A robot intelligent terminal automatic replacement device

An intelligent and automatic replacement technology of robots, applied in the directions of manipulators, chucks, manufacturing tools, etc., can solve the problems of cumbersome replacement of work heads, larger processing errors, limiting the promotion and popularization of industrial robots, etc., to improve flexibility and adaptability. , Overcome the effect of large floor space and single work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention is described in further detail below in conjunction with accompanying drawing:

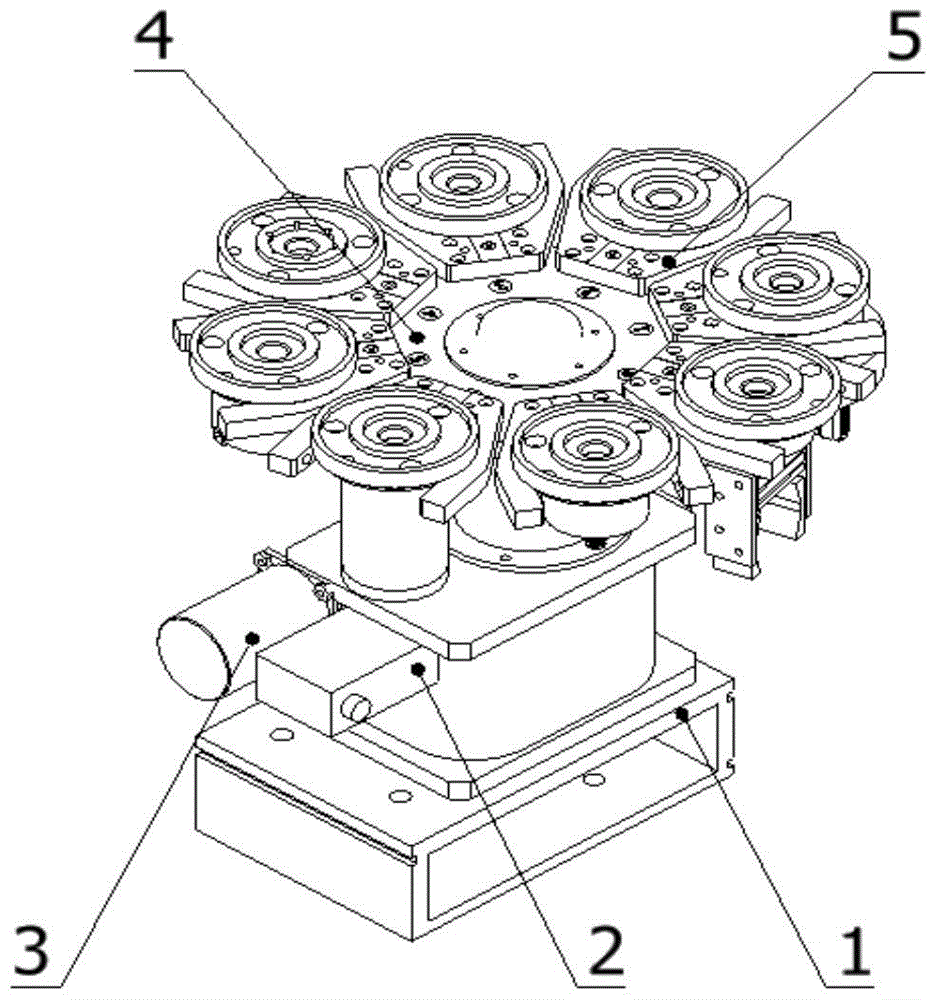

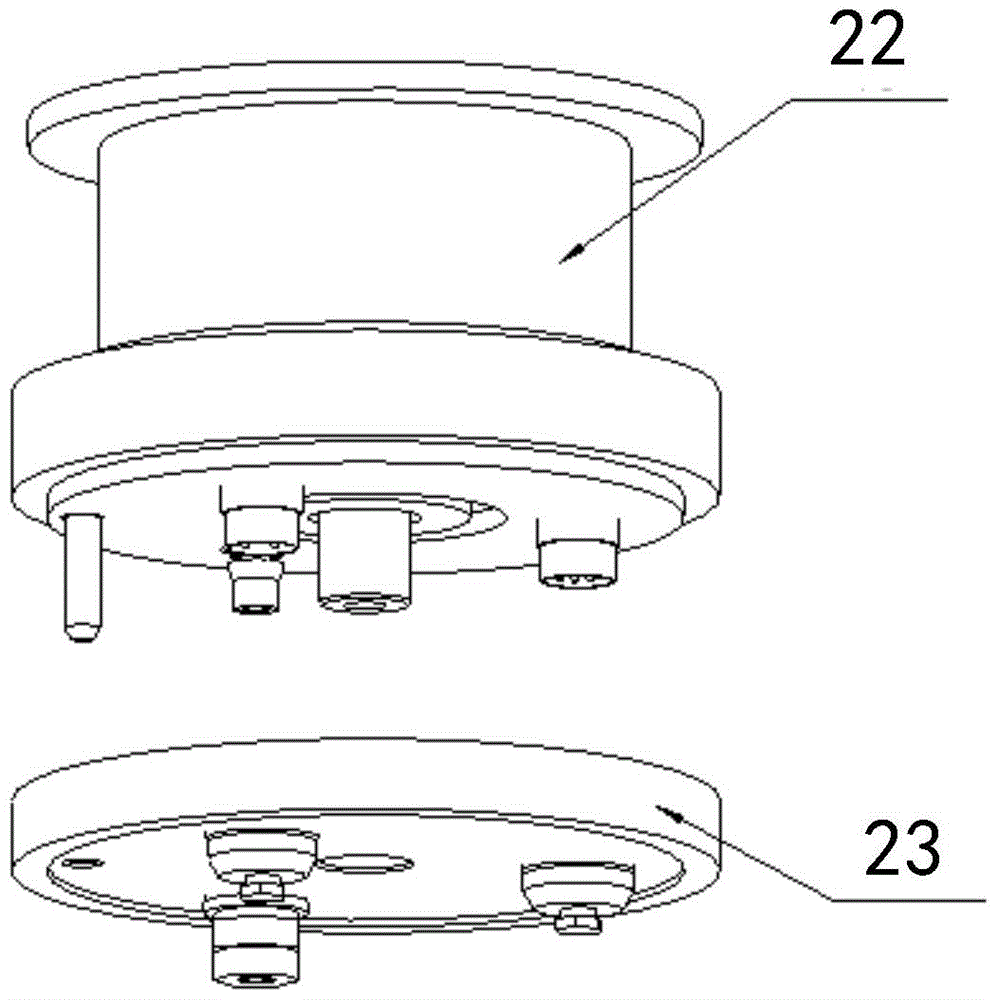

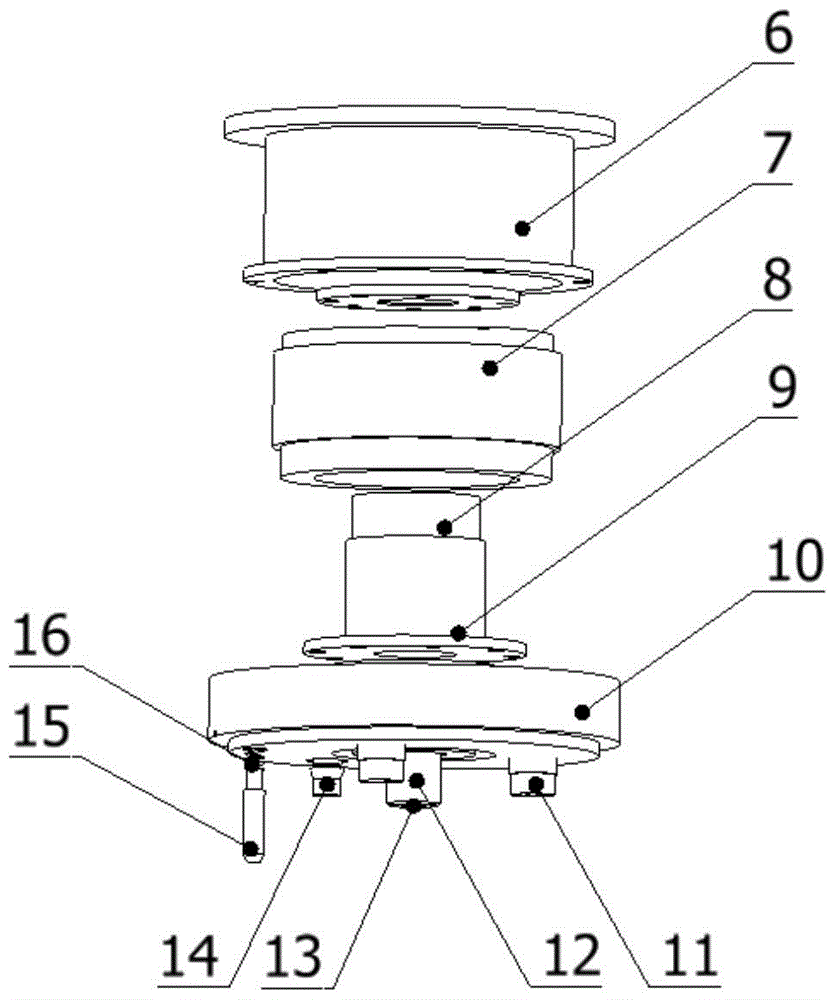

[0028] see Figure 1-Figure 4 , the present invention is composed of two parts, the terminal working head storehouse and the quick switching mechanism, and the quick switching mechanism is composed of a male head 22 fixedly connected to the end of the robot and a female head 23 fixedly connected to the working head; wherein, the terminal working head storehouse Including: head library base 1, transmission system 2, drive motor 3, turntable 4, claw 5; male head structure includes: connecting flange 6; direct drive device 7, synchronous drive device 8, motor cover 9, male head base 10 , electrical interface male 11, threaded shaft 12, positioning detection device 13, air interface male 14, positioning pin 15, buffer device 16; female structure includes: female base 17, positioning hole 18, air interface female 19, Threaded hole 20, electrical interface female head 21. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com