Reprocessed plastic classification recycling method and device

A recycling device and recycled plastic technology, applied in plastic recycling, recycling technology, cleaning methods and utensils, etc., can solve the problems of time-consuming, labor-intensive, low recycling efficiency, etc., and achieve the effect of improving recycling efficiency, improving efficiency and reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

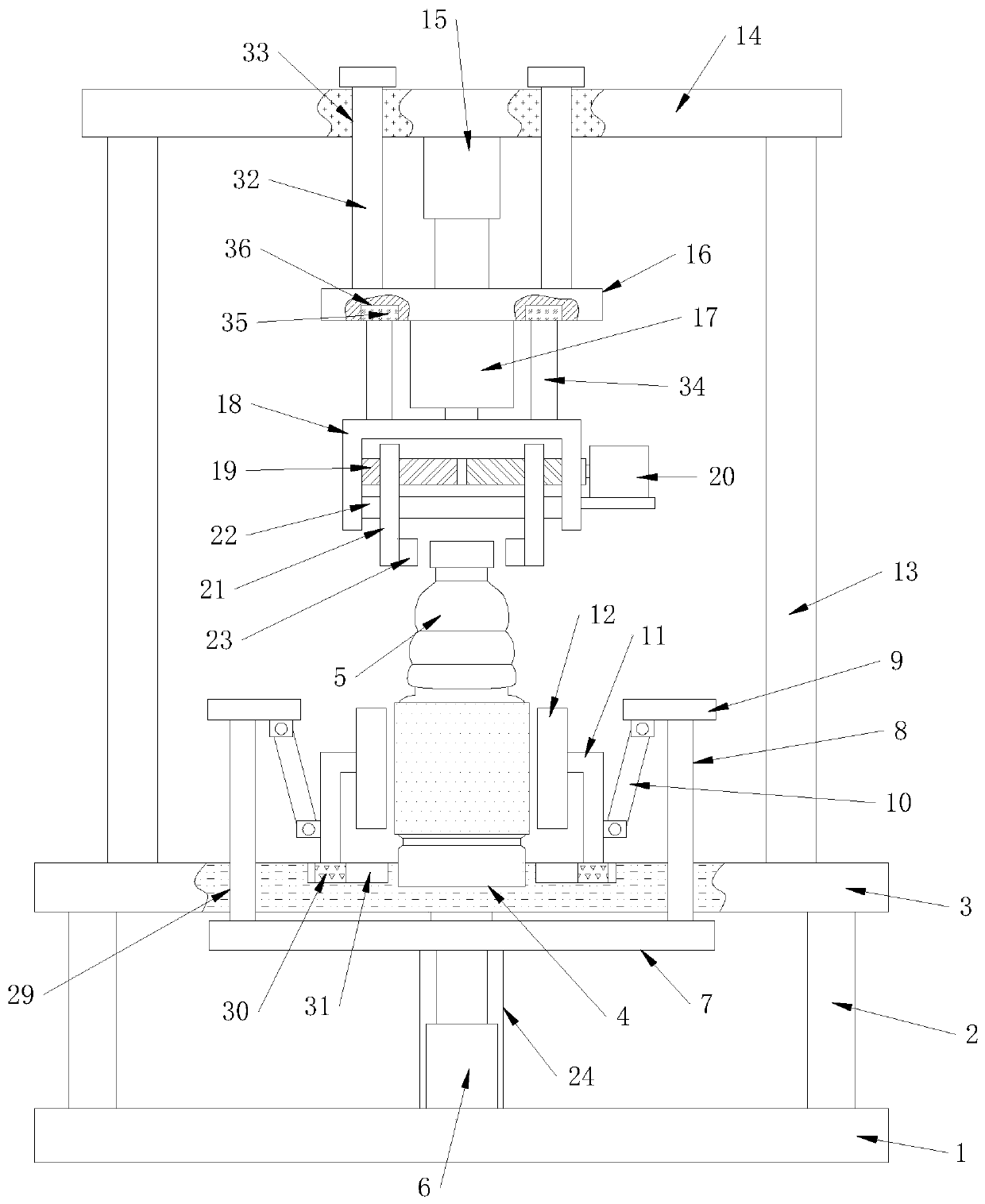

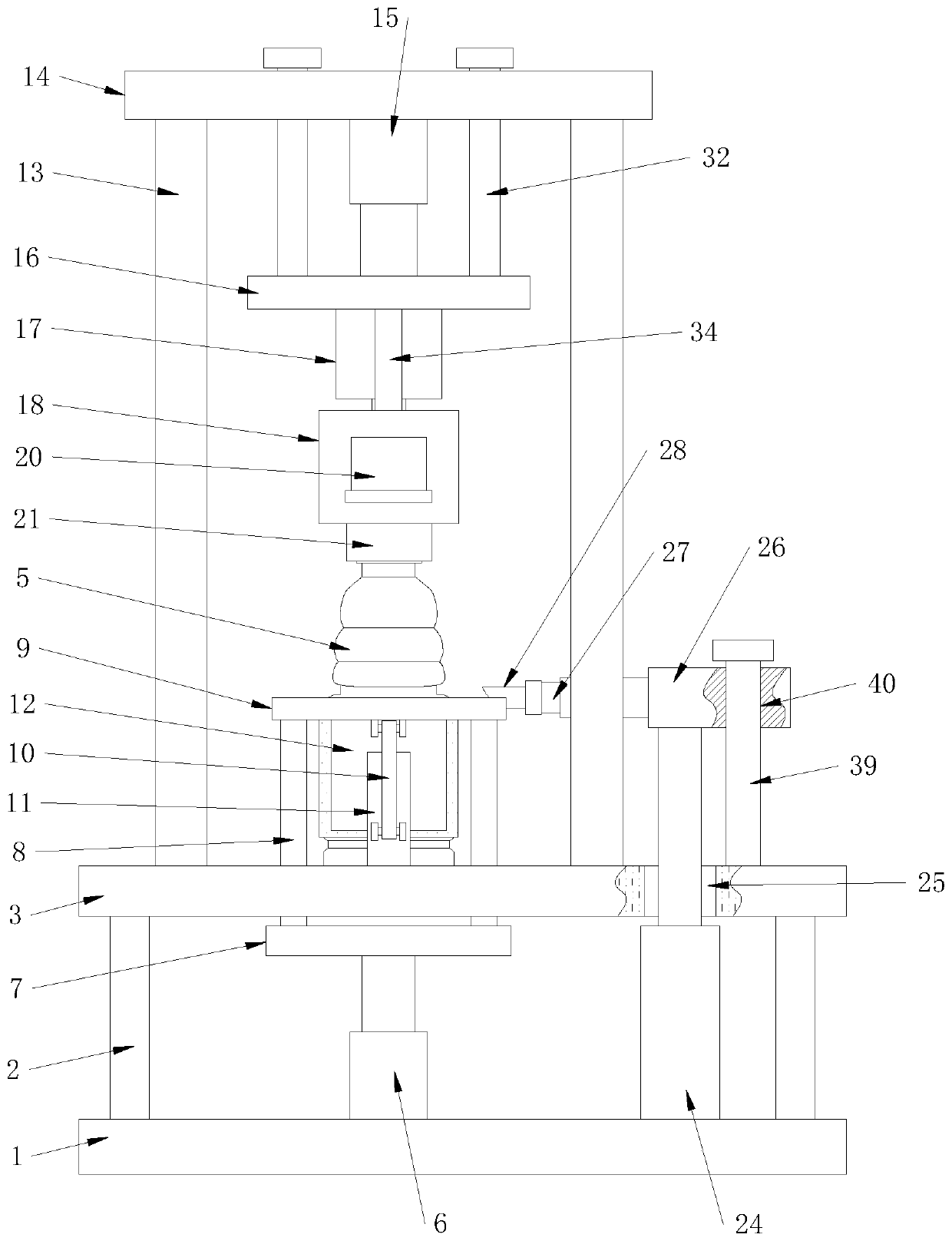

[0032] see Figure 1-6 , the recycled plastics classification recovery method provided by the present invention, comprises the following steps:

[0033] S1: First screen out the hard plastic bottle body;

[0034] S2: Place the hard plastic bottle on the recycling device, and the recycling device clamps and fixes the hard plastic bottle;

[0035] S3: Twist off the bottle cap of the hard plastic bottle body through the recovery device, scratch the bottle label of the hard plastic bottle body, and further tear off the bottle label;

[0036] S4: Finally, put the cap, bottle body and bottle label of the hard plastic bottle into three recycling bins for collection to complete sorting and recycling.

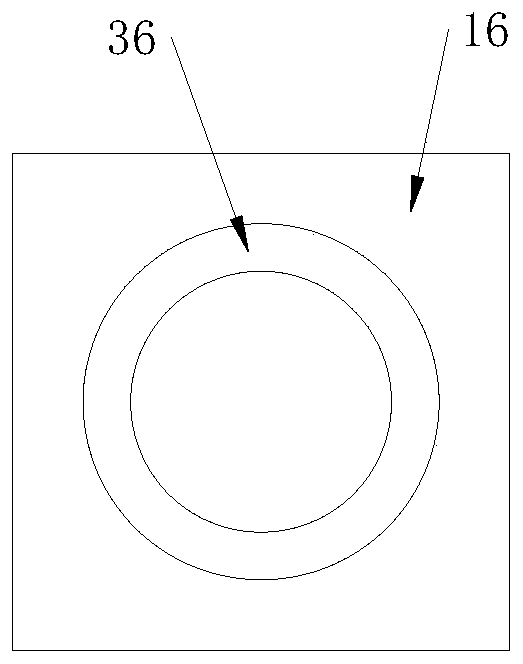

[0037]A sorting and recycling device for recycled plastics that implements the above method, which includes a base 1, support legs 2 are fixed on the top four corners of the base 1, a support plate 3 is arranged above the base 1, and the tops of the support legs 2 are connected to the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com