An ore granulation device and method with adjustable inclination angle and rotating speed

A technology of ore and rotation speed, which is applied in the field of ore granulation devices with adjustable inclination angle and rotation speed, can solve problems such as lack, influence on granulation efficiency, final leaching rate of granulated particles with pore structure, and inaccurate adjustment of inclination angle, etc., to achieve stable position and state Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

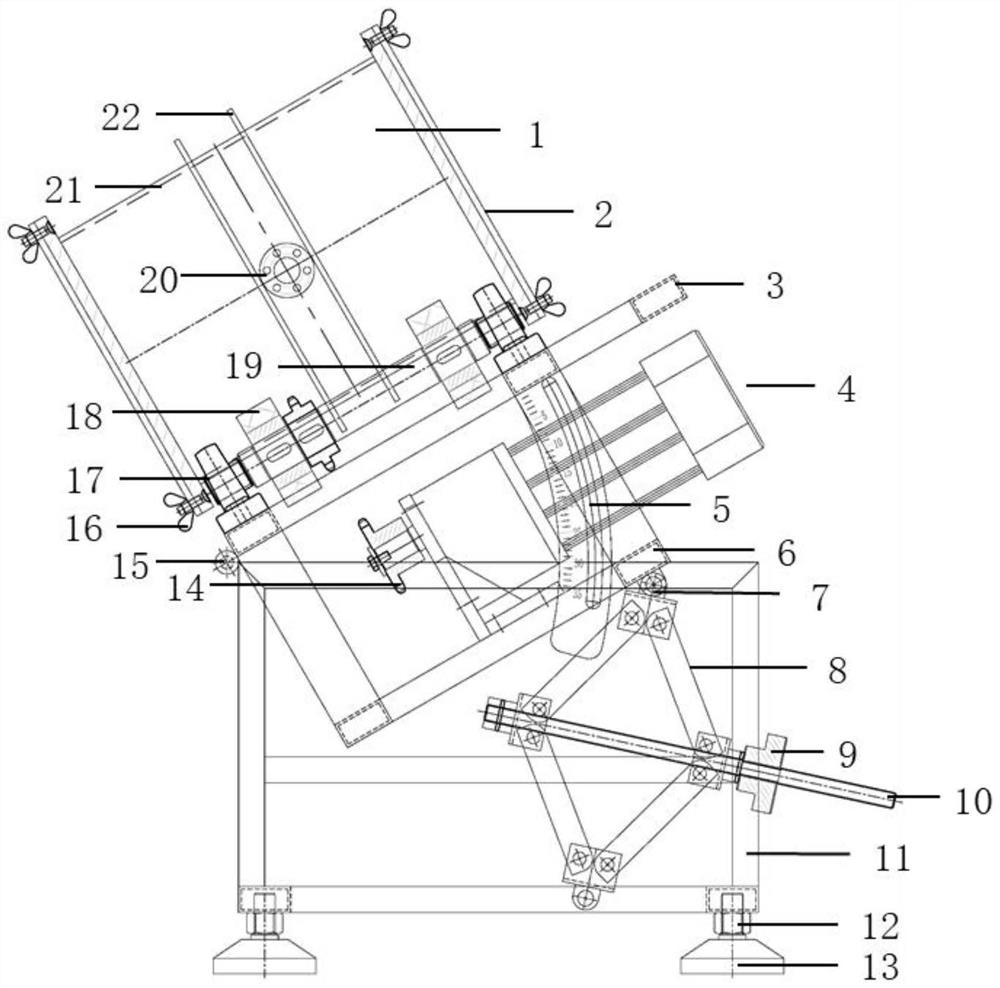

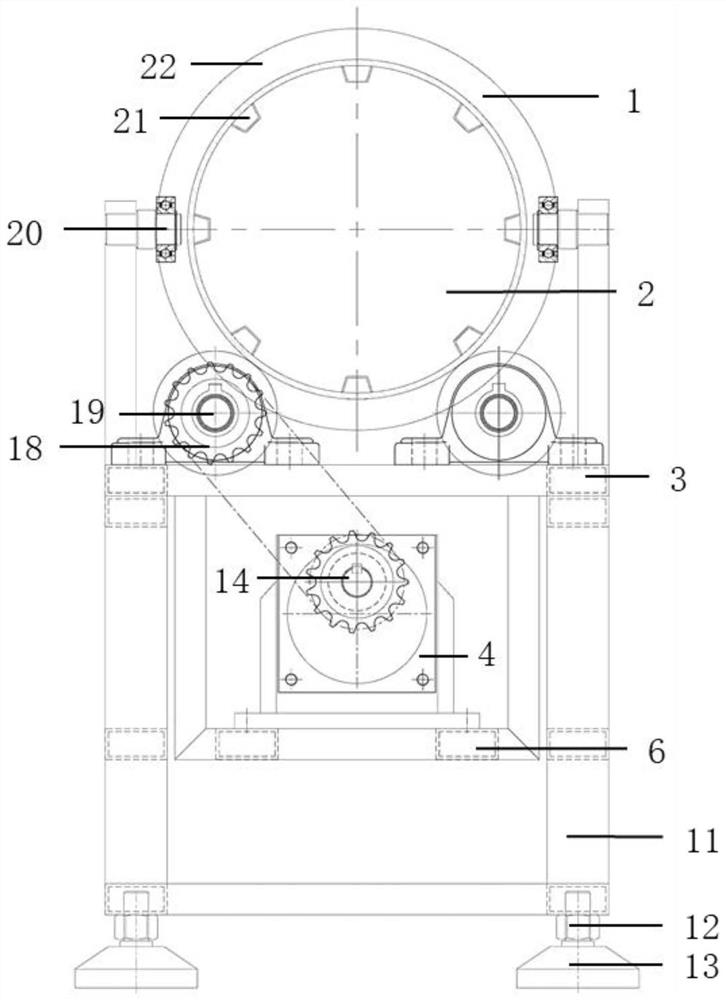

[0023] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0024] The invention provides an ore granulation device and method with adjustable inclination angle and rotating speed.

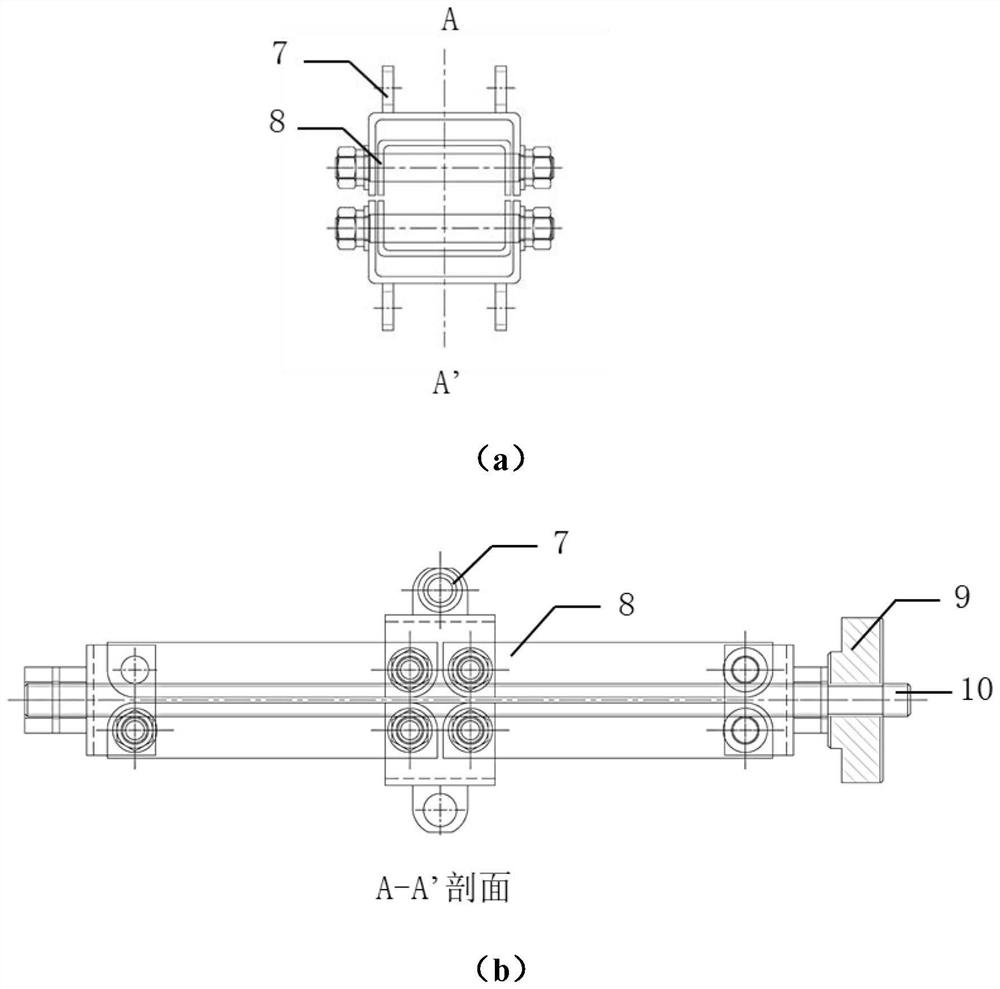

[0025] like figure 1 and figure 2 As shown, the device includes a granulation system, an angle adjustment system, a speed regulation system, a rolling and support system, the granulation system includes a granulation drum 1, a partition 2, a fixed knob 16 and a trapezoidal keel 21, and the angle adjustment system includes a rotating support Platform 3, angle scale 5, angle-adjusting bracket 8, angle-adjusting knob 9, threaded screw 10, main turning roller 7 and from turning roller 15, speed regulating system comprises variable speed motor 4, motor support 6 and transmission device 14, rolling and The support system includes stainl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com