Faced foam insulation board and froth-foaming method for making same

a foam insulation board and foam technology, applied in the field of methods, can solve the problems of material loss and contamination of equipment, impair commercial production, etc., and achieve the effect of simple and economical manner, without significant loss of foamable chemicals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example i

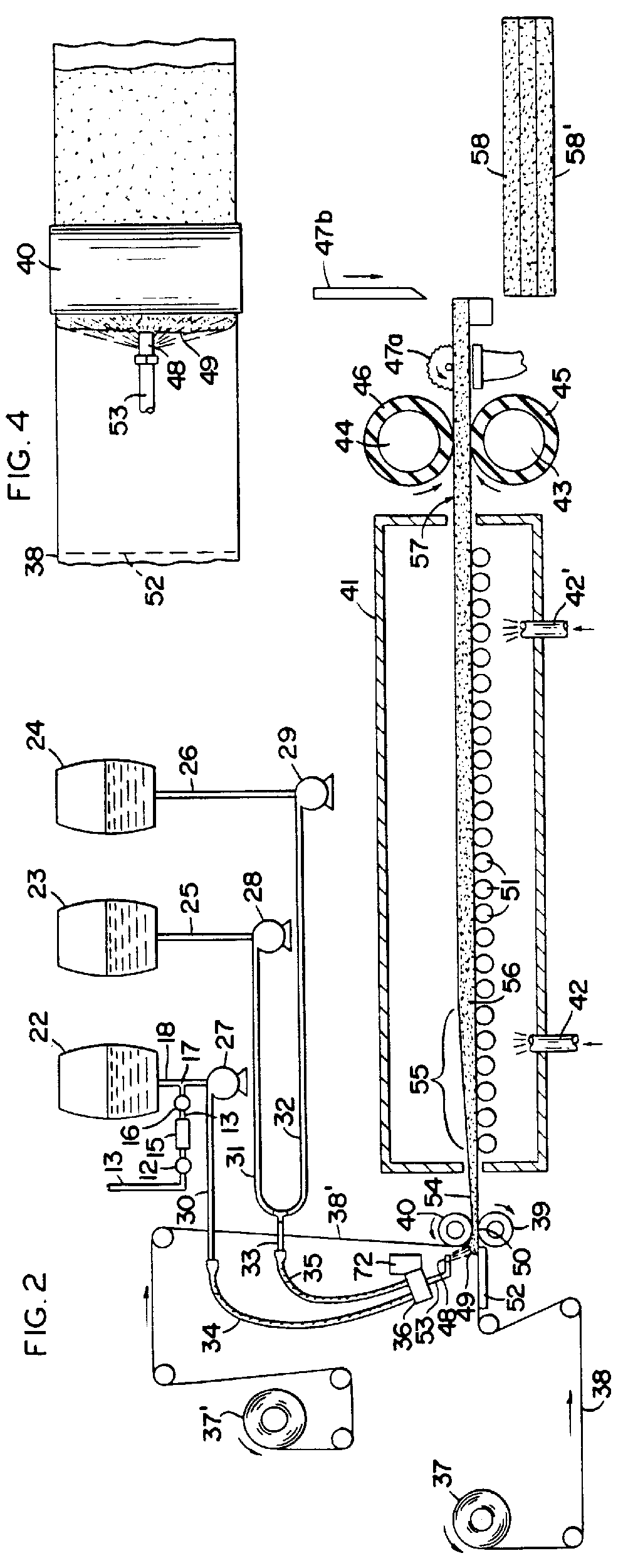

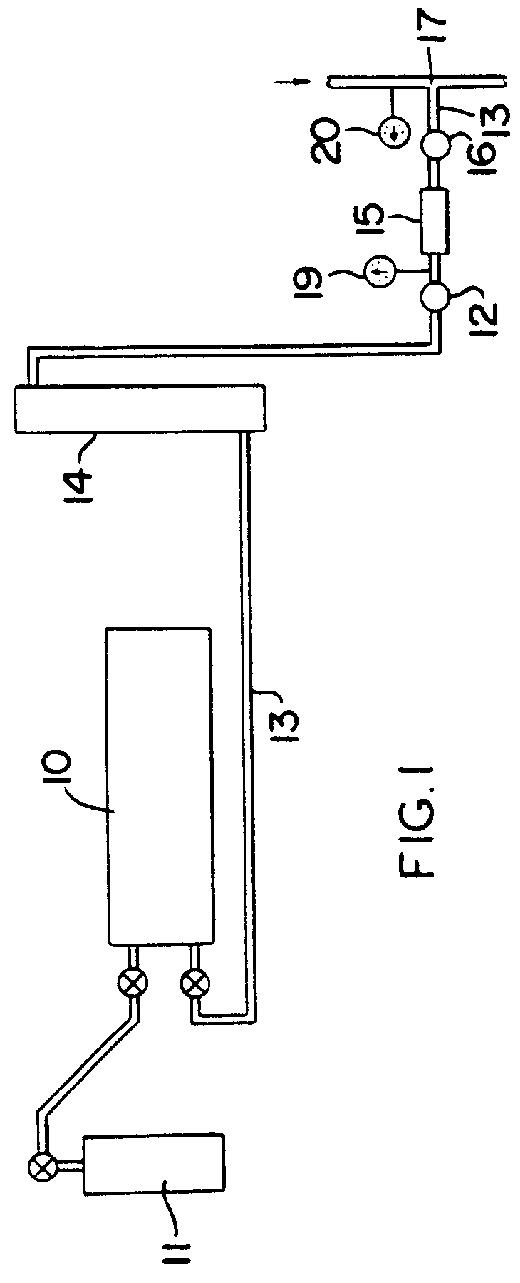

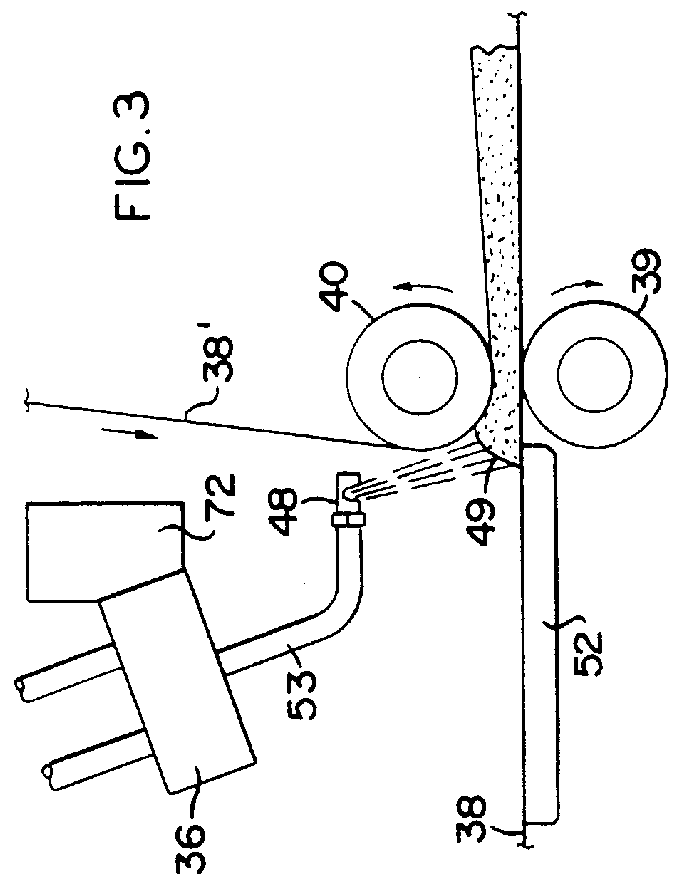

This example illustrates the process of the present invention for producing an insulation board in a free-rise mode by reference to FIGS. 1, 2, 3 and 4 of the drawings.

A. ISOCYANURATE FORMULATION USED IN PREPARING FOAM CORE OF INSULATION BOARD

The following isocyanurate formulation was used in preparing the foam core of the insulation board.

______________________________________ Item Ingredient Parts by Weight ______________________________________ A Polymethylene polyphenyl 230 isocyanate.sup.1 B Aromatic polyester polyol.sup.2 70 C Trichloromonofluoromethane 50 D Dichlorodifluoromethane 4.4 E Polydimethylsiloxane polyoxy- 3.5 alkylene copolymers.sup.3 F 2,4,6-tris(dimethylaminomethyl) (See below) phenol.sup.4 G Potassium-2-ethylhexoate.sup.4 " H Diethylene glycol.sup.4 " ______________________________________ .sup.1 Item A is a polymethylene polyphenyl isocyanate having an equivalent weight of 140, an acidity of 0.03% HCl, and a viscosity of 200 centipoises at 25.degree. C. and is ...

example 2

This example illustrates the process of the present invention for producing two insulation boards in a restrained-rise mode by reference to FIGS. 1 and 5 of the drawings.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com