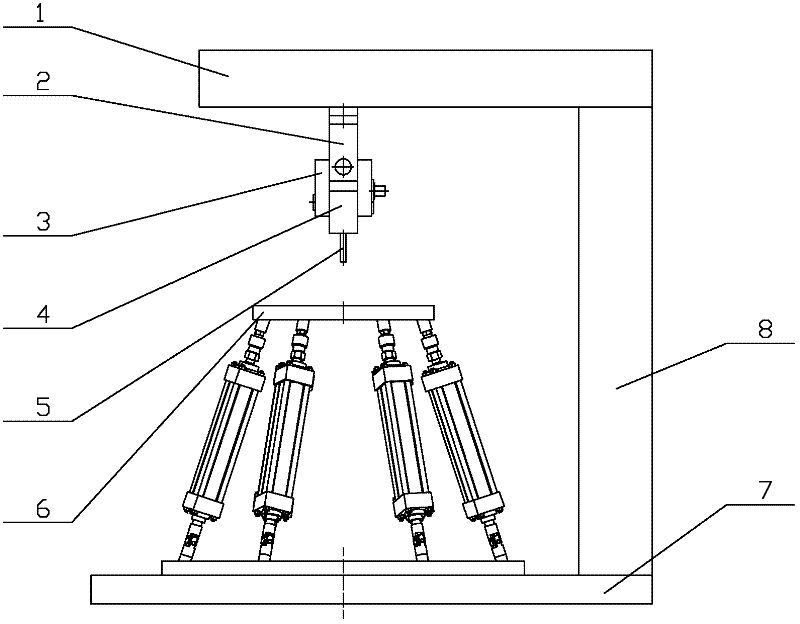

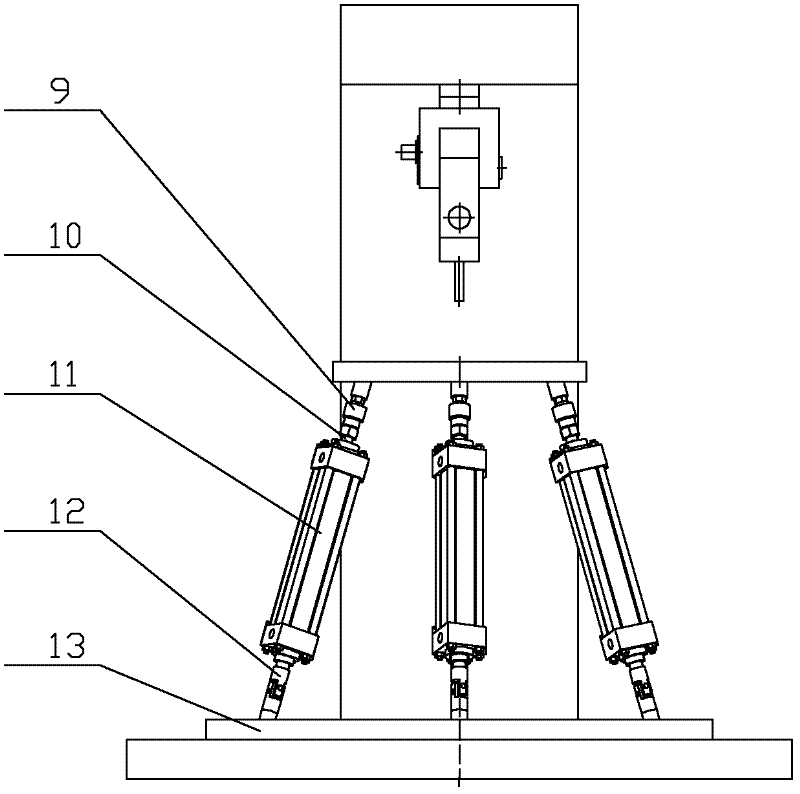

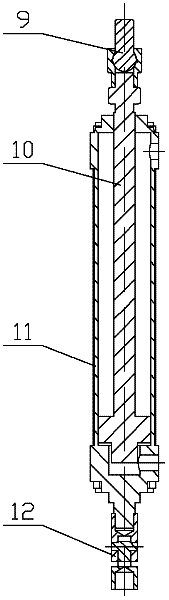

[0036] figure 1 Among them, the high melting point metal arc spraying intelligent manufacturing system of the present invention is composed of five parts, namely the equipment body, a six-degree-of-freedom parallel platform, a three-degree-of-freedom swing head, a master mold heating device and a control computer. 7 is equipped with a six-degree-of-freedom parallel platform for clamping the master mold, and a three-degree-of-freedom swing head is installed on the beam 1 of the equipment body. The three-degree-of-freedom swing head is equipped with a nozzle 5 and is installed opposite to the moving platform 6 of the six-degree-of-freedom parallel platform. , the moving platform 6 of the six-degree-of-freedom parallel platform is provided with a master mold heating device, and at the same time, the three-degree-of-freedom swing head can carry out the Z-ax...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com