Food packaging equipment and food packaging method

A technology of food packaging and equipment, which is applied in the field of food packaging equipment and its food packaging, can solve the problems of complex packaging process, low production efficiency, high equipment price, etc., and achieve the effect of simplifying the process, convenient use and saving electric energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

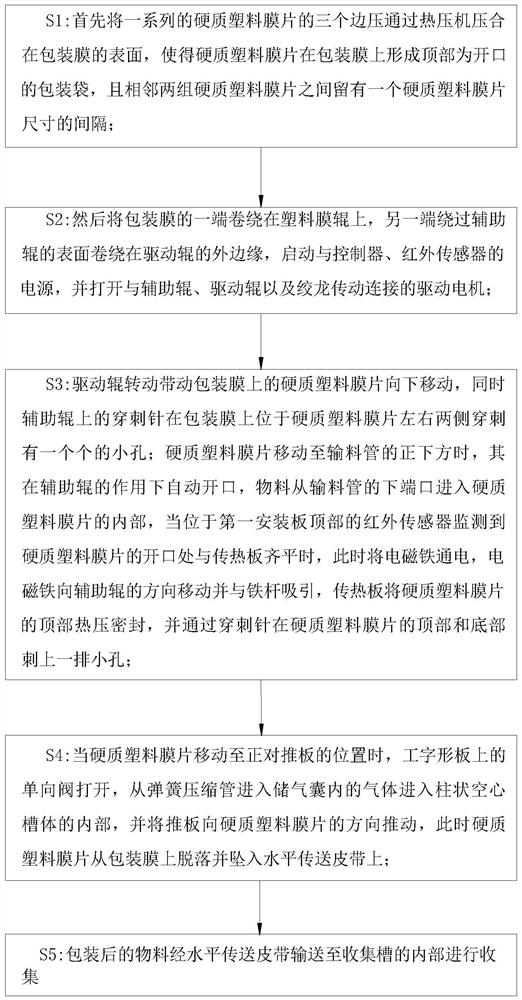

Method used

Image

Examples

Embodiment approach

[0036] As an embodiment of the present invention, the top of the annular cavity 35 is provided with a cleaning ring 37; the top of the annular cavity 35 is fixedly provided with a mounting column; the surface of the mounting column is fixedly provided with a scroll spring 28; the end of the scroll spring 28 is fixedly connected to the top of the cleaning ring 37; the bottom edge of the cleaning ring 37 is evenly provided with several groups of tension ropes 31; the bottom end of the tension rope 31 passes through the filter The outer wall of the net 34 and the annular cavity 35 is also bolted to the draw ring; during work, after dust and debris are accumulated on the inner wall of the annular cavity 35, the cleaning ring 37 can be cleaned directly by pulling the draw ring. Move, and then the cleaning ring 37 can clean the inner wall of the annular cavity, unclamp the pull ring after cleaning, and the cleaning ring 37 will move up under the effect of the scroll spring 28.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com