Complex-structural well formation flow and internal flow coupled flow experiment system

A technology of complex structure and experimental system, applied in wellbore/well components, construction, measurement, etc., can solve problems such as lack of formation simulation system and inability to simulate the coupling of formation flow and wellbore flow of oil, gas and water seepage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

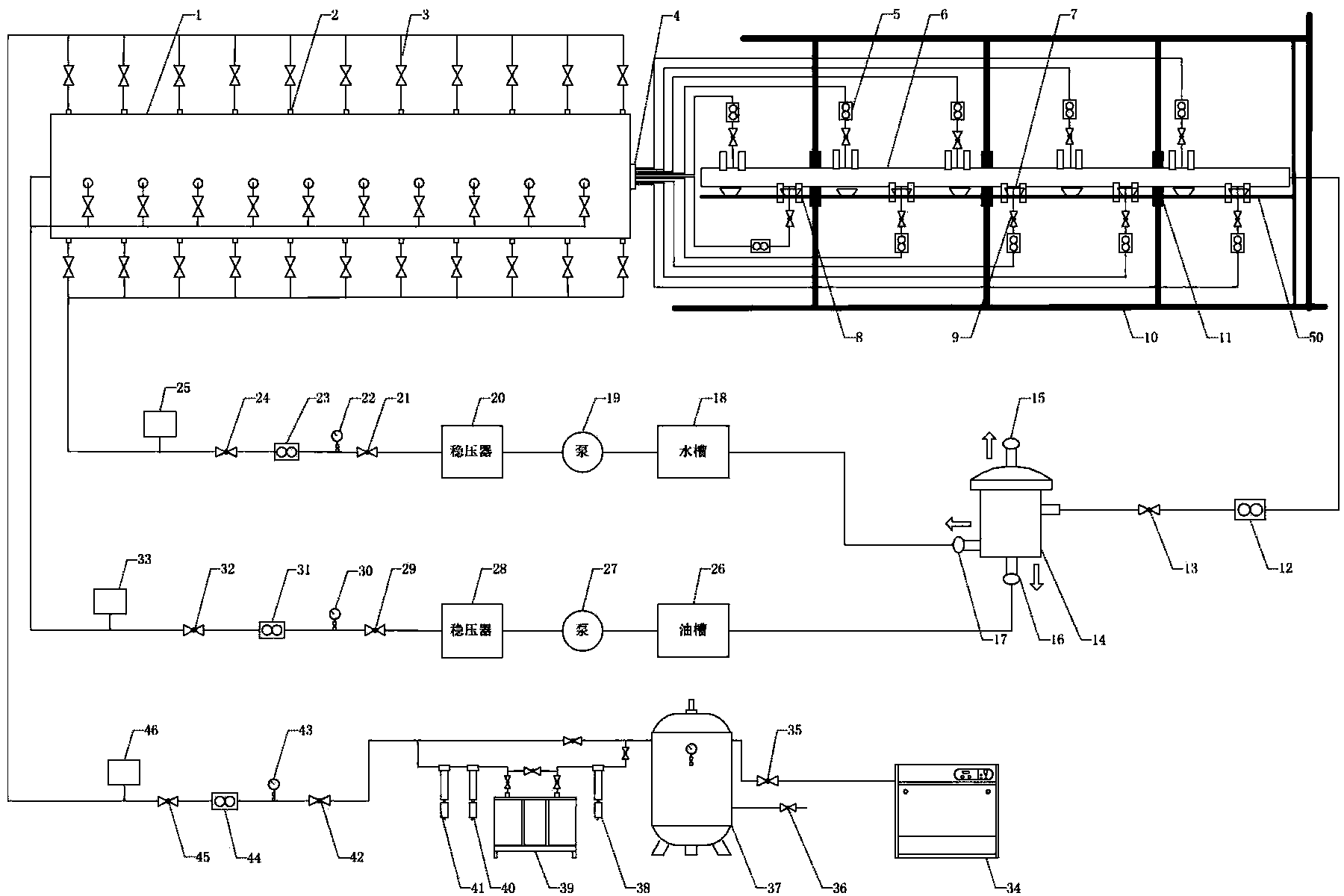

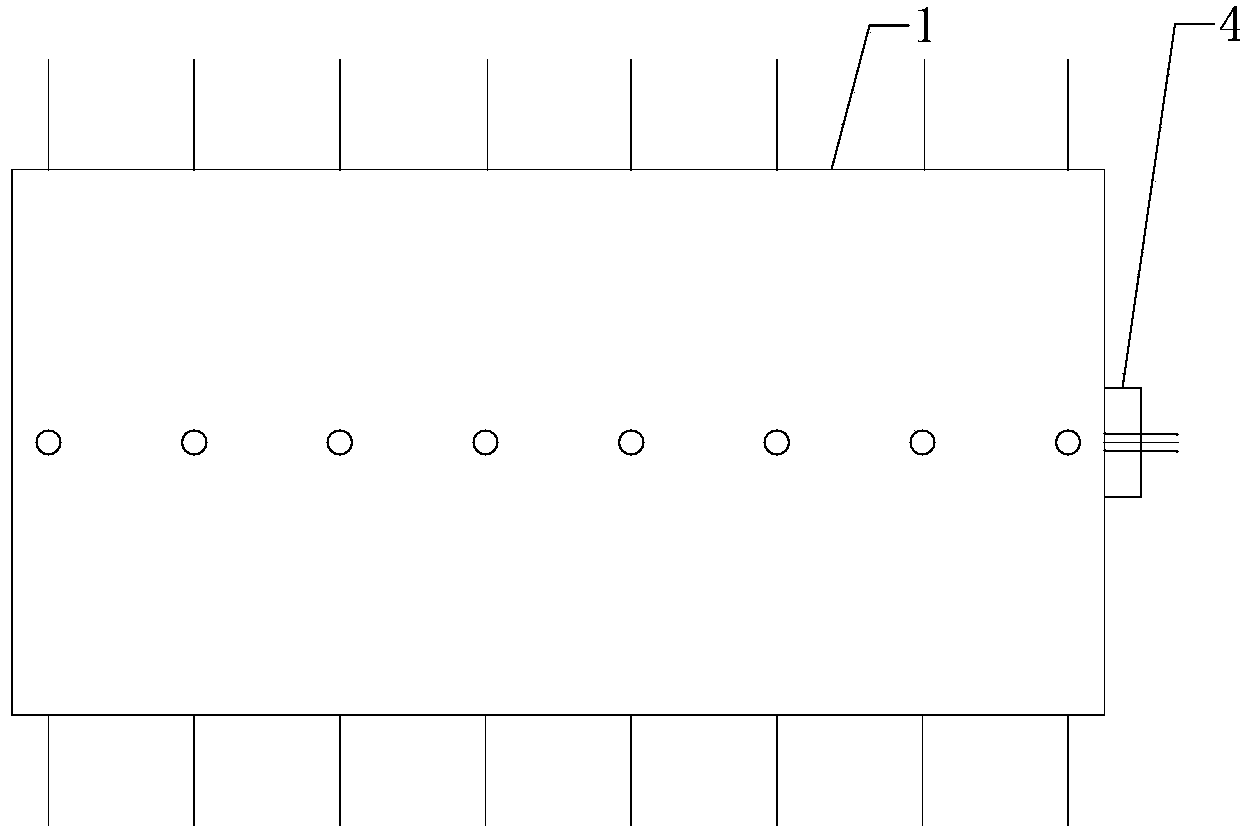

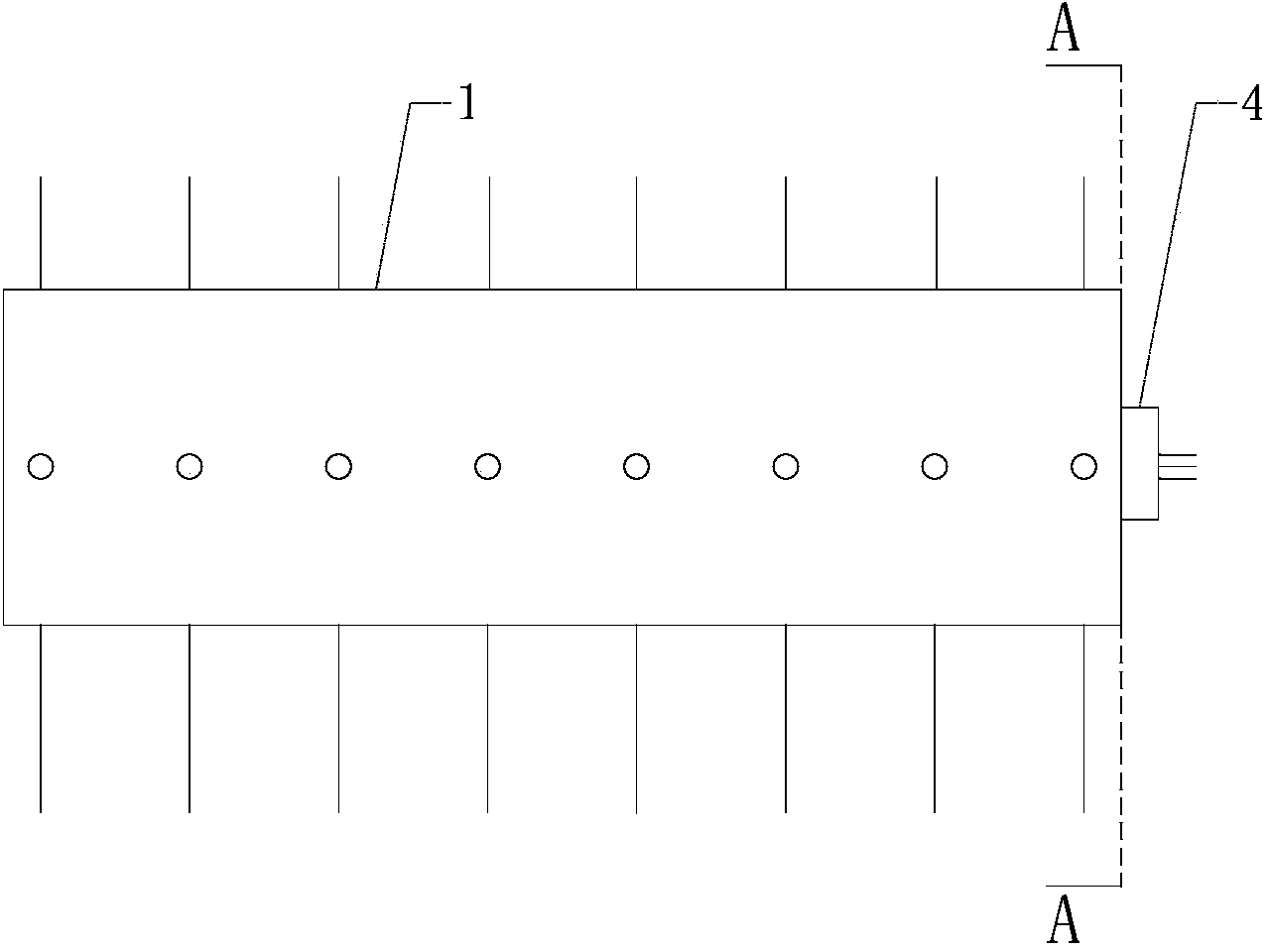

Method used

Image

Examples

Embodiment 1

[0061] Embodiment 1 (natural energy extraction of oil-gas-water three-phase closed oil and gas reservoir):

[0062] Before the experiment starts, set the initial state of the reservoir, close the throttle valve 9 on the outflow pipeline of seepage tank 1, open the first control valve 21 and the second control valve 24, inject water into the seepage tank 1, and close the first control valve after reaching a predetermined value. Control valve 21 and second control valve 24; open first control valve 29 and second control valve 32, inject oil into seepage tank 1, close first control valve 29 and second control valve 32 after reaching a predetermined value; open first The control valve 42 and the second control valve 45 inject gas into the seepage tank 1, and close the first control valve 42 and the second control valve 45 after reaching a predetermined value; start the experiment after the initial state of the seepage tank 1 is set, and open the seepage tank to flow out The thrott...

Embodiment 2

[0063] Example 2 (oil-water two-phase large-scale edge-bottom water displacement reservoir natural energy recovery):

[0064] Before the experiment starts, set the initial state of the reservoir, close the throttle valve 9 on the outflow pipeline of seepage tank 1, open the first control valve 21 and the second control valve 24, inject water into the seepage tank, and close the first control valve after reaching the predetermined value. valve 21 and the second control valve 24; open the first control valve 29 and the second control valve 32, inject the oil into the seepage tank, and close the first control valve 29 and the second control valve 32 after reaching a predetermined value; the initial state of the seepage tank is set Start the experiment after being set, open the throttle valve 9 on the seepage tank outflow pipeline, the fluid in the seepage tank flows into the horizontal simulated wellbore 48, then flows into the equivalent horizontal well simulated wellbore 6 throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com