Method for realizing intelligent manufacturing system by using memory type RFID tags

A technology of RFID tags and intelligent manufacturing, which is applied in the direction of recording carriers used in machines, instruments, computer parts, etc., can solve the problems of not realizing the intelligentization of workpieces and the inability to guarantee them, and achieve the effect of reducing data access time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

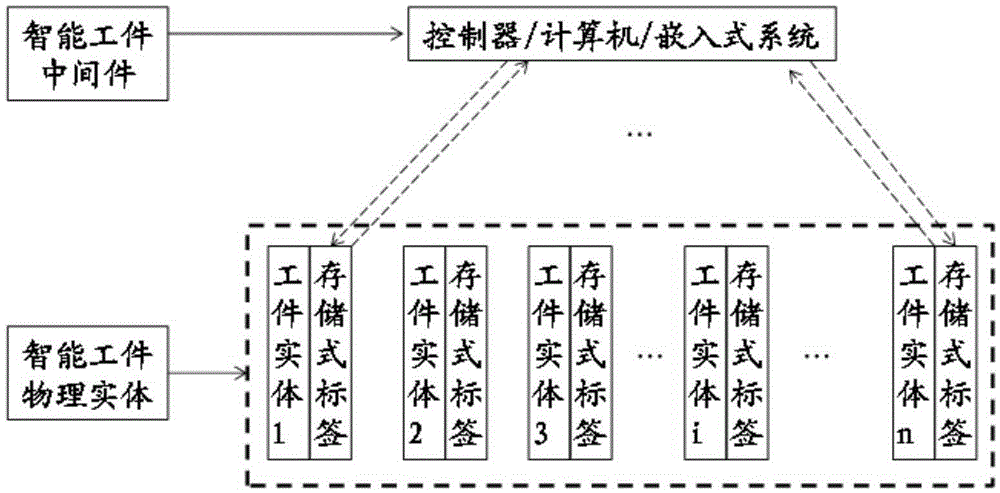

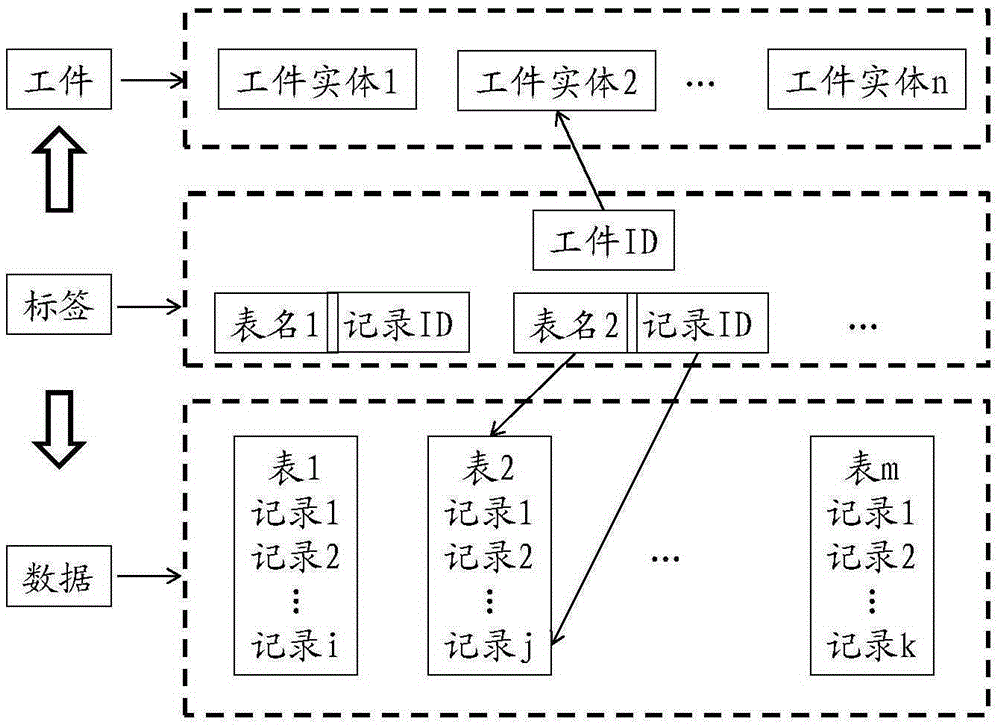

[0033] A method for realizing an intelligent manufacturing system by utilizing a storage type RFID tag, comprising the following steps:

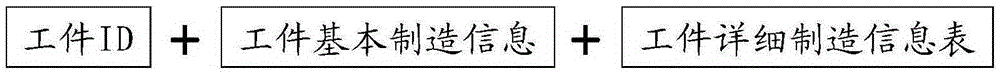

[0034] Step 1. Store the data content in the storage RFID tag. The stored content includes three parts: the ID code of the workpiece, the basic manufacturing information of the workpiece, and the detailed manufacturing information index table of the workpiece. Refer to figure 1 :

[0035] Using relational algebra to express the label content as:

[0036] tag i ={P_ID i , B_INFO i , Index_F_INFO i}

[0037] in:

[0038] P_ID i is the ID code of the workpiece i, which is a unified code for the workpiece manufactured in the workshop, and has unique indexing for the workpiece.

[0039] B_INFO i The basic manufacturing information for the workpiece is to reduce the amount of communication data in the system and realize the transformation of the manufacturing system from centralized control to decentralized enhanced production. The basic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com