Preparation method of flexible electrode complex pattern based on nanowire material

A flexible electrode and nanowire technology, which is applied in the direction of nanotechnology, metal material coating technology, and technology for producing decorative surface effects, etc., can solve the problems of low utilization rate of nanowire materials, low efficiency of mask placement, and low production efficiency and other problems, to achieve the effect of high pattern preparation efficiency, good application prospects, and high material utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

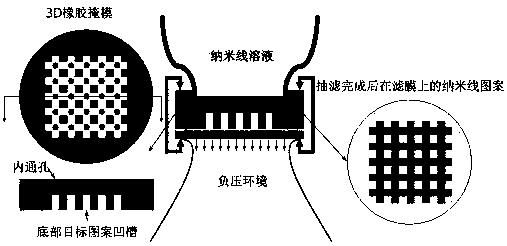

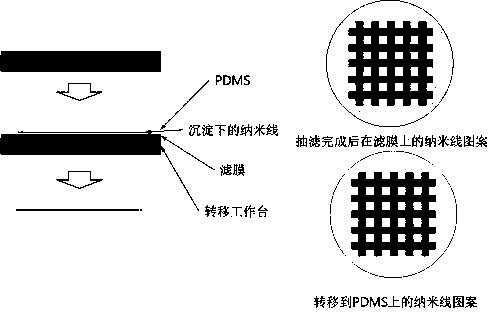

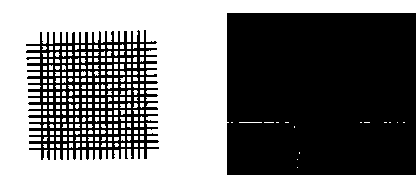

[0029] Combine below figure 1 , figure 2 and image 3 This embodiment will be described, and this embodiment includes the following steps.

[0030] (1) Cover the filter membrane on the suction filter port of the container with a negative pressure environment, cover the 3D rubber mask with an inner hole structure on the filter membrane, press the tubular container with a smooth bottom on the 3D rubber mask, and use a clip After fixing, pour 250mL of silver nanowire solution with a concentration of 25ug / mL into the top container for suction filtration; the suction filter port is circular with a diameter of 40mm, and the filter aperture is 10-50um. The 3D rubber mask is made of PDMS material, and the inner hole and the bottom target pattern groove are prepared by the reverse molding process. The groove is a 17×17mm grid pattern with a depth of 1mm.

[0031] (2) After all the liquid has been filtered, remove the top container and 3D mask in turn, and then use tweezers to trans...

Embodiment 2

[0035] Combine below figure 1 , figure 2 and Figure 4 This embodiment will be described, and this embodiment includes the following steps.

[0036] (1) Cover the filter membrane on the suction filter port of the container with a negative pressure environment, cover the 3D rubber mask with an inner hole structure on the filter membrane, press the tubular container with a smooth bottom on the 3D rubber mask, and use a clip After fixing, pour 250mL of nano-copper wire solution with a concentration of 25ug / mL into the top container for suction filtration; the suction filter port is circular with a diameter of 40mm, and the filter aperture is 10-50um. The 3D rubber mask is made of PDMS material, and the inner hole and the bottom target pattern groove are prepared by the reverse molding process. The groove is a double ring pattern with a depth of 1mm.

[0037] (2) After all the liquid has been filtered, remove the top container and 3D mask in turn, and then use tweezers to tran...

Embodiment 3

[0041] Combine below figure 1 , figure 2 and Figure 5 This embodiment will be described, and this embodiment includes the following steps.

[0042] (1) Cover the filter membrane on the suction filter port of the container with a negative pressure environment, cover the 3D rubber mask with an inner hole structure on the filter membrane, press the tubular container with a smooth bottom on the 3D rubber mask, and use a clip After fixing, pour 250mL of carbon nanotube solution with a concentration of 25ug / mL into the top container for suction filtration; the suction filter port is circular with a diameter of 40mm, and the filter aperture is 10-50um. The 3D rubber mask is made of PDMS material. The inner hole and the target pattern groove at the bottom are prepared by the reverse molding process. The groove double-ring + cross-shaped closed-loop pattern has a depth of 1mm.

[0043] (2) After all the liquid has been filtered, remove the top container and 3D mask in turn, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com