A vision-guided mirror milling top support device for thin-walled parts

A technology for visual guidance and thin-walled parts, which can be used in positioning devices, metal processing machinery parts, manufacturing tools, etc., and can solve the problems of poor follow-up performance of support technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

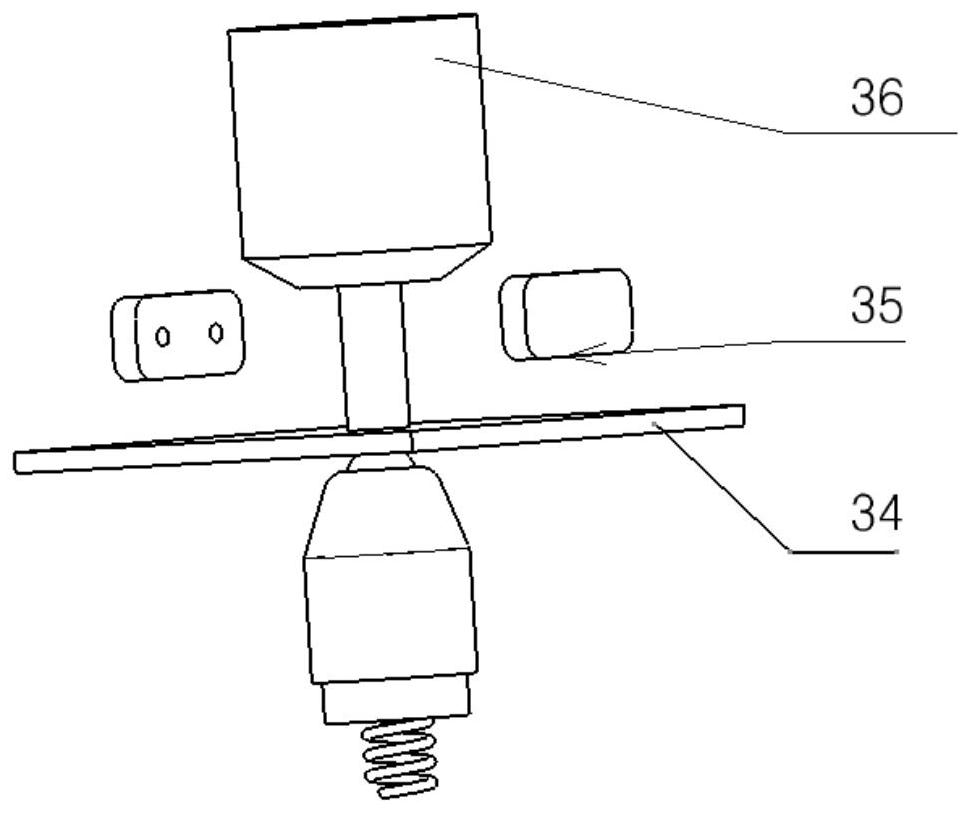

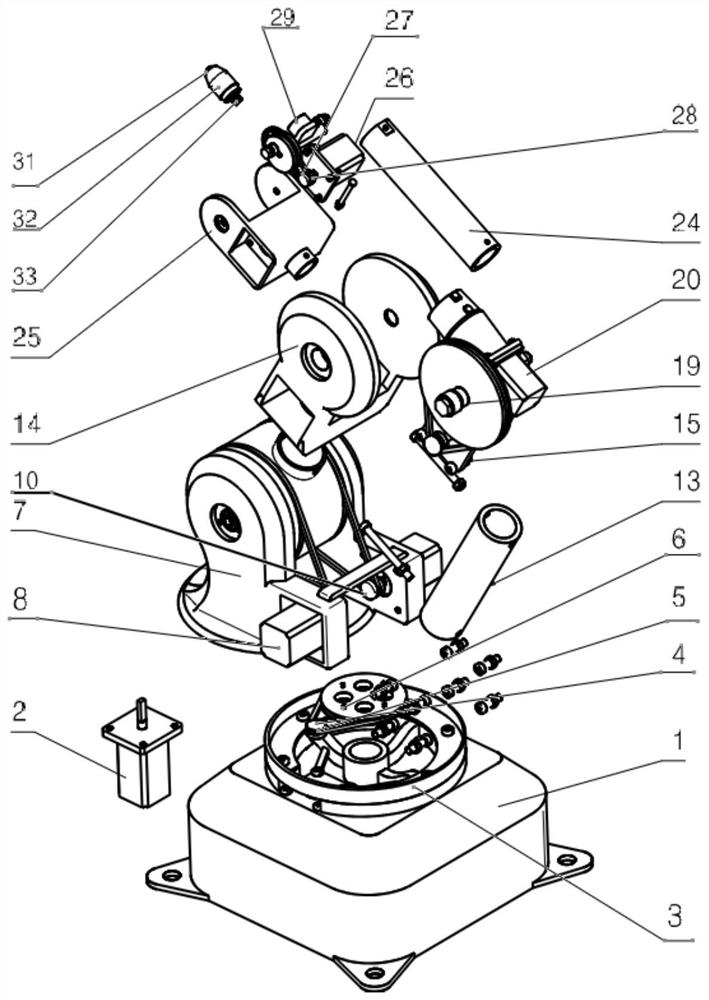

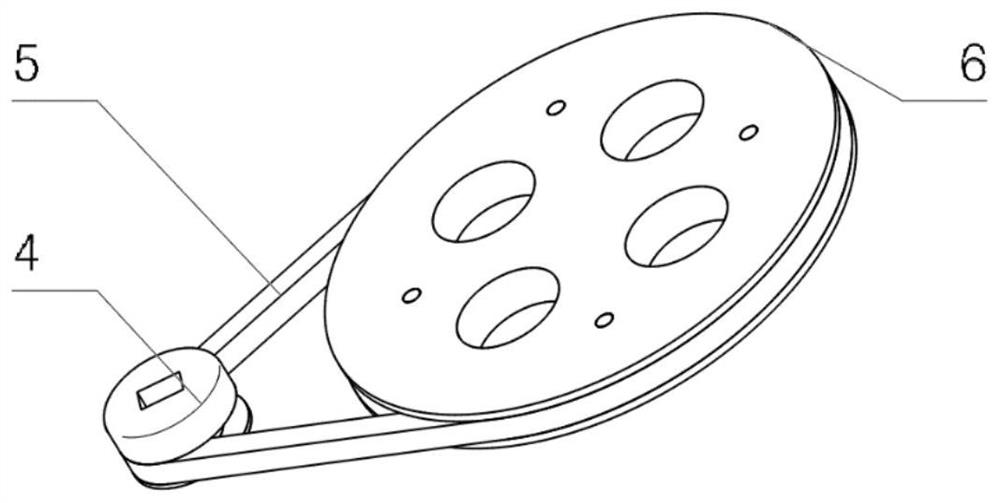

[0031] This embodiment is a vision-guided mirror milling and supporting device for thin-walled parts.

[0032] First, install two binocular vision cameras on one side of the processing head, so that the binocular cameras can see any pose of the processing head in real time. The visual part adopts two binocular vision cameras 35, and the binocular vision cameras are placed on one side of the processing head 36 of the mirror milling machine. The feature picture of the processing head is taken before processing and stored in the computer. When the processing head is processing the workpiece 34, the binocular camera will capture its pose in real time, and apply the feature matching technology based on the GMS algorithm to perform feature matching on each image and the image stored in the computer before, and use RPNP technology to calculate in real time after the matching is completed Output the pose of the processing head relative to the camera. Determine the pose transformatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com