Intelligent manufacturing system based on industrial robot

An industrial robot and intelligent manufacturing technology, applied in the direction of manufacturing tools, conveyors, manipulators, etc., can solve the problems of time-consuming, laborious, high cost, difficult to complete palletizing work, etc., achieve high palletizing efficiency, enhance stability, and save money The effect of taking up space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In order to enable those skilled in the art to better understand the technical solution of the present invention, the technical solution of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

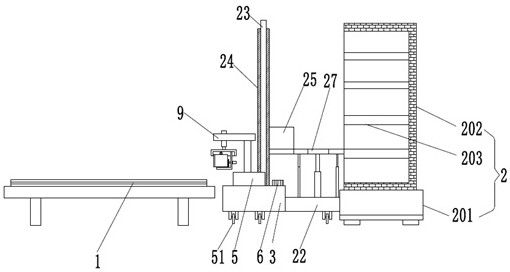

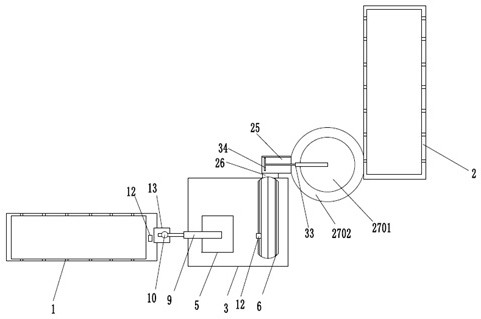

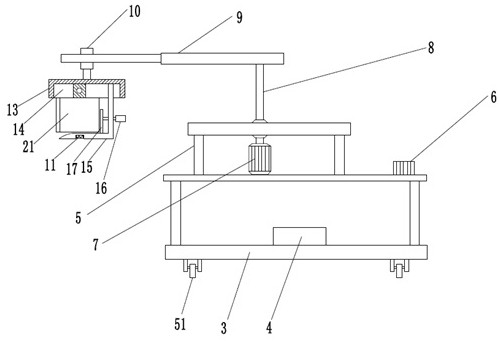

[0039] Refer to attached Figure 1-10 An intelligent manufacturing system based on industrial robots is shown. The intelligent manufacturing system includes a first conveyor belt 1, an intermediate transfer module and a palletizing rack 2 from left to right. The first conveyor belt 1 is installed on a bracket or Any carrier is used to transport the goods, the palletizing rack 2 is used to arrange the goods, and the intermediate transfer module transfers the goods on the first conveyor belt 1 to the palletizing rack 2 ;

[0040] The intermediate transfer module includes an intelligent grabbing device and a lifting transfer device, the smart grabbing device is located on the front side of the lifting transfer device,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com