Granulating device for cold and heat shrinking material of insulation joint

A technology of insulating joints and granulation devices, which is applied in the field of processing equipment for cold and heat shrinkable materials, can solve the problems of easy agglomeration and blockage of cold and heat shrinkable materials, and affect the granulation effect, and achieve novel design, increase granulation quality, The effect of high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

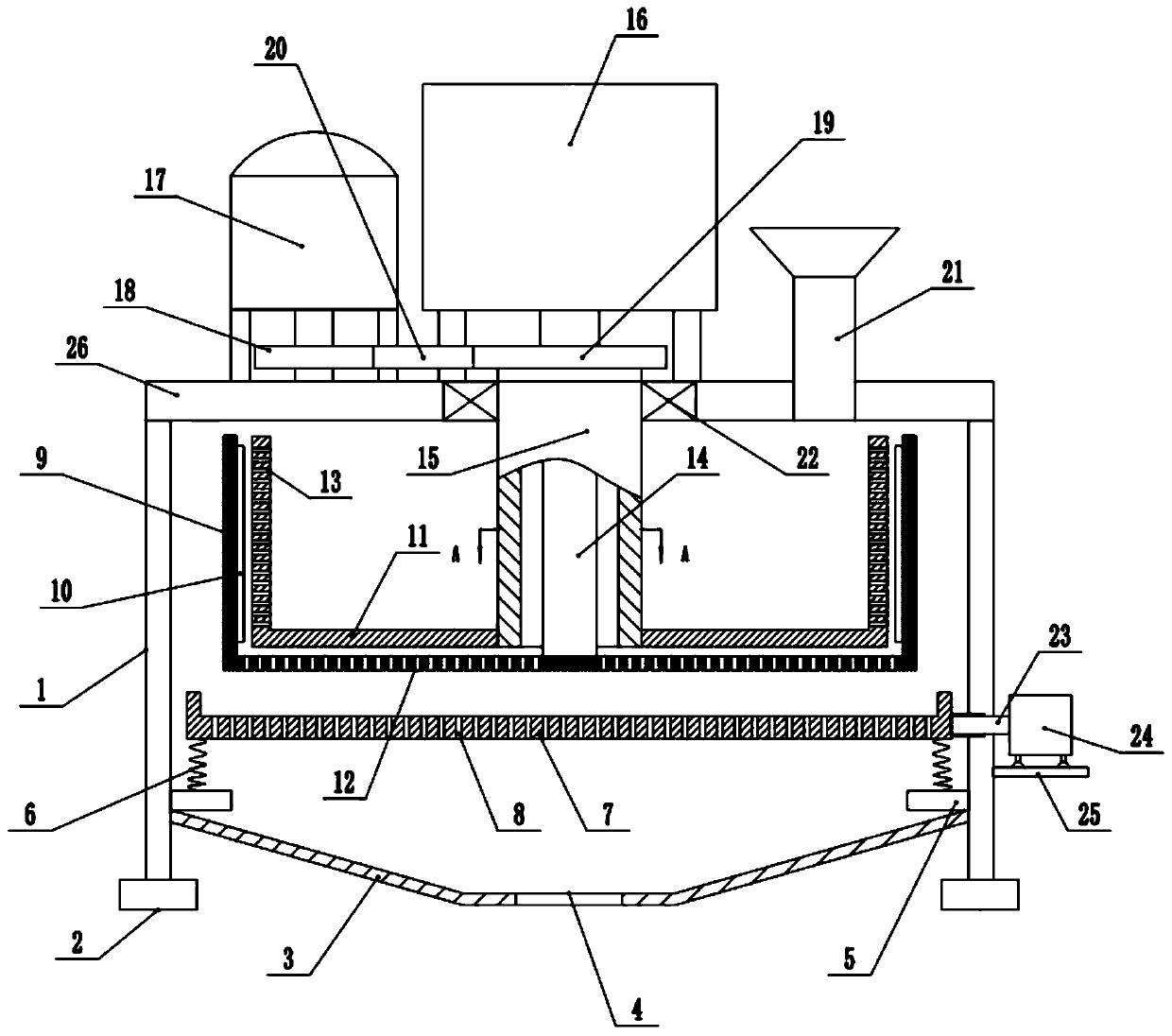

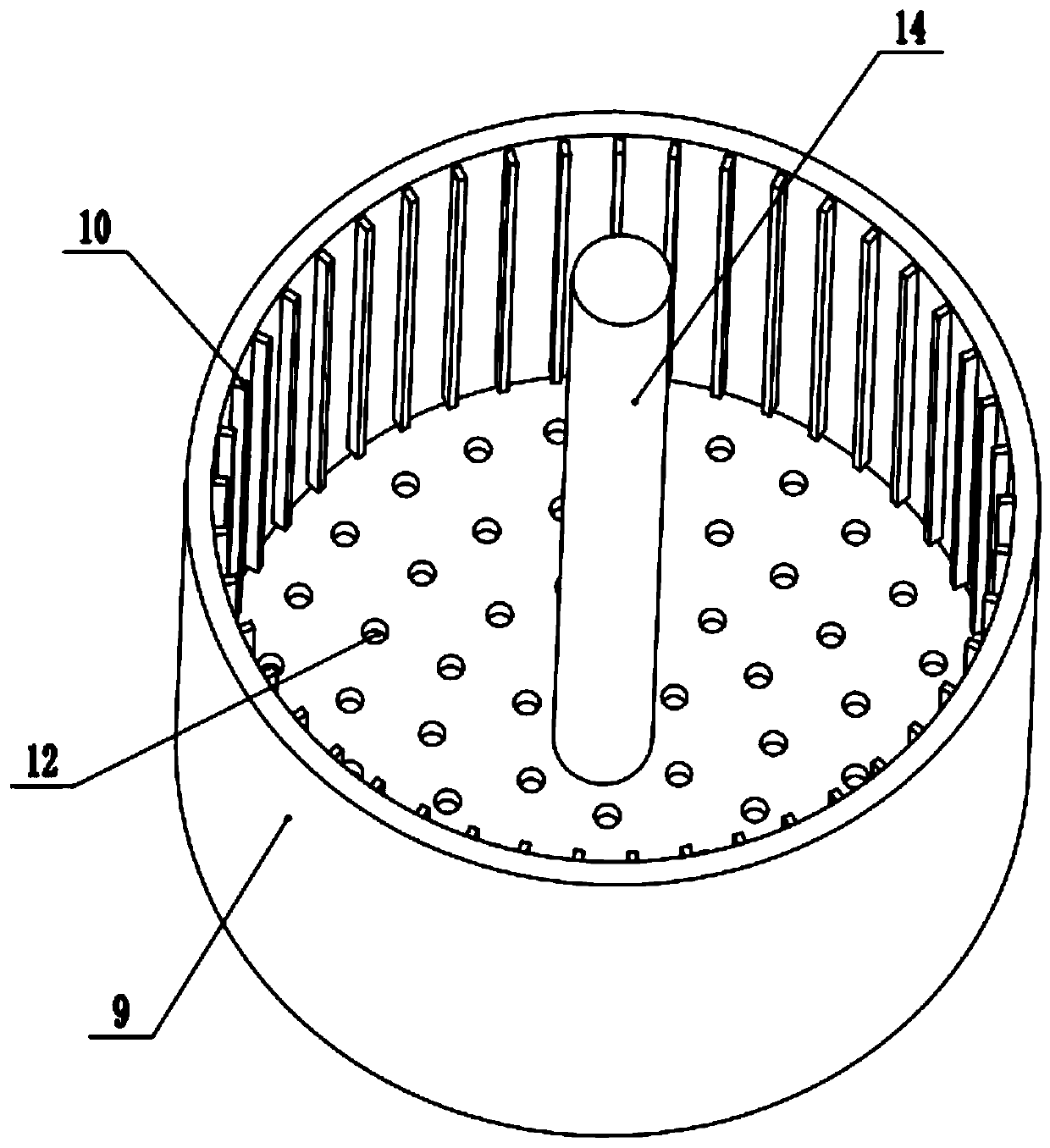

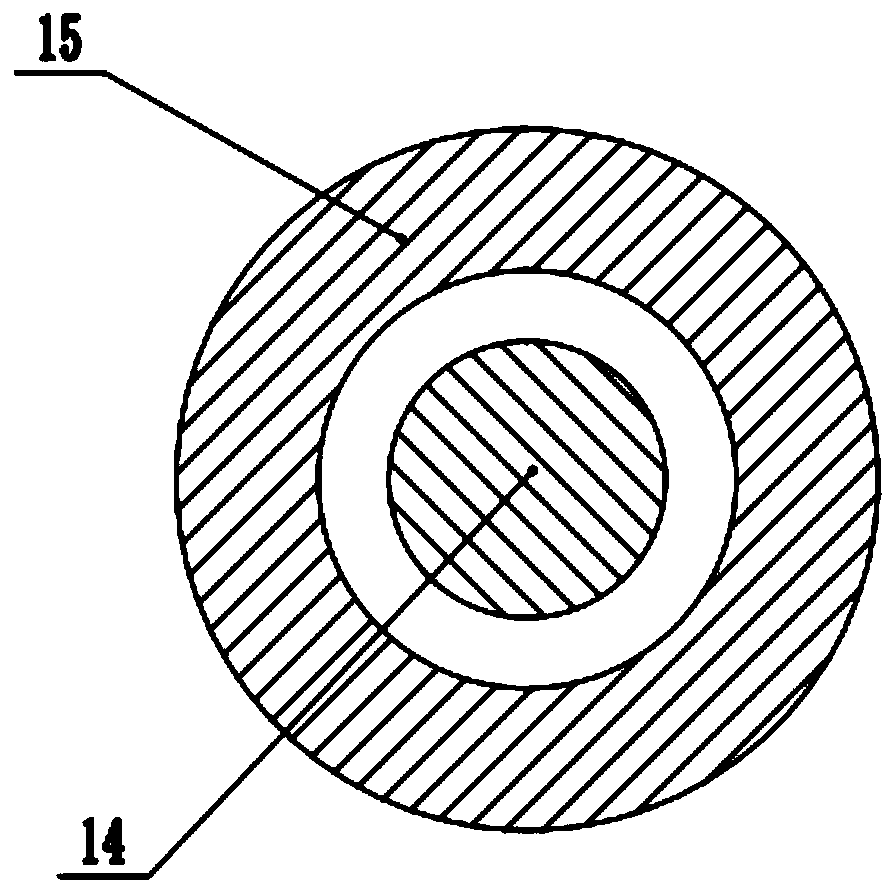

[0028] refer to Figure 1~3 , in an embodiment of the present invention, a granulation device for heat-shrinkable materials for insulating joints includes a granulation frame 1, and a motor plate 25 is installed on the right end of the granulation frame 1 for installing and fixing the vibration motor 24. The motor plate The vibration motor 24 is installed on the upper end of the 25, thereby realizing the installation and fixing of the vibration motor 24, and the buffer pad 2 is installed at the bottom of the granulation frame 1, which reduces the shaking generated by the entire granulation frame 1 during work. A sealing cover 26 is installed on the top of the granulation rack 1, which is used to seal the top of the granulation rack 1, ensuring the stability of the whole device. The middle part of the upper end of the sealing cover 26 is installed with the main shaft 15 through the bearing seat 22, so that the main shaft 15 is in the process of rotation. Rotational movement can...

Embodiment 2

[0030] In another embodiment of the present invention, the difference between this embodiment and the above-mentioned embodiment is that the outer side of the granulation knife 10 is close to the outer wall of the raw material barrel 11. On the other hand, the granulation knife 10 can scrape and cut the material in the centrifuge hole 13 of the raw material bucket 11 in an orderly manner during the rotation process, thereby increasing the reliability of granulation.

[0031]In the present invention, when working, the raw materials of cold and heat shrinkable materials are introduced into the raw material barrel 11 through the feeding hopper 21, and then the main motor 17, the auxiliary motor 16 and the vibration motor 24 are started simultaneously, and the main motor 17 drives the main shaft 15 to rotate, and then The raw material barrel 11 is rotated to ensure that the raw material inside the raw material barrel 11 can be thrown out under the action of the centrifugal hole 13....

PUM

| Property | Measurement | Unit |

|---|---|---|

| shrinkage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com