Special high-temperature-resisting and radiation-resisting insulating material for nuclear power station and preparation method of special high-temperature-resisting and radiation-resisting insulating material

A high temperature resistant, nuclear power plant technology, applied in the direction of rubber insulators, organic insulators, etc., can solve the problems of material mechanical properties and electrical properties degradation, etc., to achieve high performance retention rate, increase compatibility, good dispersion and compatibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

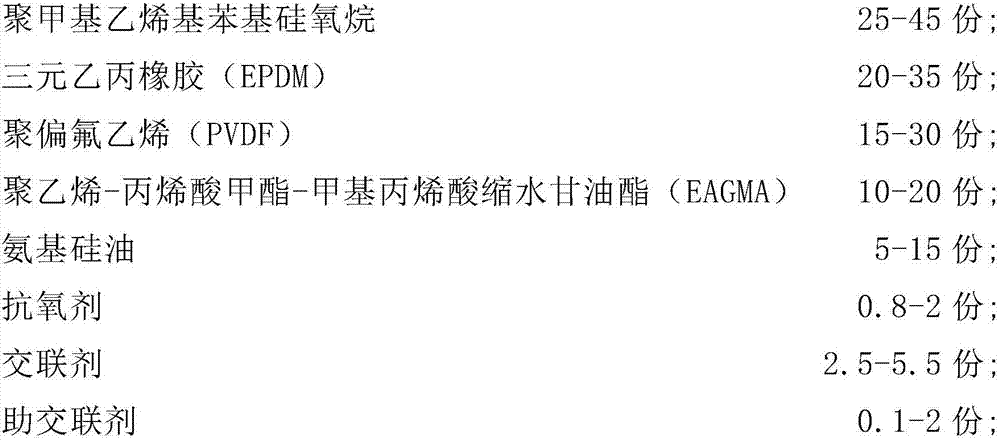

[0023] Further elaborate technical characteristics of the present invention below in conjunction with embodiment:

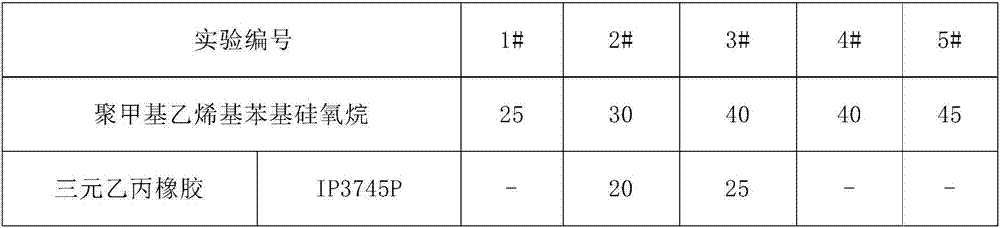

[0024] The following polymethylvinylphenylsiloxane has a vinyl content of 15% and a phenyl content of 32%;

[0025] The ethylene content of IP3745P in ethylene propylene rubber is 70%, and the third monomer content is 0.5%;

[0026] The ethylene content of IP3760P in ethylene propylene rubber is 67%, and the third monomer content is 2.2%;

[0027] The amino group content of amino silicone oil is 0.75%.

[0028] Table 1 is the embodiment formula:

[0029]

[0030]

[0031] The preparation method of the above-mentioned high-temperature-resistant and radiation-resistant insulating material special for nuclear power plants comprises the following steps:

[0032] (1) According to polymethyl vinyl phenyl siloxane, EPDM rubber, polyethylene-methyl acrylate-glycidyl methacrylate, amino silicone oil is fully mixed with an internal mixer at 130-145 °C , the mixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com