Thermoplastic anti-blocking agent and screening device for preparing thermoplastic anti-blocking agent

The technology of a screening device and an opening agent is applied in the field of thermoplastic opening agent and the screening device used for its preparation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further explained below in conjunction with specific embodiments.

[0037] A thermoplastic anti-blocking agent is proposed in this embodiment, including the following raw materials: 270-330 parts of silicon dioxide, 60-100 parts of polyethylene wax, 0-10 parts of hyperdispersant, 5-15 parts of elastomer, and 400-630 parts of polyethylene parts, polyethylene B0-200 parts, antioxidant A0-6 parts, antioxidant B0-6 parts, ethylene-propylene rubber 0-6 parts.

[0038] In this example, each component is weighed according to weight, mixed and placed in a reaction tank, heated and stirred for 1 hour to obtain a mixture, which is extruded at a specific temperature and pressure, cooled, dried, granulated, sieved, and weighed. After packaging, the preparation can be completed.

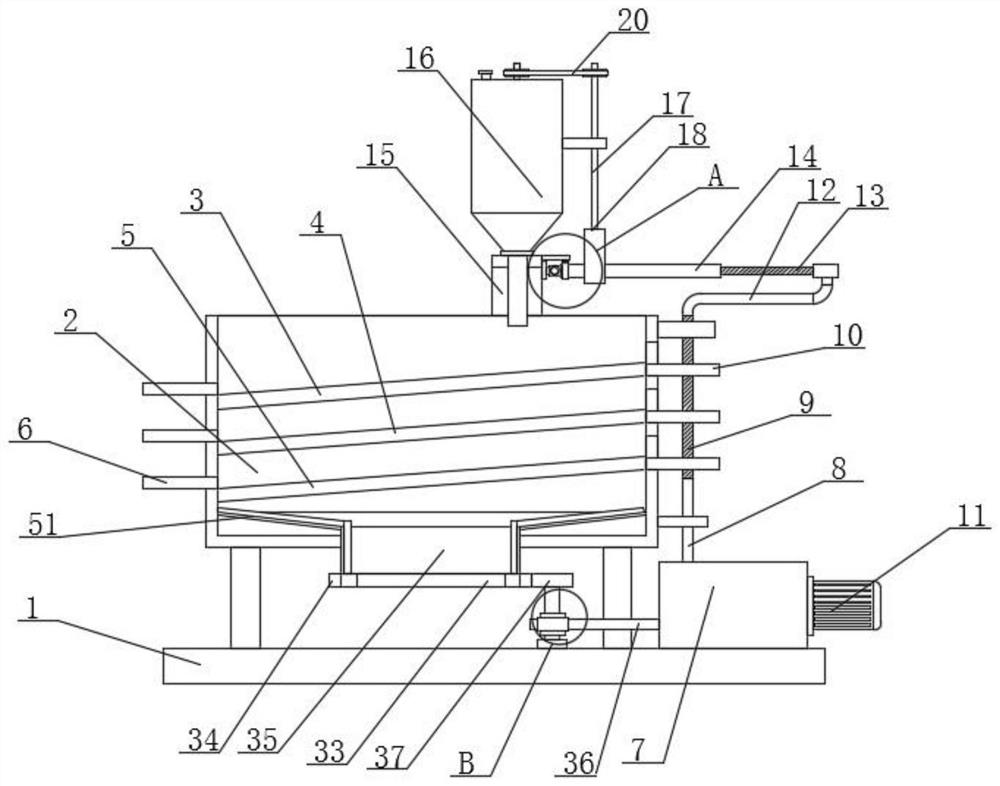

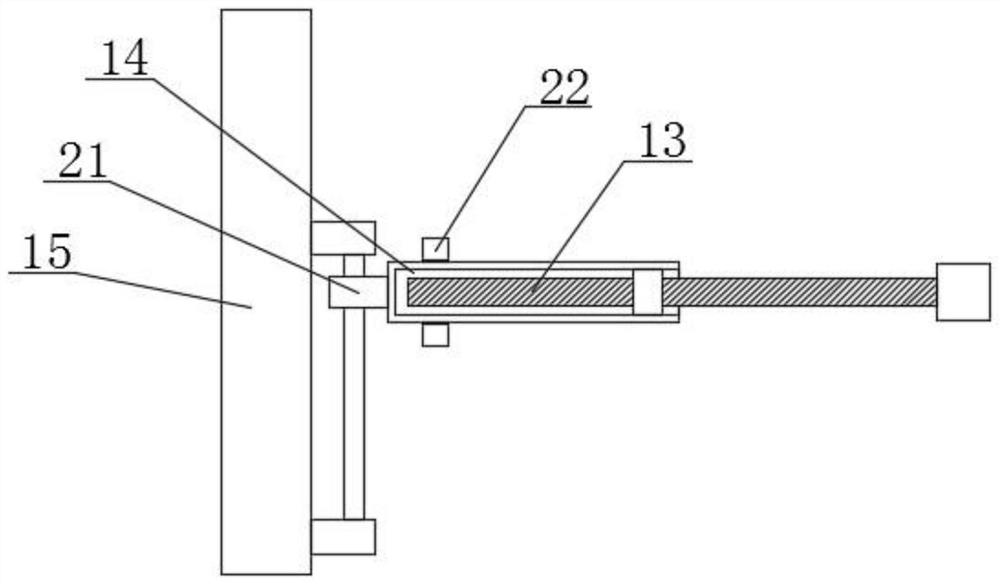

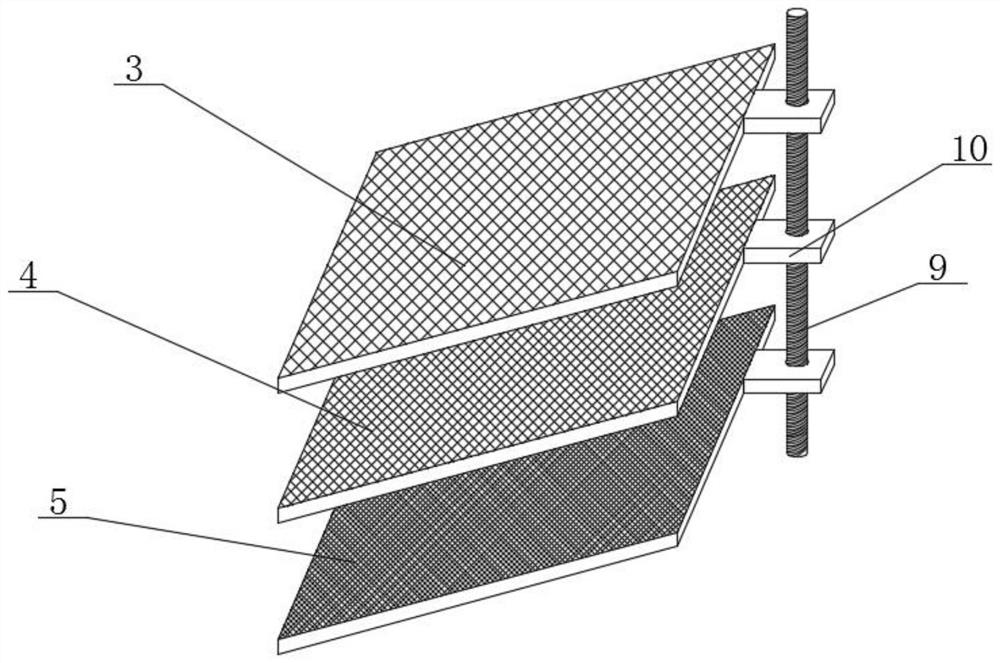

[0039] refer to Figure 1-13 , the present embodiment also proposes a screening device for the preparation of thermoplastic anti-blocking agents, including a base 1, a proce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com