PVC (polyvinyl chloride) colorful coextruded material and application thereof

A PVC resin and color technology, applied in the direction of coating, layered products, synthetic resin layered products, etc., can solve the problems of high cost, aging, discoloration and deformation, etc., and achieve the effect of good weather resistance, excellent mechanical properties and bright colors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1 was prepared according to the weight parts shown in Table 1 for each component.

[0030] Table 1 Example 1 Composition of PVC color co-extrusion material

[0031] Component number of copies PVC SG-7 100 copies calcium zinc stabilizer 5.5 servings ACR-401 2.0 servings CPE135B 8.0 servings light calcium carbonate 8.0 servings Stearic acid SA1801 0.5 servings polyethylene wax 0.6 servings Antioxidant 1010 0.3 servings UV531 0.6 servings Carbon Black N330 0.25 servings Phthalocyanine Blue 0.85 servings permanent yellow 0.35 servings

[0032] Preparation

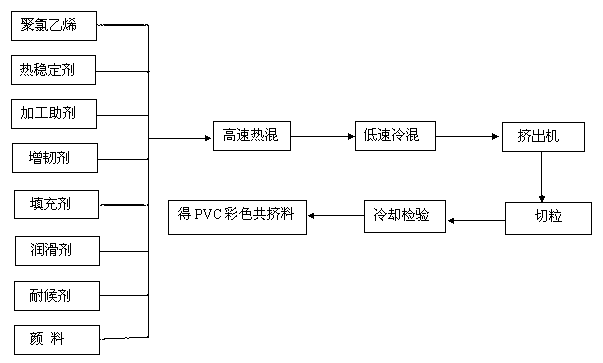

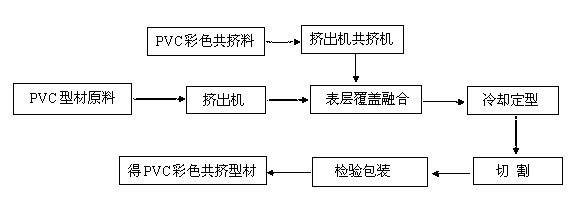

[0033] 1. Preparation method of colored co-extruded material (such as figure 1 shown):

[0034] (1) Pour all the materials into a high-speed mixer and stir them evenly according to the parts by weight of the materials in the formula table 1, stir the temperature to 110°C, and then put the materials into the l...

Embodiment 2

[0040] Example 2 was prepared according to the weight parts of the components shown in Table 2.

[0041] The composition of table 2 embodiment 2 PVC color co-extrusion material

[0042] Material name number of copies PVC SG-5 100 copies Rare earth lead salt composite stabilizer (Weilina) 5.0 servings ACR-401 2.0 servings MBS 5.0 servings CPE135B 3.0 servings DOP 3.0 servings light calcium carbonate 10.0 servings Stearic acid SA1837 0.5 servings Paraffin No. 56 0.6 servings Antioxidant 1010 0.4 servings UV531 0.8 servings Carbon Black N330 0.25 servings fast red 0.85 servings permanent yellow 0.55 servings

[0043] Preparation:

[0044] 1. Pour all the materials into a high-speed mixer and stir them evenly according to the parts by weight of the materials in the formula table 2, stir the temperature to 115°C, and then put the materials into the low-speed cold mixi...

Embodiment 3

[0049] Example 3 was prepared according to the weight parts shown in Table 3 for each component.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com