Patents

Literature

280results about How to "Easy to clip" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

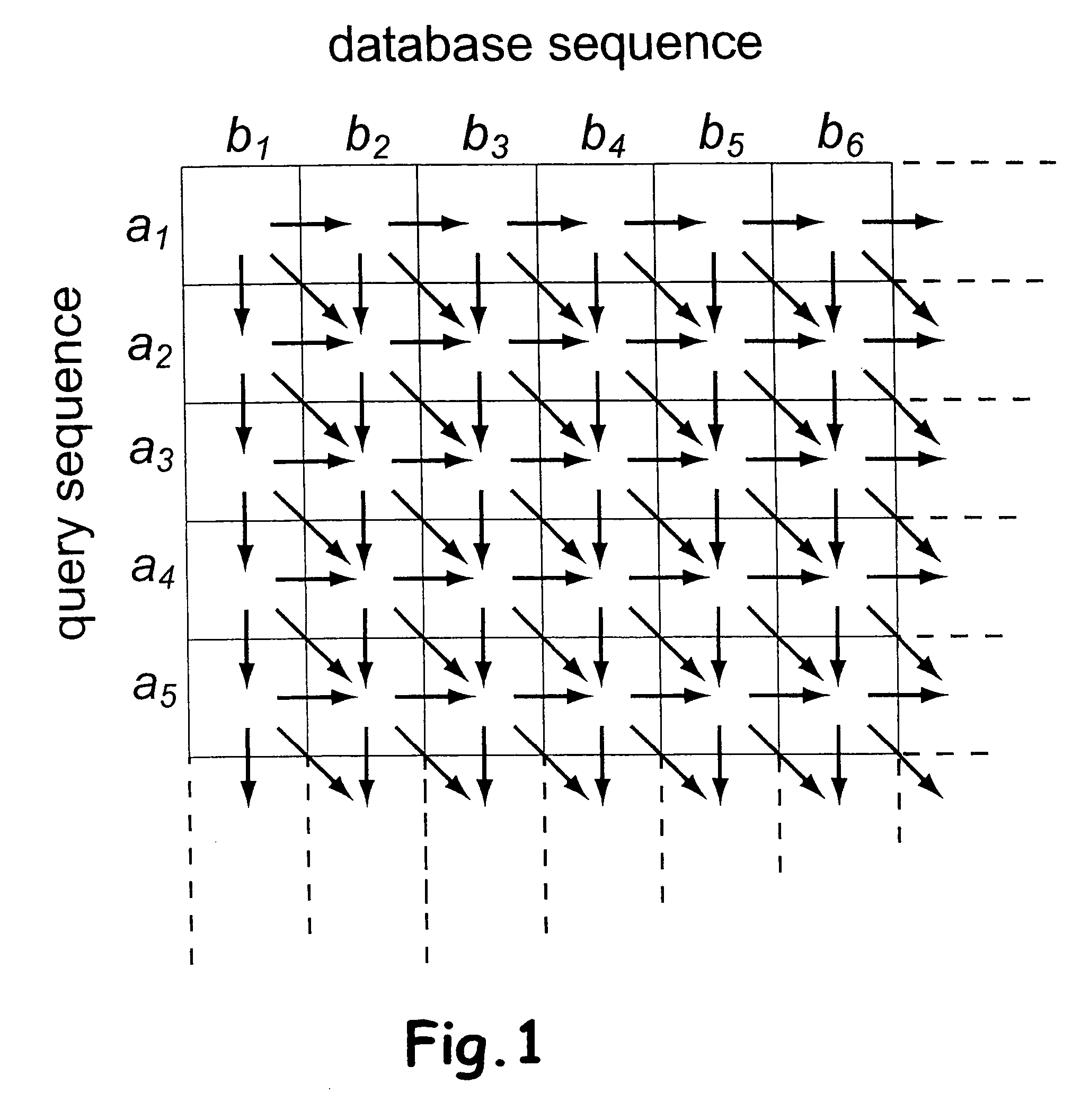

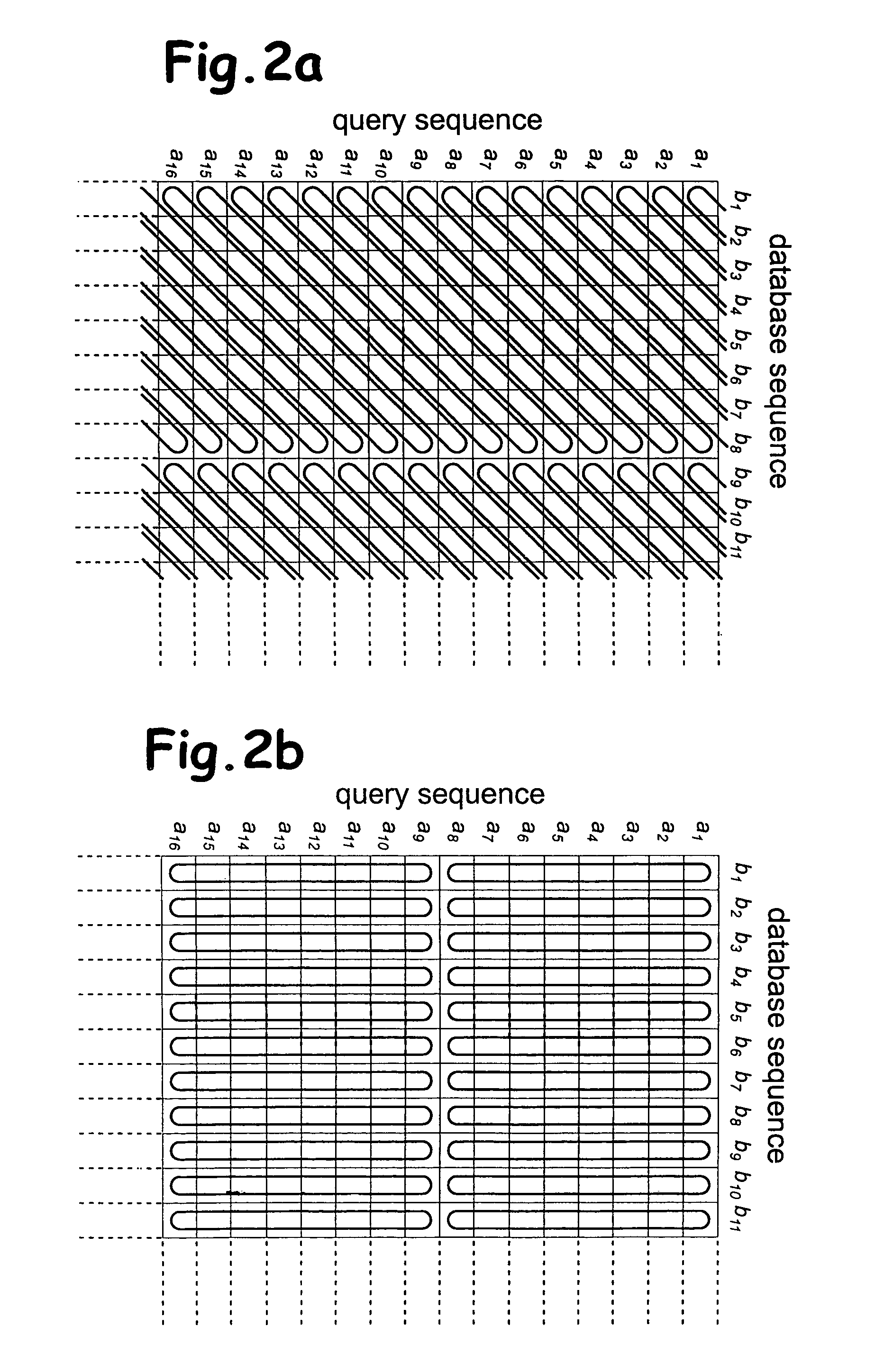

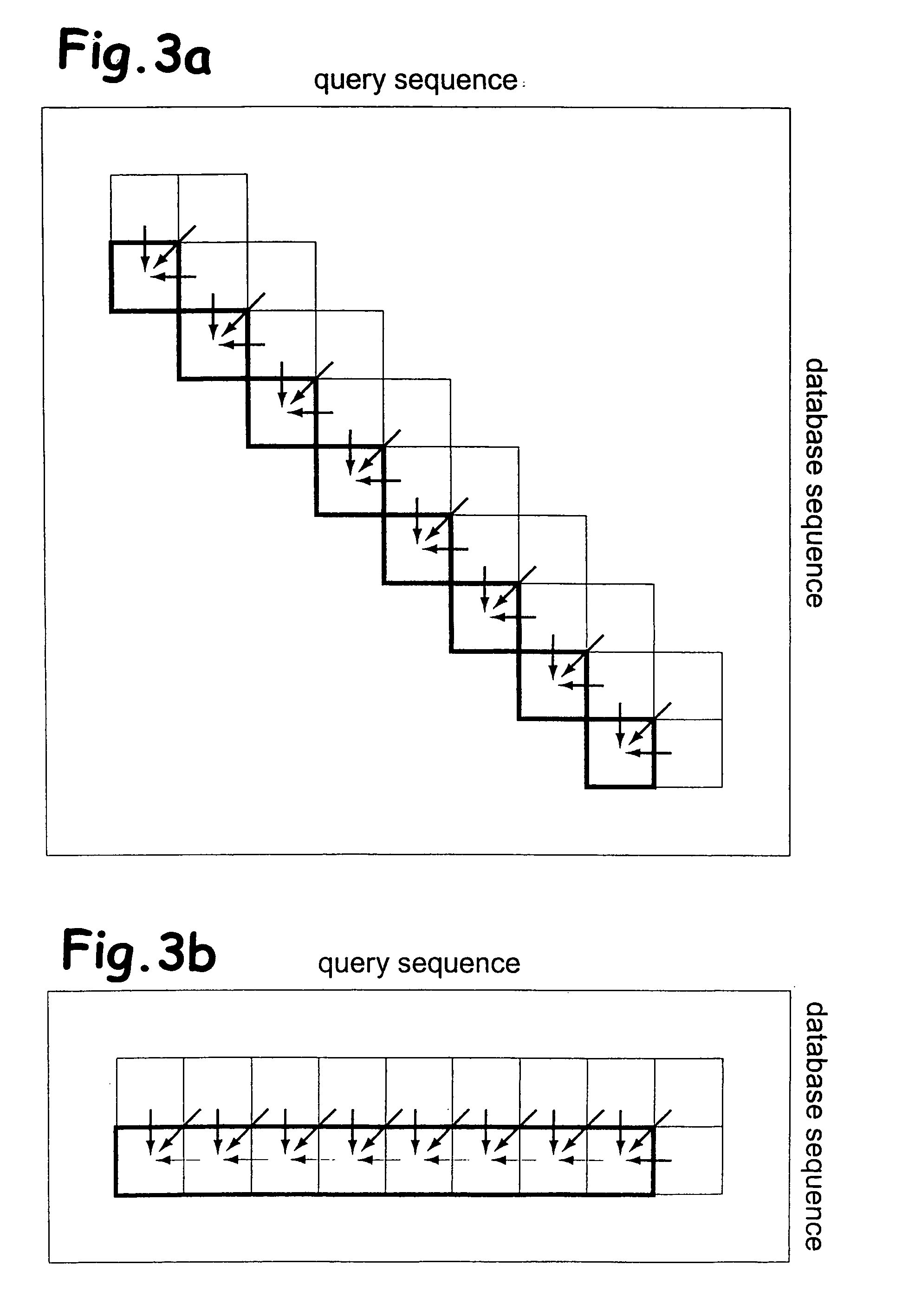

Determination of optimal local sequence alignment similarity score

InactiveUS7917302B2Low costShorten the timeMicrobiological testing/measurementRecombinant DNA-technologyLocal sequence alignmentProtein function prediction

Sequence alignment and sequence database similarity searching are among the most important and challenging task in bio informatics, and are used for several purposes, including protein function prediction. An efficient parallelisation of the Smith-Waterman sequence alignment algorithm using parallel processing in the form of SIMD (Single-Instruction, Multiple-Data) technology is presented. The method has been implementation using the MMX (MultiMedia eXtensions) and SSE (Streaming SIMD Extensions) technology that is embedded in Intel's latest microprocessors, but the method can also be implemented using similar technology existing in other modern microprocessors. Near eight-fold speed-up relative to the fastest previously an optimised eight-way parallel processing approach achieved know non-parallel Smith-Waterman implementation on the same hardware. A speed of about 200 million cell updates per second has been obtained on a single Intel Pentium III 500 MHz microprocessor.

Owner:SEEBERG ERLING CHRISTEN +1

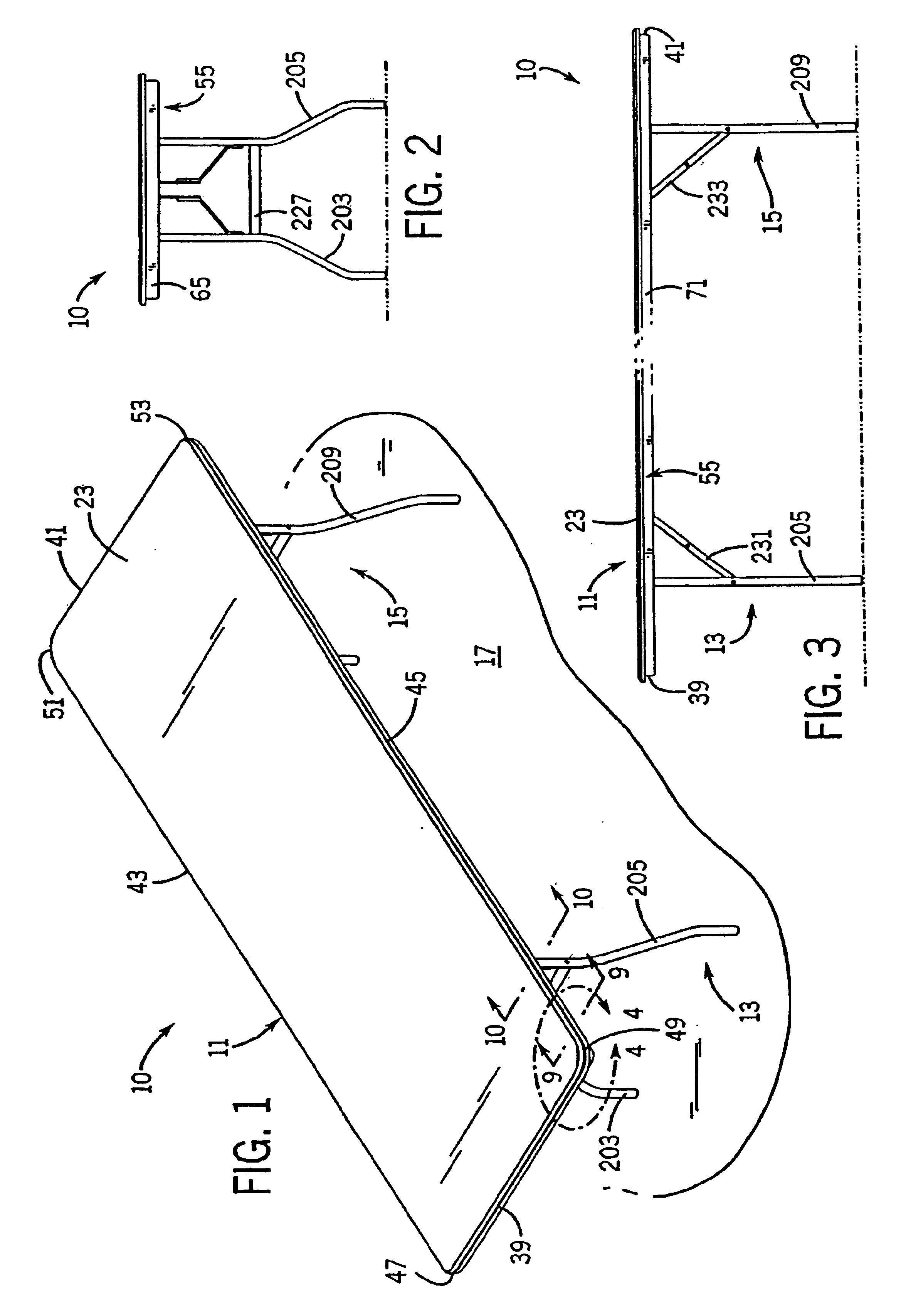

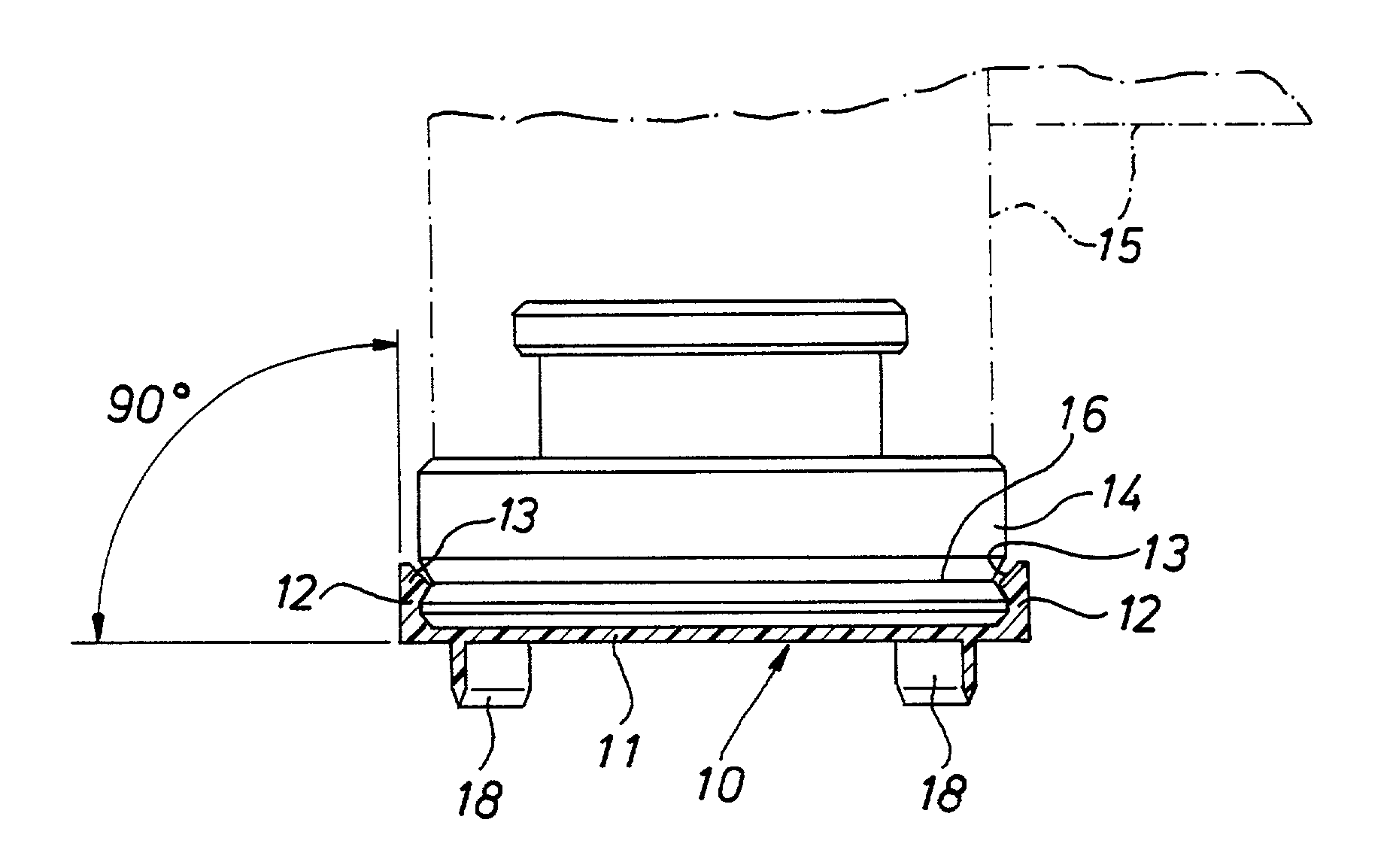

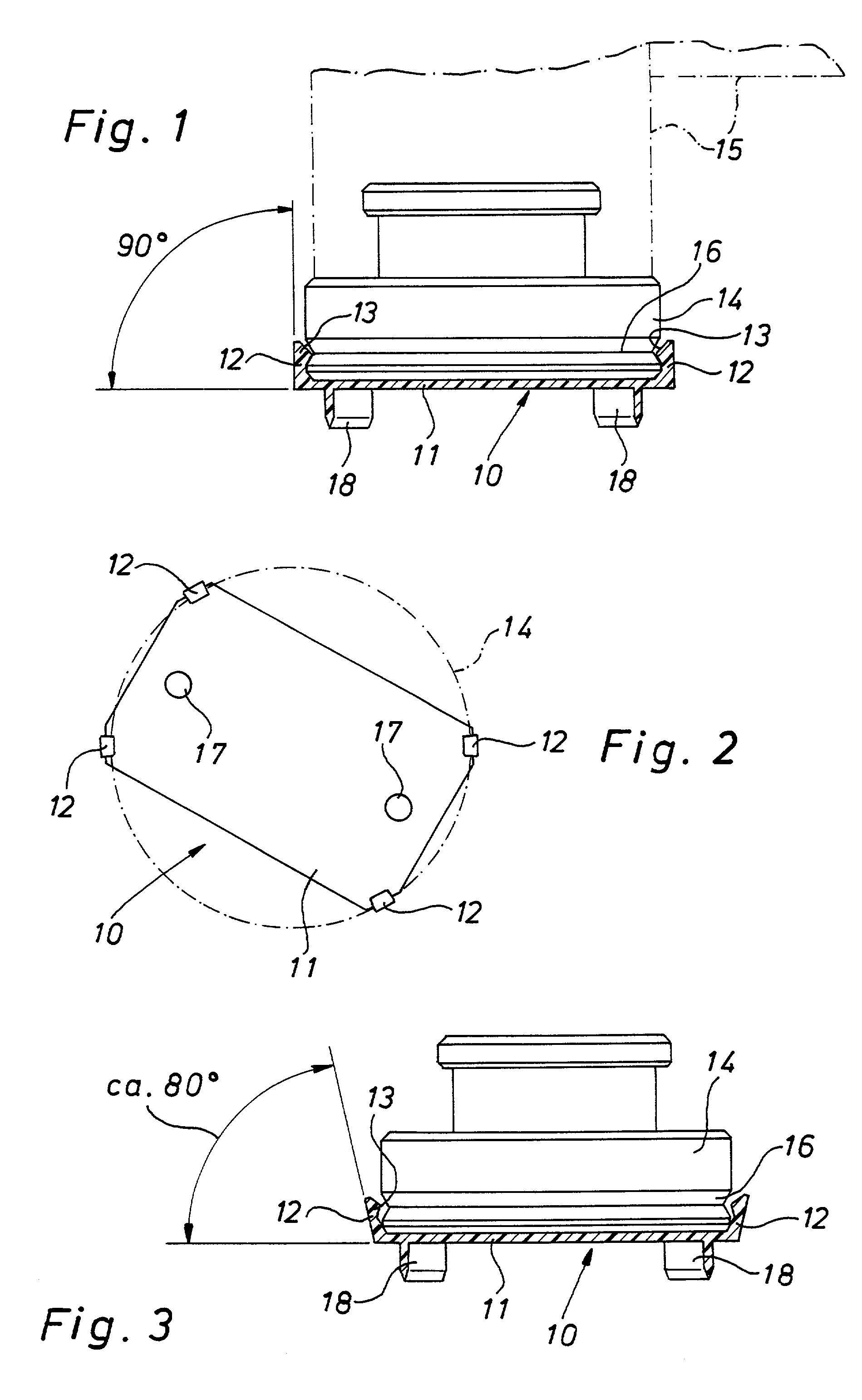

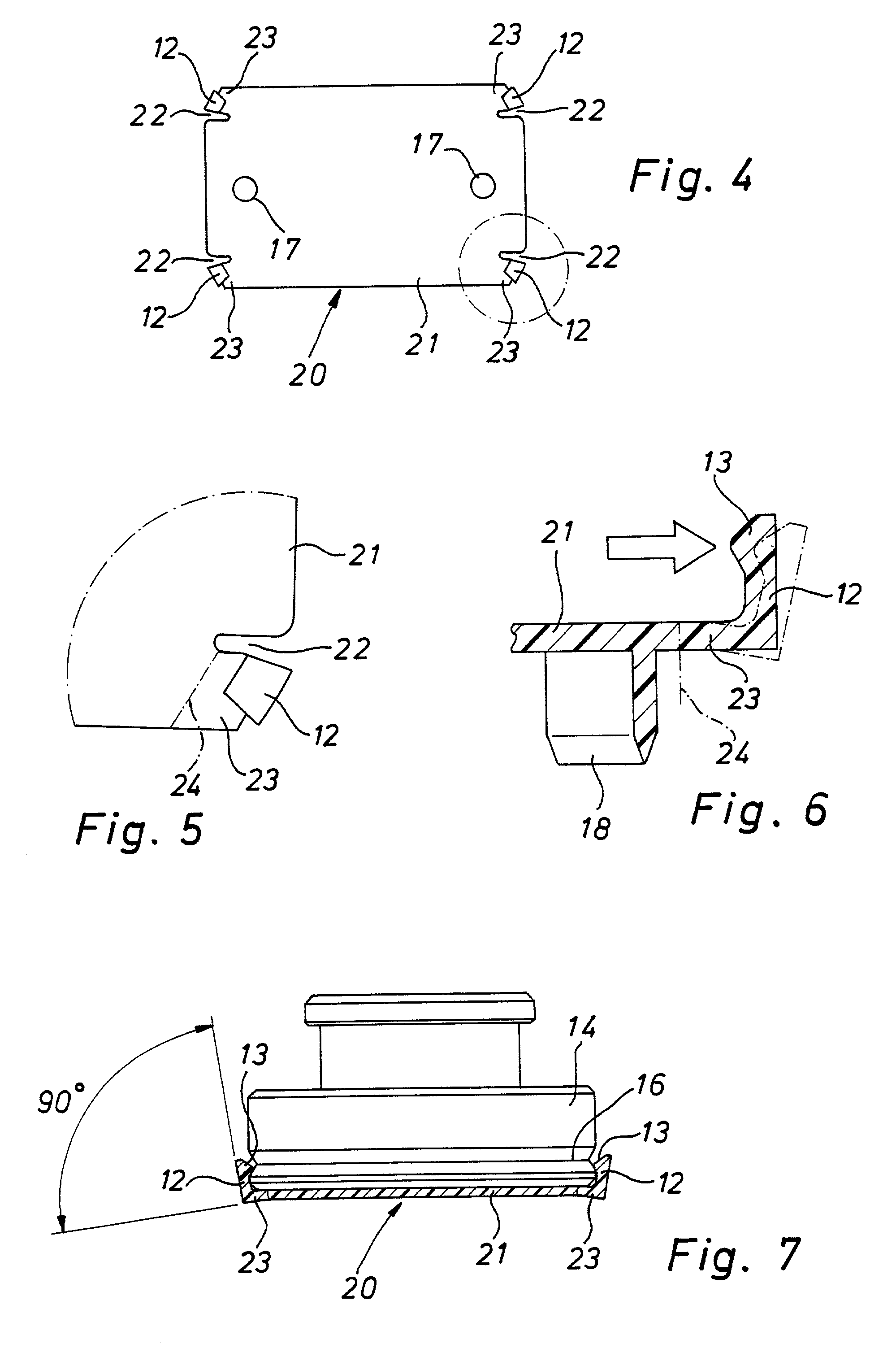

Lightweight table with unitized table top

InactiveUS6837171B1Easy to transportEasy to clipFoldable tablesStowable tablesStructural engineeringMechanical engineering

Owner:PS FURNITURE

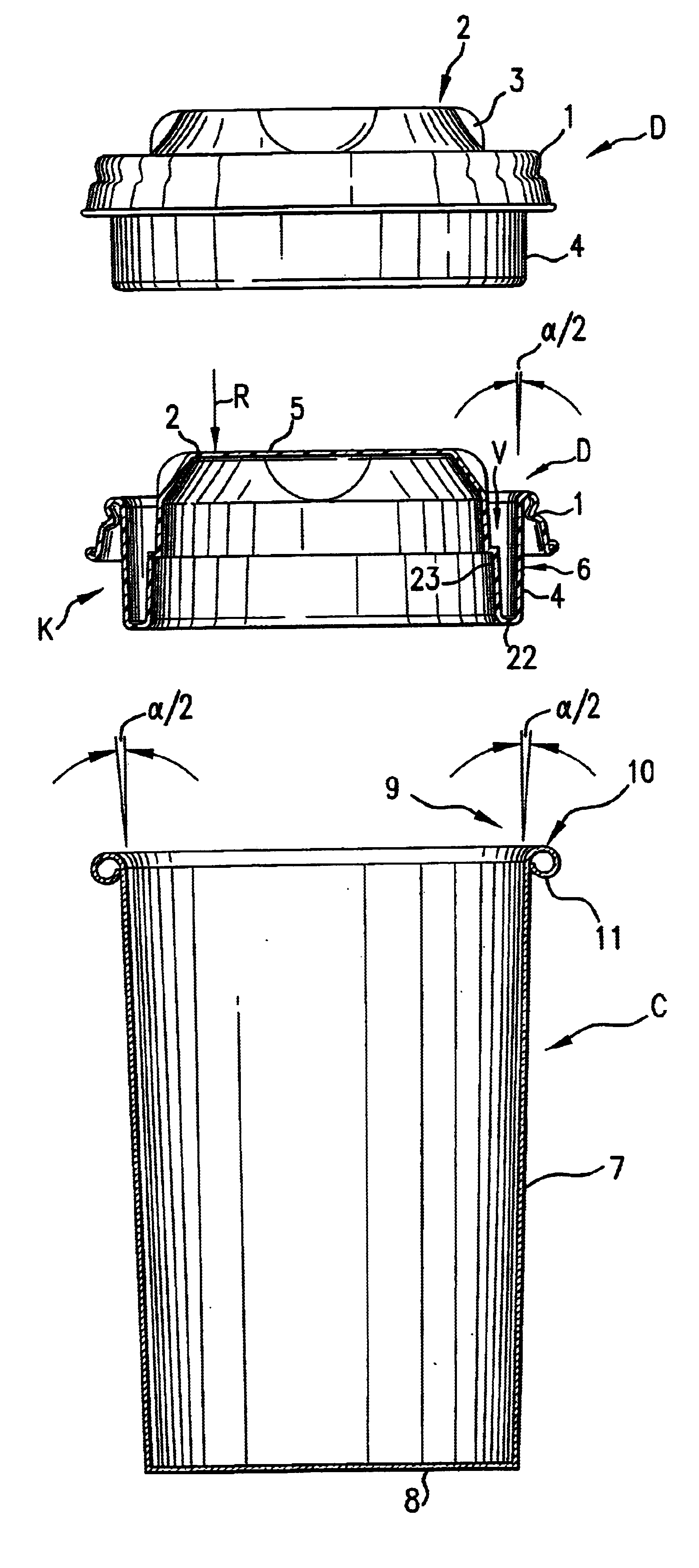

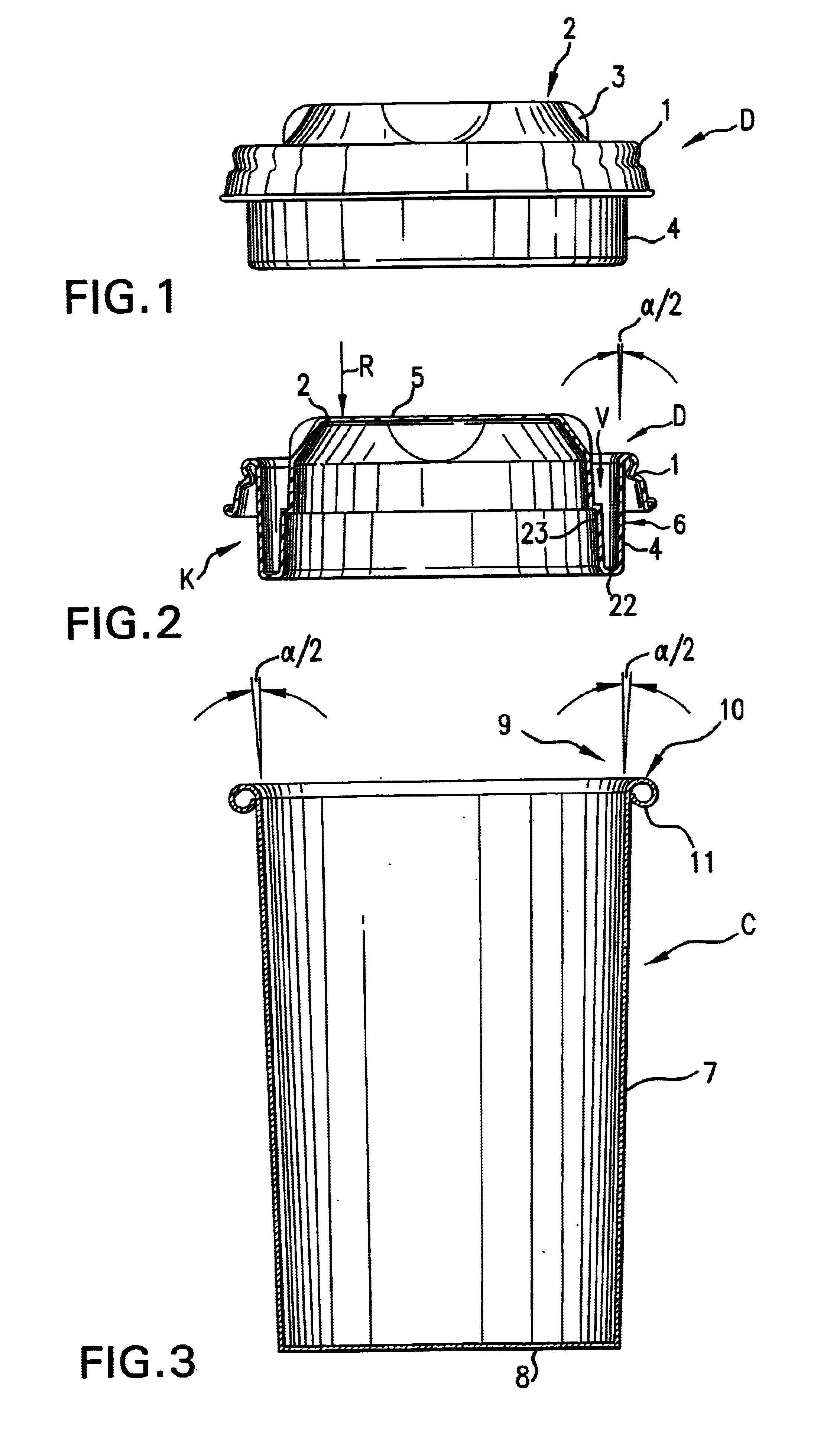

Cup-shaped receptacle and lid

InactiveUS6932234B2Intensified sealing effectImprove retentionContainer decorationsCapsBiomedical engineeringEngineering

A cup-shaped receptacle has an outer bead in its opening area for clipping on a plastic lid, which has a circumferentially continuous clamping groove for receiving the bead. The clamping groove is continued outwards by an elastically deformable constriction, and inwards by an outer wall of a circumferentially continuous, U-shaped lid recess, whose U-web of is situated below the height position of the constriction and whose inner leg wall forms a part of a dome wall of a dome which extends upwardly beyond the height position. The lid recess extends downwards beyond the height position and has an outer diameter at its outer surface which is adapted to the inner diameter of the receptacle wall such that the lid recess functions at least as a centring and guide projection for the lid-clip-on action, which projection slidingly co-operates with the receptacle wall already at least while the bead passes the constriction.

Owner:SEDA SPA

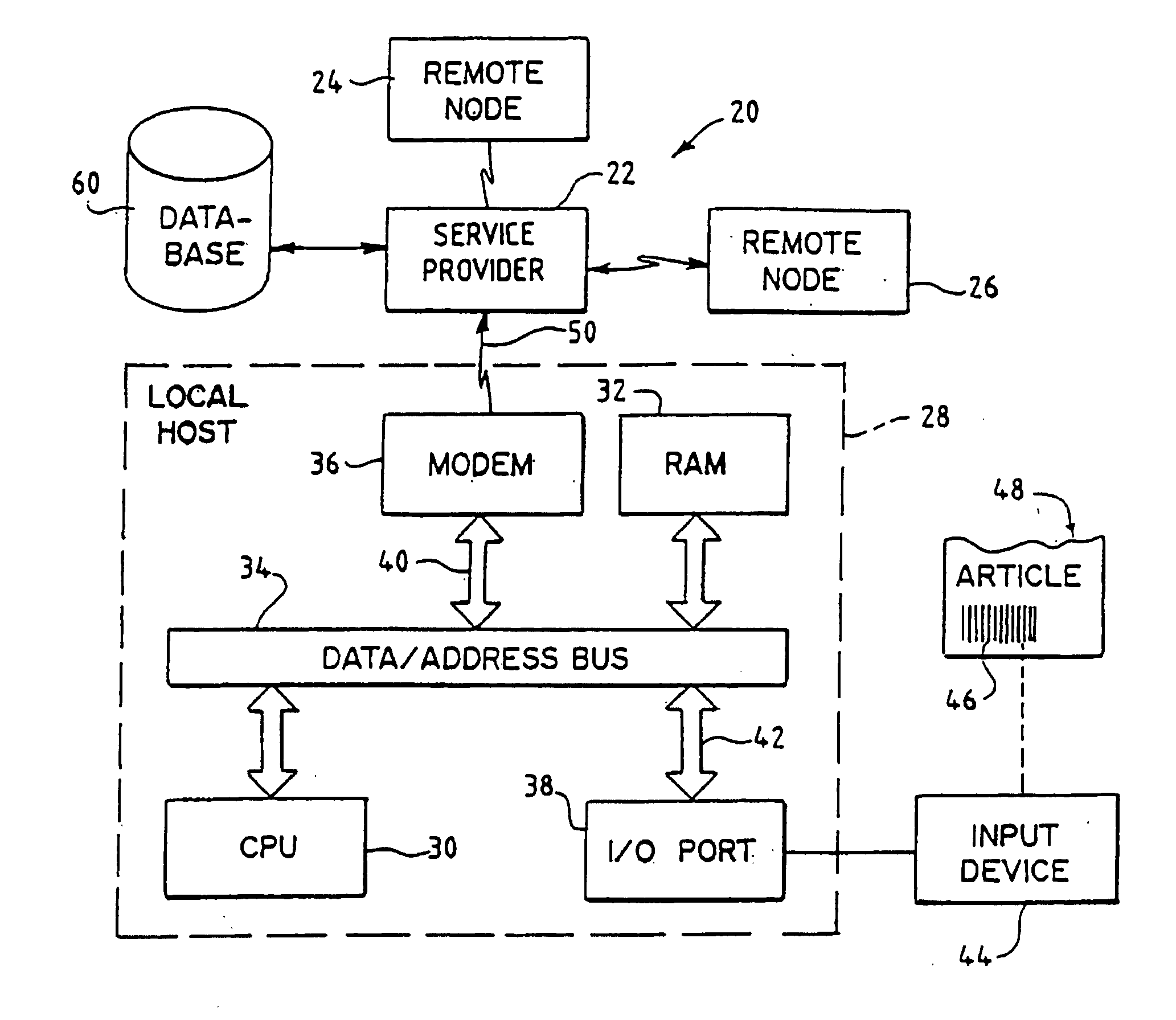

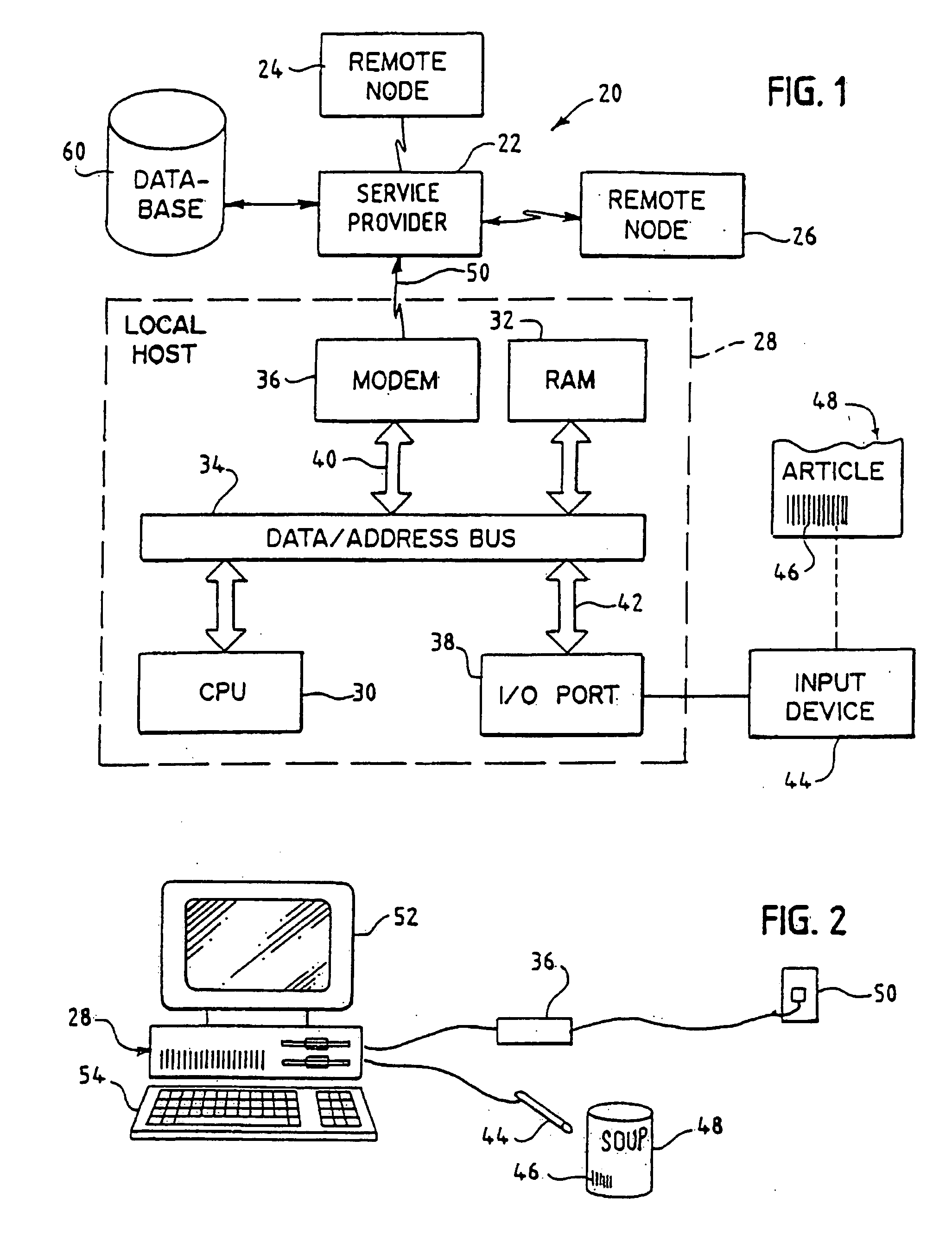

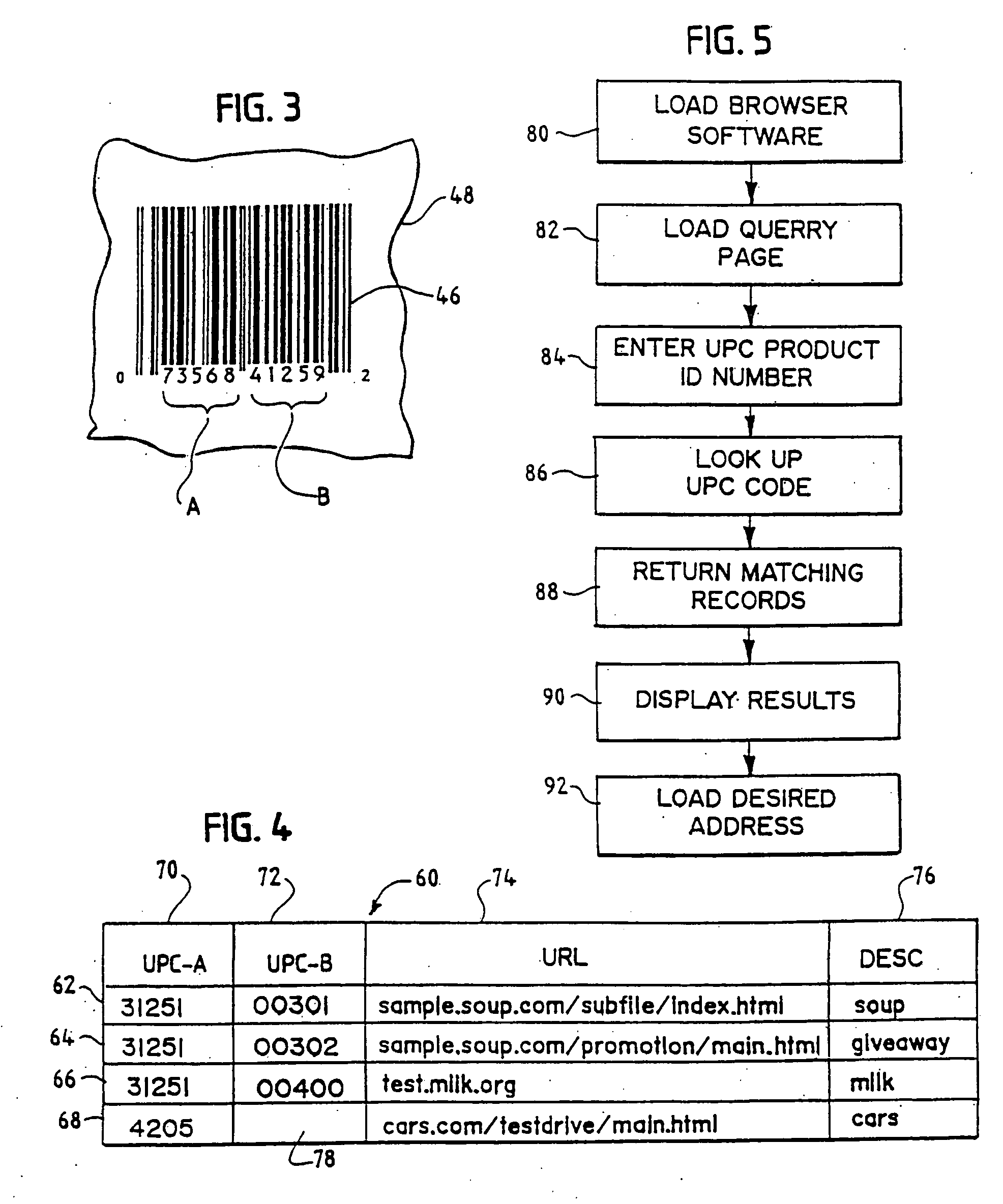

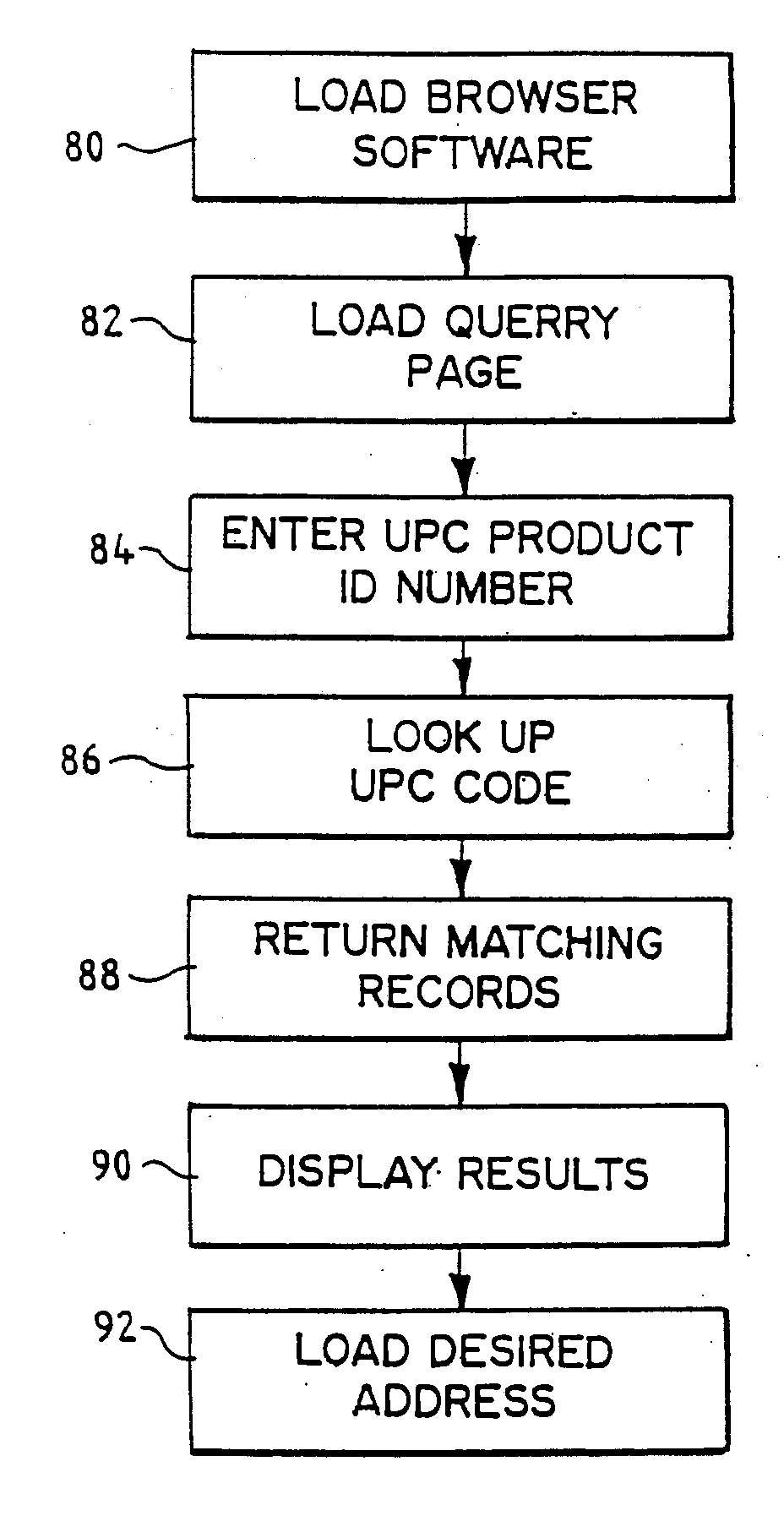

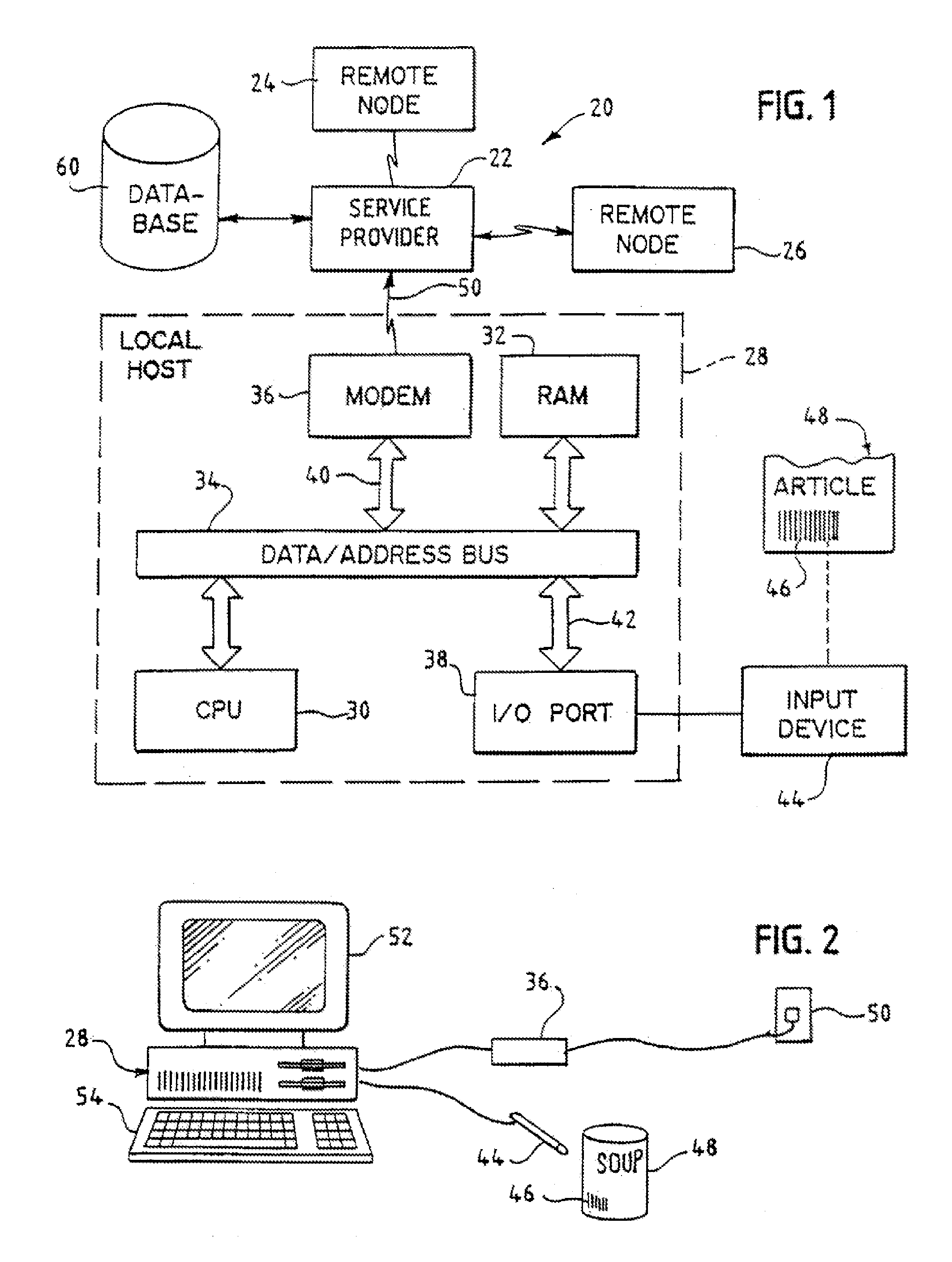

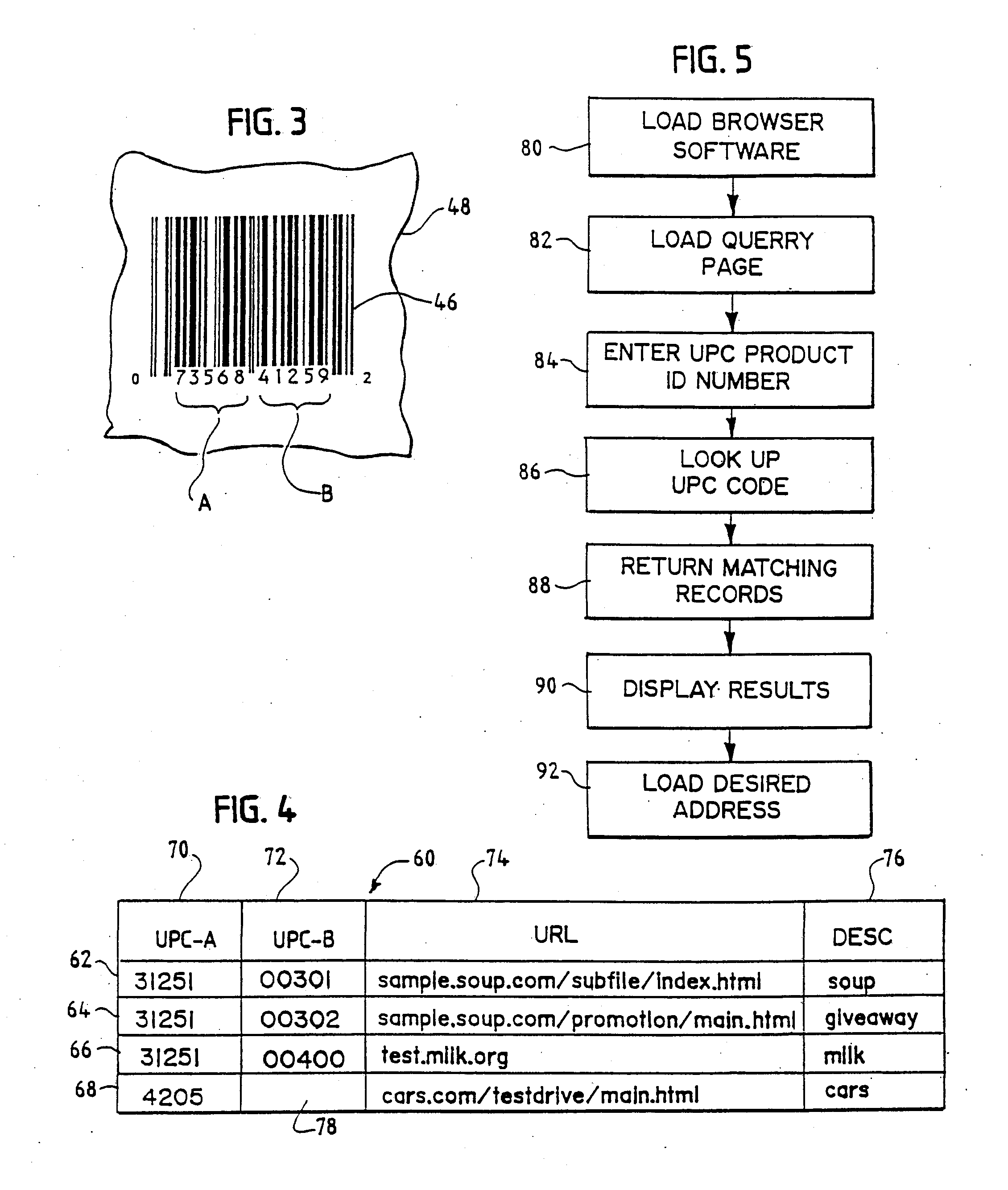

System and method for automatic access of a remote computer over a network

InactiveUS20050246237A1Resource optimizationEliminate needDigital data information retrievalCredit registering devices actuationInternet networkRemote computer

A system and method for using identification codes found on ordinary articles of commerce to access remote computers on a network. In accordance with one embodiment of the invention, a computer is provided having a database that relates Uniform Product Code (“UPC”) numbers to Internet network addresses (or “URLs”). To access an Internet resource relating to a particular product, a user enters the product's UPC symbol manually, by swiping a bar code reader over the UPC symbol, or via other suitable input means. The database retrieves the URL corresponding to the UPC code. This location information is then used to access the desired resource.

Owner:NM LLC

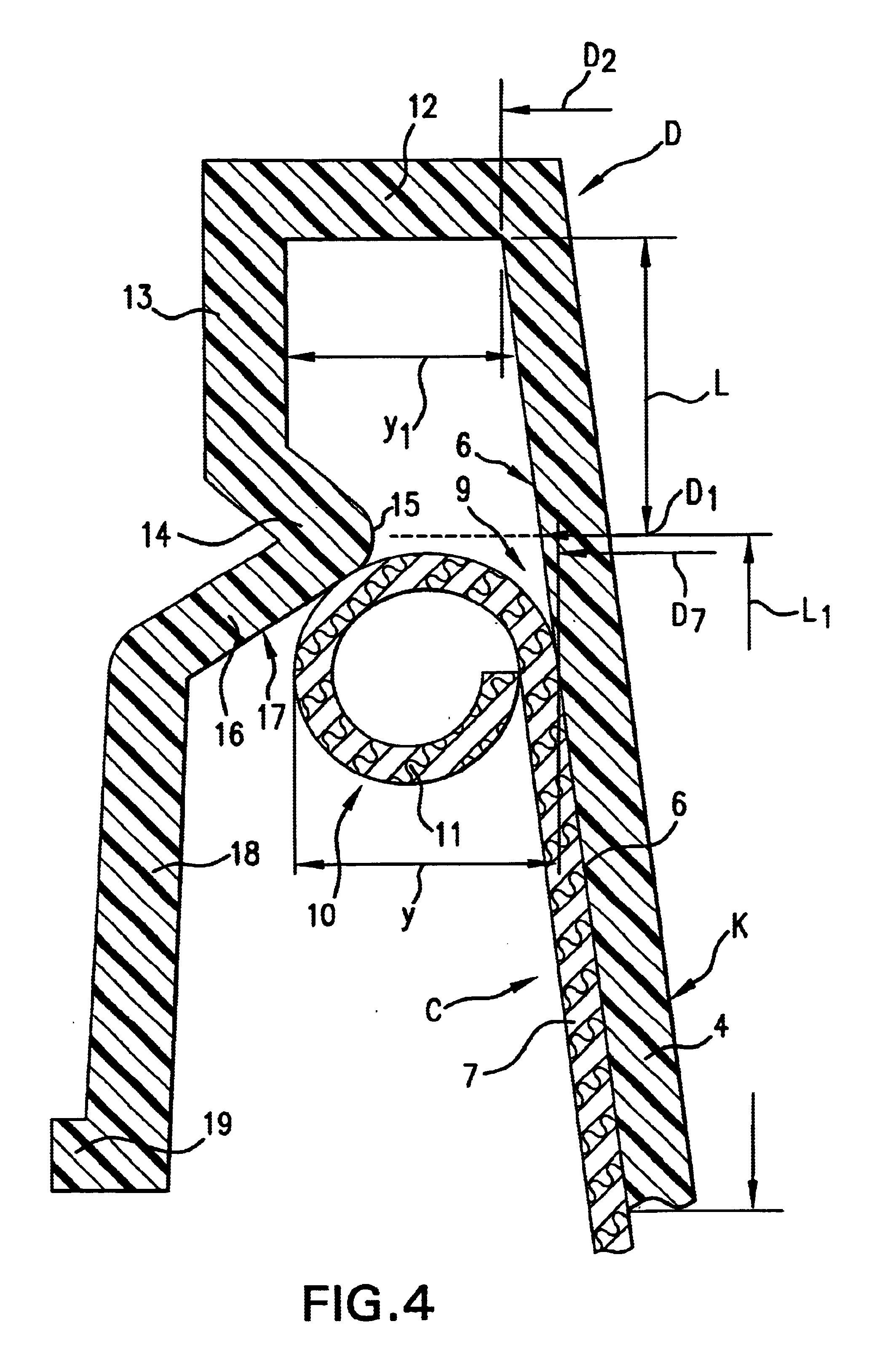

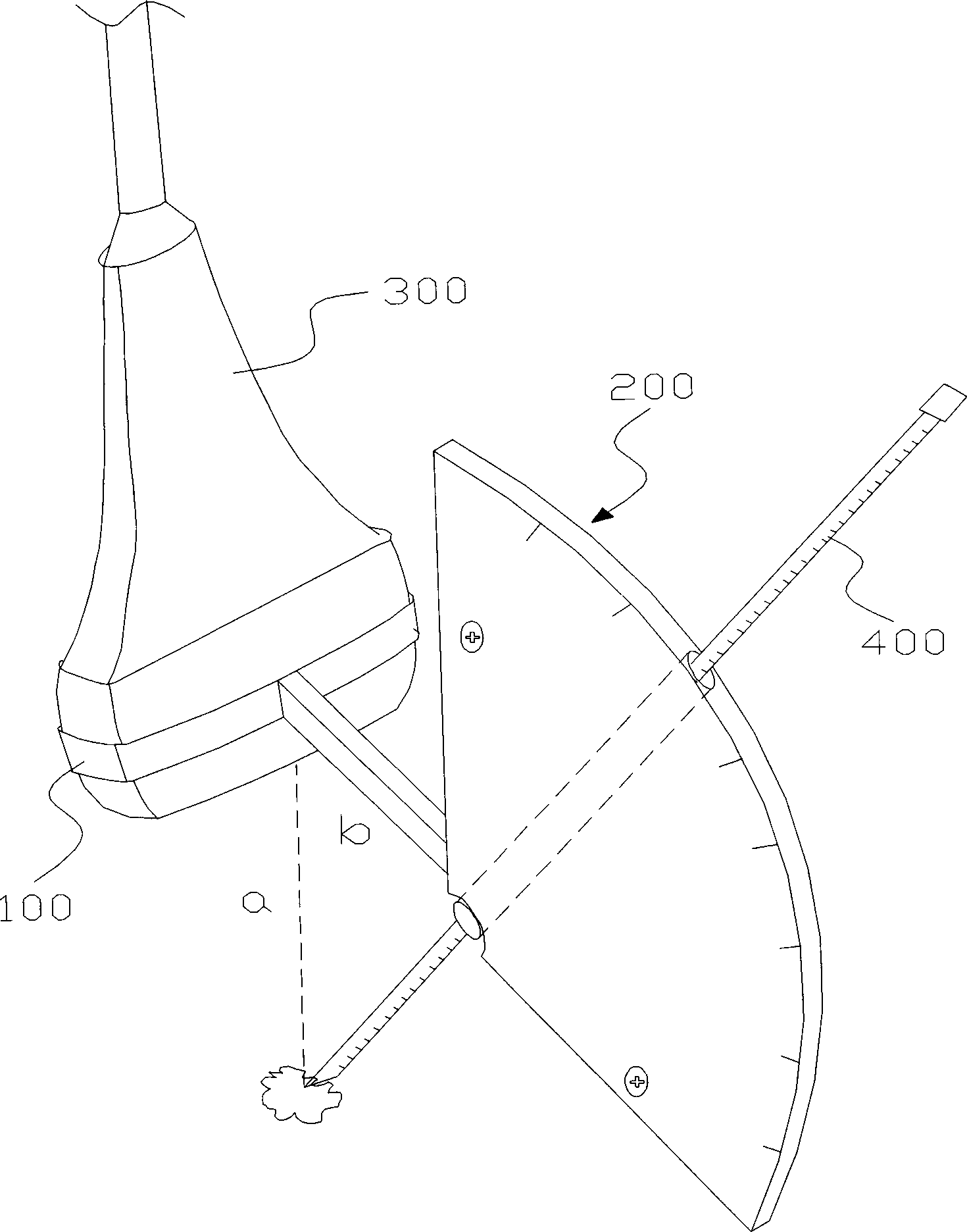

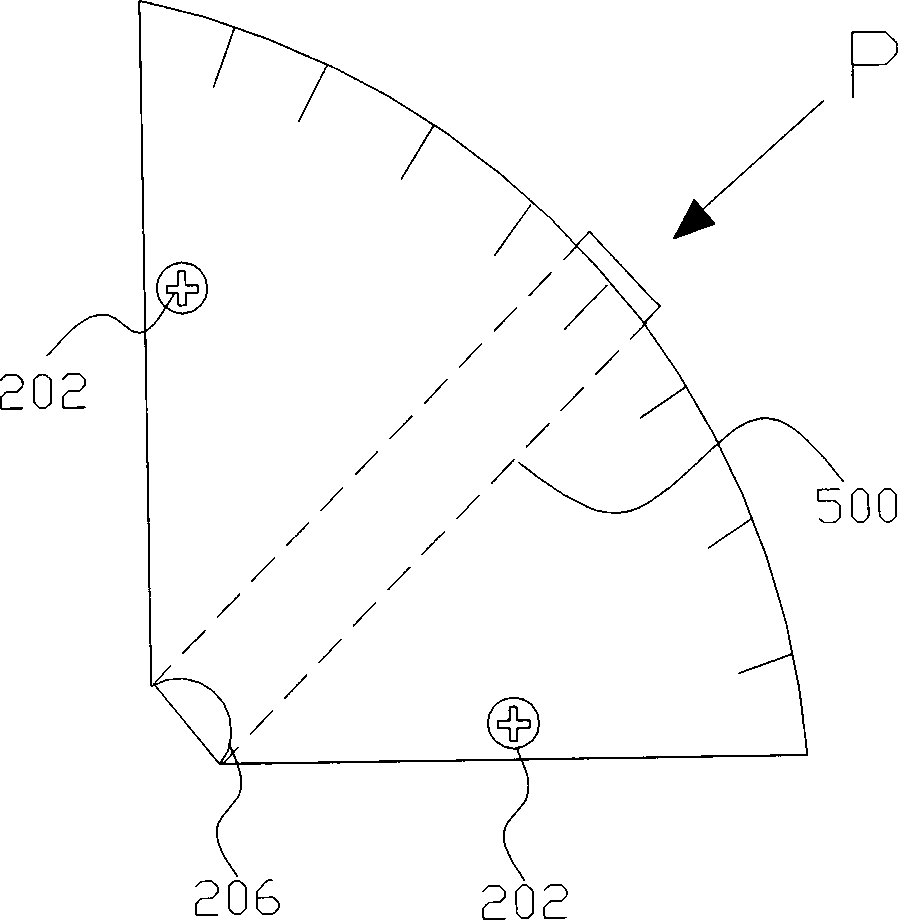

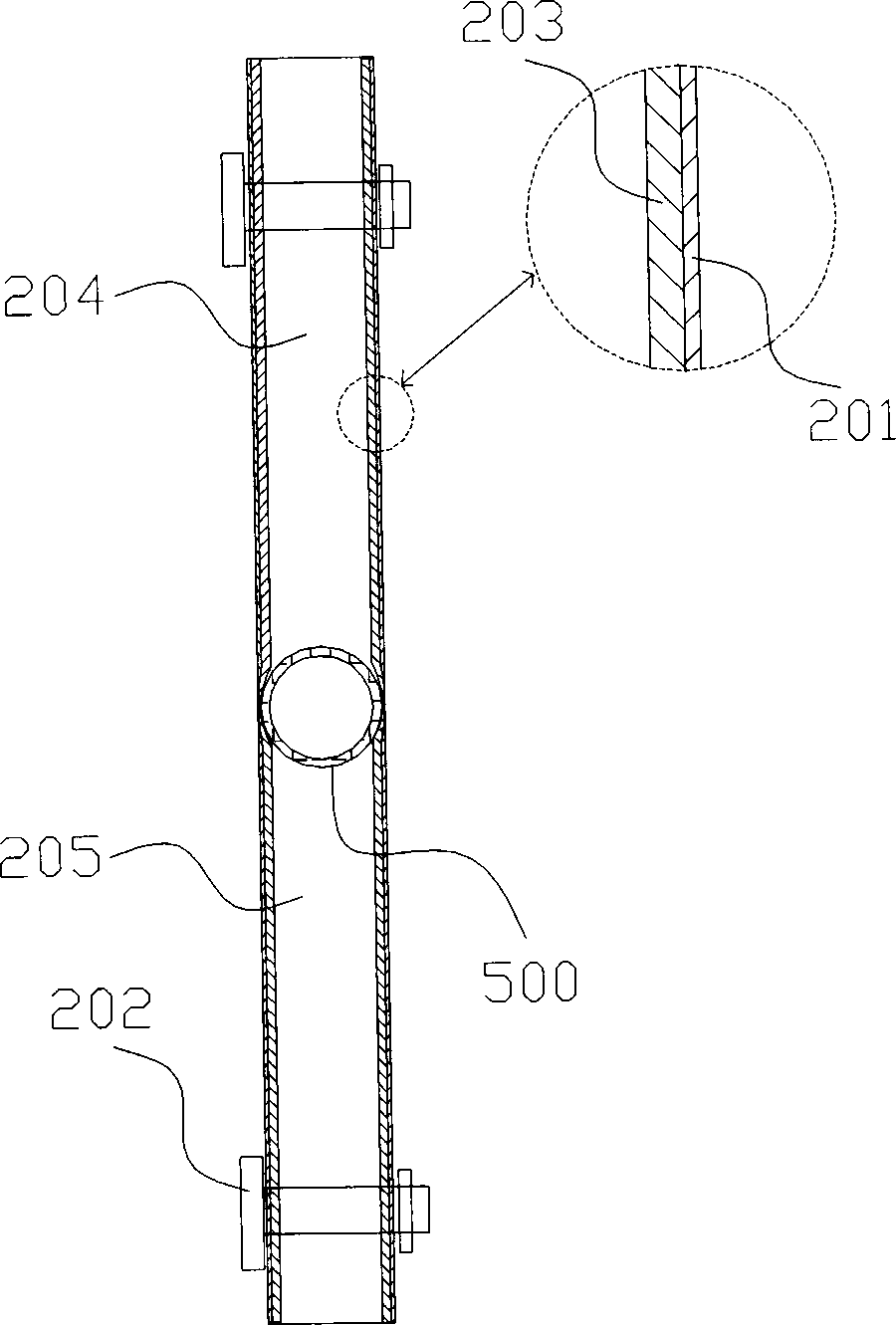

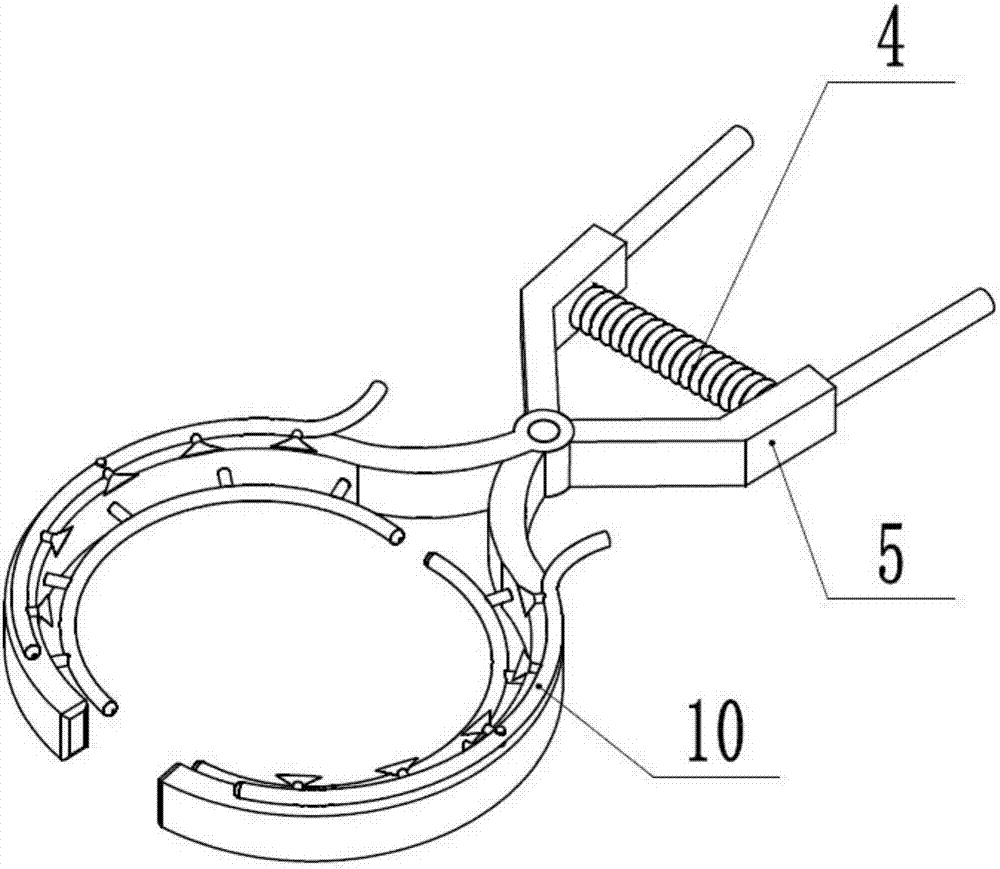

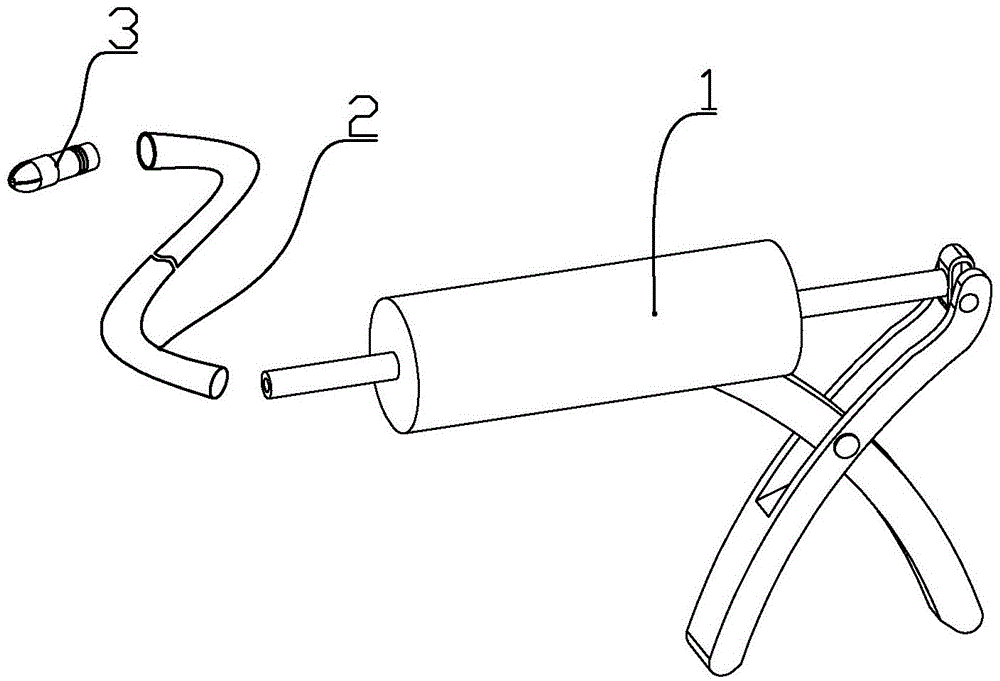

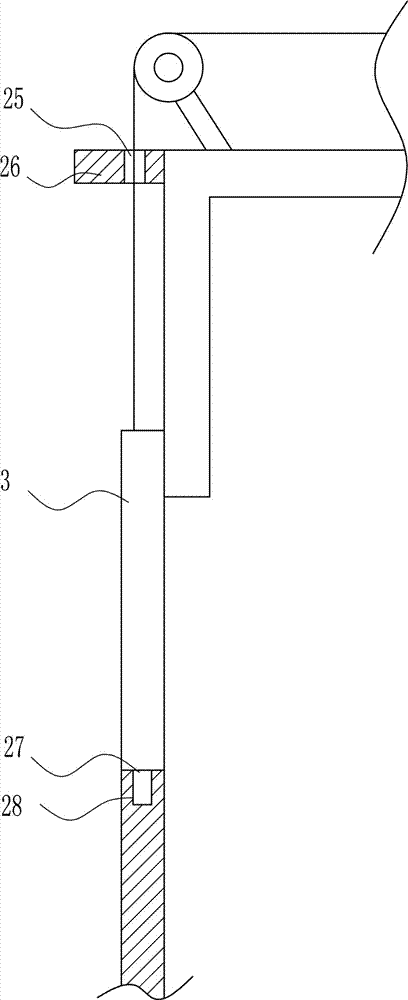

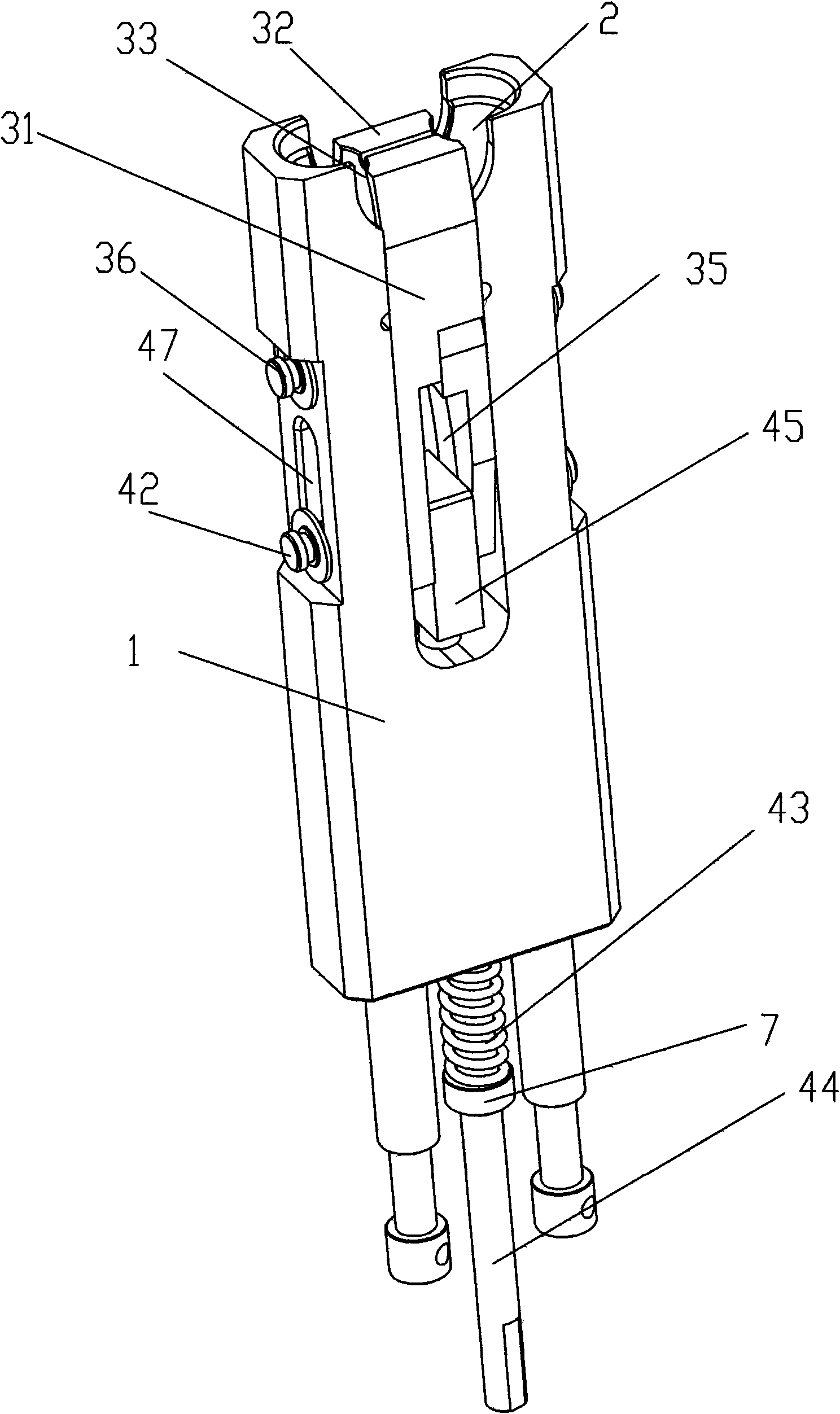

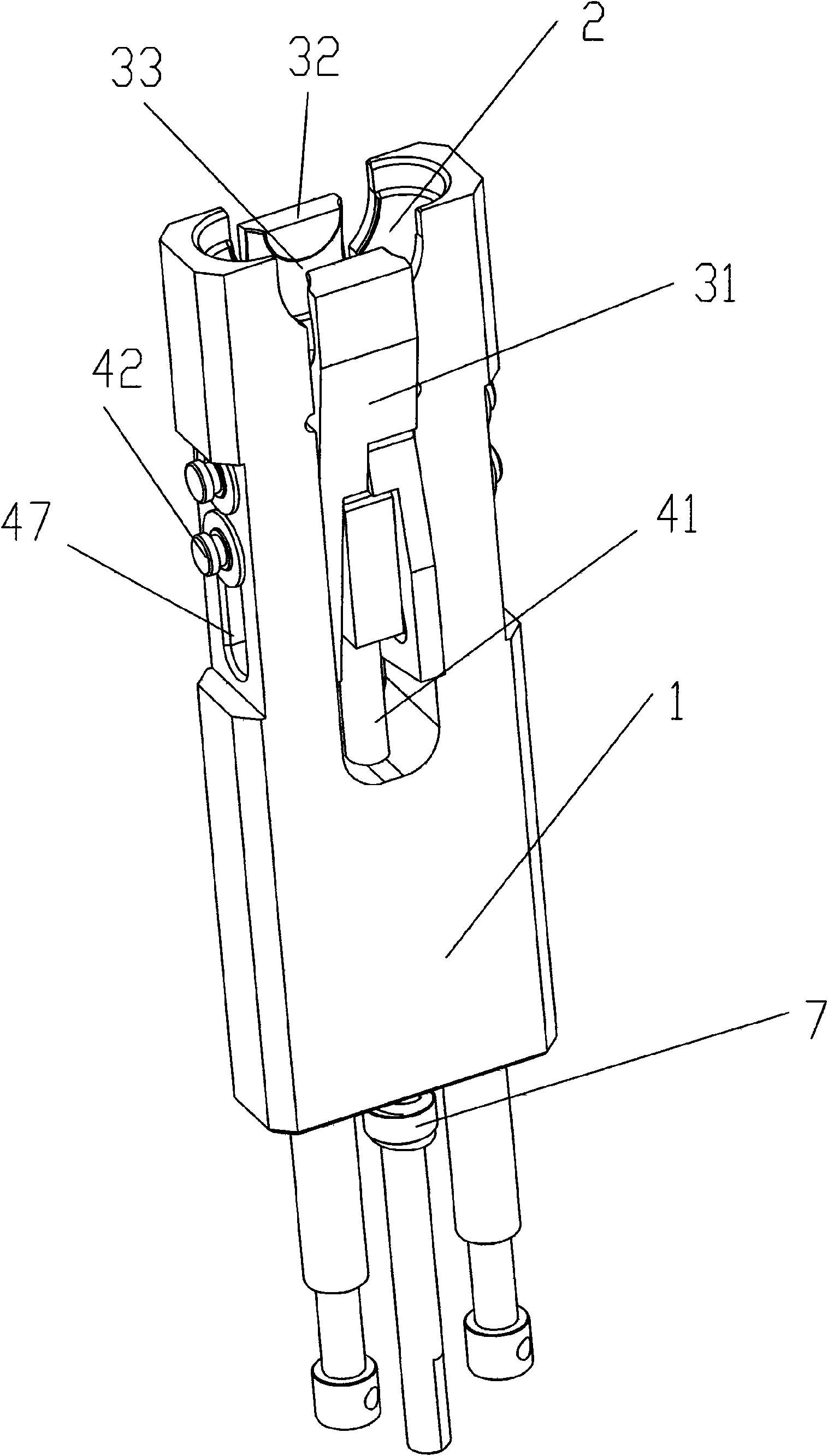

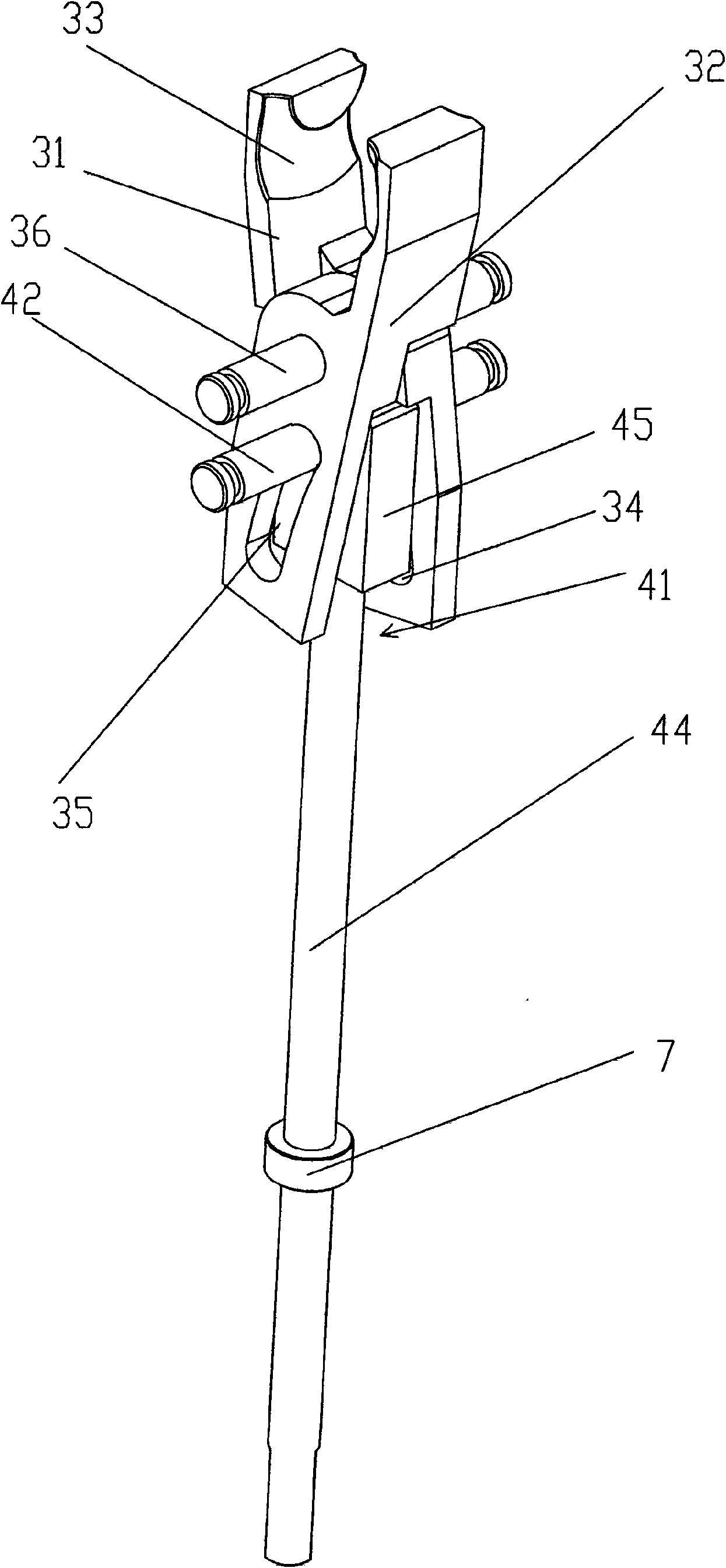

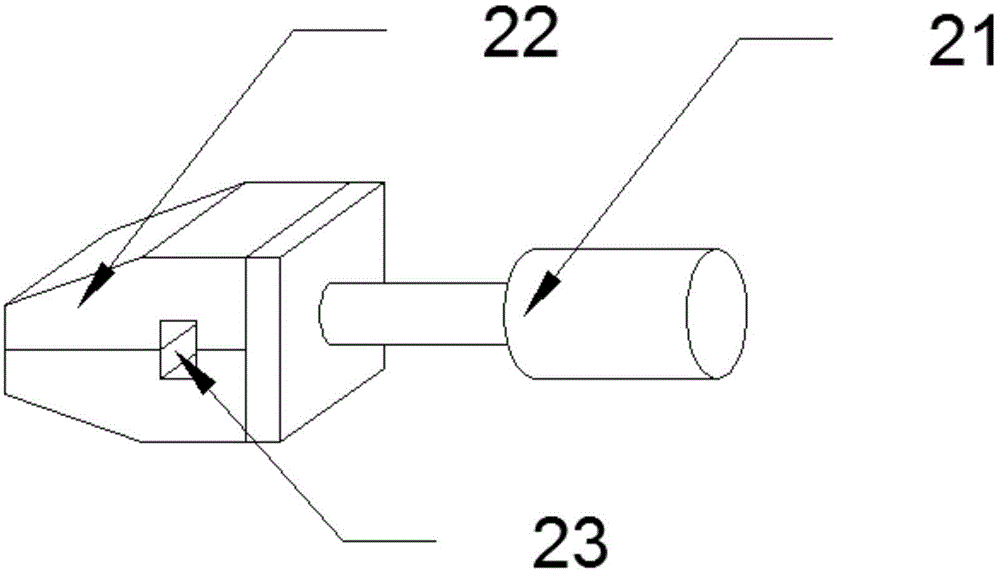

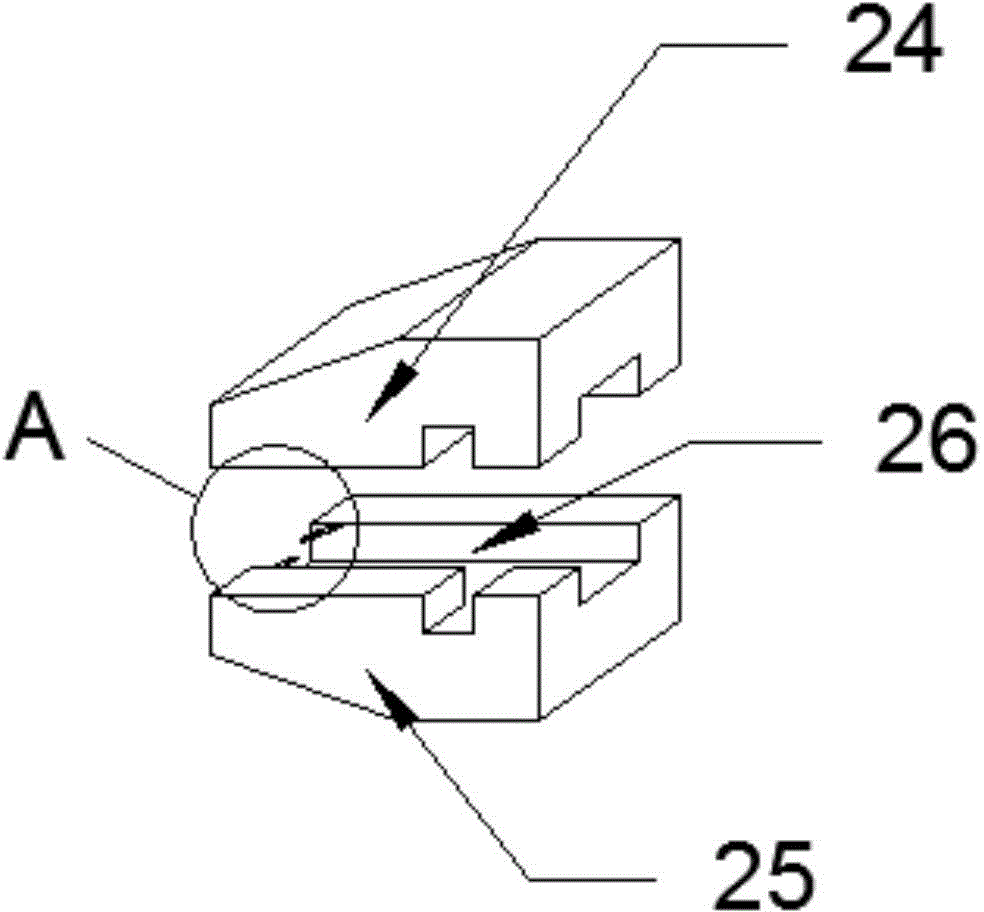

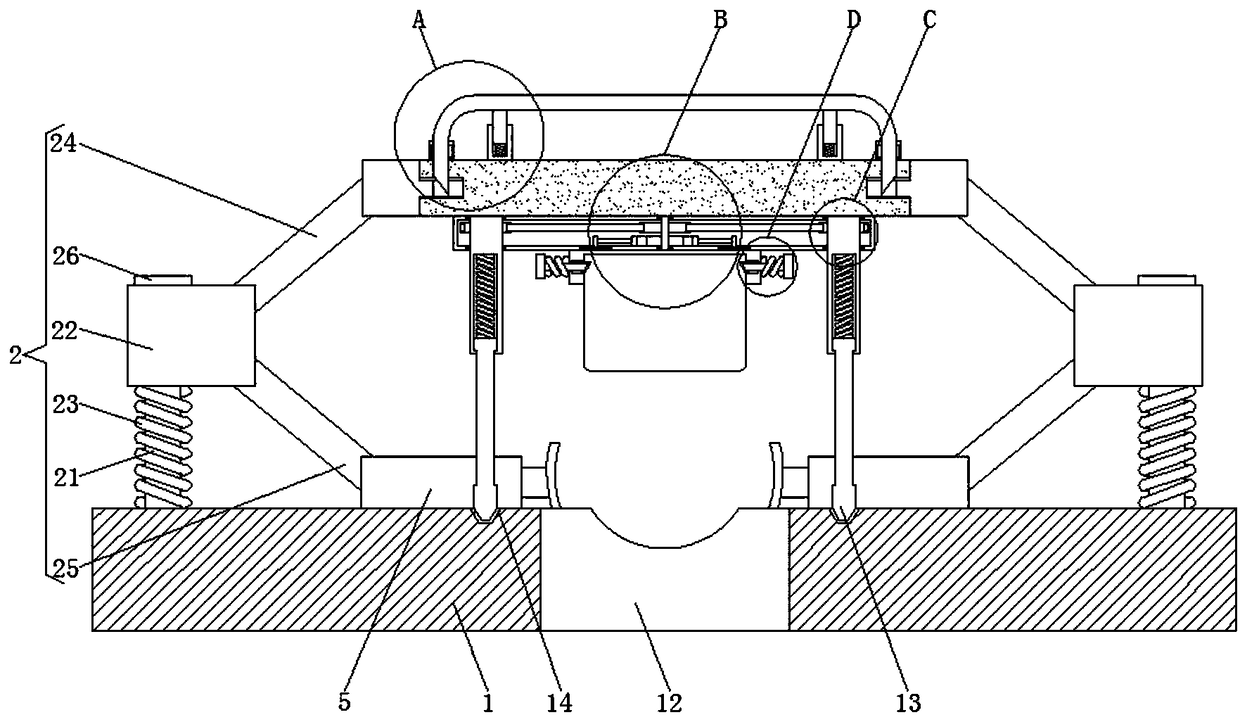

Ultrasound-guided out-of-plane puncture adapter, ultrasound-guided puncture device with same, and corresponding method

InactiveCN103222897AAchieve fixed positionNo angular shiftDiagnosticsSurgical needlesEngineeringOut of plane

The invention relates to the technical field of out-of-plane puncture, and discloses an ultrasound-guided out-of-plane puncture adapter which is mounted on an ultrasonic probe. The adapter comprises a first fixing device mounted on the ultrasonic probe and a second fixing device used for fixing a puncture needle and connected with the first fixing device, wherein the second fixing device corresponds to a center short shaft of the ultrasonic probe and comprises two opposite right-angle fan-shaped clamping pieces and a locking device used for locking the former two; a movable sleeve is arranged between the two right-angle fan-shaped clamping pieces; the puncture needle is arranged in the movable sleeve; and one end of the movable sleeve is arranged at the right-angled vertices of the right-angle fan-shaped clamping pieces, and the other end thereof moves along the circular arcs of the right-angle fan-shaped clamping pieces. The invention further discloses an ultrasound-guided out-of-plane puncture device and a puncture method thereof. According to the invention, the problem that the corresponding puncture adapter is not available in an ultrasound-guided out-of-plane puncture technology is solved, and the application of the ultrasound-guided out-of-plane puncture technology in the clinical medical field is greatly promoted.

Owner:SUZHOU SCI&TECH TOWN HOSPITAL

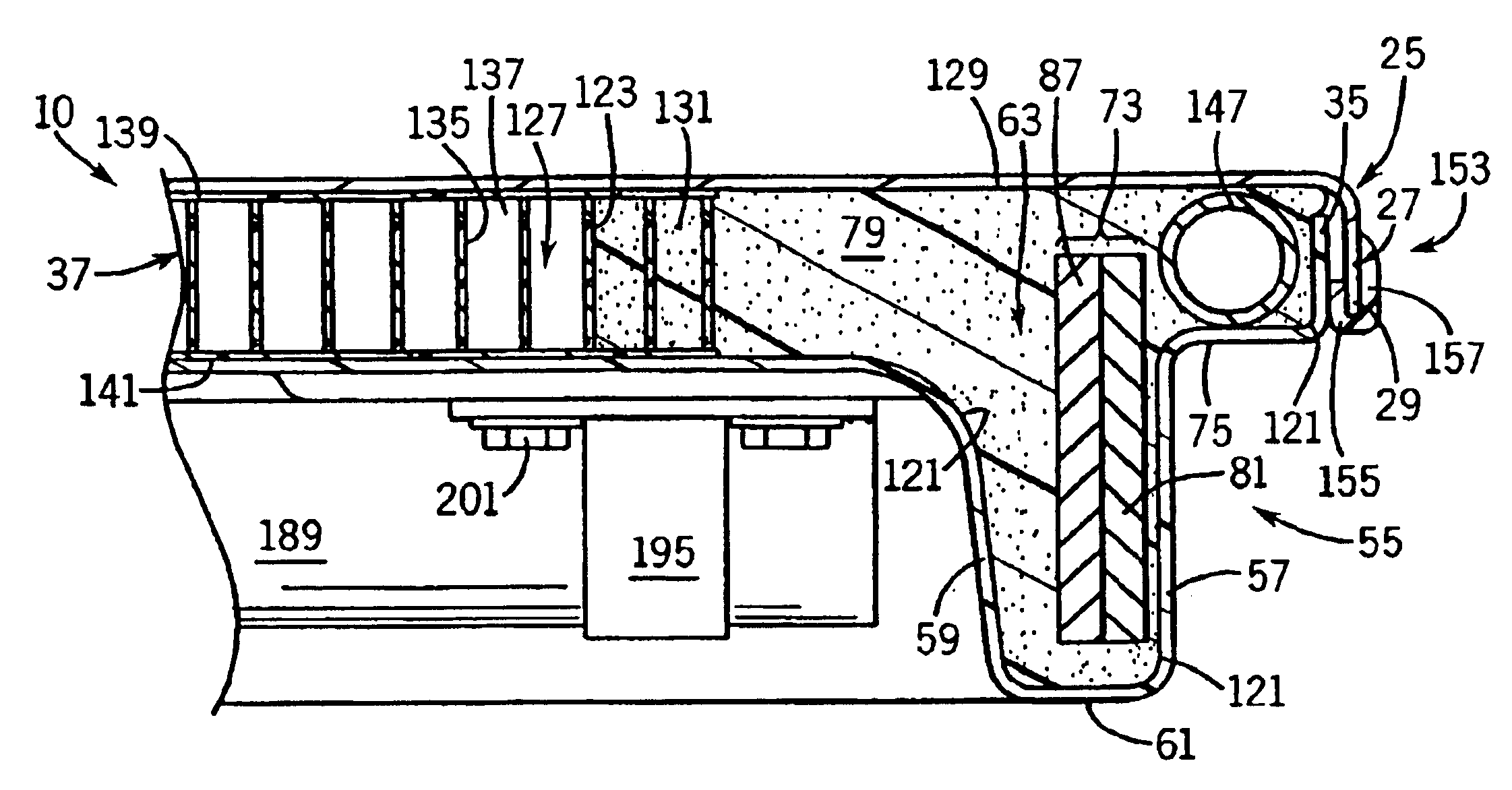

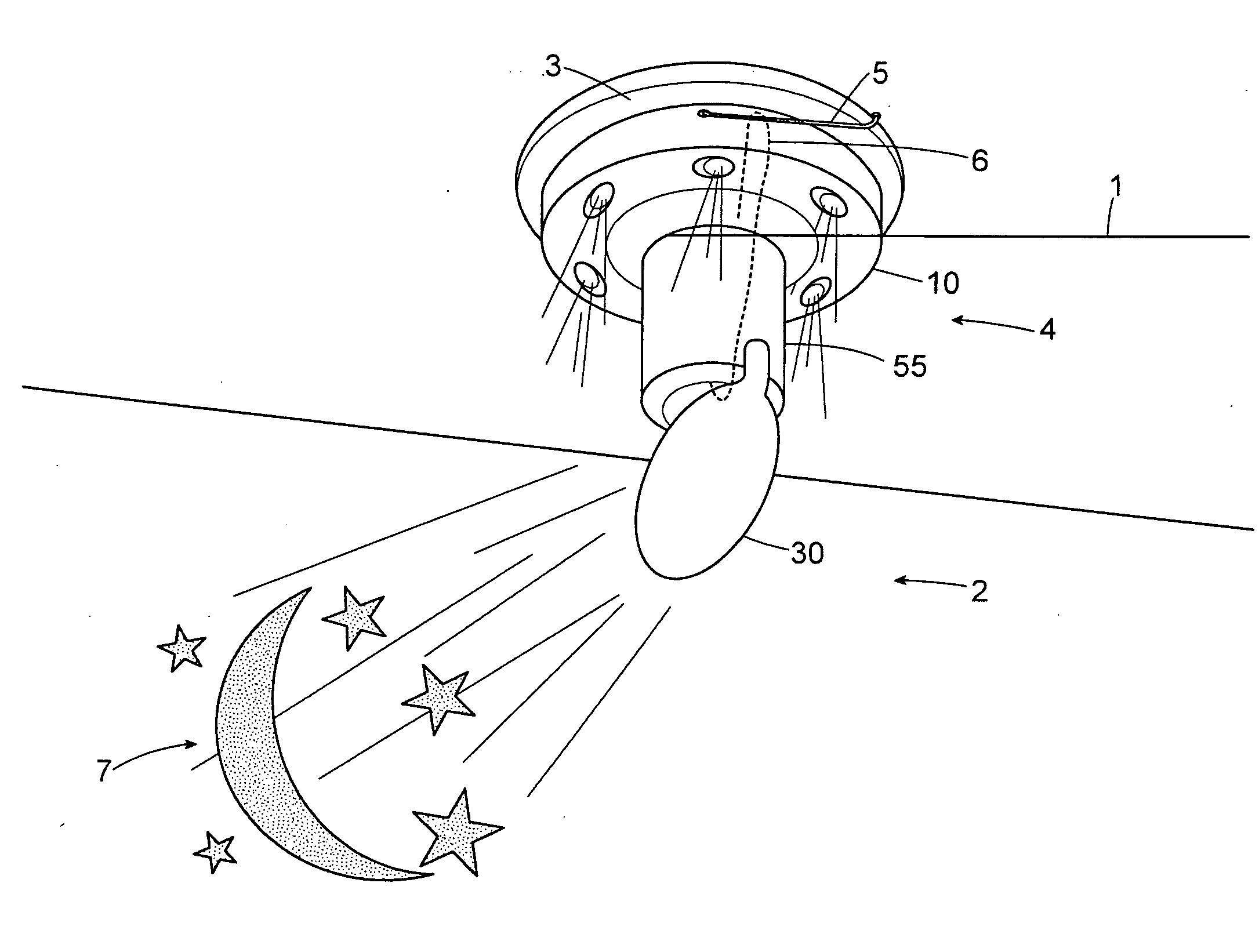

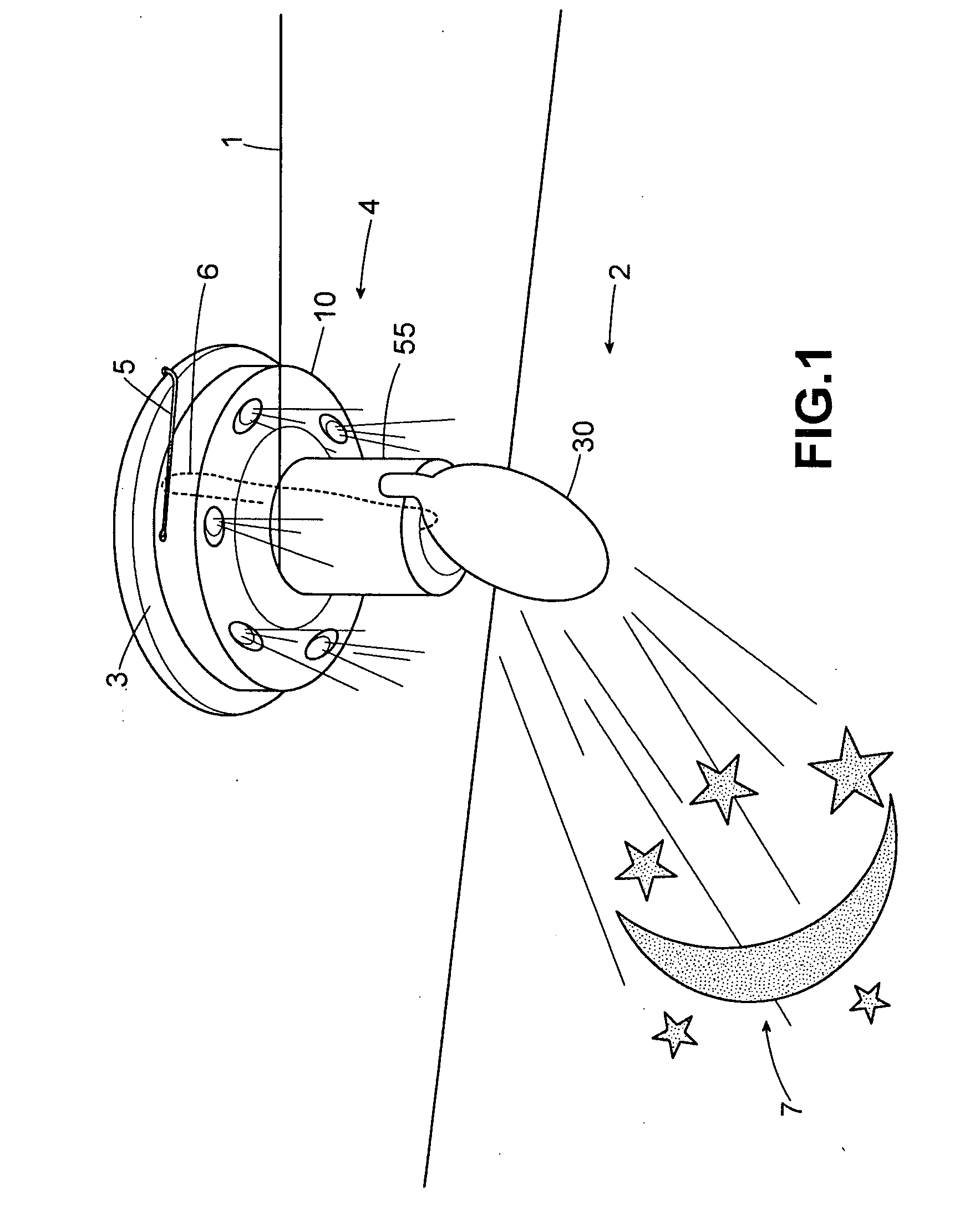

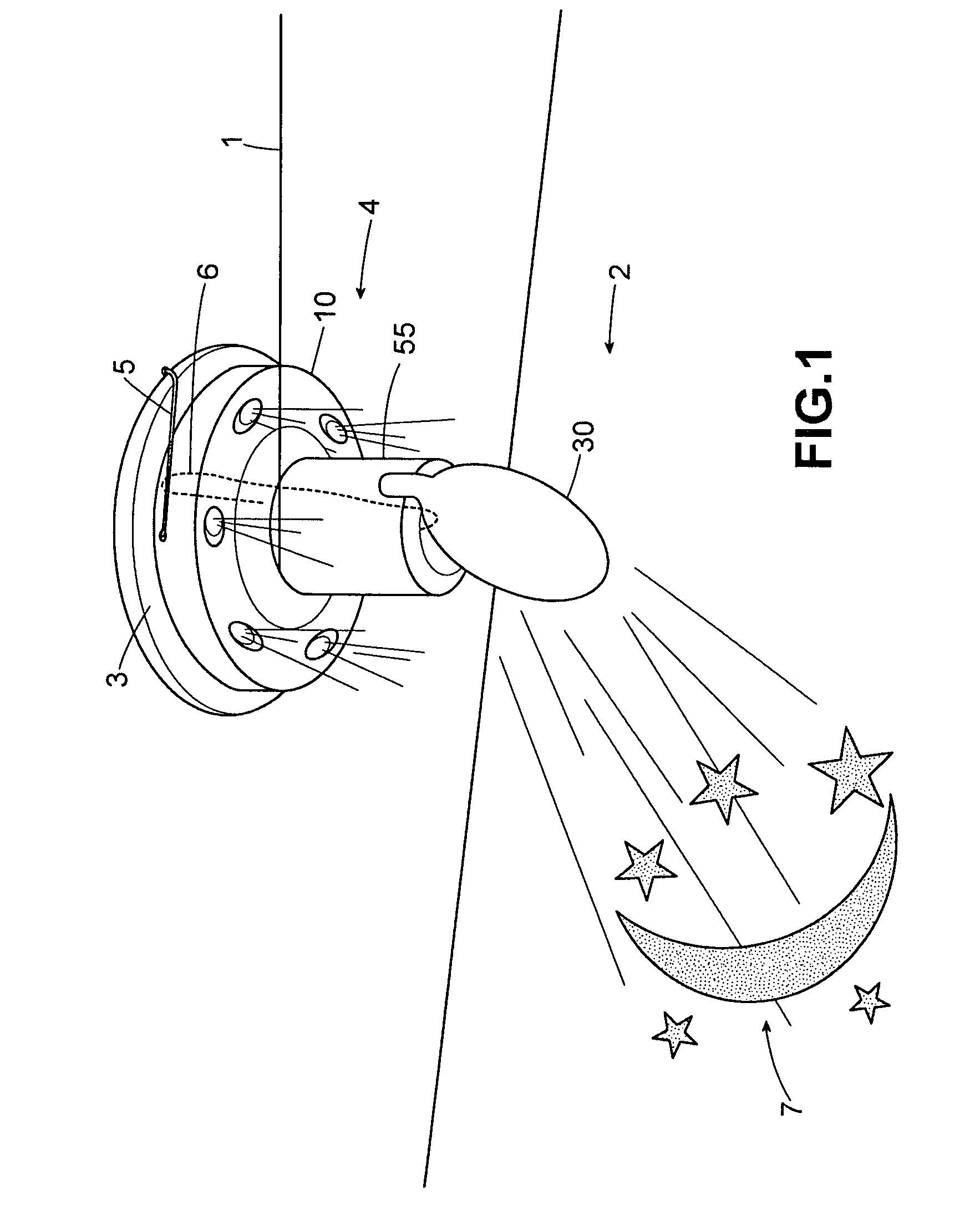

Light projector accessory for recessed lighting fixtures

InactiveUS20070211475A1Easy to disassemblePrevent fallingLighting applicationsMechanical apparatusEffect lightEngineering

A light projector accessory is used in combination with a recessed lighting fixture. The accessory includes one or more lenses, one or more gobo templates, a suitable attachment for the accessory to be attached to a recessed light fixture, and a focusing mechanism for the projected image from the gobo.

Owner:TRIPAR

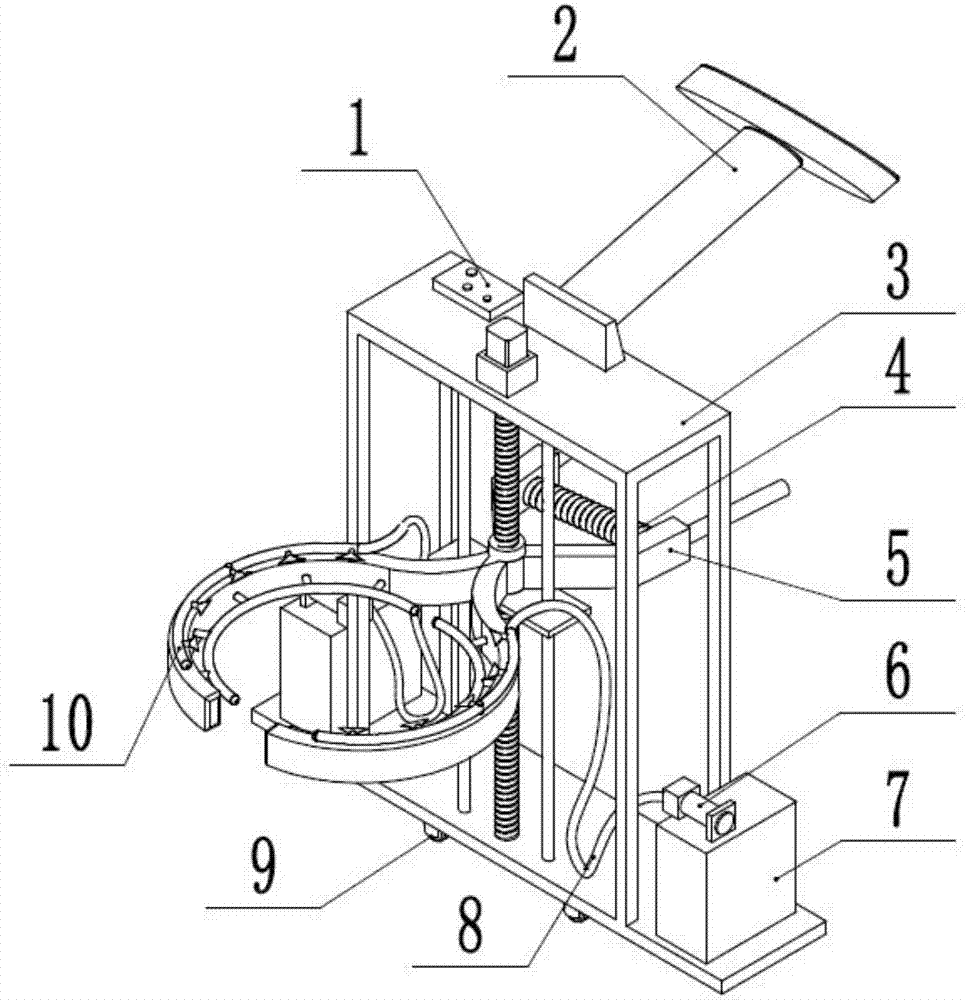

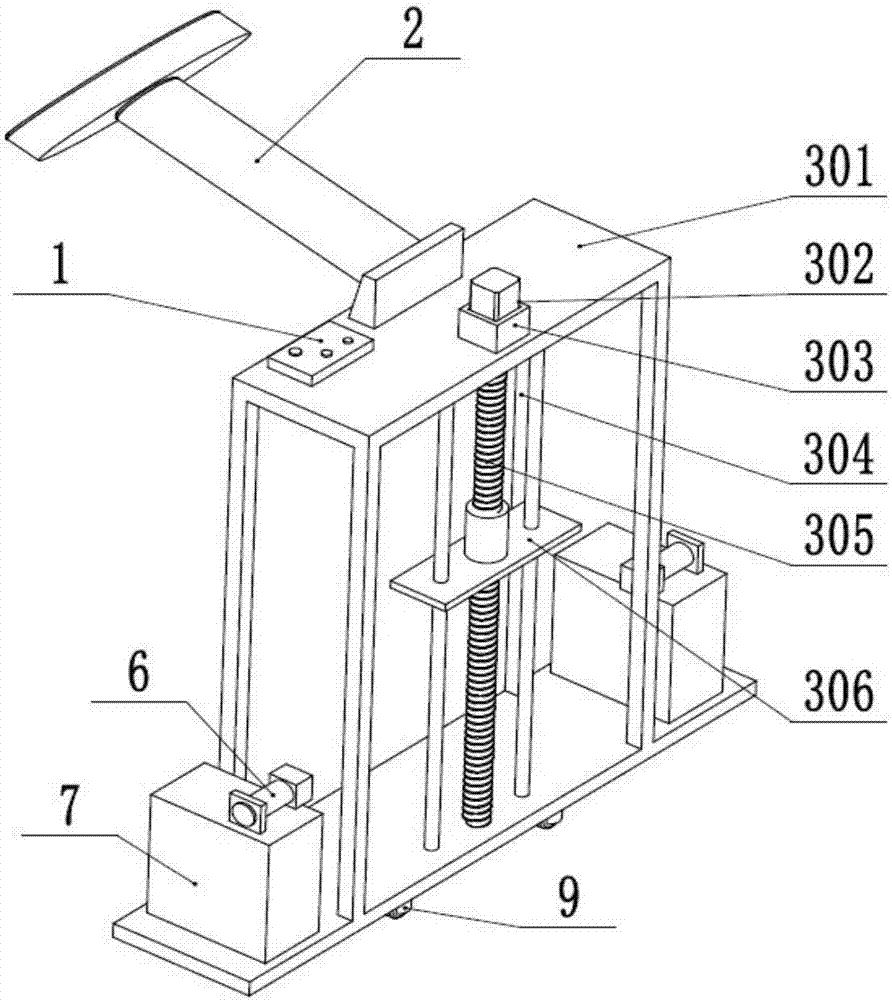

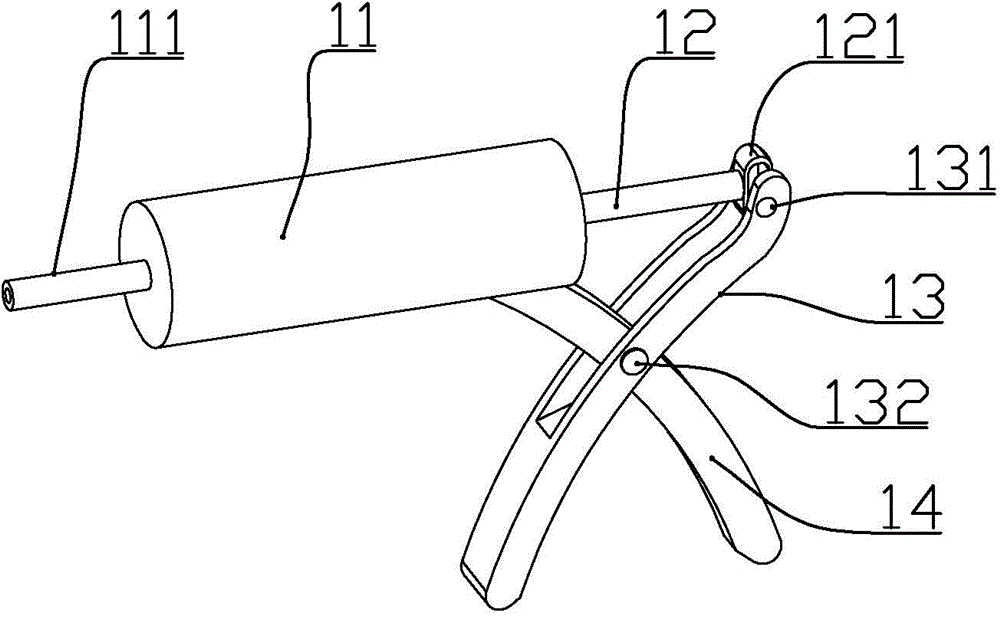

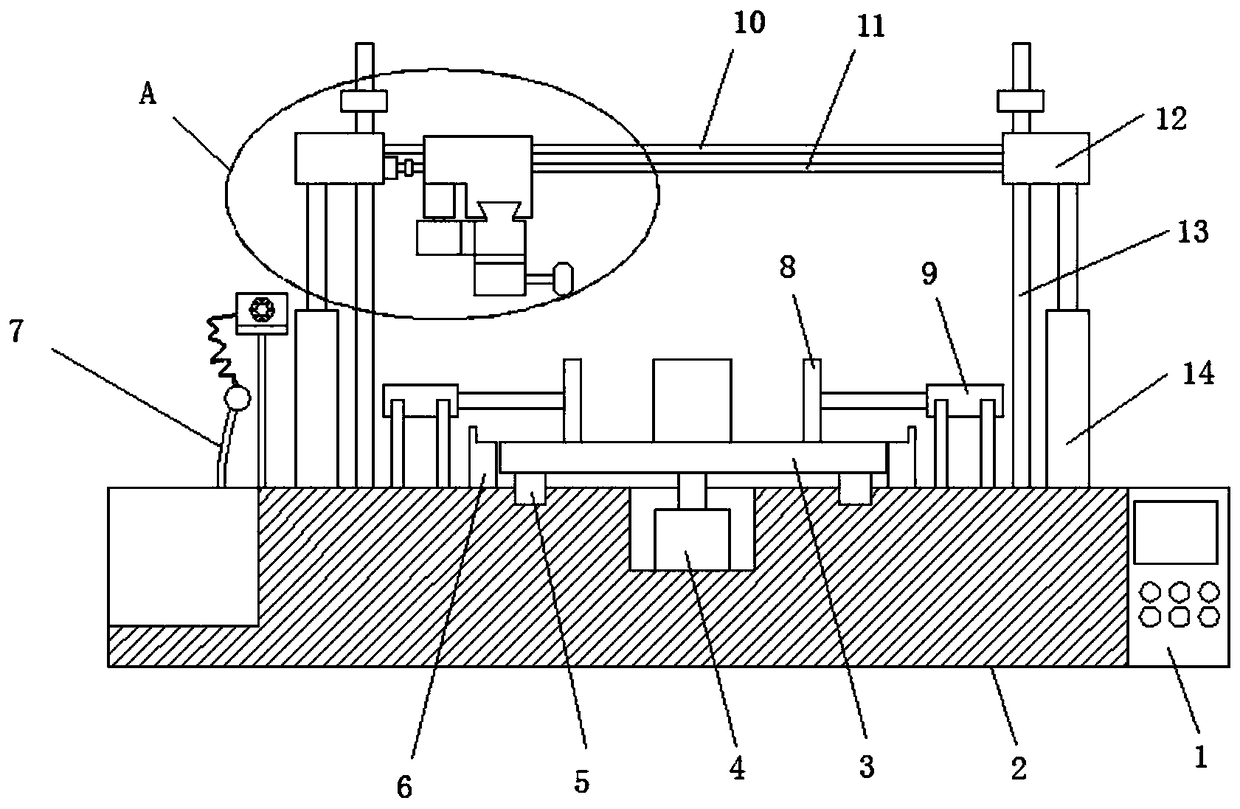

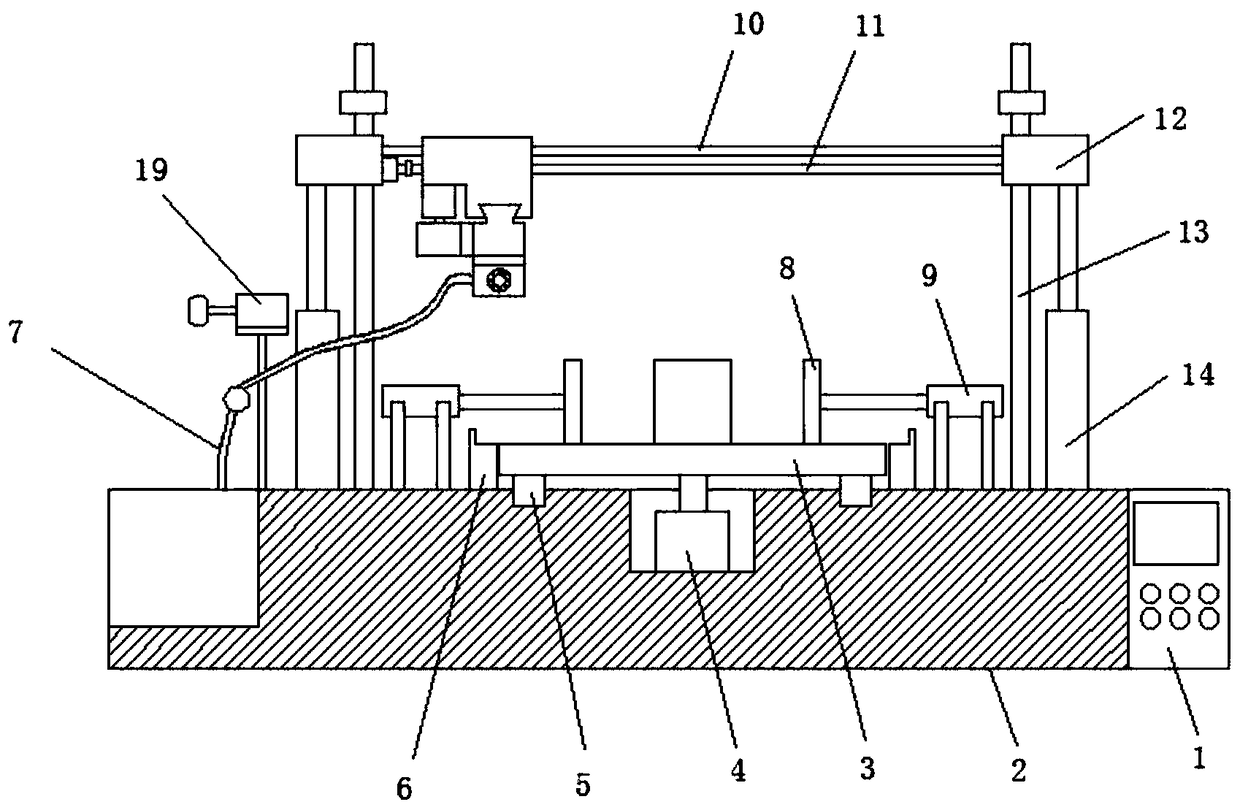

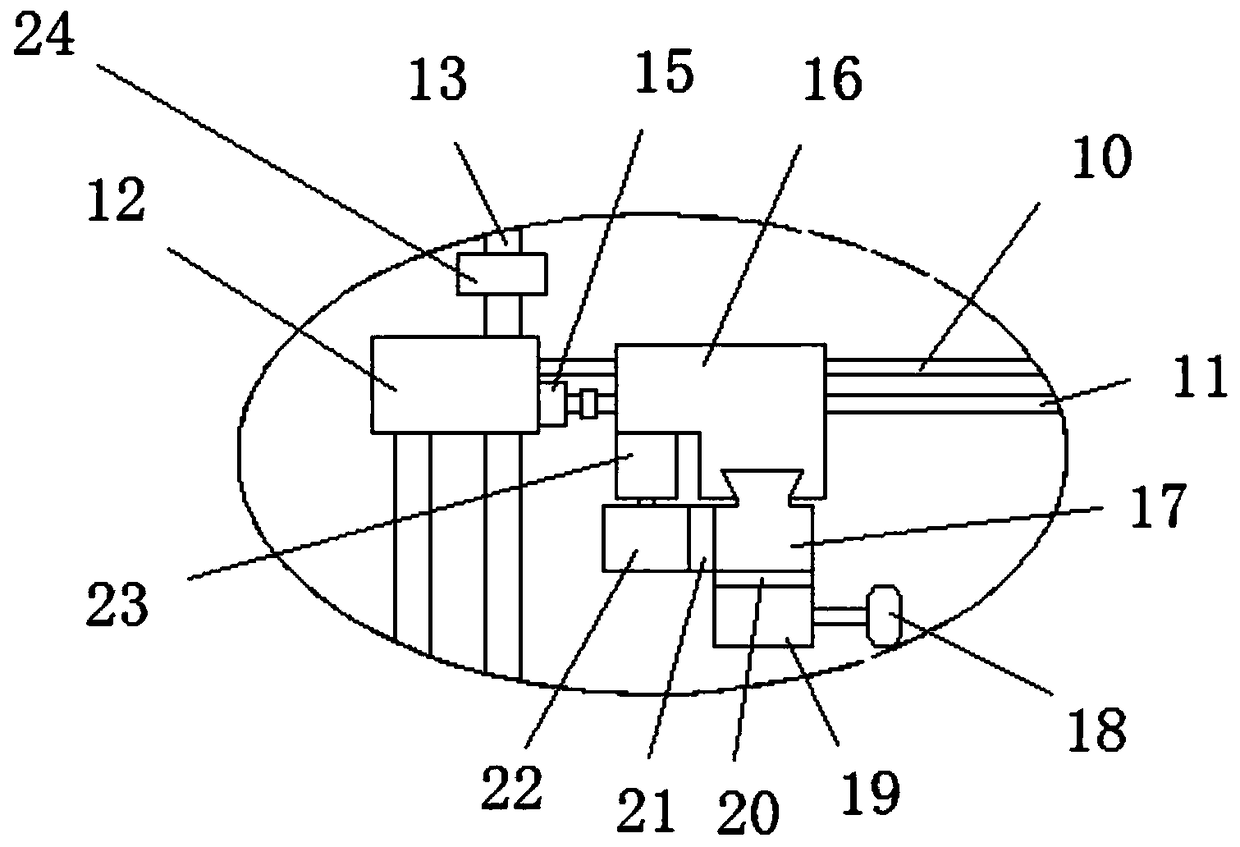

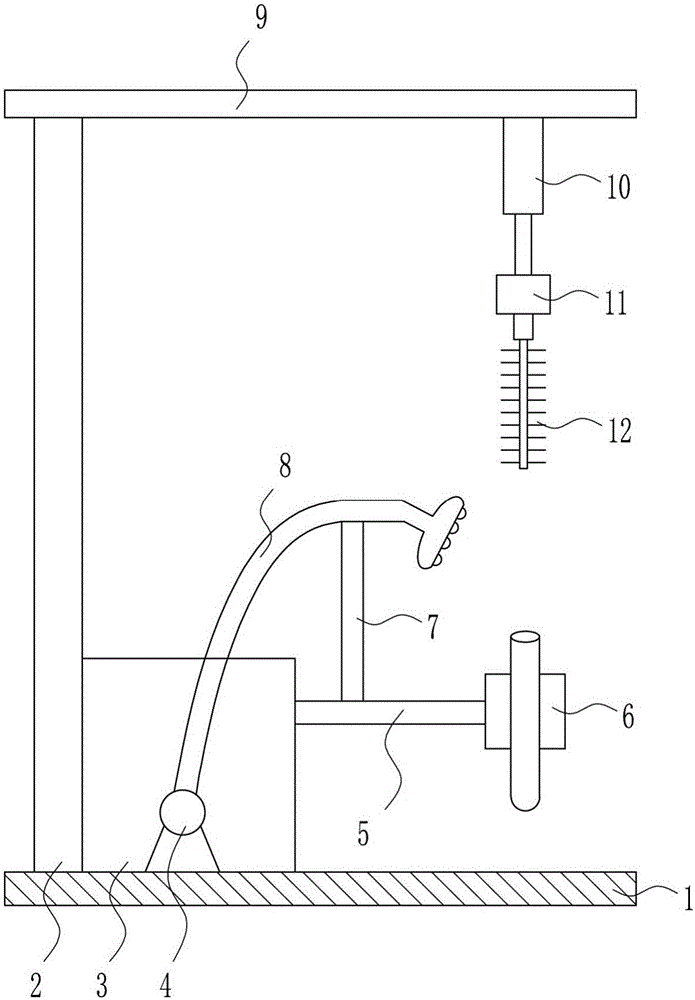

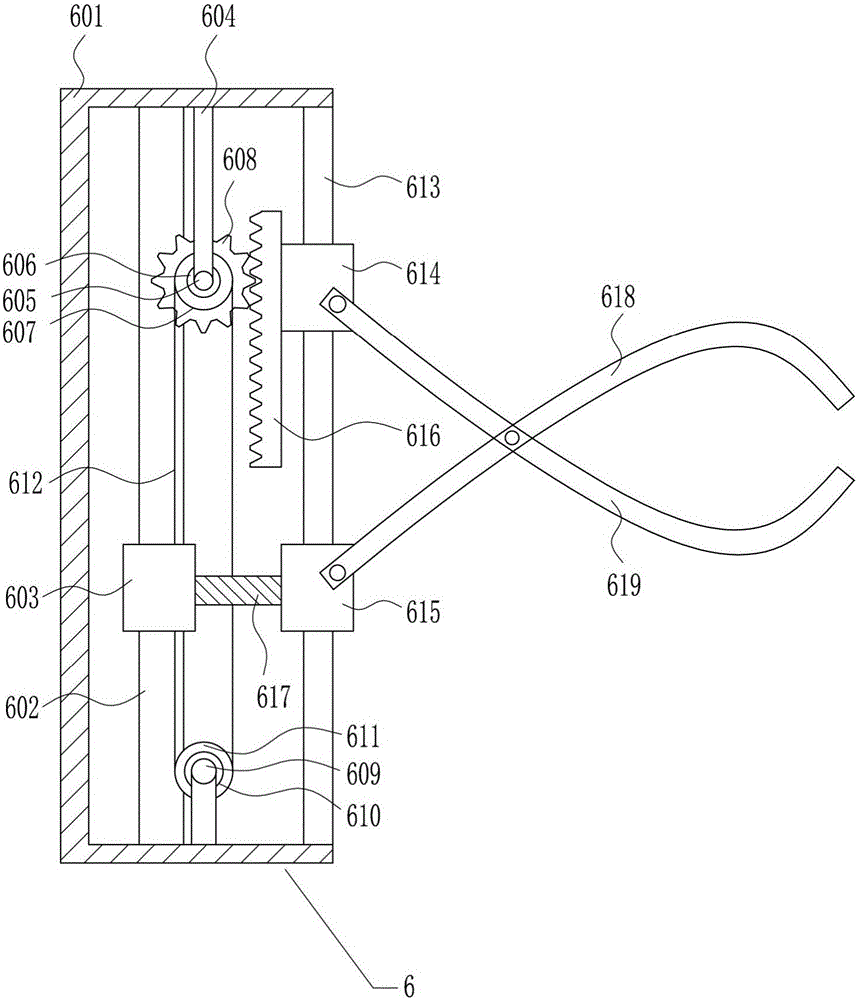

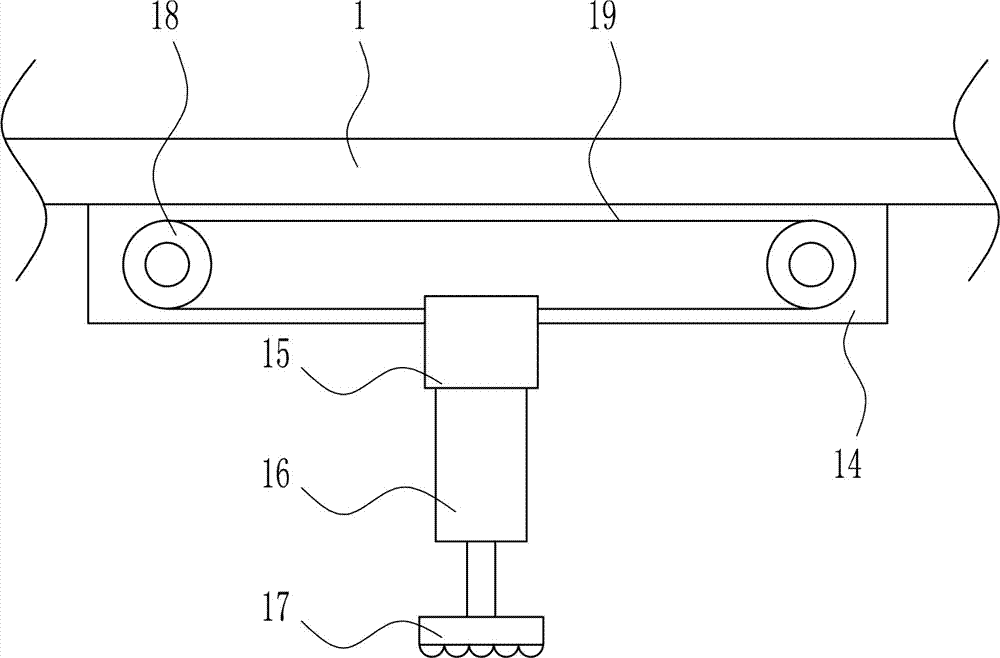

Tree trunk whitewashing equipment

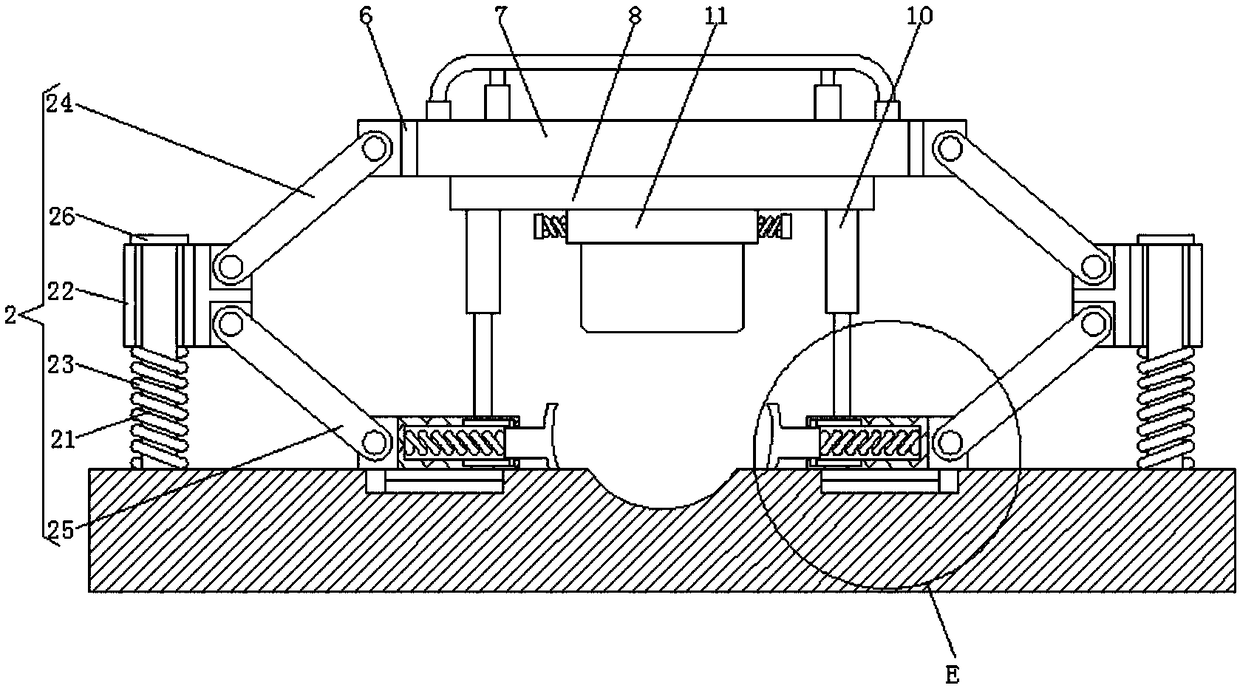

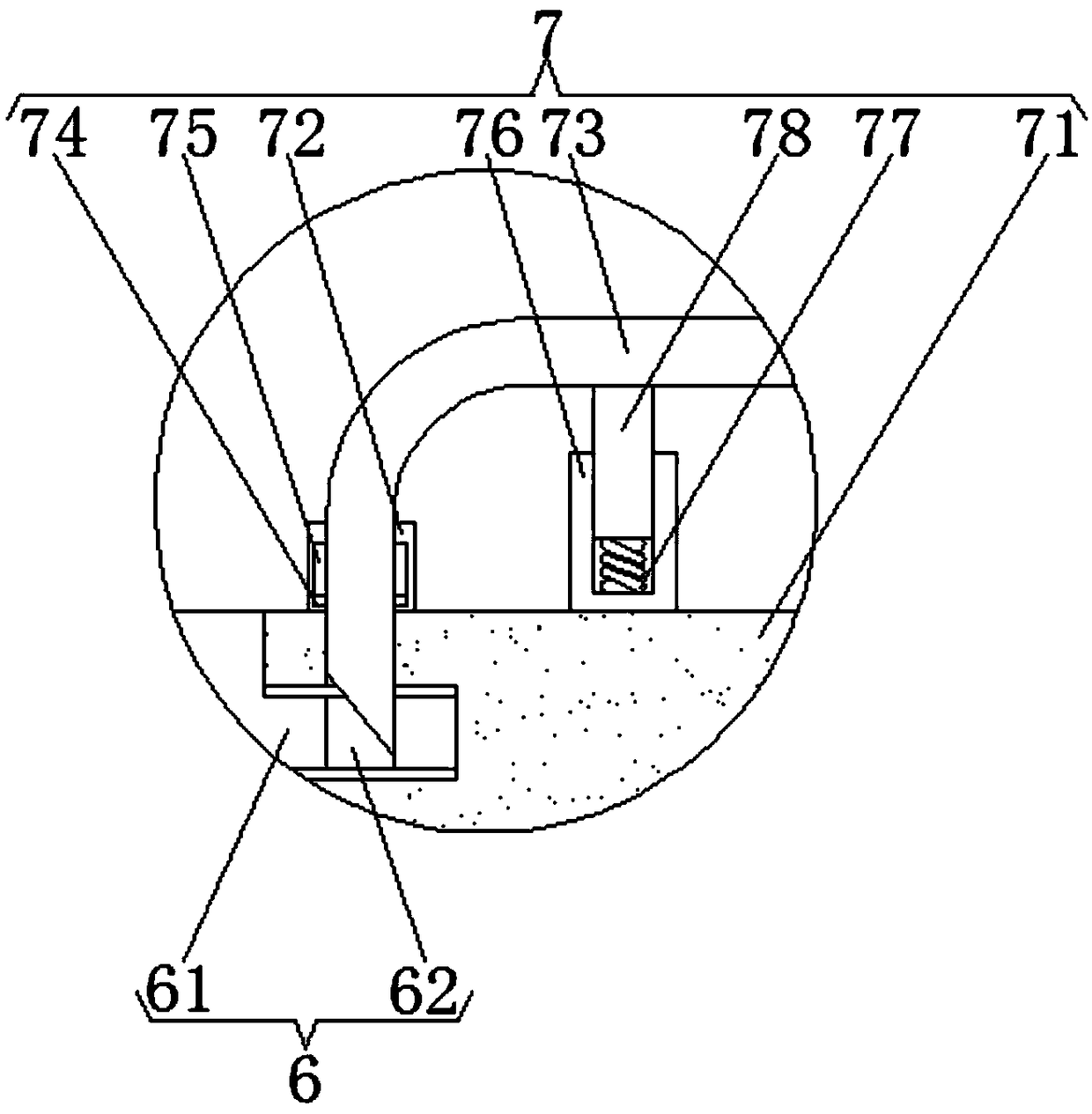

ActiveCN107138329AImprove work efficiencyEasy to clipLiquid spraying apparatusPlant protectionTree trunkSemi automatic

The invention discloses tree trunk whitewashing equipment, and belongs to the field of agricultural machinery. The tree trunk whitewashing equipment consists of a control box, a handle, a lifting structure, a compression spring, spraying frames, coating pumps, coating boxes, conveying pipes, universal wheels, and nozzle and spraying pipe combined structures. The tree trunk whitewashing equipment is characterized in that the control box and the handle are positioned at the upper part of the lifting structure; the universal wheels are mounted at the bottom of the lifting structure; the coating pumps and the coating boxes are positioned on a baseplate at the lower part of the lifting structure; the nozzle and spraying pipe combined structures are mounted on the spraying frames; the coating pumps are separately connected with the coating boxes and the nozzle and spraying pipe combined structures through the conveying pipes; and the compression spring is positioned at the tail ends of the two spraying frames. The equipment realizes semi-automatic trunk whitewashing through such structures as the coating pumps, the spraying frames and the nozzle and spraying pipe combined structures, and greatly improves the working efficiency.

Owner:海光建设集团有限公司

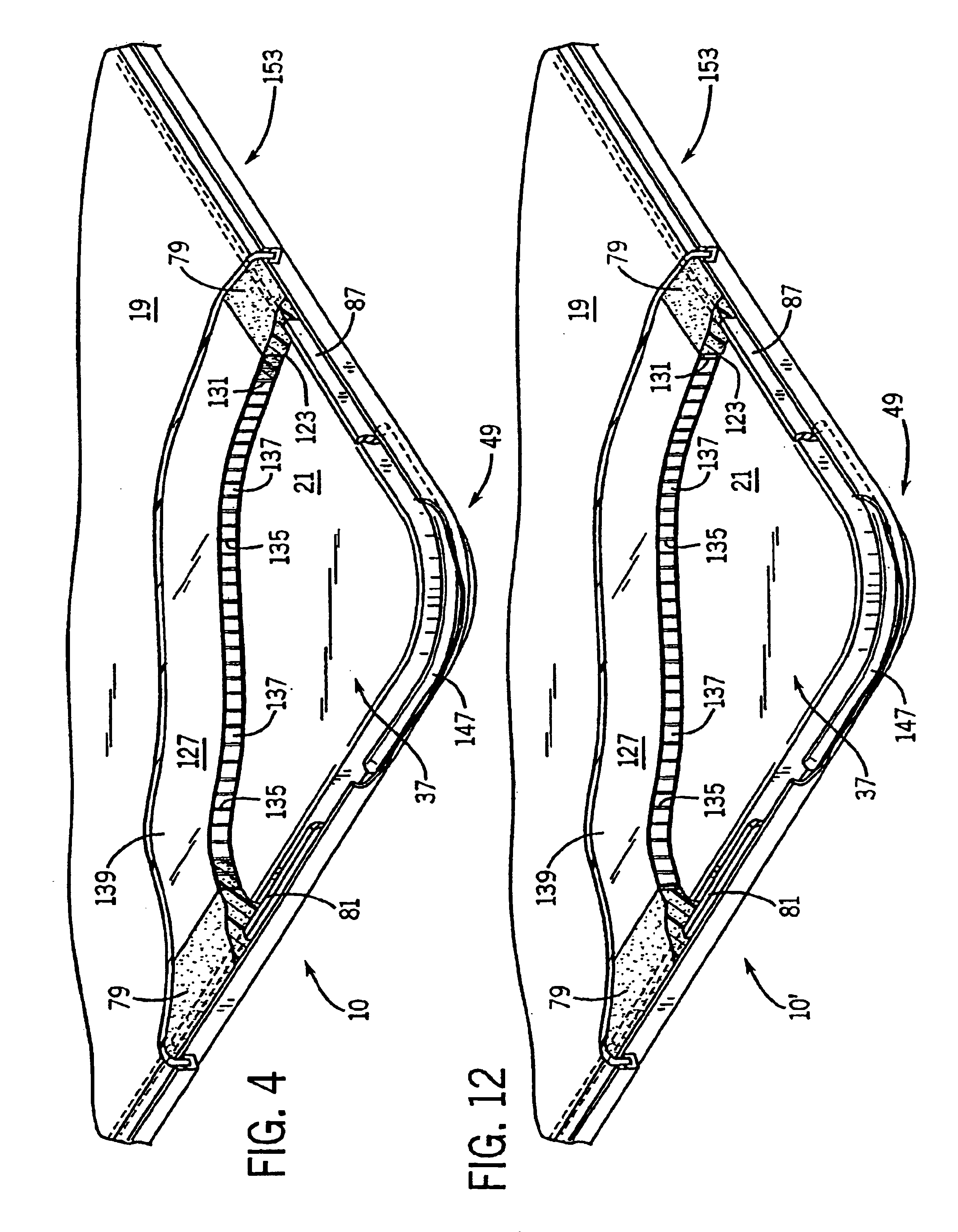

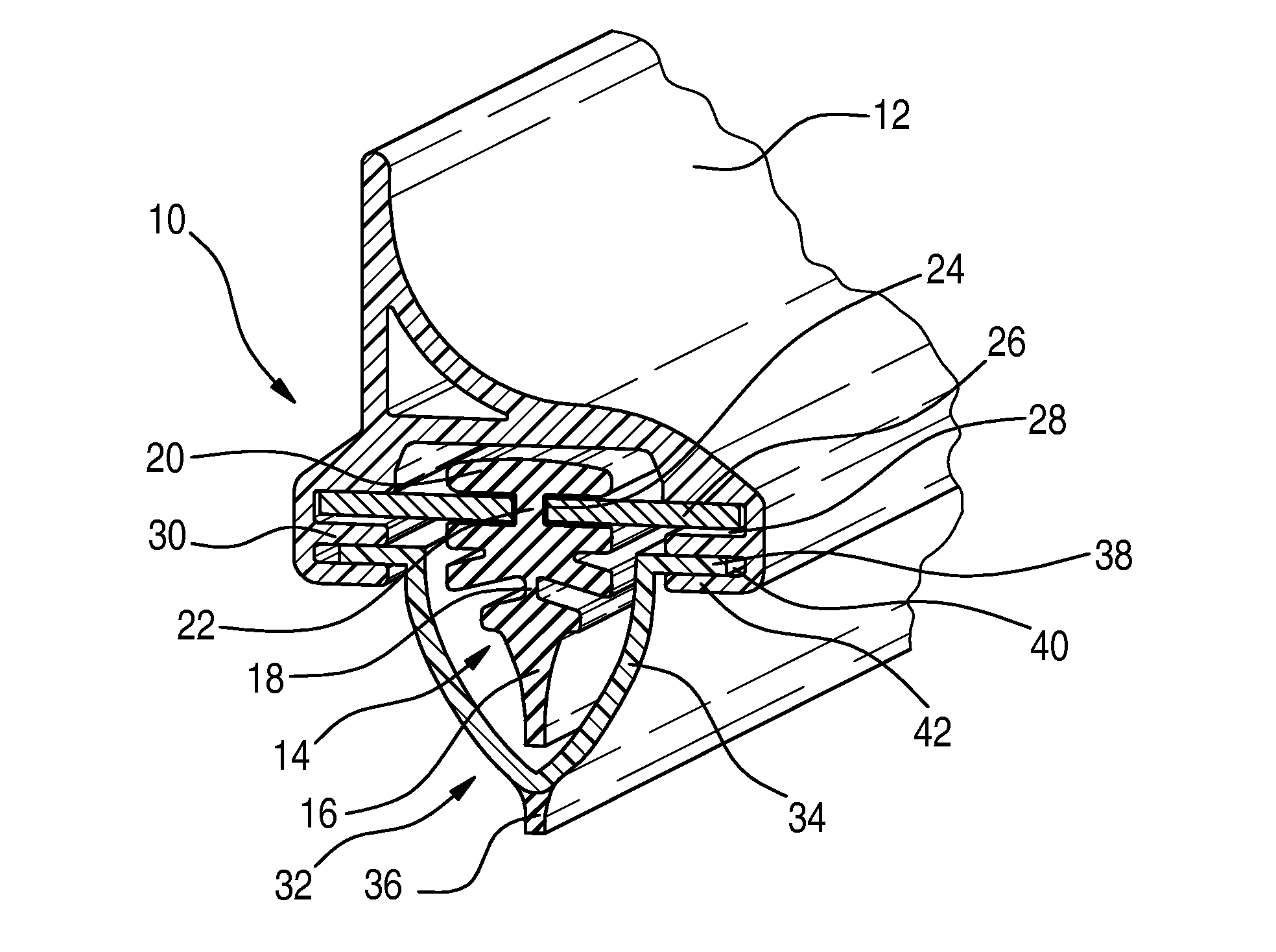

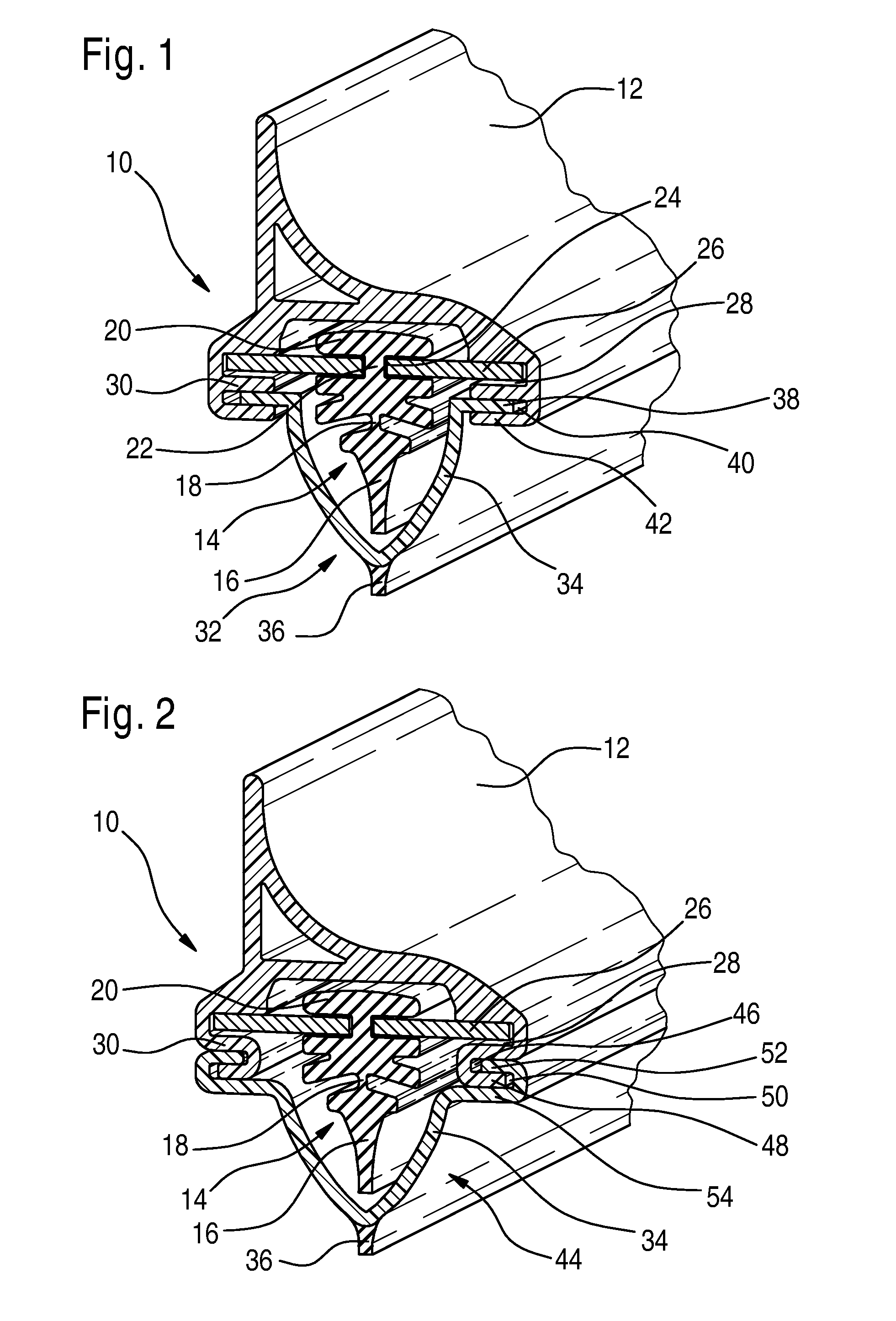

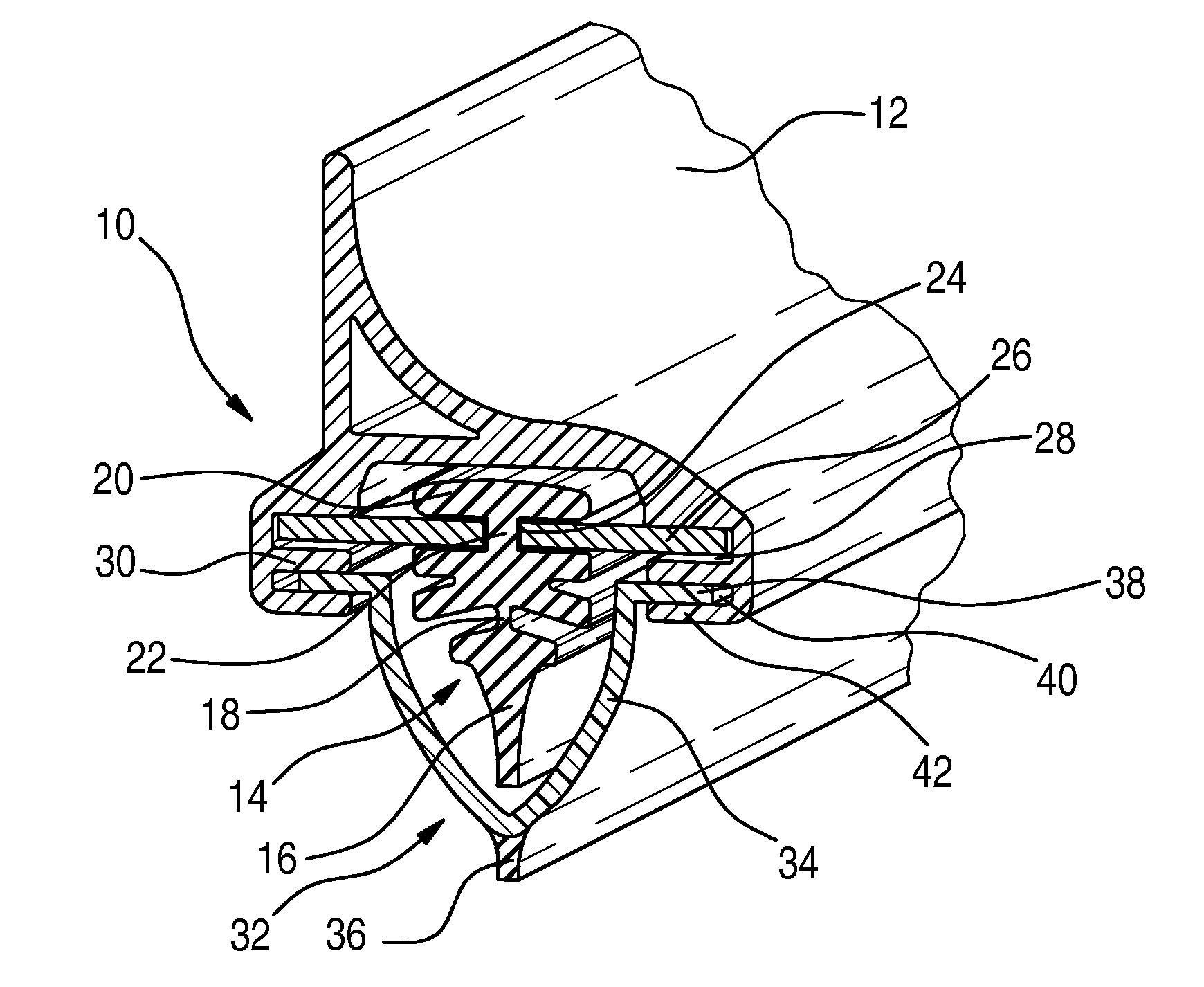

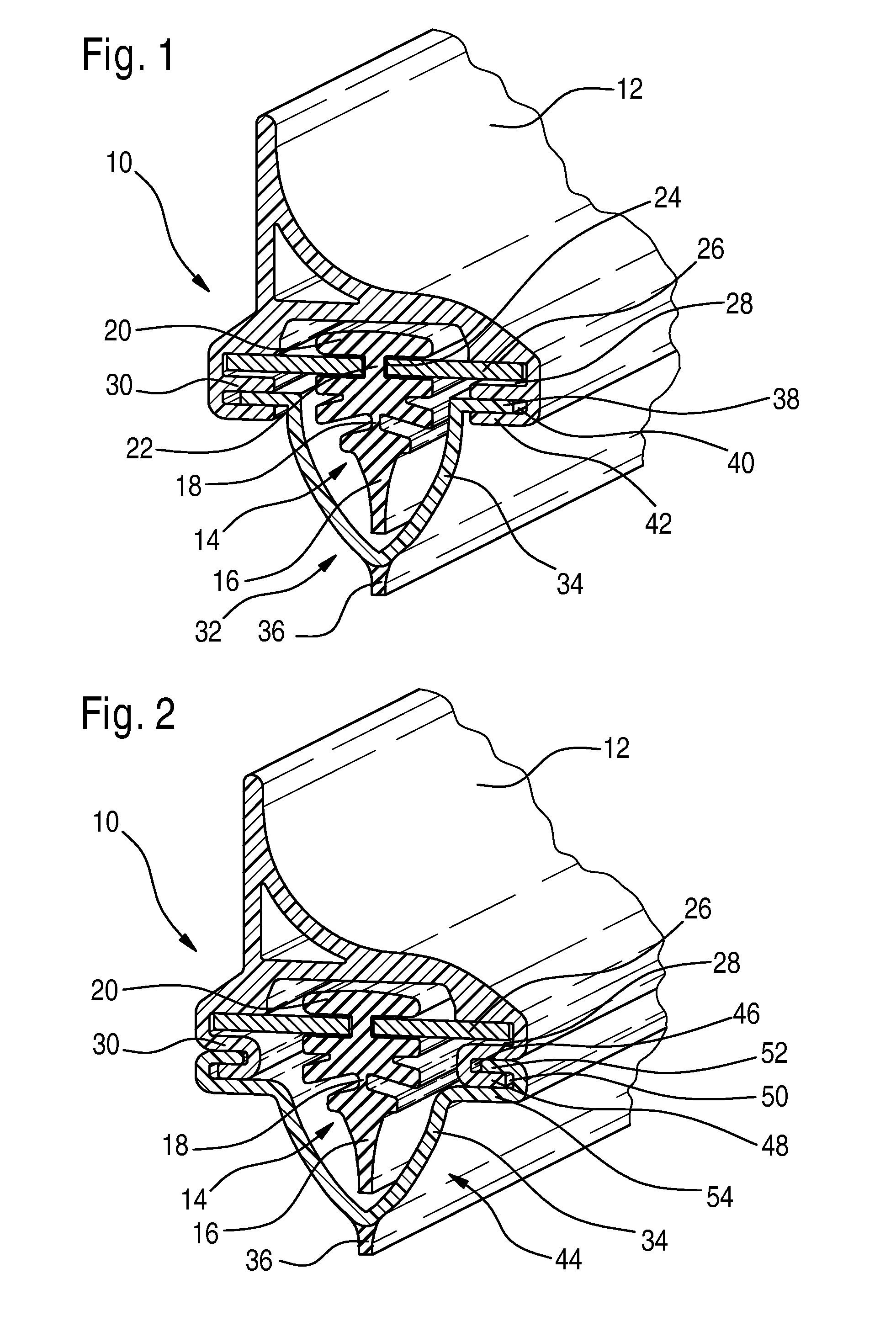

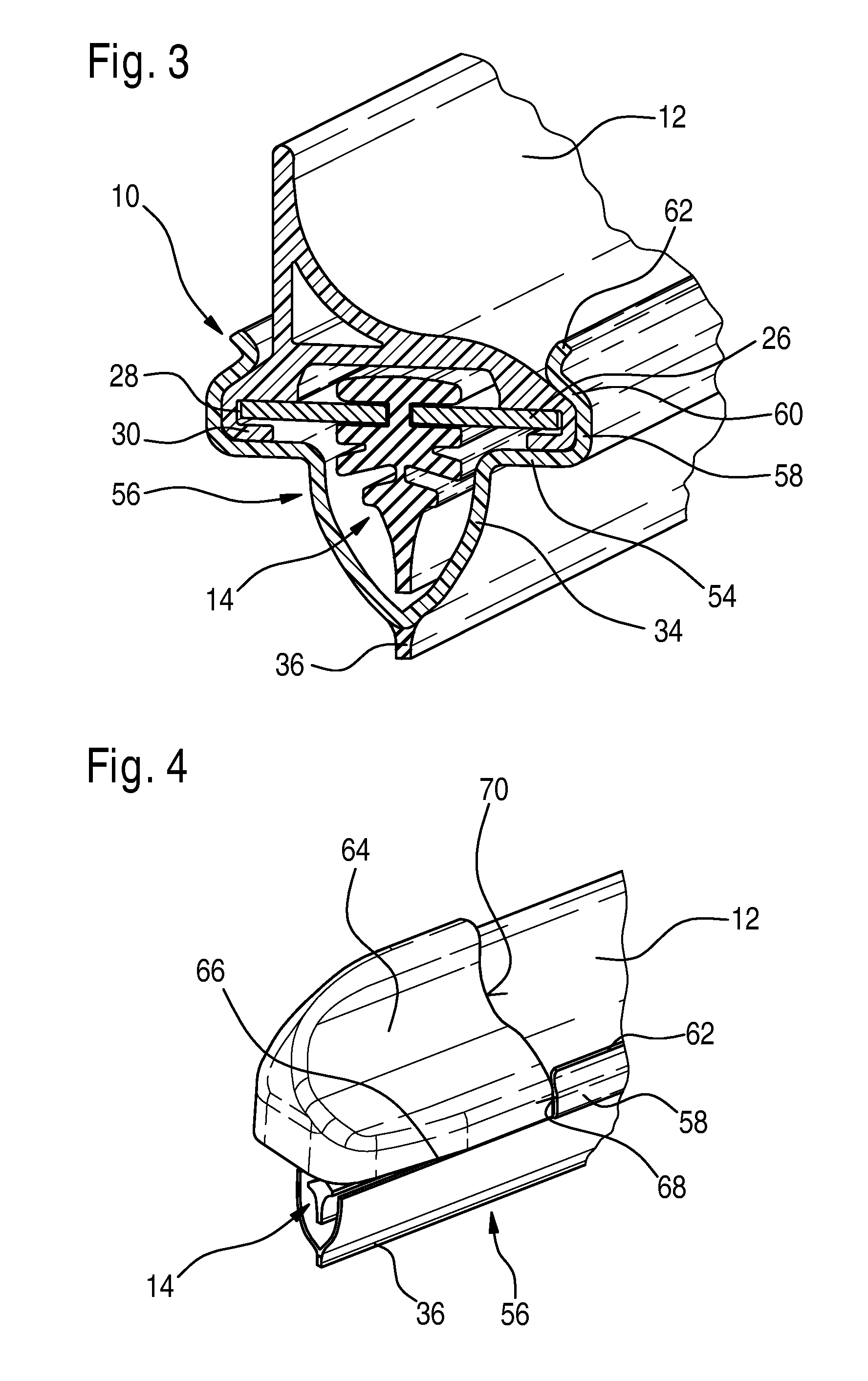

Wiper blade of a windscreen wiper, provided with a protective rail

The invention relates to a wiper blade (10) of a windshield wiper provided with a protective rail (32, 44, 56, 72, 88), comprising a base body (34) that has an essentially V-shaped cross section and a wiper lip (36) of the wiper blade (10) and that is detachably fixed to the wiper blade (10) with the aid of fixing elements (38, 52, 58, 78, 90). It is proposed that the wiper blade (10) consist of a wiper strip (14) with at least one flat, bar-type, elastic support element (26) and a spoiler (12), wherein the protective rail (32, 44, 56, 72, 88) rests on the support element (26) or spoiler (12).

Owner:ROBERT BOSCH GMBH +1

System and method for automatic access of a remote computer over a network

InactiveUS20080082353A1Resource optimizationEliminate needCredit registering devices actuationDigital data information retrievalInternet networkNetwork on

A system and method for using identification codes found on ordinary articles of commerce to access remote computers on a network. In accordance with one embodiment of the invention, a computer is provided having a database that relates Uniform Product Code (“UPC”) numbers to Internet network addresses (or “URLs”). To access an Internet resource relating to a particular product, a user enters the product's UPC symbol manually, by swiping a bar code reader over the UPC symbol, or via other suitable input means. The database retrieves the URL corresponding to the UPC code. This location information is then used to access the desired resource.

Owner:NM LLC

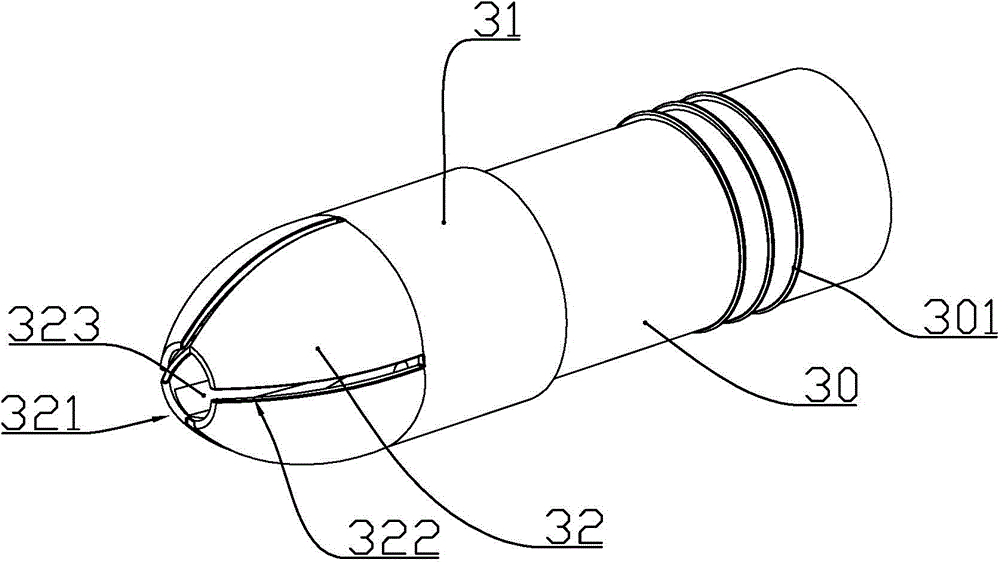

Tracheal foreign body forceps device and forceps body

The invention discloses a tracheal foreign body forceps device and forceps body. The forceps body is integrally molded by elastic rubber or plastic. The structure of the forceps body is formed by successively and integrally connecting a circular tubular tube joint b, a circular tubular supporting ring, a spherical rib connecting surface and four clamping slices, wherein the rib connecting surface concavely extends into the supporting ring; the four clamping slices are evenly and tightly connected at the periphery of the outer surface of the rib connecting surface; the end parts of the four clamping slices are surrounded to form a circular front opening; a side gap is formed between the adjacent two clamping slices; supporting ribs are formed on the inner side of each clamping slice; the bottoms of the supporting ribs are connected onto the outer surface of the rib connecting surface. The forceps body is integrally molded by the elastic rubber or plastic, so that the forceps body is convenient to machine, low in production cost and smooth in surface, and has no burr or sharp end part. Thus, the discomfortableness and the damage of the forceps body to tracheas are tiny.

Owner:HUAIAN ANJIE MEDICAL EQUIP LIMITED BY SHARE

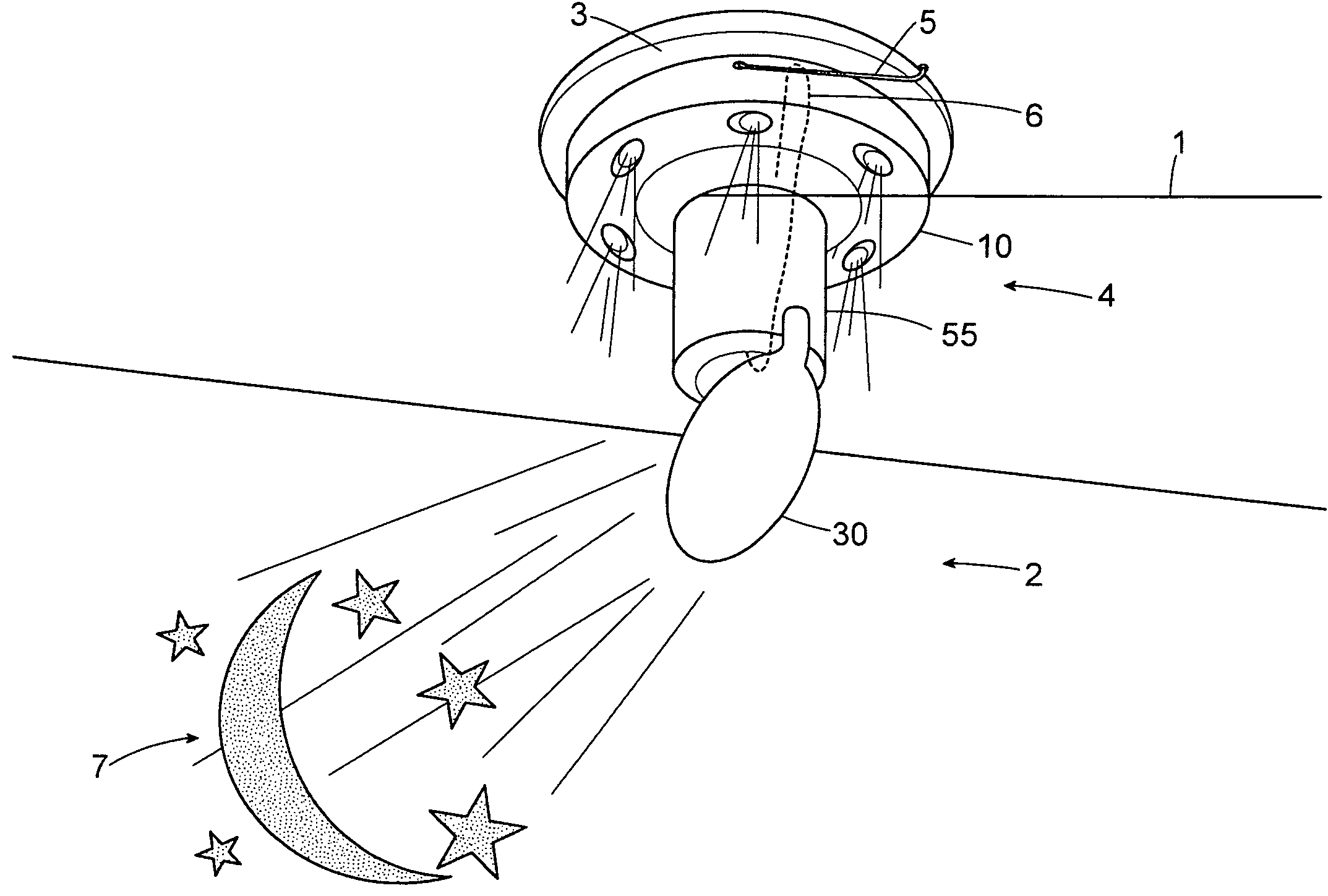

Recessed lighting fixtures with projector accessory

InactiveUS7748869B2Easy to clipQuick changeLighting applicationsMechanical apparatusEffect lightRecessed light

Owner:TRIPAR

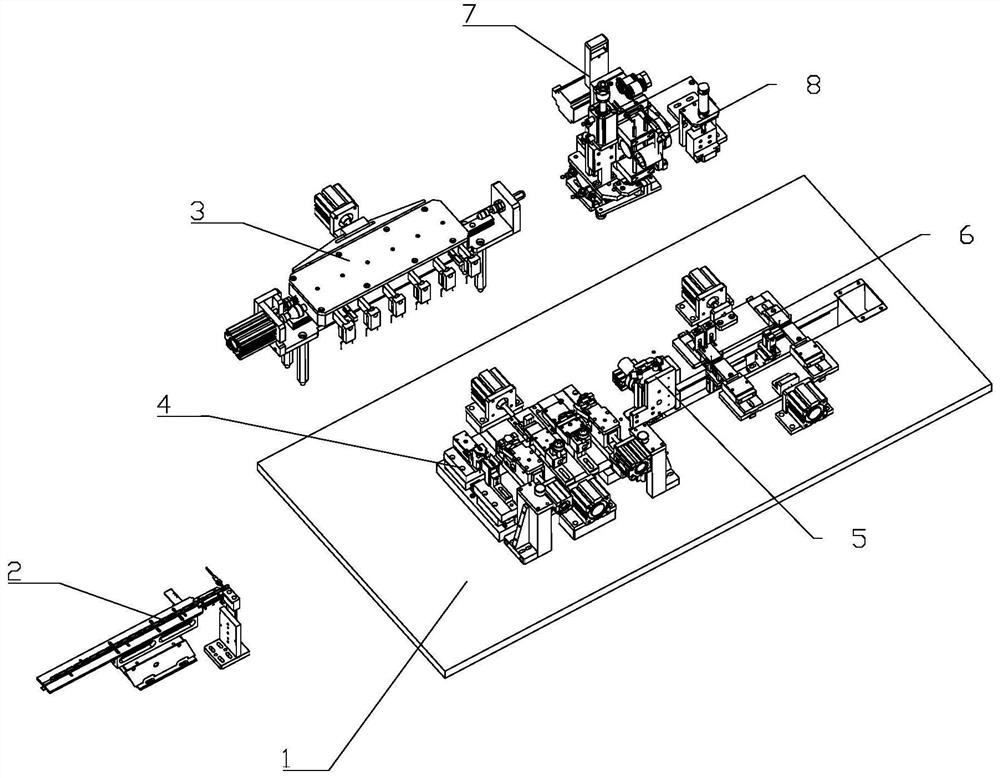

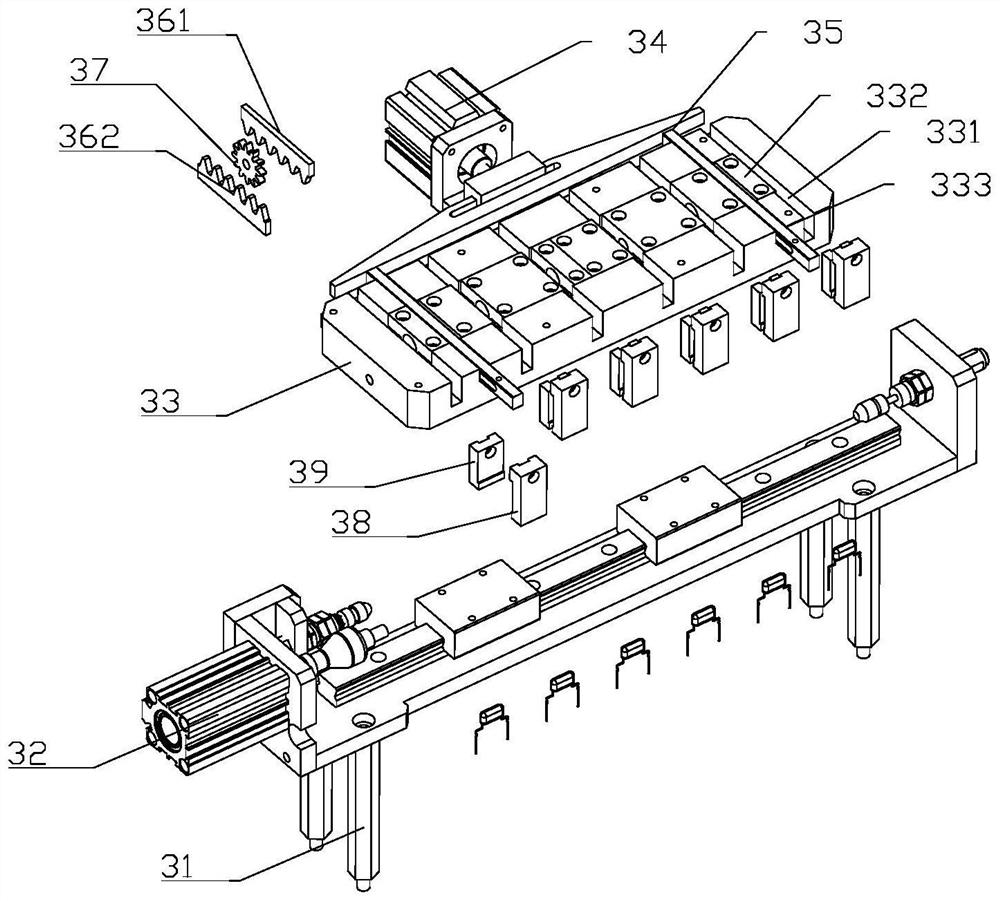

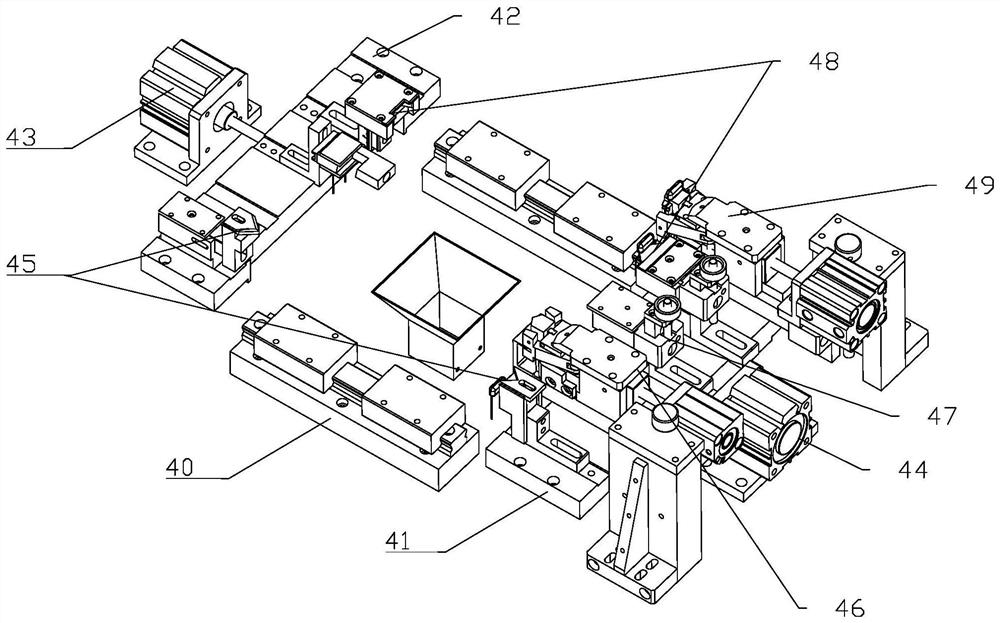

Production device for super-huge type new energy battery box body

InactiveCN109365157AEasy to clipGuaranteed stabilityCell component detailsLiquid spraying apparatusNew energyElectrical battery

The invention belongs to the technical field of new energy battery box bodies, and particularly relates to a production device for a super-huge type new energy battery box body. The production deviceaims at solving the problems that in existing machining devices, machining and spraying need to be separately operated, clamping is troublesome, and the machining efficiency is low. According to the scheme, the production device comprises a base, a mounting groove and a first sliding groove are formed in the top of the base, the first sliding groove is of an annular structure, the first sliding groove is located outside the mounting groove, a first motor is installed inside the mounting groove, a rotating disc is arranged on an output shaft of the first motor, an annular first sliding block isfixed at the bottom of the rotating disc, the first sliding block is arranged in the first sliding groove in the top of the base in a sliding mode, and the top of the base is provided with supportingseats, first air cylinders, second air cylinders, second sliding rods and a paint spraying device. According to the production device, through the movement in the X-axis direction, the Y-axis direction and the Z-axis direction, and then through the rotation of the rotating disc, machining or spraying operation can be carried out on any position of the side edge of the battery box body, so that the operation is quite simple.

Owner:东莞市益合康五金压铸制品有限公司

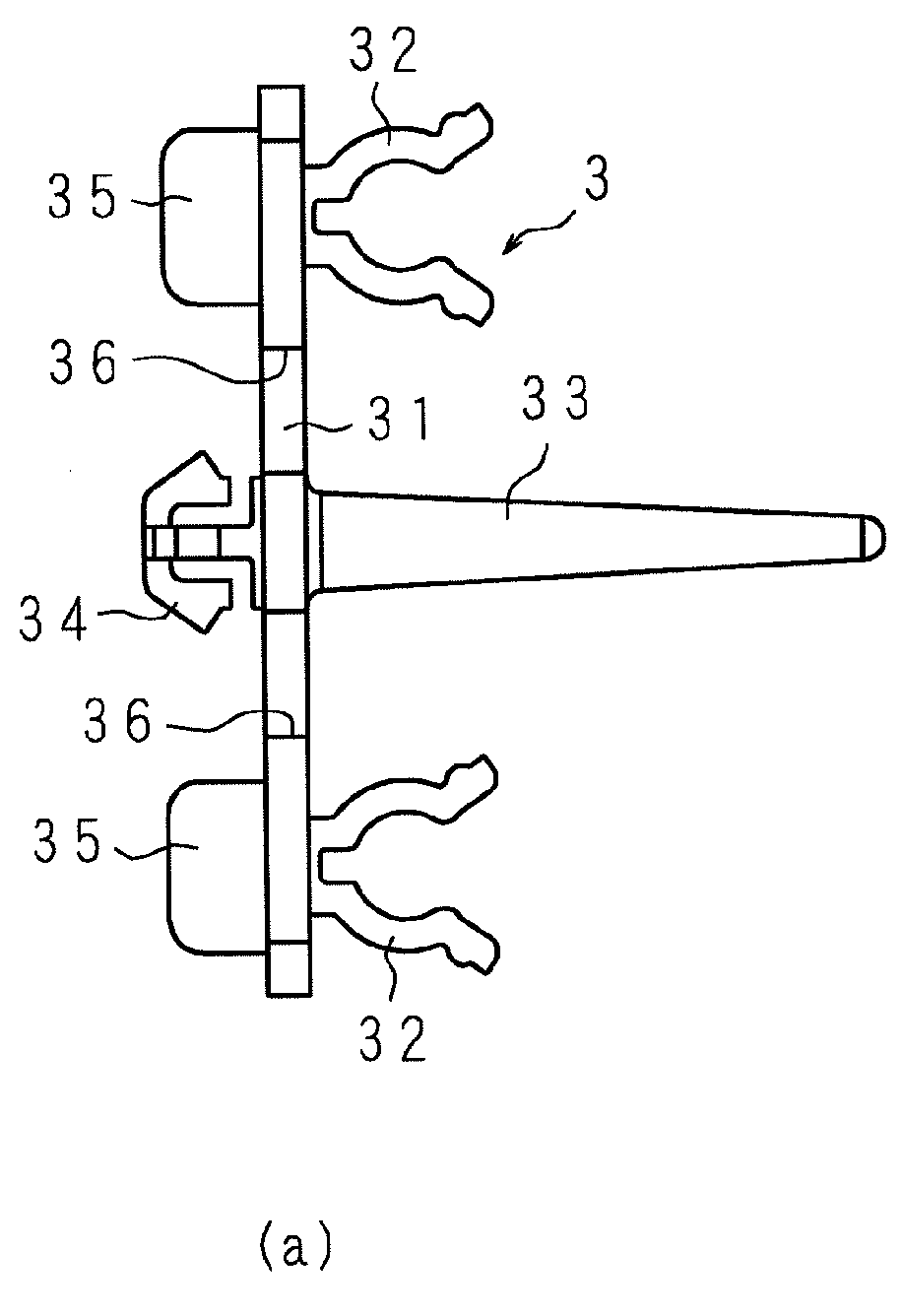

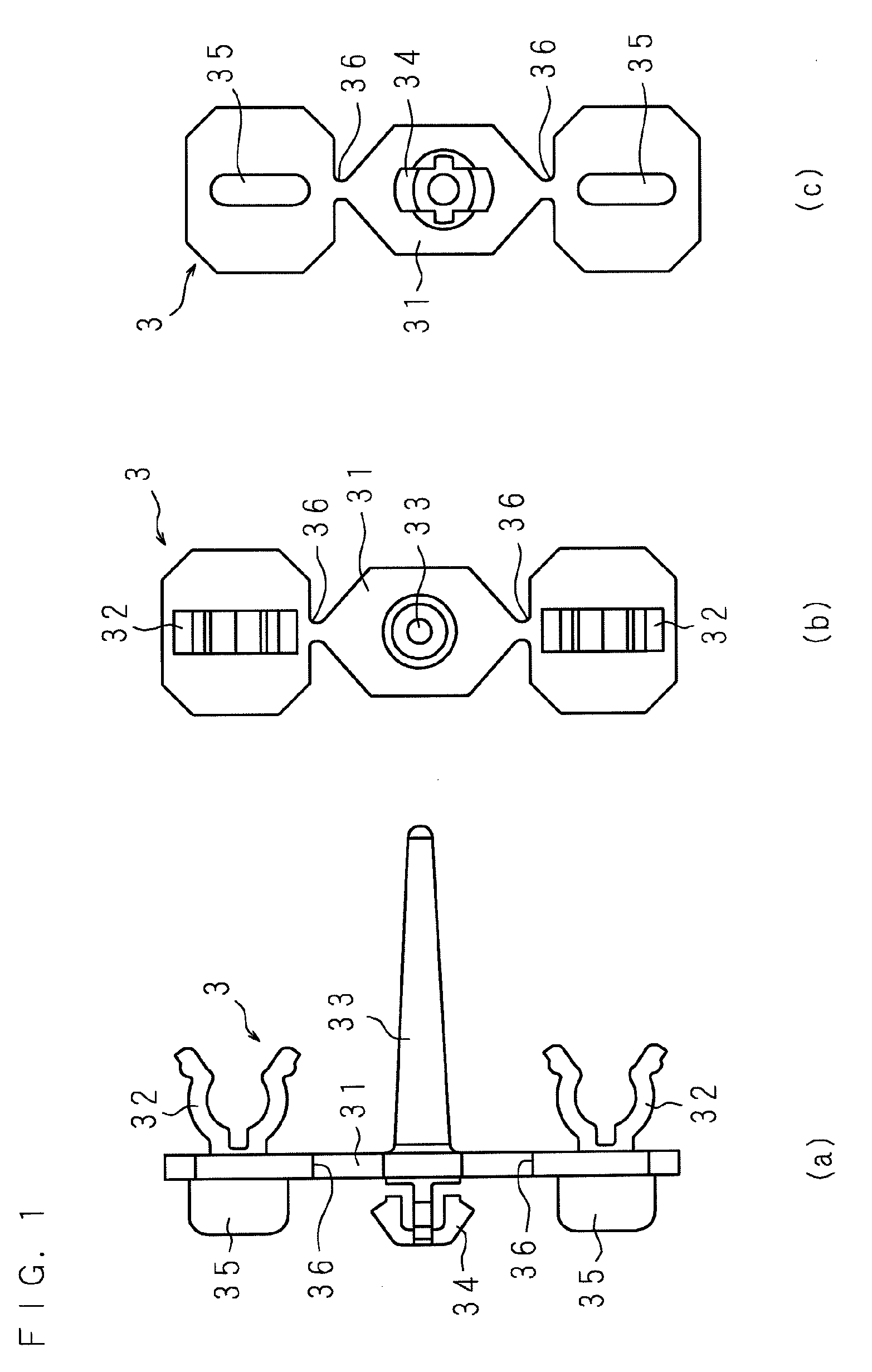

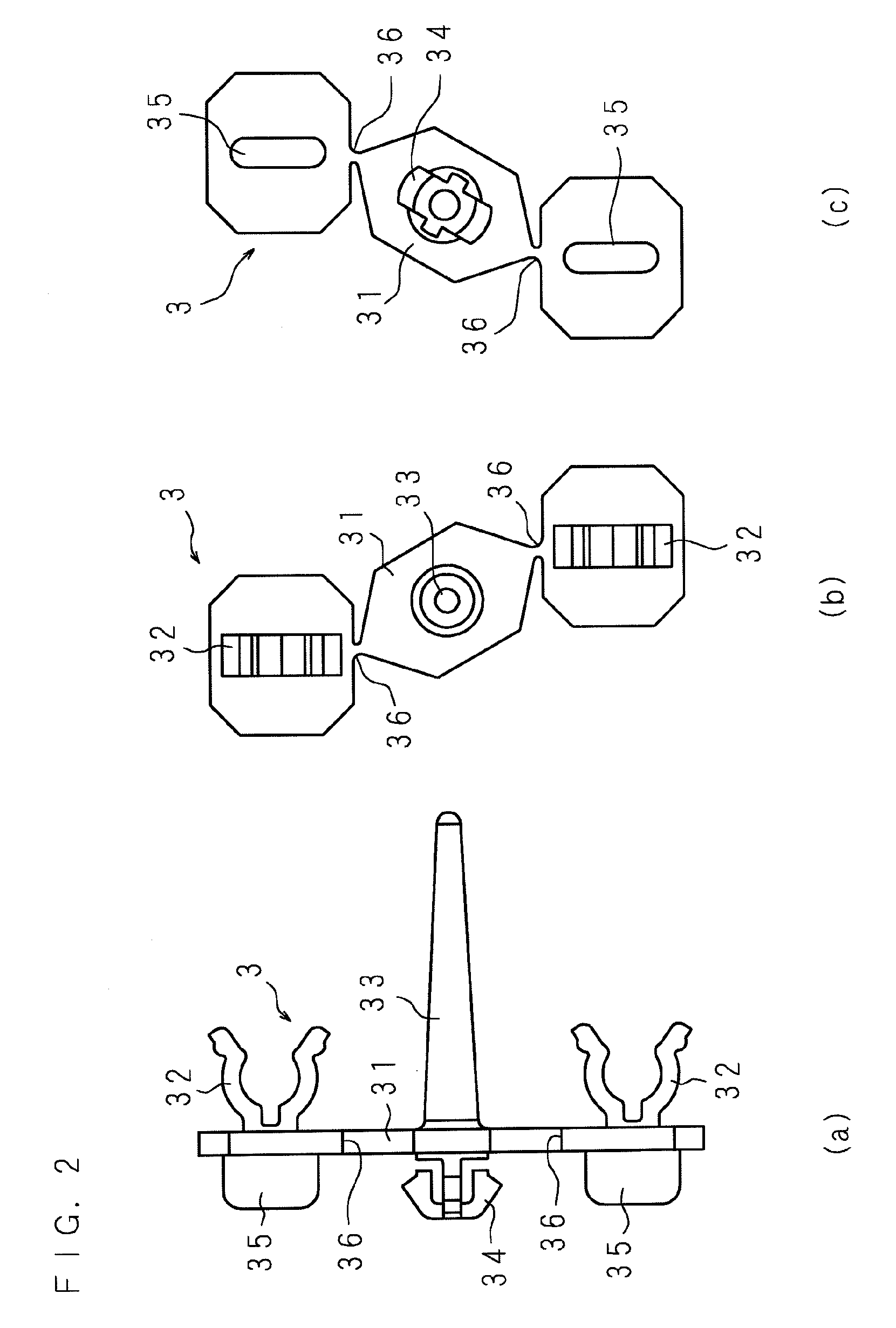

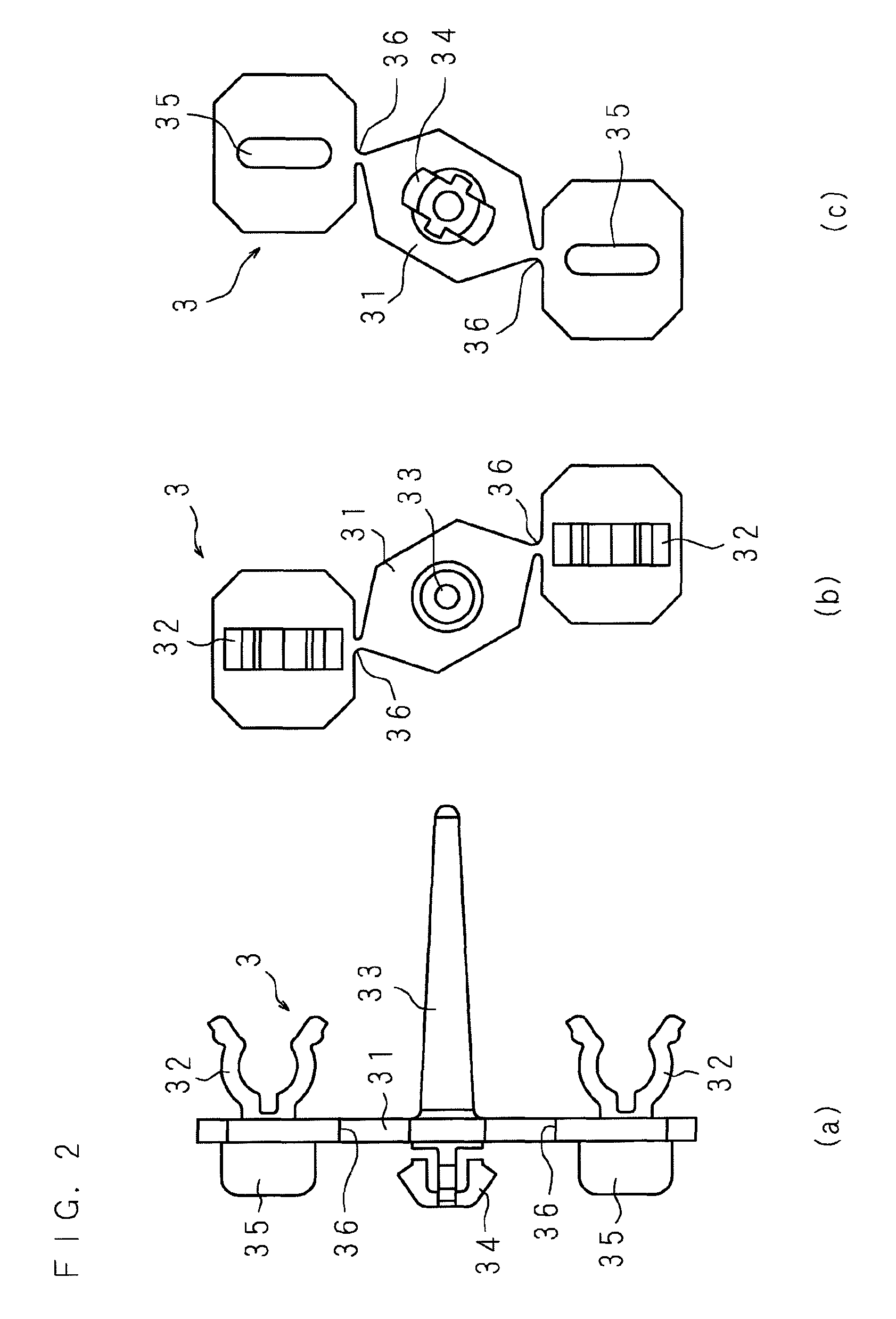

Clip and illuminate device

InactiveUS20090279320A1Easy to clipSnap fastenersPoint-like light sourceMechanical engineeringEngineering

Owner:SHARP KK

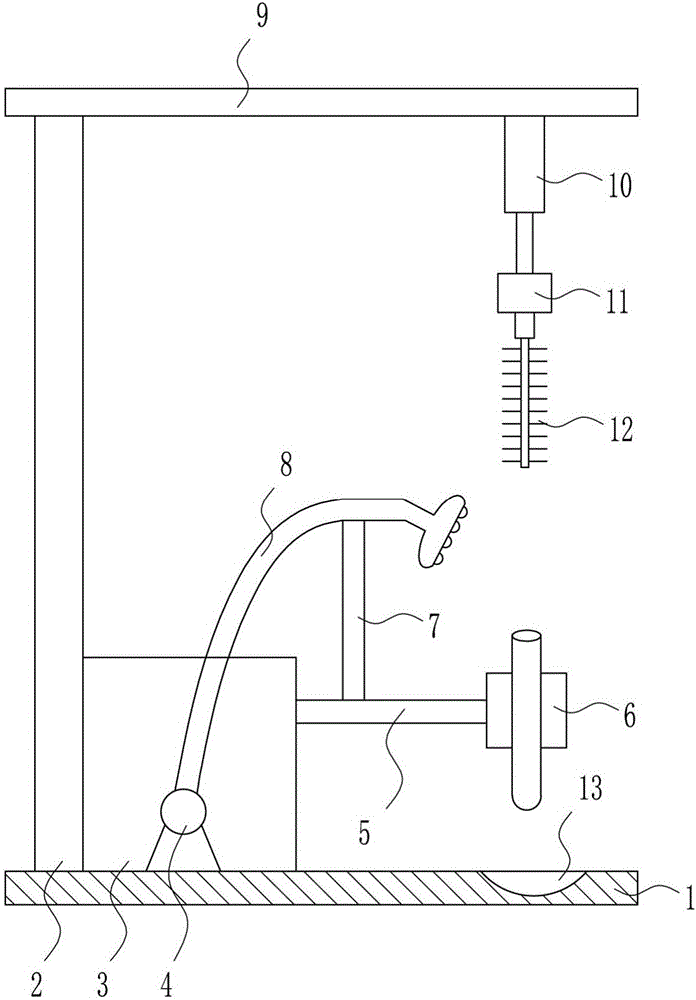

Test tube inner wall cleaning device for gene engineering experiments

The invention belongs to the technical field of gene engineering, particularly relates to a test tube inner wall cleaning device for gene engineering experiments, and aims to provide a test tube inner wall cleaning device which saves time and labor and is good in cleaning effect and capable of stabilizing and protecting a test tube. The test tube inner wall cleaning device comprises a bottom plate, a left side plate, a water tank, a water pump, a cross rod, a clamping device, a supporting rod, a spray pipe and the like, the left side plate and the water tank are connected at the top of the bottom plate through bolts, the left side plate is arranged on the left side of the water tank, the water pump is connected at the inner bottom of the water tank, the spray pipe is connected on the water pump through a flange, and the cross rod is welded on the upper portion of the right side of the water tank. According to the test tube inner wall cleaning device, test tubes can be effectively clamped by the aid of rubber sleeves and cannot be damaged, and inner walls of the test tubes are cleaned and brushed by the aid of hairbrushes.

Owner:生工生物工程(上海)股份有限公司

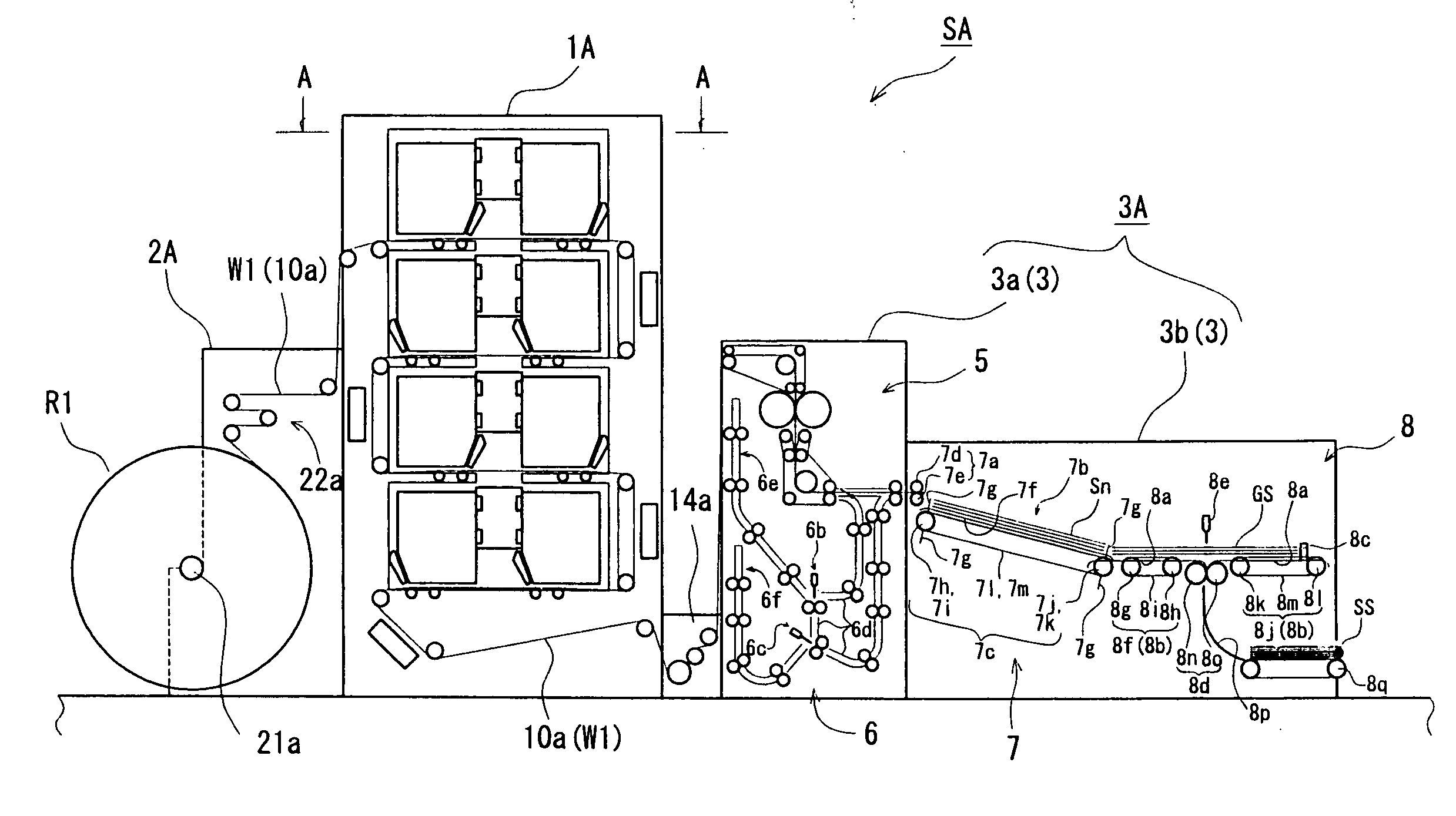

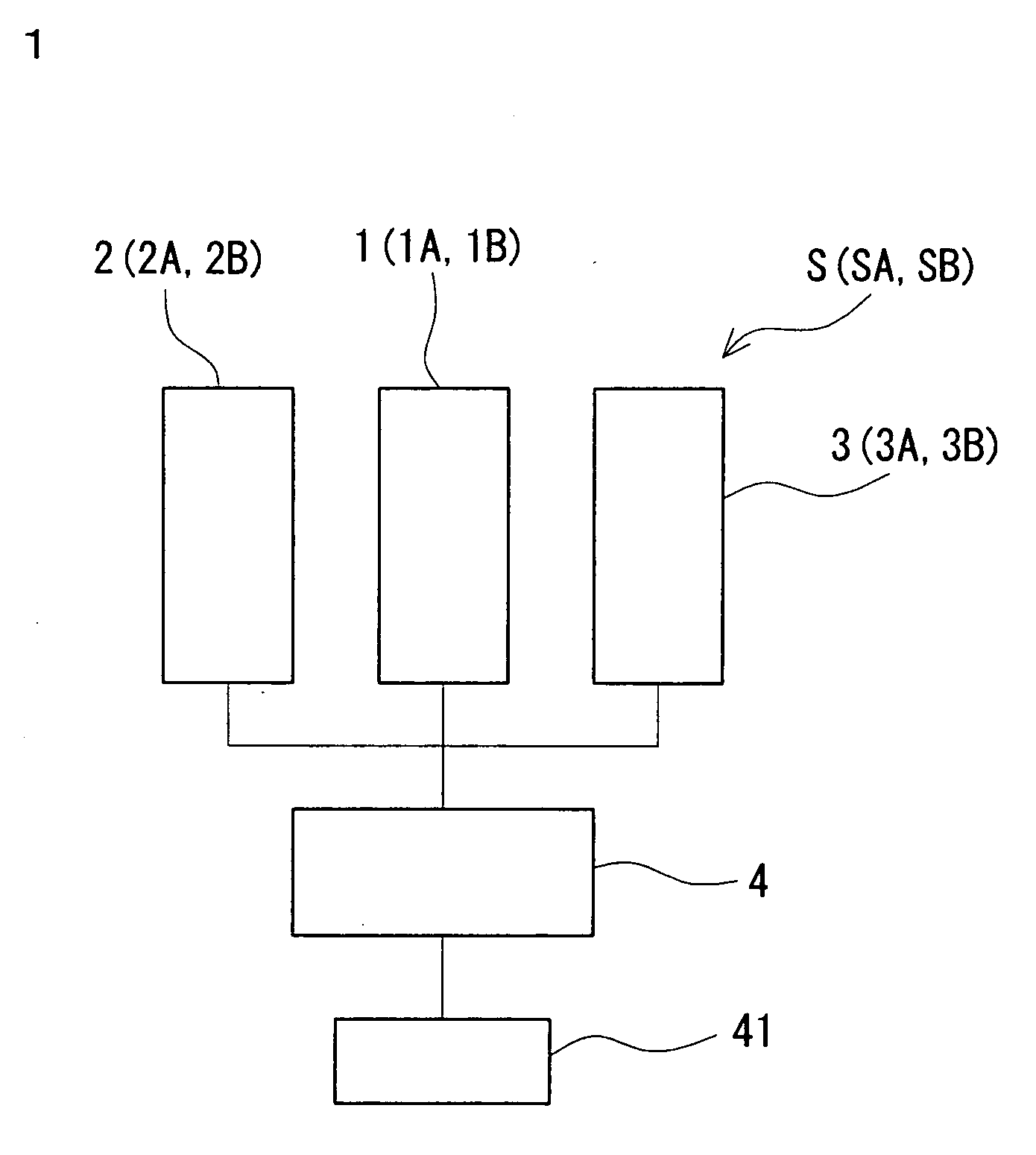

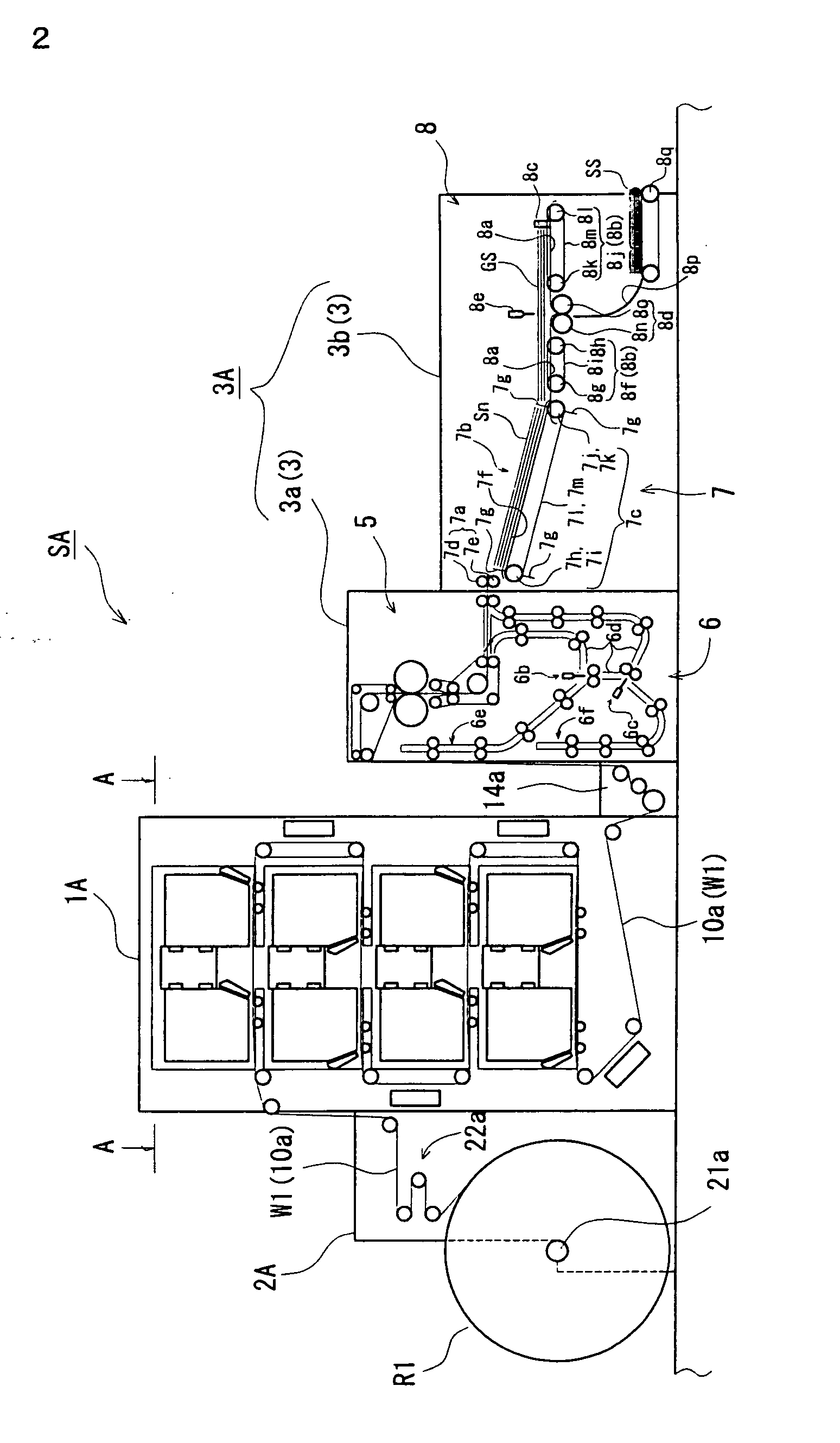

Newspaper production system and production method for newspaper

InactiveUS20100201774A1Small areaEasily carry outRecording apparatusLamination ancillary operationsPaper sheetTreatment unit

Owner:TOKYO KIKAI SEISAKUCHI LTD

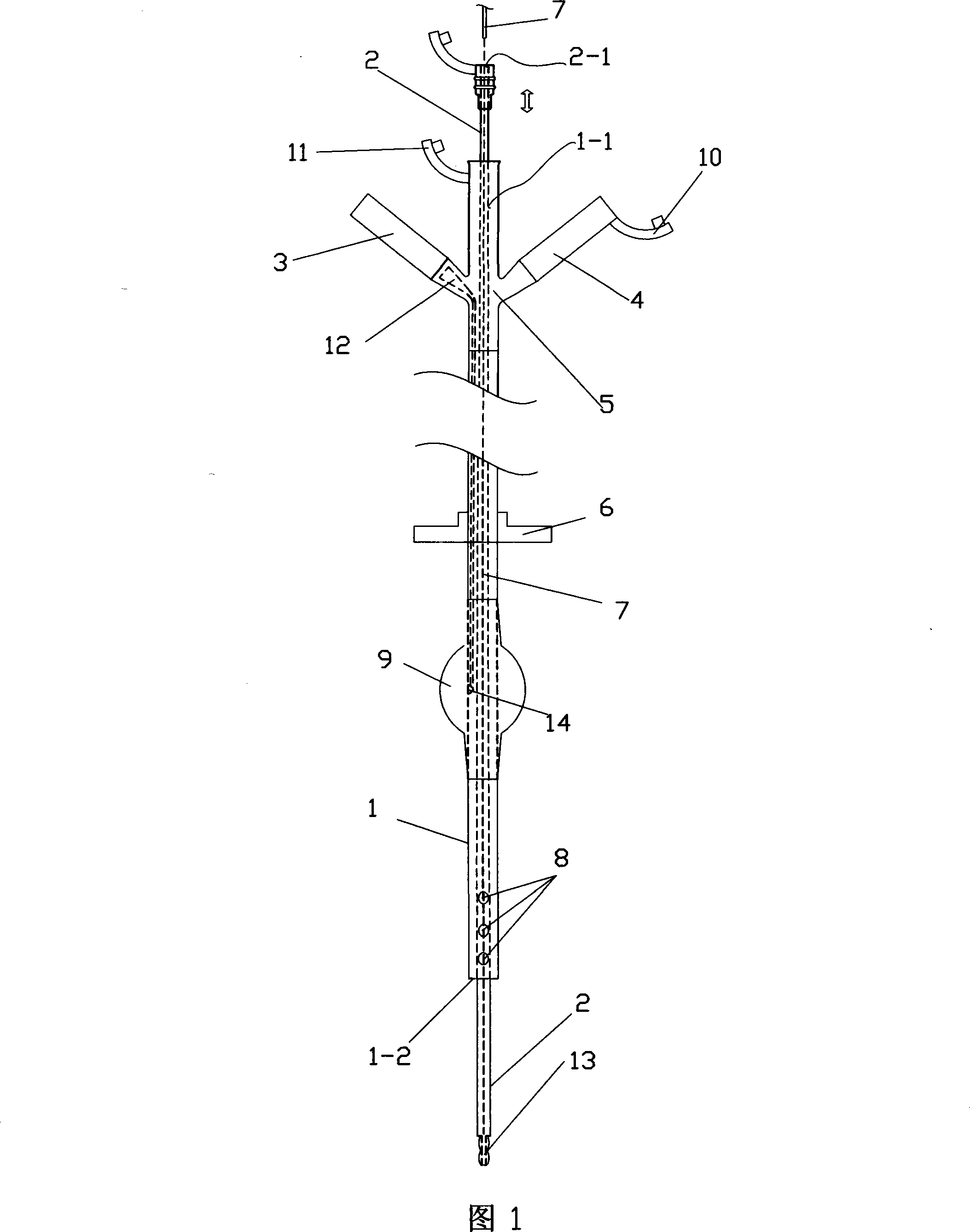

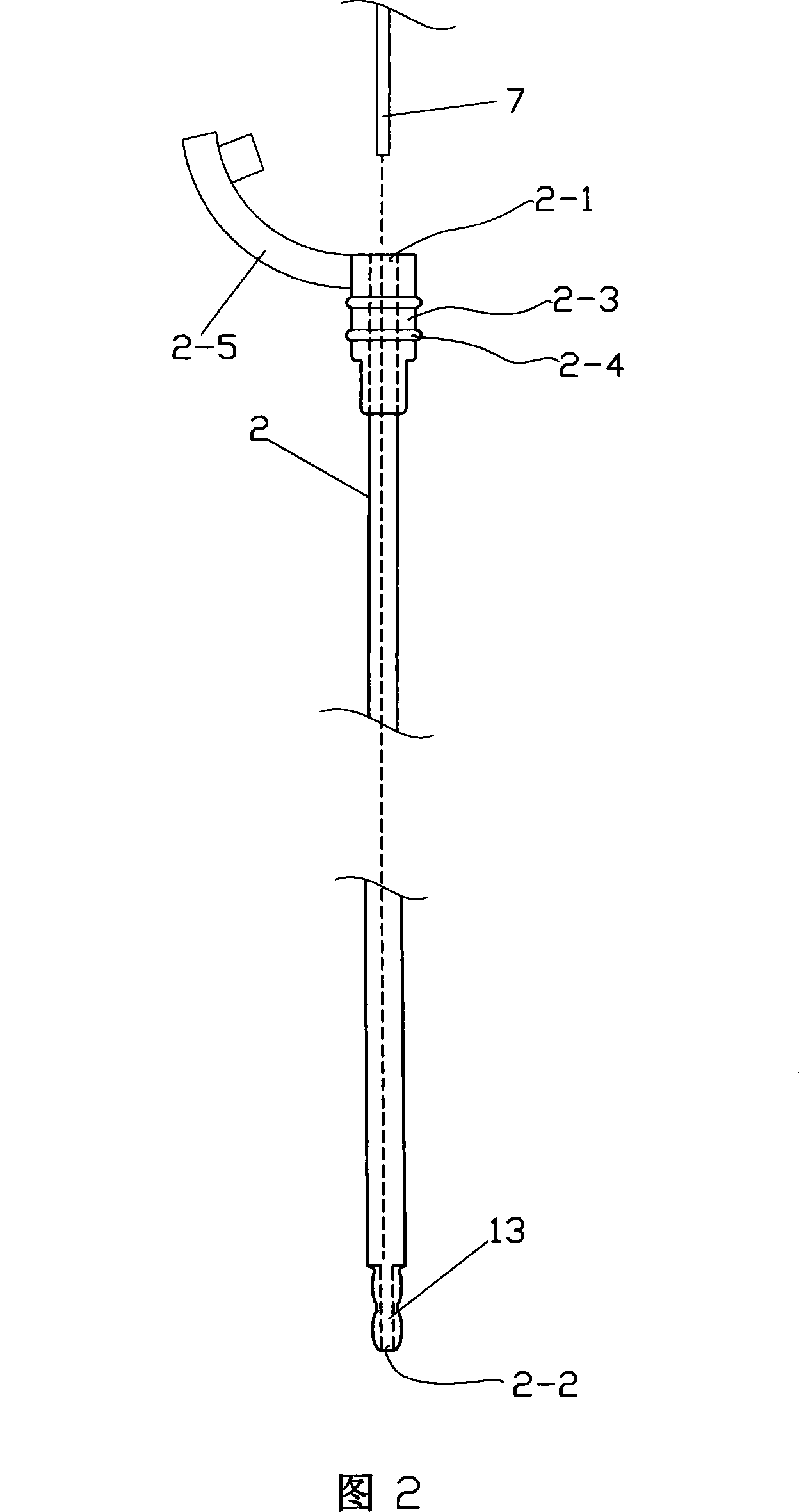

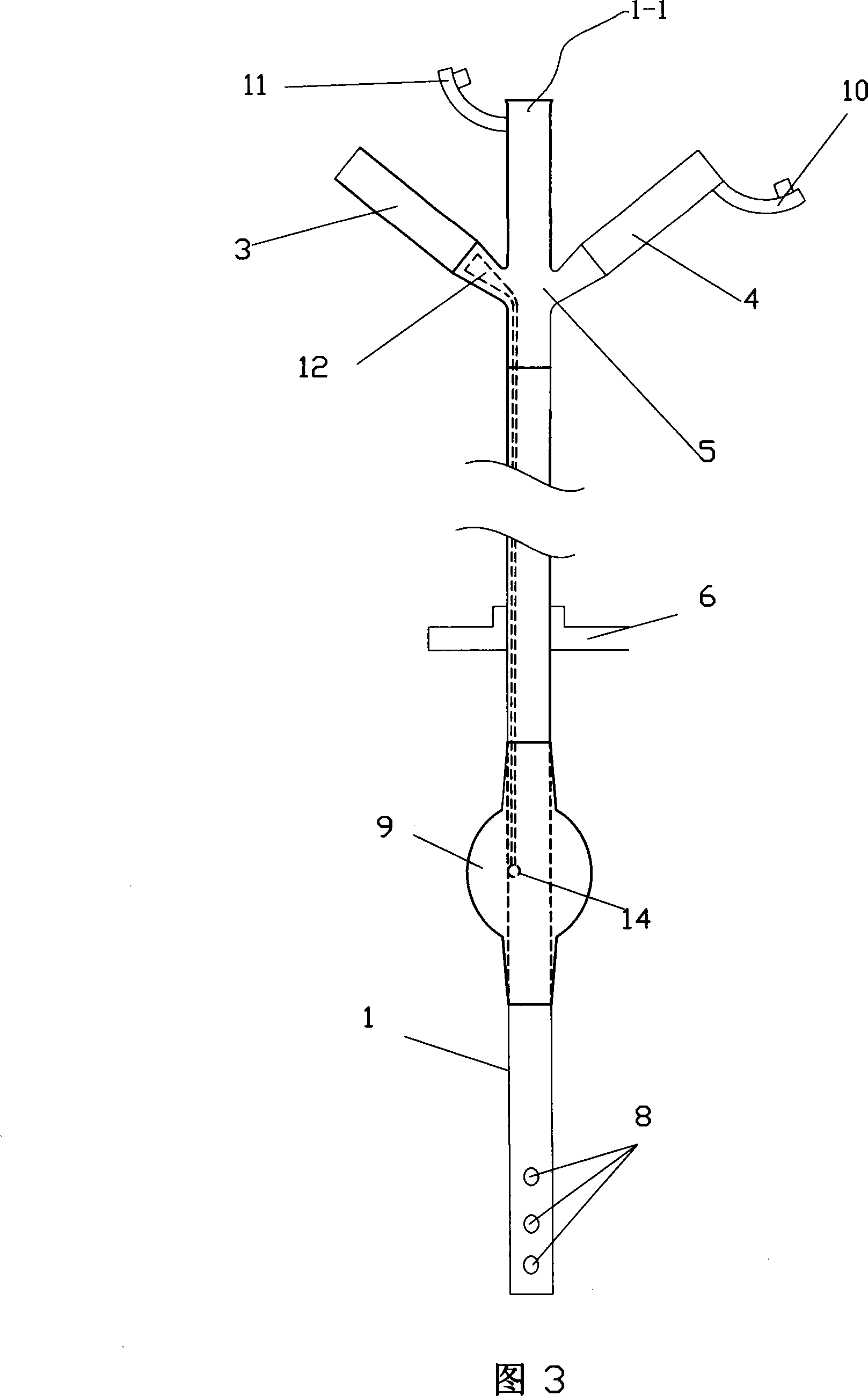

Nutrient canal of intestine for reducing pressure of stomach

InactiveCN101181181AEasy to useEasy to operateCatheterFeeding-tubesIntestinal structureGastric canal

The invention relates to a gastric decompression intestinal nutrition tube, which includes: a gastric tube, and the upper end of the gastric tube is provided with a multi-way connector; the upper end of the multi-way connector is the entrance of the gastric tube, and a first side end of the multi-way connector is a gastric decompression orifice, and an adjustable fixed ring and a gastric tube ball bag are respectively arranged on the gastric tube from top to bottom; a gas / water one-way valve is arranged on a second side end of the multi-way connector, and a ball bag gas / water inlet is arranged on the gastric tube in the gastric tube ball bag, wherein the gas / water one-way valve is connected with the ball bag gas / water inlet by a gastric tube ball bag gas / water tube; an intestinal nutrition tube which is inserted in the gastric tube from the entrance of the gastric tube and has the length which is longer than that of the gastric tube is assembled in the gastric tube. The intestinal nutrition tube and the gastric tube are detachable and can be used in combination, and the length of the gastric tube and / or the intestinal nutrition tube can be cut during specific clinical use to meet the requirements of different cases.

Owner:马博平

Wiper blade of a windscreen wiper, provided with a protective rail

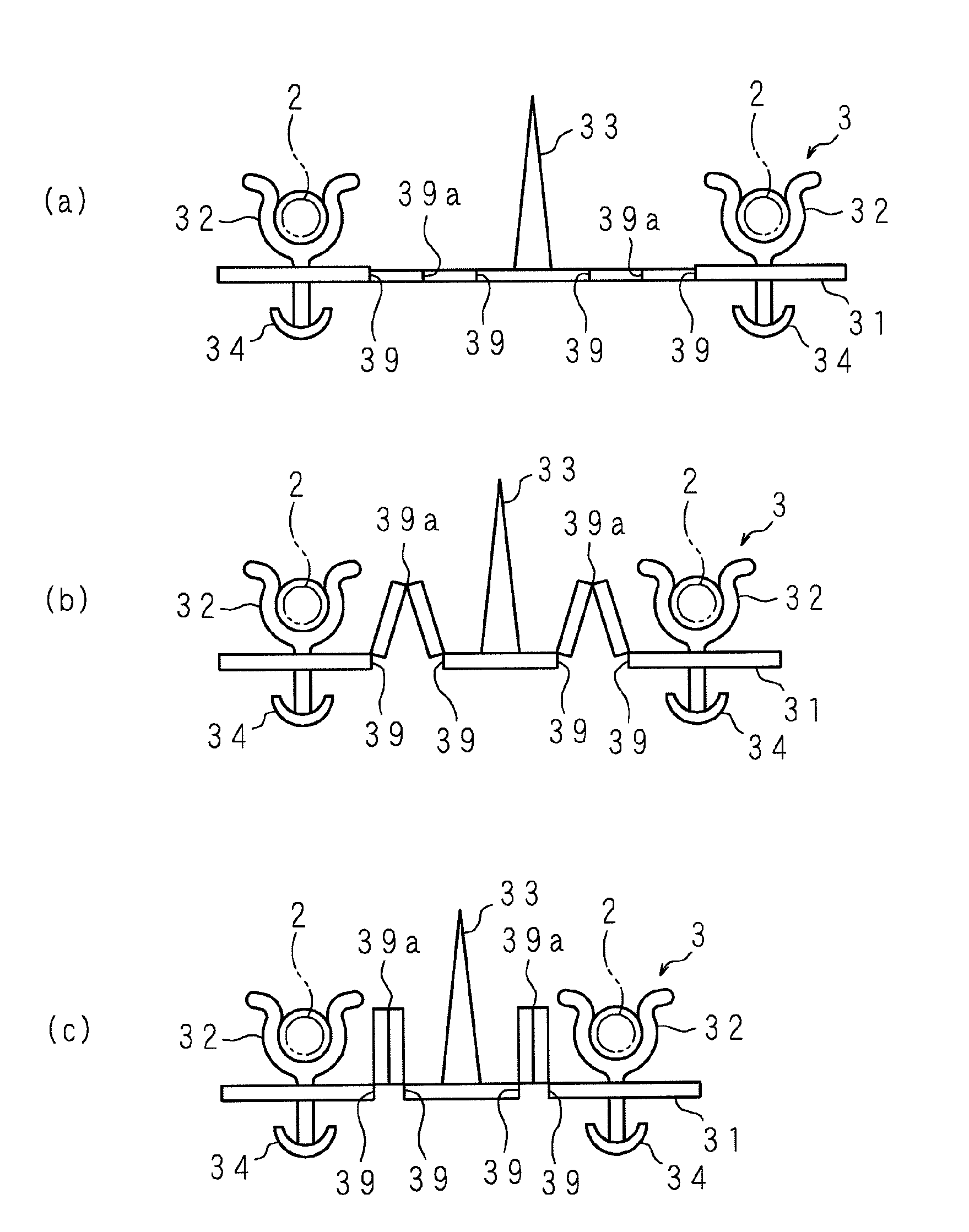

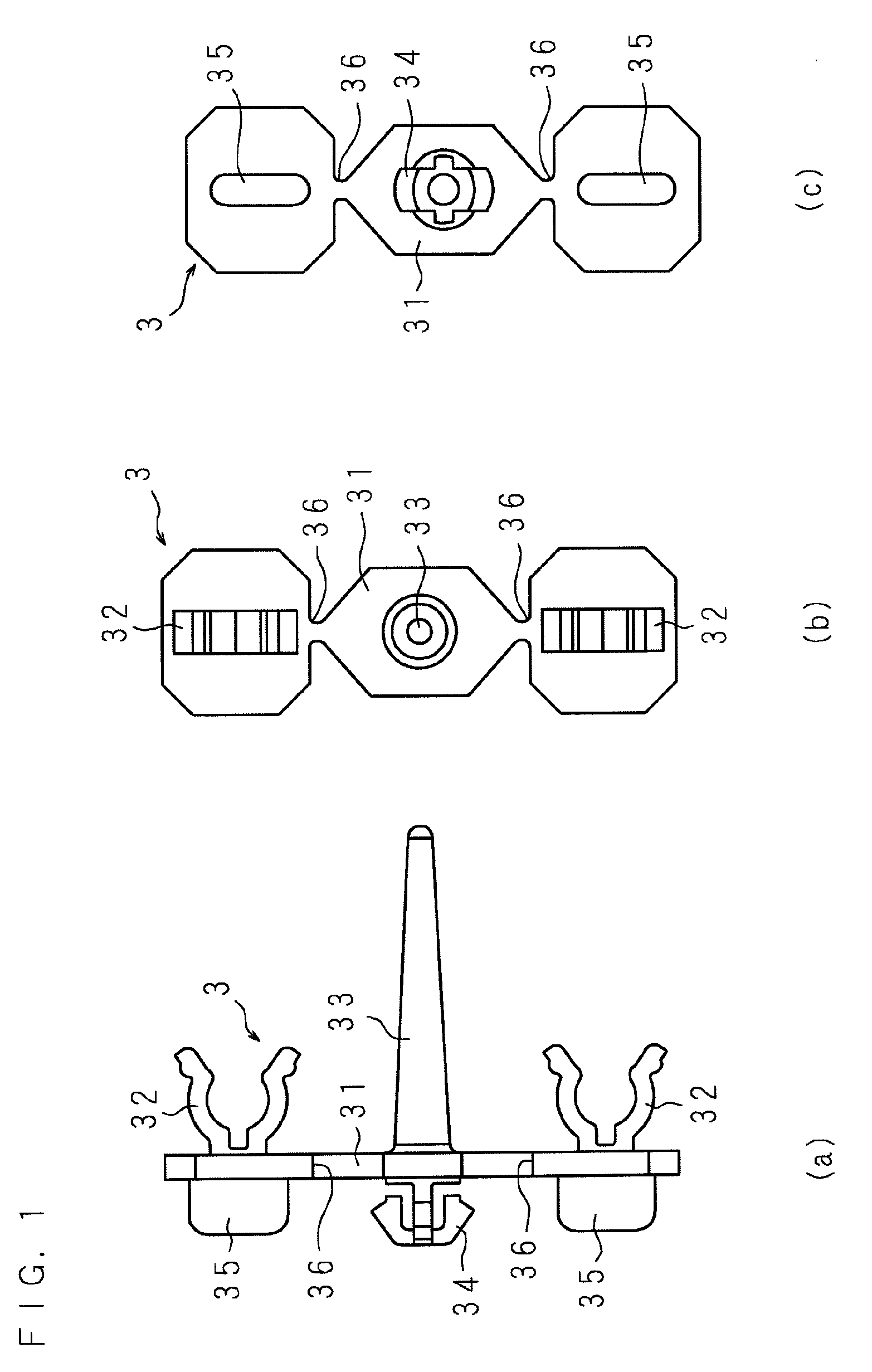

InactiveUS20090025174A1More flexibleIncrease arcWindow cleanersVehicle cleaningWindscreen wiperEngineering

The invention relates to a wiper blade (10) of a windshield wiper provided with a protective rail (32, 44, 56, 72, 88), comprising a base body (34) that has an essentially V-shaped cross section and a wiper lip (36) of the wiper blade (10) and that is detachably fixed to the wiper blade (10) with the aid of fixing elements (38, 52, 58, 78, 90). It is proposed that the wiper blade (10) consist of a wiper strip (14) with at least one flat, bar-type, elastic support element (26) and a spoiler (12), wherein the protective rail (32, 44, 56, 72, 88) rests on the support element (26) or spoiler (12).

Owner:ROBERT BOSCH GMBH +1

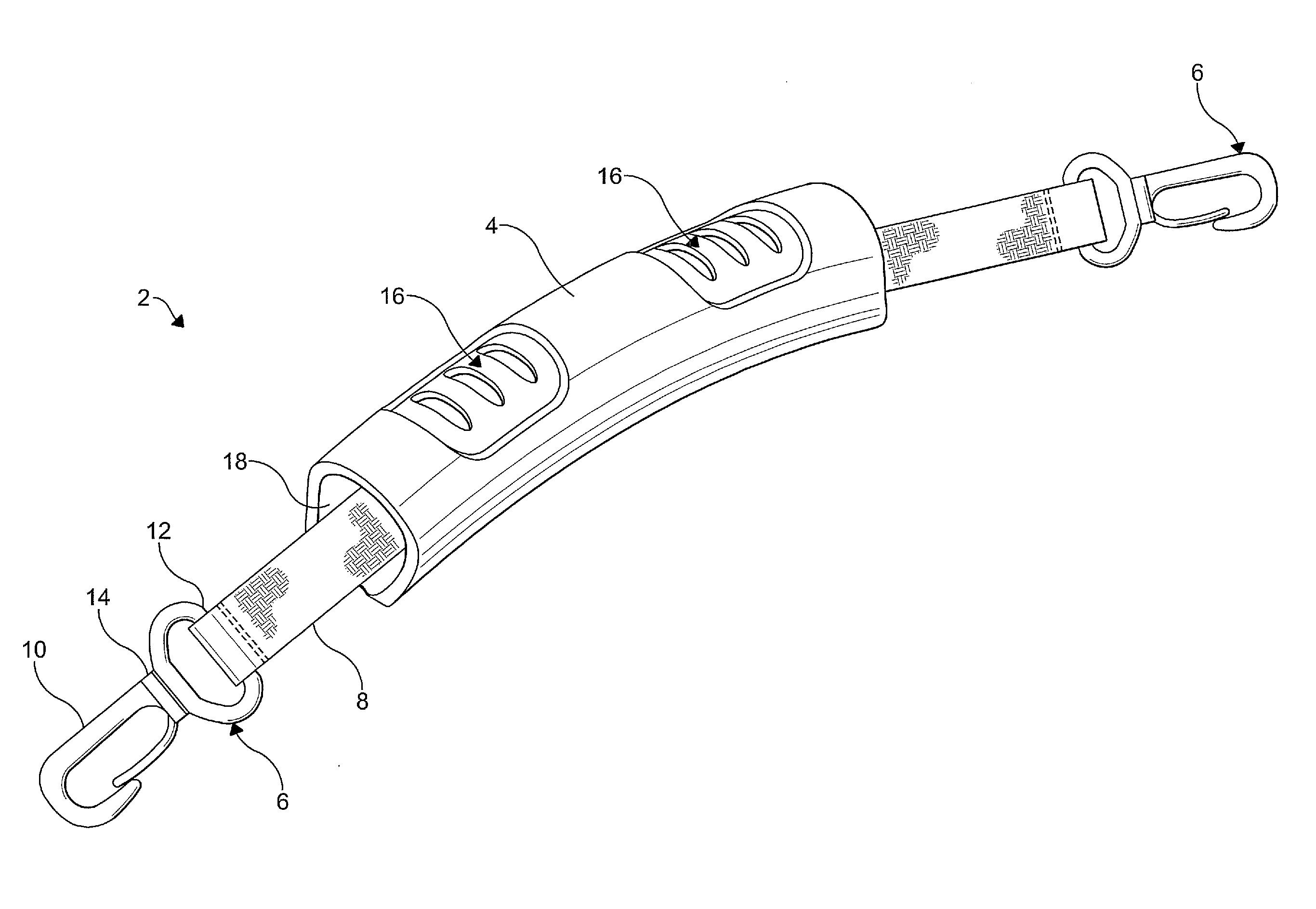

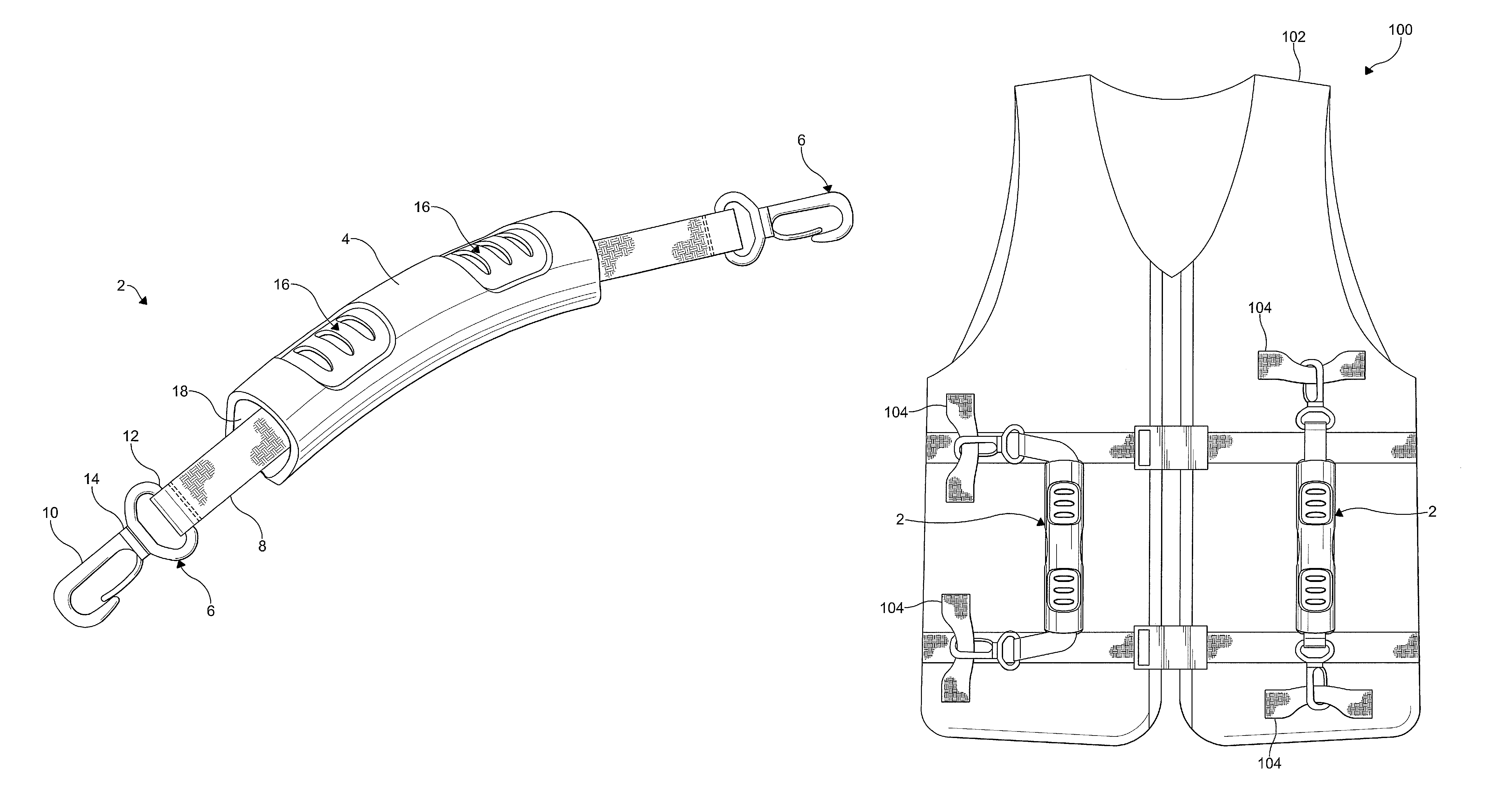

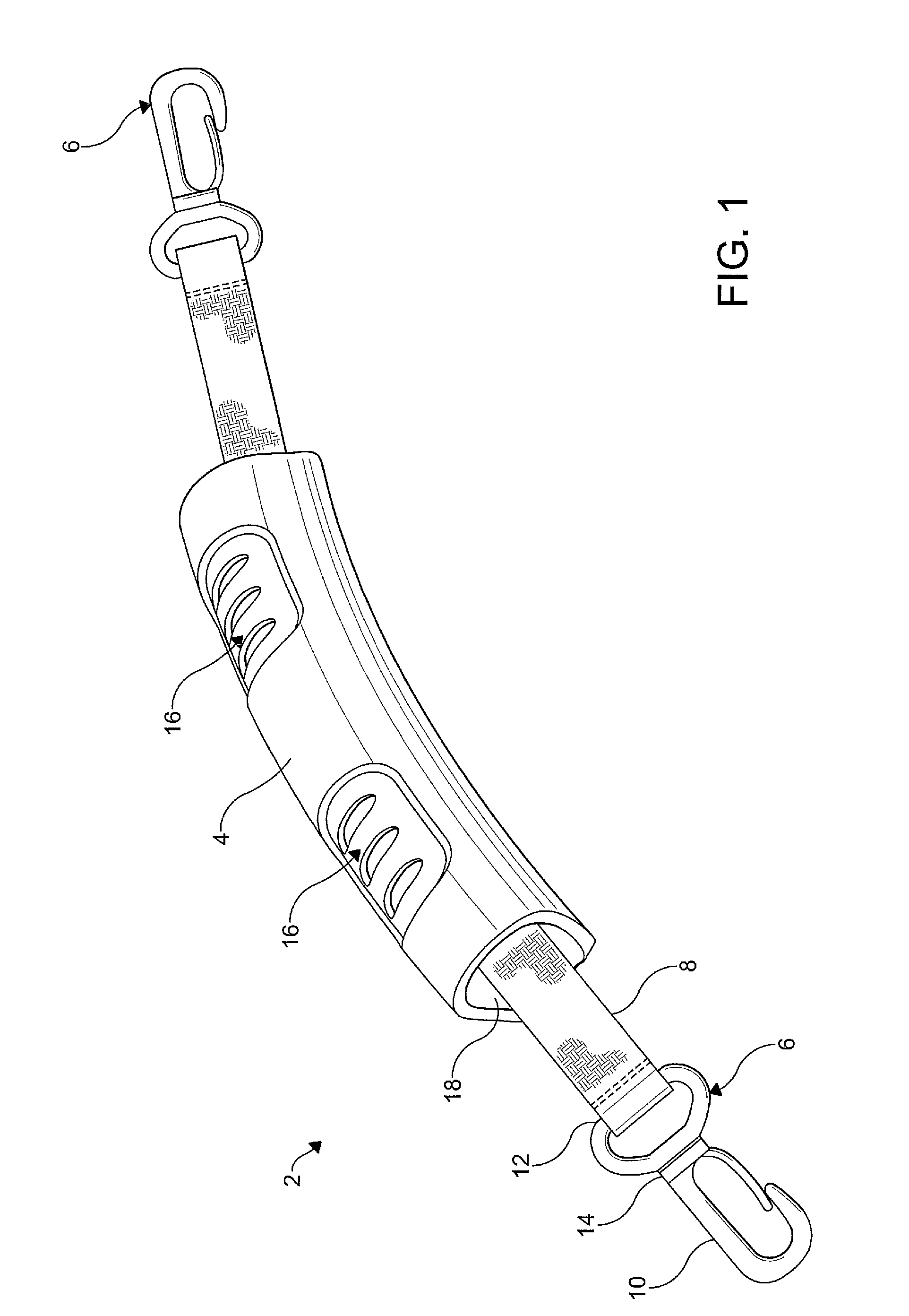

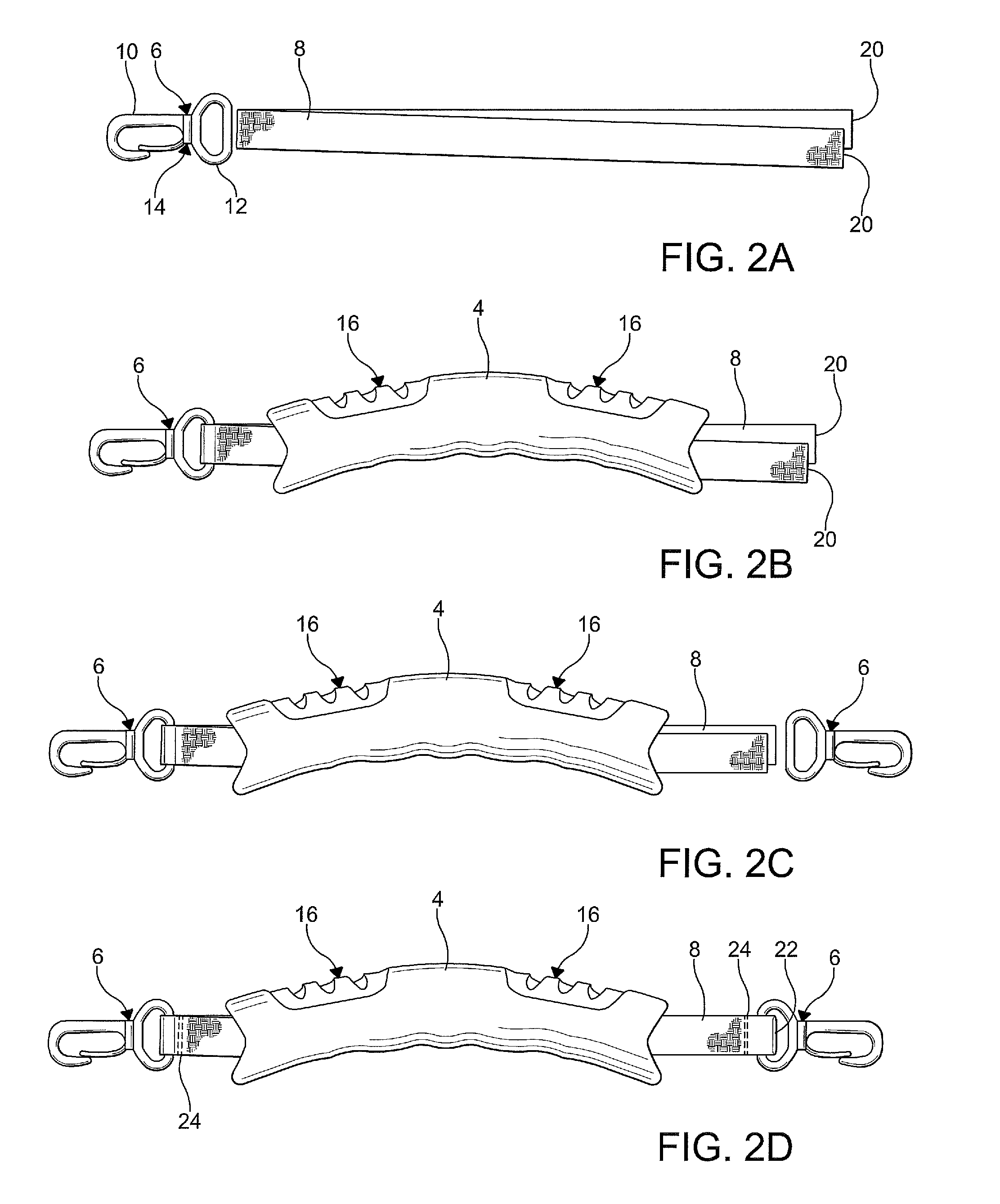

Detachable grab handle

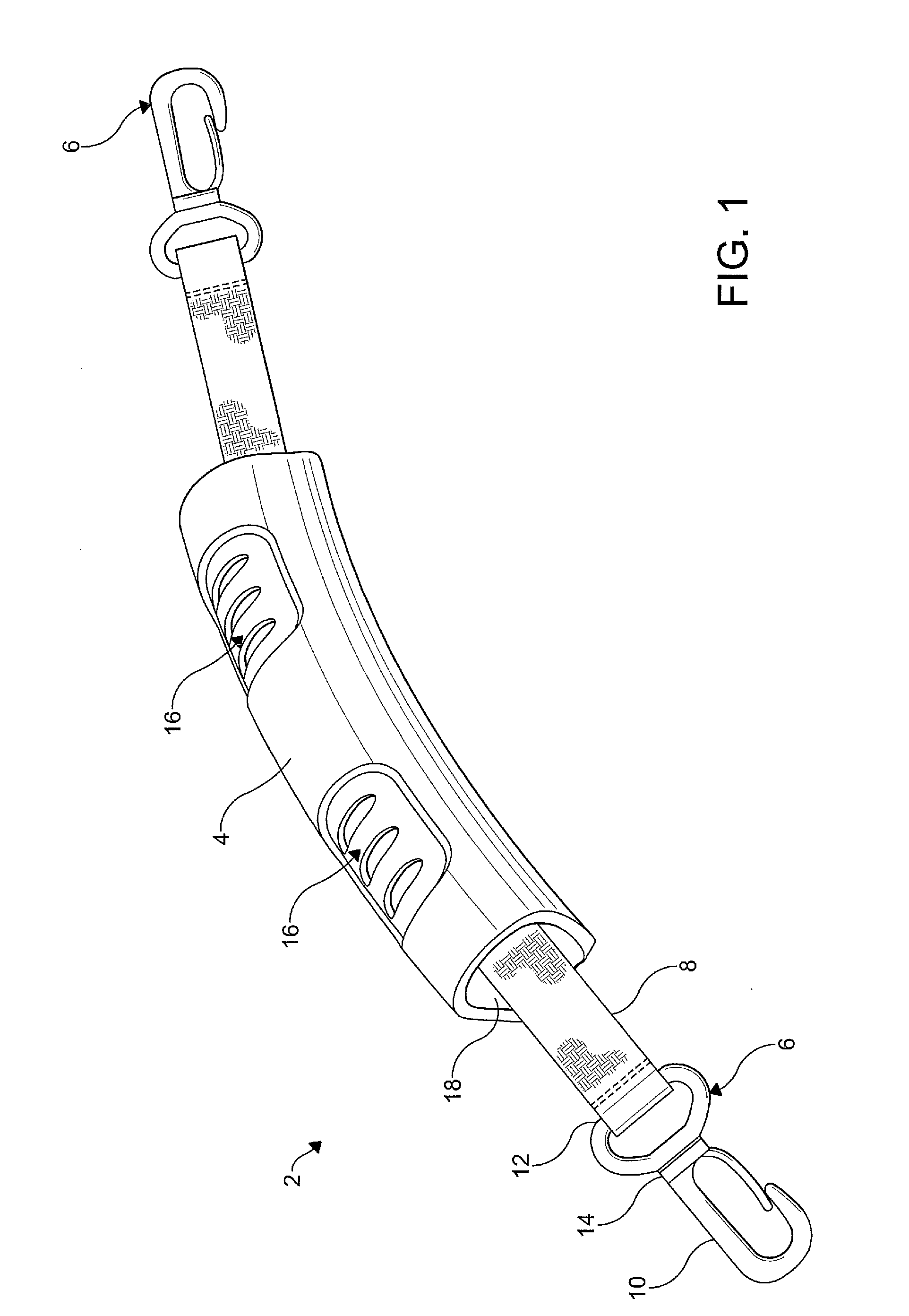

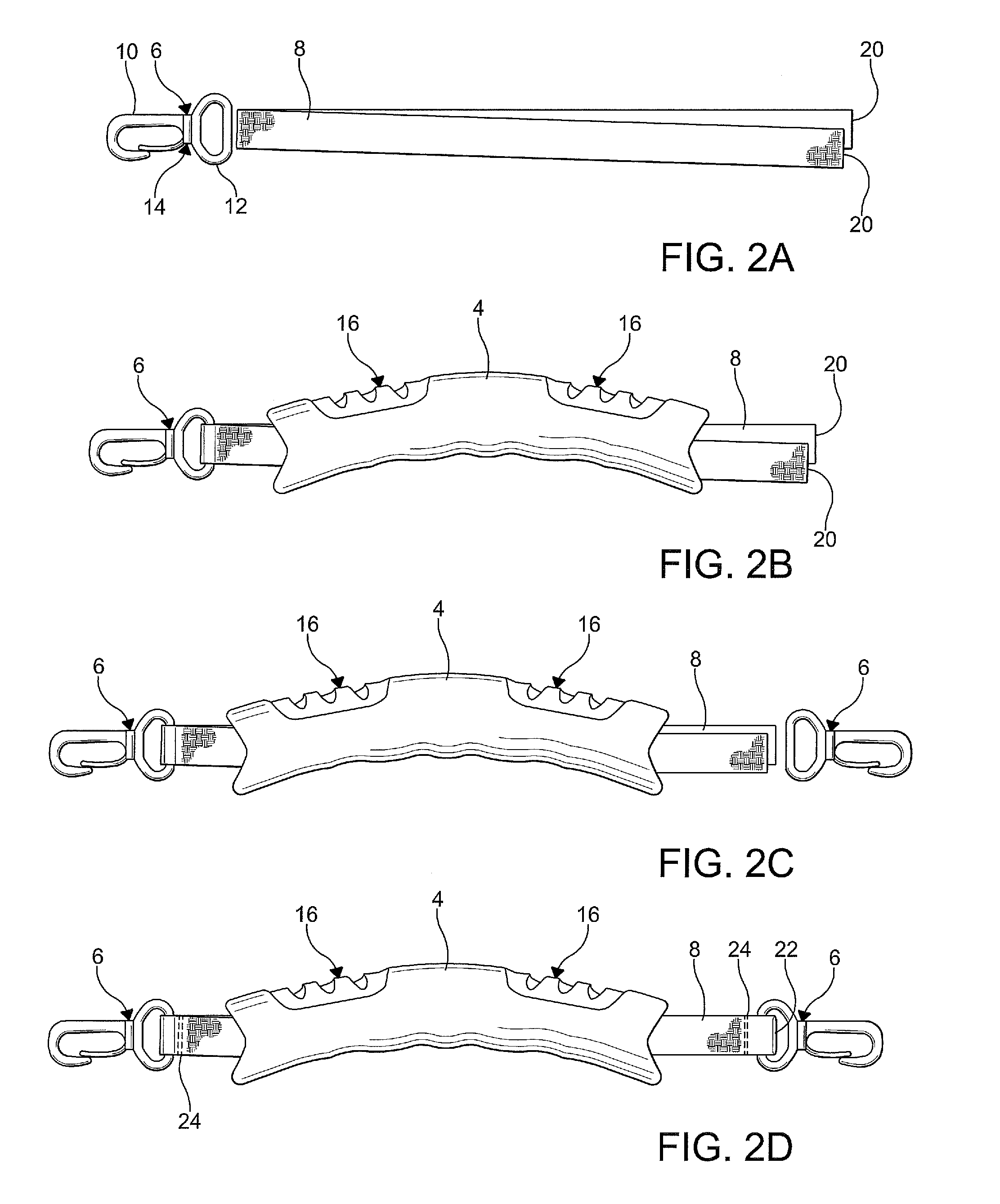

ActiveUS20130145581A1Easy and more comfortable experienceEasy to clipTravelling carriersHoldersEngineeringMechanical engineering

A detachable handle includes a flexible elongate member, a pair of swivel clips, and a tubular grip. Each of the swivel clips is coupled to the flexible elongate member. The flexible elongate member is disposed through the tubular grip. The swivel clips are disposed at opposite ends of the tubular grip, and militate against a removal of the flexible elongate member from the tubular grip.

Owner:BAILEY KELLY R

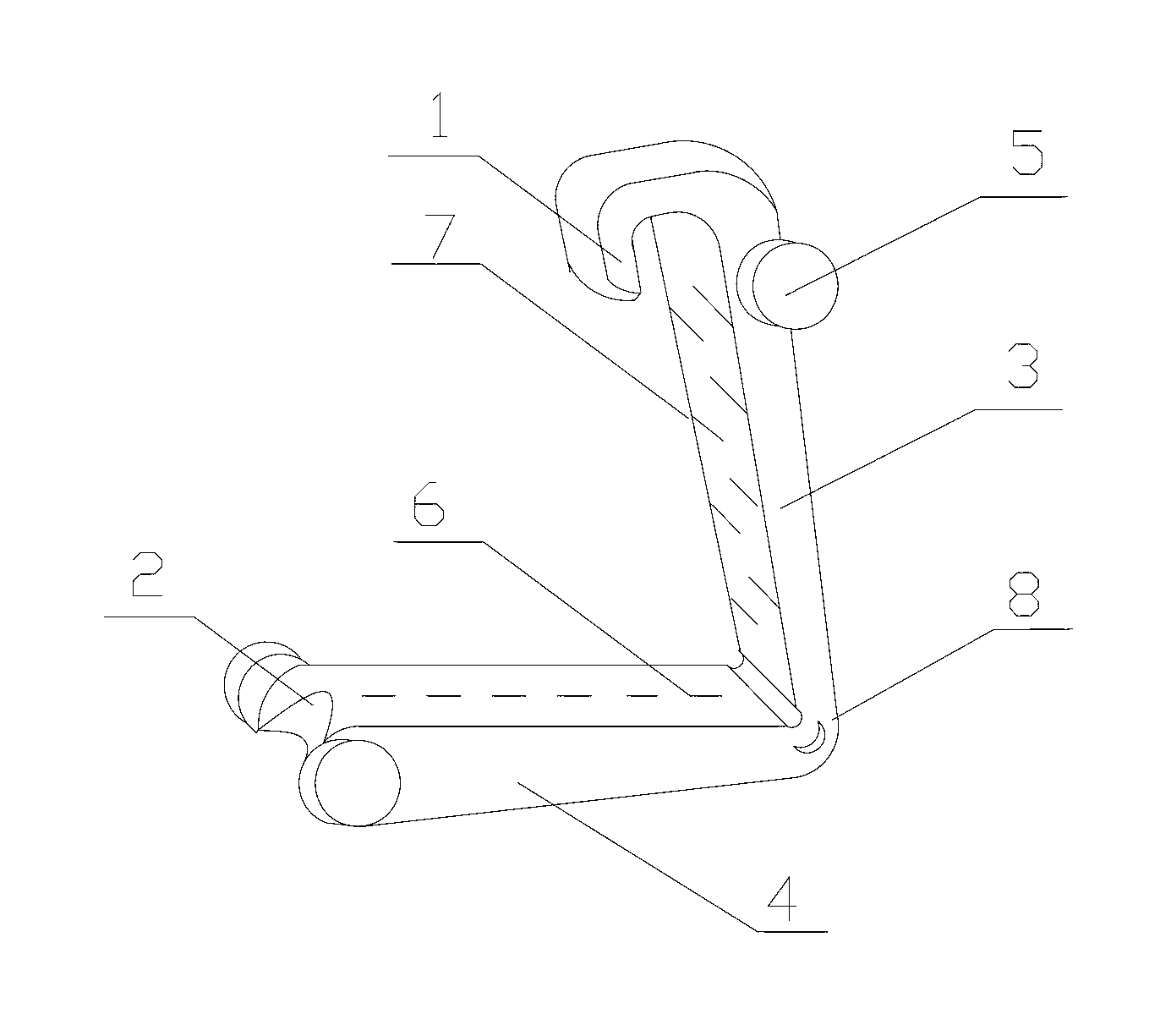

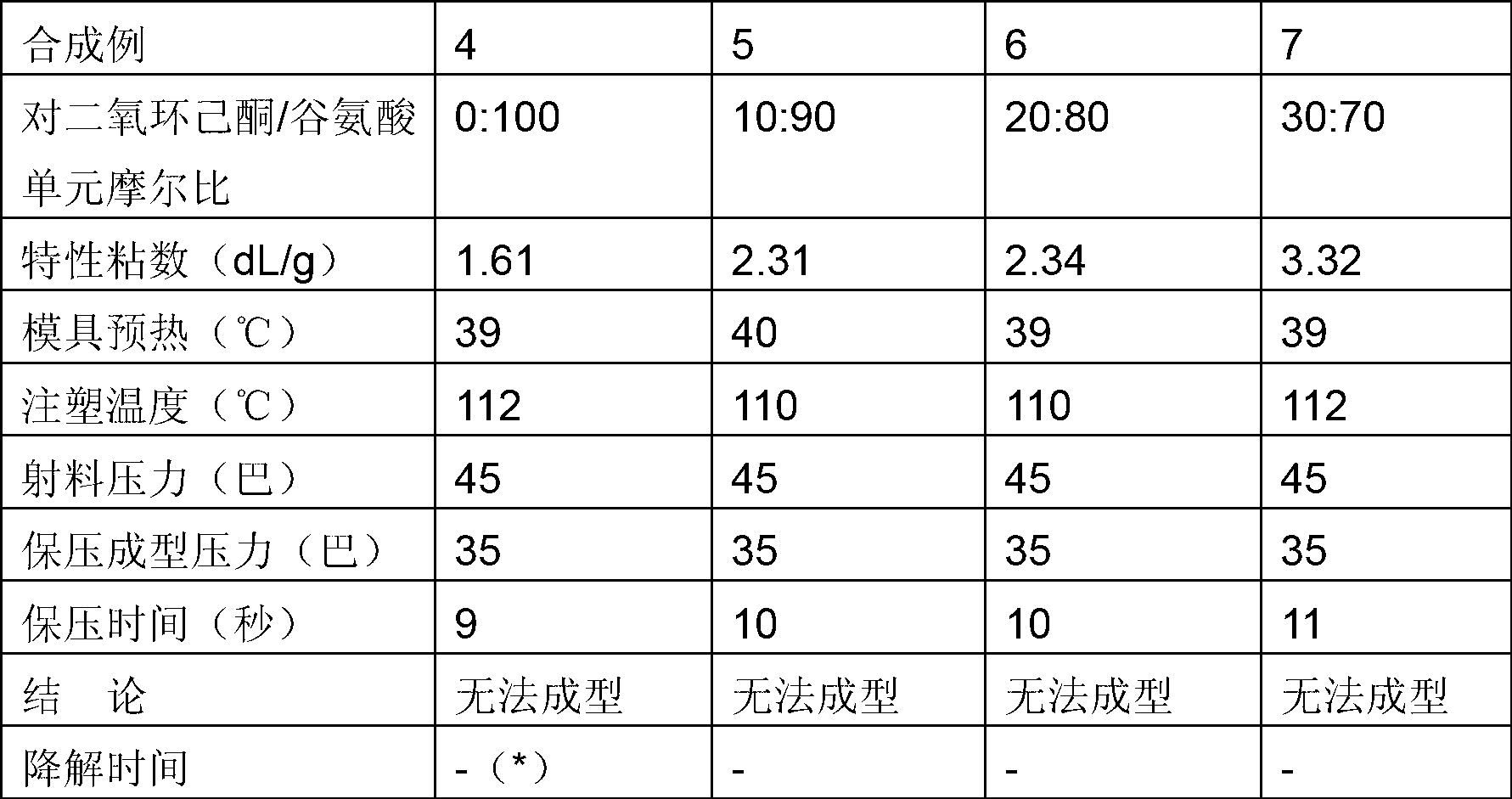

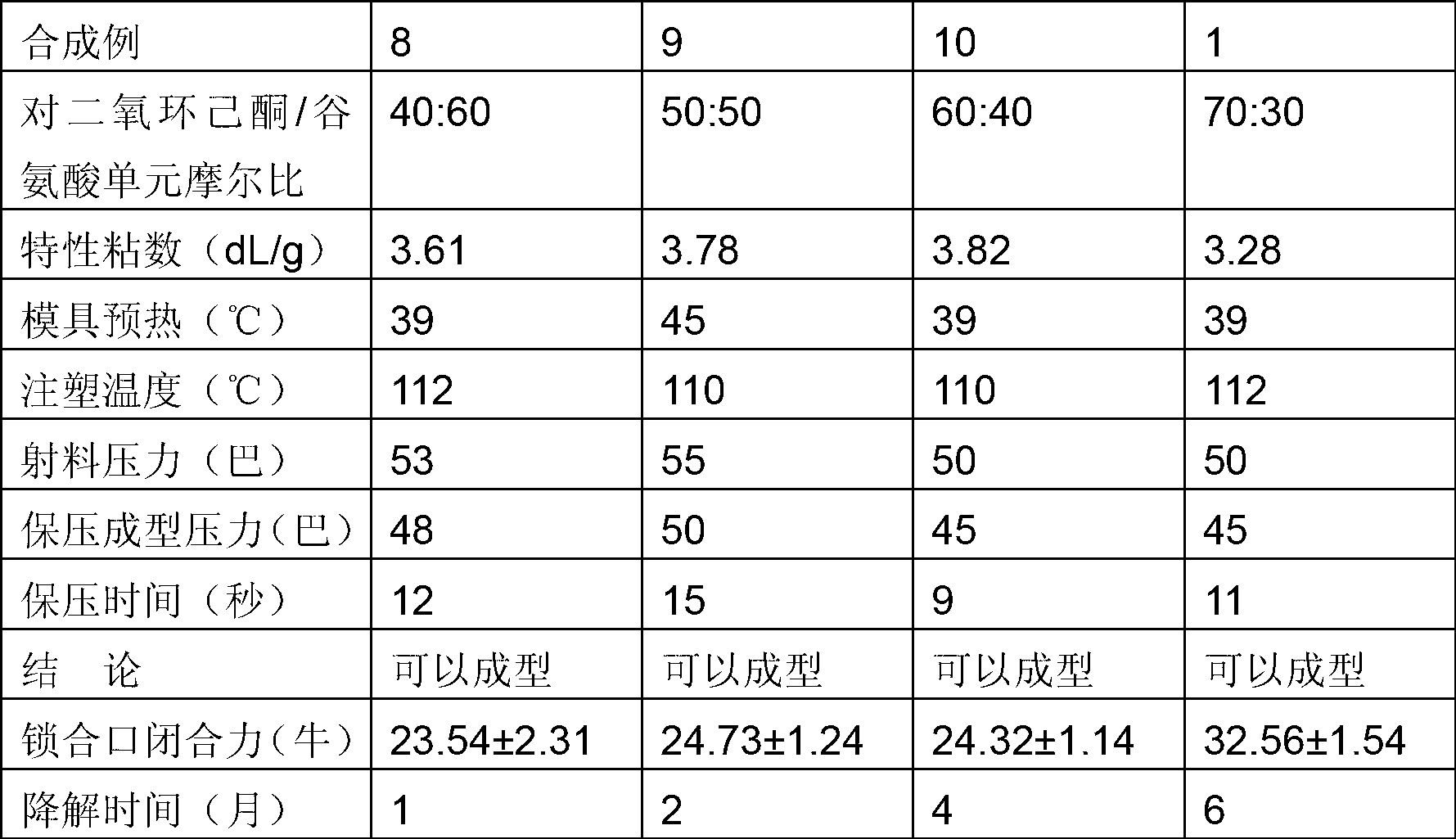

V-shaped vessel ligature clamp with single-layer structure and method for preparing V-shaped vessel ligature clamp

ActiveCN103006288ASimple and efficient operationEasy to clamp blood vesselsWound clampsOrthodontic ligaturePolyester

The invention provides an absorbable vessel ligature clamp for a surgical operation and a method for preparing the absorbable vessel ligature clamp. The vessel ligature clamp is formed by the fusing and injection molding of a raw material which contains a biodegradable aliphatic polyester material by using a specifically-shaped mold. The vessel ligature clamp has a single-layer structure and is V-shaped. The ligature clamp is high in biocompatibility. Degradation time is controllable and can be matched with a vessel healing period after operation.

Owner:HANGZHOU MEDZONE BIO-TECH CO LTD

Safety electric power cable storing and taking device capable of achieving reeling

ActiveCN106927302AFully wipeSmooth motionFilament handlingMechanical energy handlingMotor driveElectric power

The invention relates to a storing and taking device, in particular to a safety electric power cable storing and taking device capable of achieving reeling. According to the technical aims, the safety electric power cable storing and taking device capable of achieving reeling is multifunctional and higher in safety performance. In order to achieve the above technical aims, the safety electric power cable storing and taking device capable of achieving reeling is provided and comprises a storage box, a first support rod, a baffle, a push device, a lifting device, a second bearing block, a rotating rod, a roller, a cable, a motor, a first connecting rod and the like; the first support rod is arranged on the left side of the bottom of the interior of the storage box, a first sliding rail is arranged at the top end of the first support rod, a first sliding block is connected to the first sliding rail in a sliding manner, and the first connecting rod is arranged at the top of the first sliding block. By means of the safety electric power cable storing and taking device capable of achieving reeling, the effects of being multifunctional and high in safety performance are achieved; and according to the safety electric power cable storing and taking device, the push device is matched with the lifting device, and therefore the cable can be effectively stored and taken, and the motor drives the roller to rotate.

Owner:江苏捷成电缆有限公司

Detachable grab handle

ActiveUS8955197B2Easy and more comfortable experienceEasy to clipTravelling carriersHoldersEngineeringMechanical engineering

Owner:BAILEY KELLY R

U-type pipe locking device

ActiveCN101633022AEasy to clipPrevent disengagementMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The invention relates to a U-type pipe locking device. The locking device comprises a pedestal, wherein the head of the pedestal is provided with a U-type groove matched with the U-type pipe. The locking device is characterized in that the inside of the pedestal is provided with a clamping device which is capable of clamping a pipe piece placed inside the U-type groove and meshed with the pipe piece; the clamping device comprises a positioning shaft arranged on the pedestal; the positioning shaft is hinged with a left clamping block and a right clamping block which are symmetrical; the heads of the left clamping block and the right clamping block are respectively provided with a groove matched with the U-type pipe; and the tail ends of the left clamping block and the right clamping block are provided with push rod components capable of driving both clamping blocks to open and close. The invention aims to provide the U-type pipe locking device which has simple structure and can conveniently clamp a pipe piece placed inside the U-type groove.

Owner:OMS MASCH CO LTD

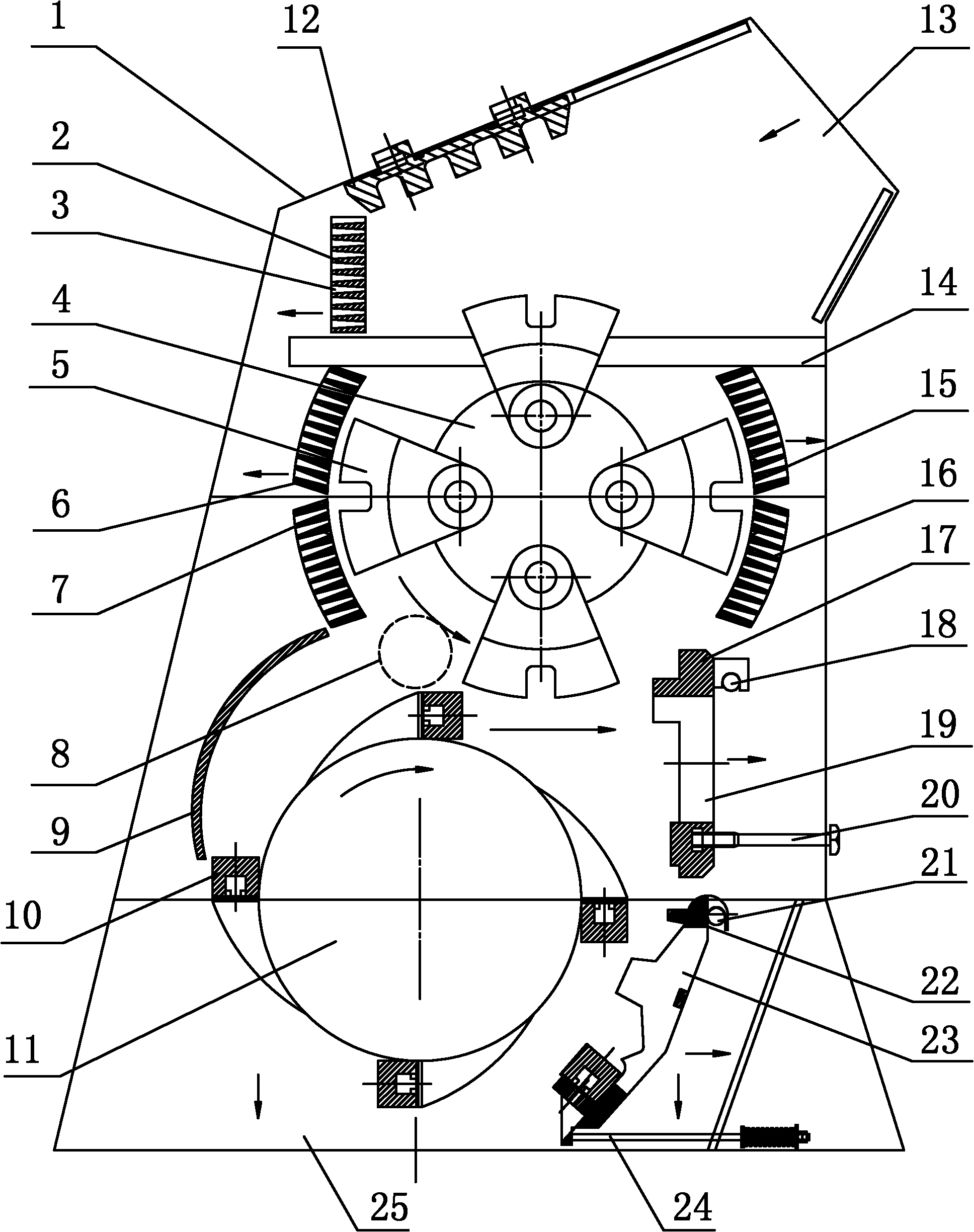

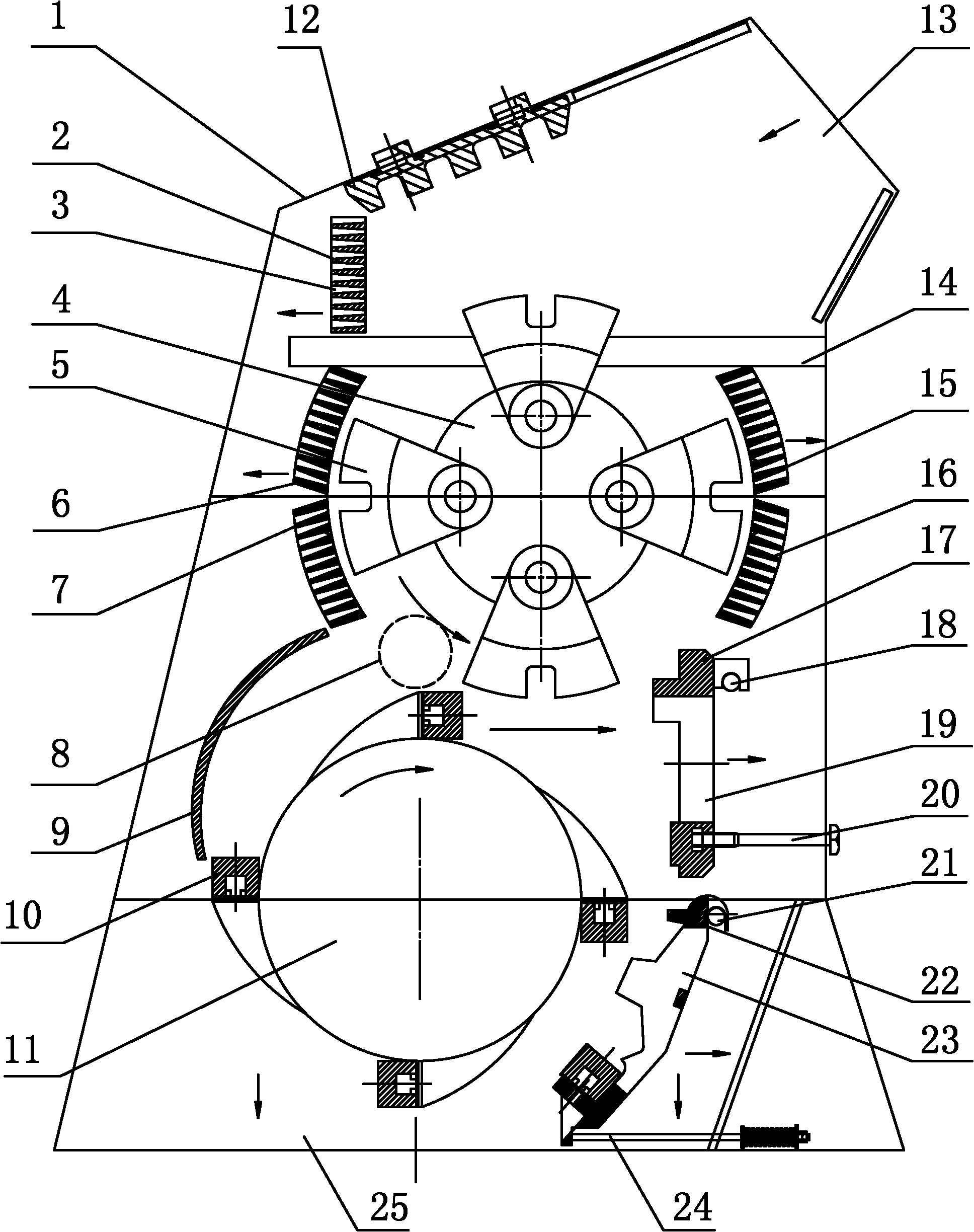

Dual-rotor combined sand making machine

The invention belongs to the field of machines for making sand from a mine and particularly relates to a sand making machine. A dual-rotor combined sand making machine comprises a machine body, a first crushing plate, an upper rotor, a pendulum bob, a second crushing plate, a third crushing plate, a fourth crushing plate, a fifth crushing plate, a sixth crushing plate, a rotary drive device, a first sieve plate and a second sieve plate and is characterized in that: a lower rotor is arranged below the upper rotor; the lower and upper rotors are arranged in a staggered way; and the lower rotor is fixed on a lower rotating shaft, the two end parts of the lower rotating shaft are connected with the machine body through bearings respectively, one end of the lower rotating shaft is positioned outside the machine body and connected with the rotary drive device, and a plate hammer is fixed on the lower rotor and along the circle edge. The sand making machine has the characteristics of low energy consumption, reduced wear and high efficiency.

Owner:松滋市中发机电实业有限公司

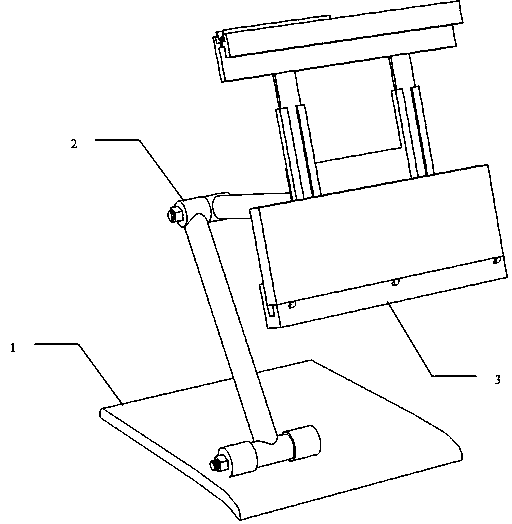

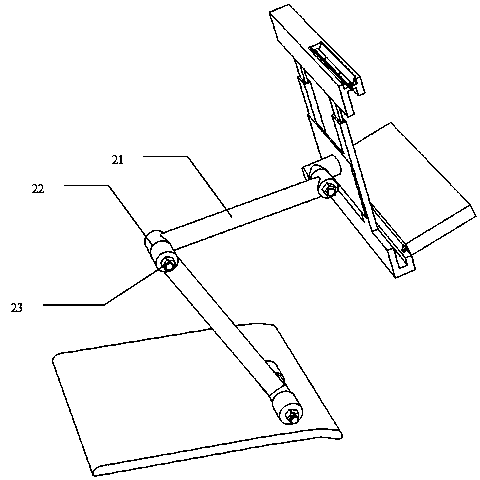

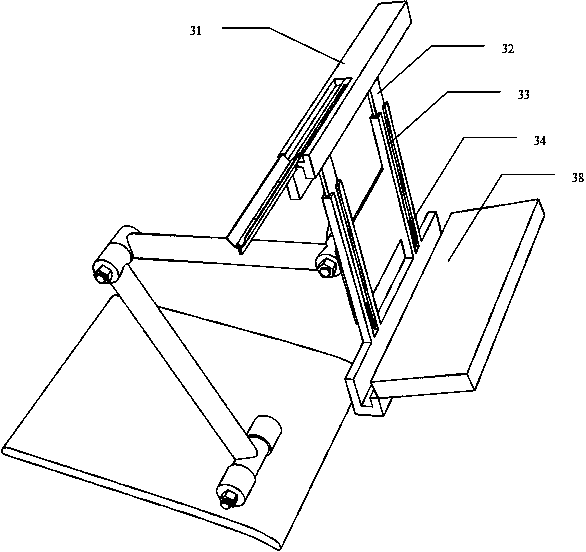

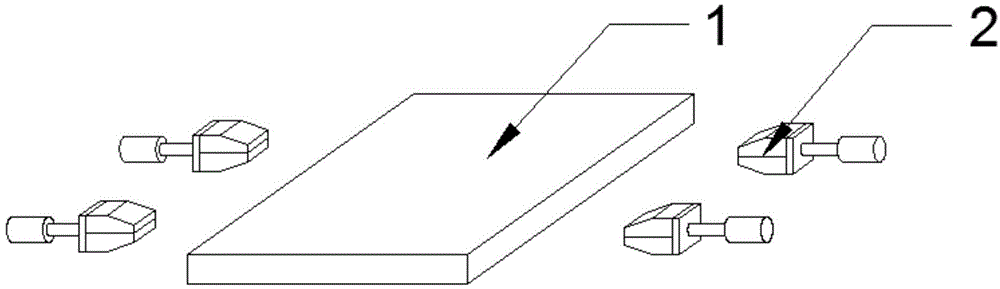

Portable folding drawing board frame

A portable folding drawing board frame comprises a base, a folding support and a drawing board bracket. The folding support is provided with a plurality of supporting rods which are staggered and provided with hinge joints with locking buttons, the base and the drawing board bracket are provided with hinge joints, the drawing board bracket is formed by socketing of an upper retaining plate frame with inserting rods and a drawing board bracket body with inserting grooves, a spring is arranged in each inserting groove, the upper retaining plate frame is provided with a long clamp containing cavity with a chute, a long clamp capable of realizing slidable limited connection is arranged in the long clamp containing cavity, and the drawing board bracket is provided with a supporting plate which is hinged and can be folded by 90 degrees. The folding support can be completely folded and contained, and a spring-type drawing board frame support, the concealed-type long clamp and the foldable supporting plate are further arranged, so that the whole drawing board frame can be in a form with extremely-small space occupied, and can be placed in a common backpack, thereby being convenient in carrying for outgoing.

Owner:WUXI X RES PROD DESIGN & RES

Fixing device of printed circuit board and frame

ActiveCN104582461ARealize automatic fixationAchieve fixationElectrical componentsEngineeringPrinted circuit board

The invention relates to a fixing device of a printed circuit board and a frame. The fixing device comprises a rack, a horizontal platform is arranged on the rack, the left side and the right side of the platform are both provided with at least one telescopic clamping mechanism, the top view of the platform is rectangular, the width of the platform is smaller than that of the printed circuit board, the length of the platform is larger than that of the printed circuit board, and when the telescopic clamping mechanisms are in a stretching state, the top ends of the telescopic clamping mechanisms are matched with the printed circuit board and the frame on the platform. The circuit board and the frame are placed on the platform, clamps are driven by the telescopic clamping mechanisms to clamp the frame and the printed circuit board, therefore, the frame and the printed circuit board are fixed, automatic fixing of the frame and the printed circuit board is achieved, and compared with an existing mode of manually clamping the frame and the printed circuit board, the yield and efficiency of the mode of automatically clamping the frame and the printed circuit board are higher.

Owner:ZHUHAI JIAYI ELECTRONICS

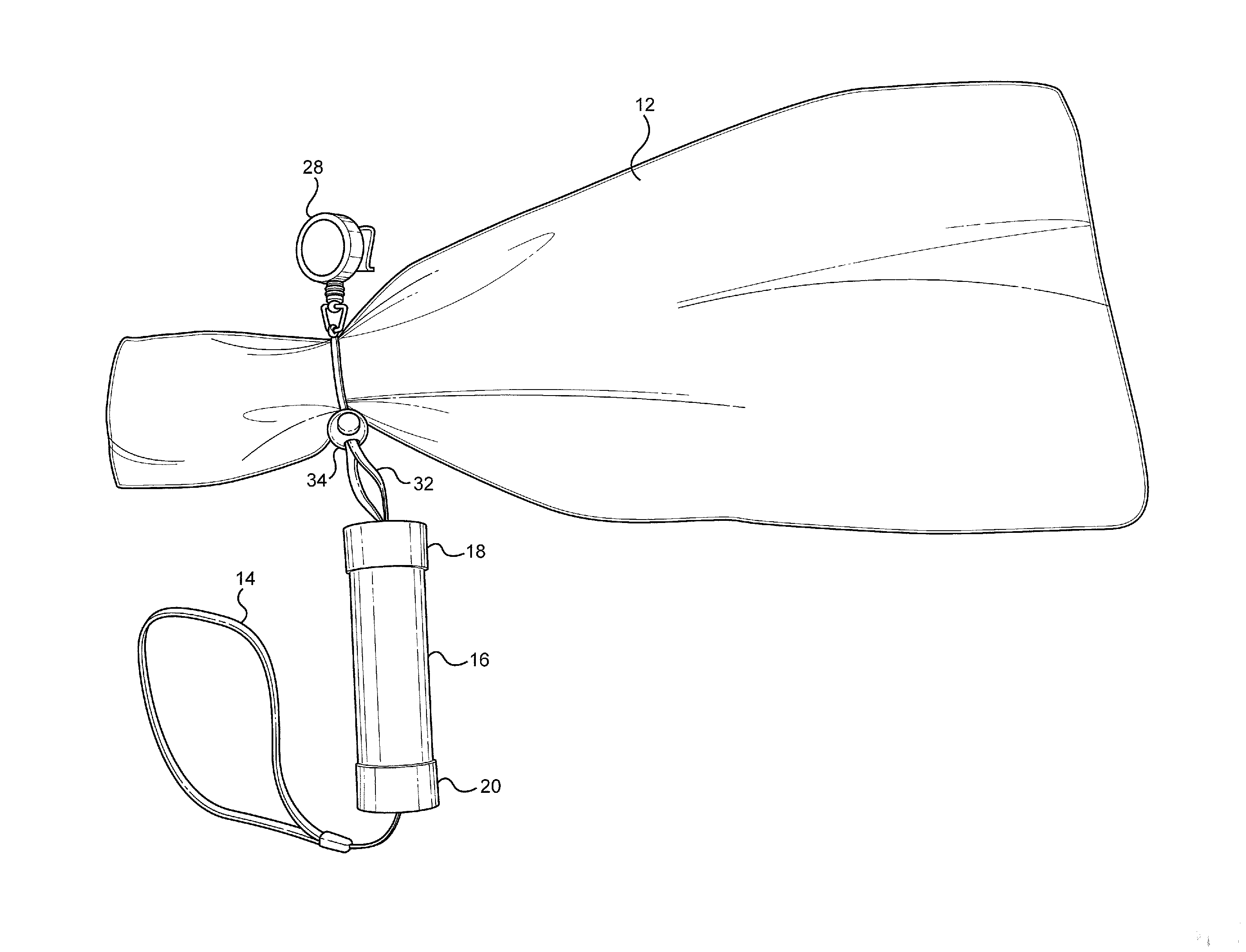

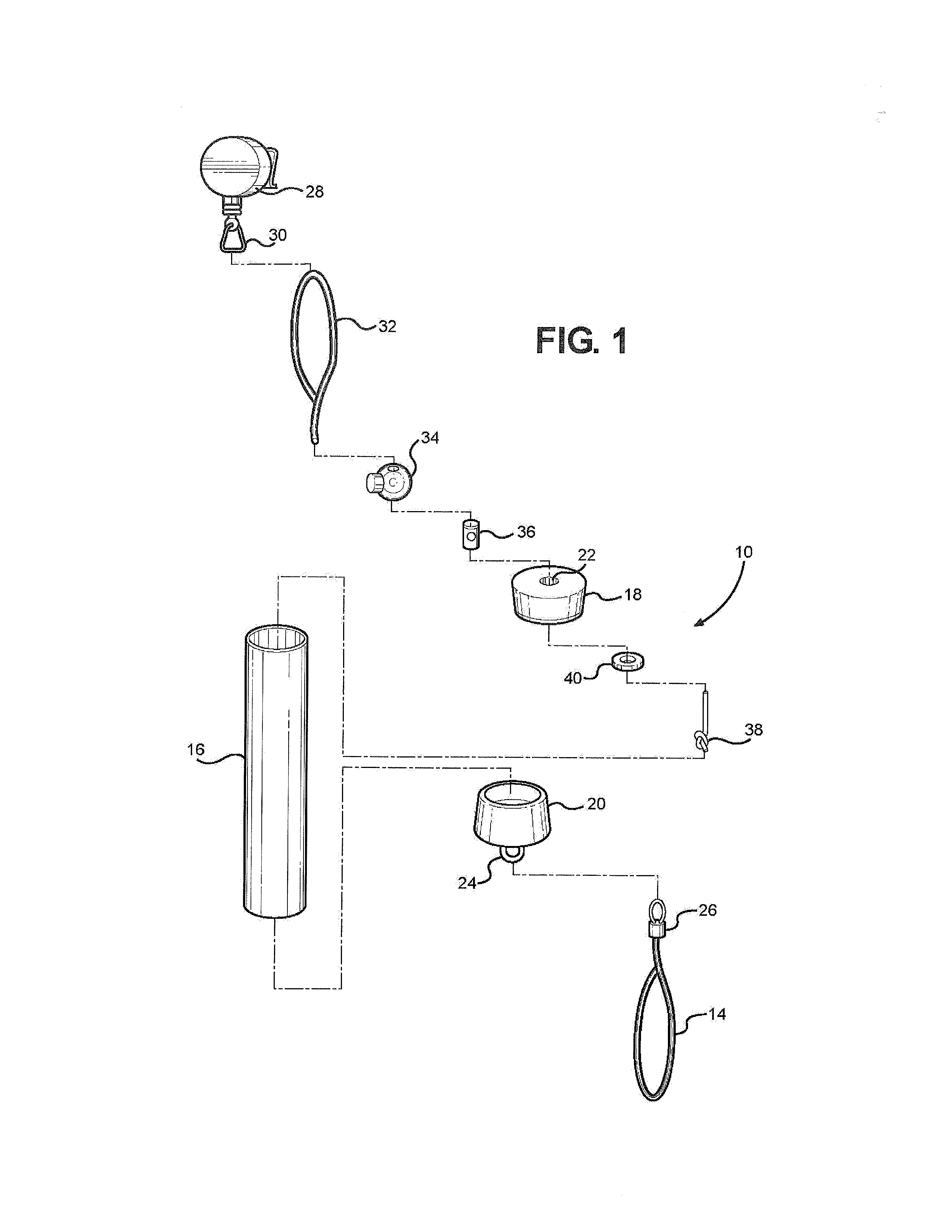

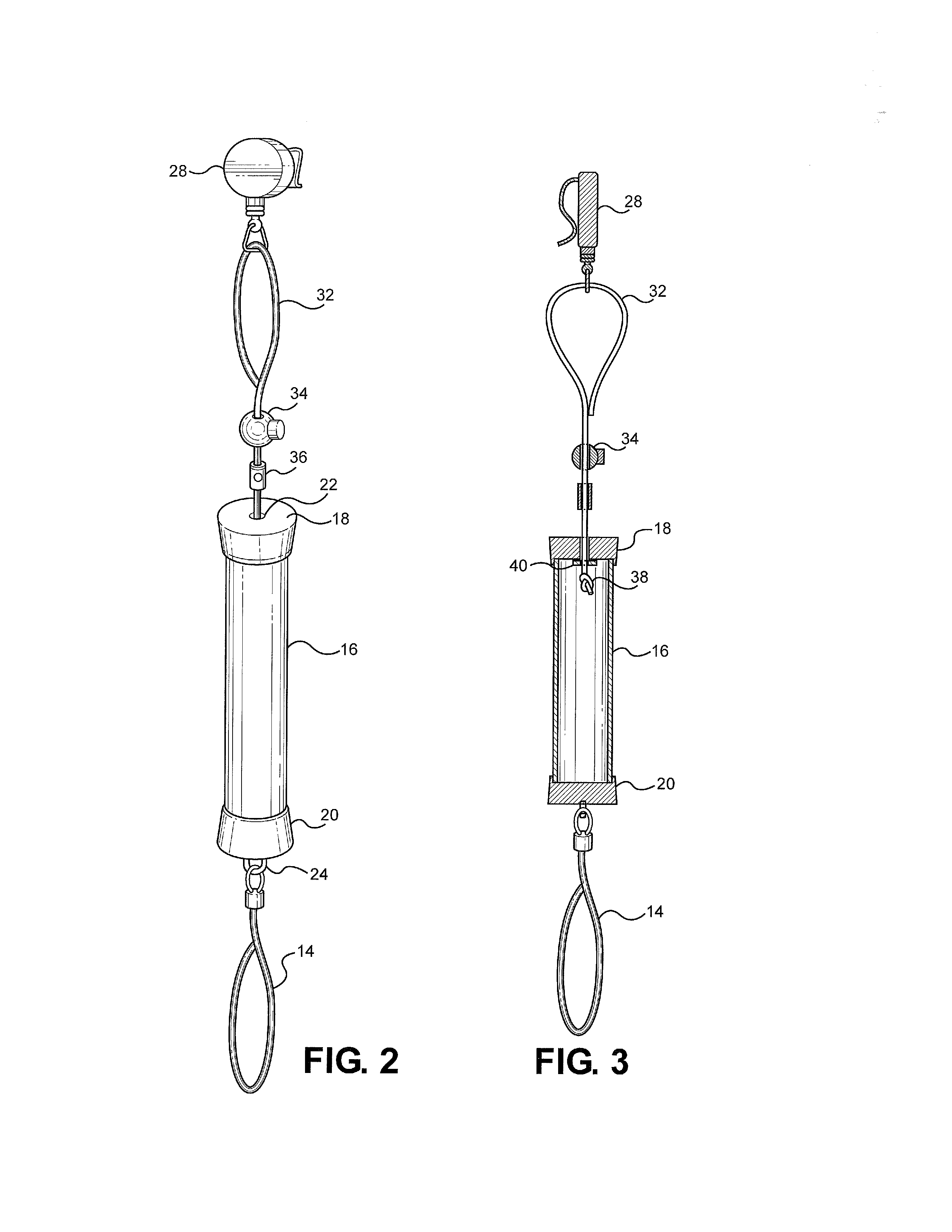

Rally towel apparatus

A rally towel apparatus comprising a body having first end and a second end. The rally towel apparatus also comprises a first end cap engaged with a first end and a second end cap engaged with a second end. The rally towel apparatus also comprises a cord connected to the first end cap and a cord lock member arranged on the cord. The rally towel apparatus also comprises a wrist strap connected to the second end cap and a rally towel arranged and secured within a loop of the cord.

Owner:WALKER CHARLES

Indicia carrying element for marking timber and more particularly logs

A indicia carrying element for marking timber and more especially logs possessing a indicia carrying body bearing such indicia and having on one side thereof clips for attachment to the head of an applicator hammer in peripheral grooves therein for prior to driving said element into timber, whereas the other side of the element is provided with spurs to be driven into the timber. The clips are arranged in spring regions like lugs in the plate-like indicia carrying body, and such regions are for instance defined by slots in the indicia carrying body. This means that such indicia carrying elements may be reliably clipped onto the standard head of an applicator hammer without there being any danger of the clips breaking off.

Owner:LATSCHBACHER

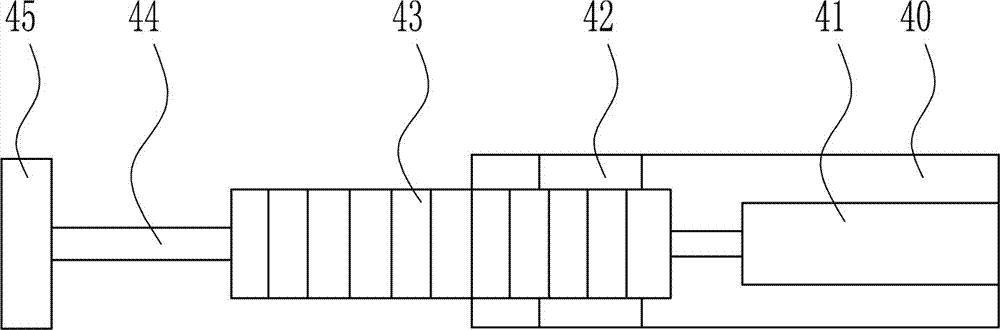

Thin-film capacitor and automatic production equipment and method thereof

InactiveCN111627706AHigh precisionRealize synchronous handlingThin/thick film capacitorStacked capacitorsCapacitanceThin membrane

The invention relates to the technical field of capacitor production. Automatic production equipment of a thin-film capacitor comprises a rack, and a feeding conveying device, a clamping and transferring device, a multifunctional forming device, a rotary material overturning device, an inverted conveying device, a pipe penetrating device and a pipe pressing device which are mounted on the rack, the feeding conveying device is connected with the clamping and transferring device, and the multifunctional forming device is located under the clamping and transferring device. The multifunctional forming device is connected with the inverted conveying device through the rotary material overturning device. The pipe penetrating device and the pipe pressing device are located over the inverted conveying device, the rack is further provided with a discharging barrel, and the discharging barrel is connected with the discharging side of the inverted conveying device. According to the invention, movement between film capacitor stations is efficient and positional accurate, the pins are flat and uniform in length, twice bending is completed by one action, and the forming and bending efficiency ishigh; the mobile capacitor is inverted to position a capacitor pin, so that pipe penetration is facilitated; and the heat shrink tube is integrally assembled, and the success rate of pipe penetrationis high.

Owner:温州源利智能科技有限公司

Spiral reciprocating based eel slicing device for processing canned eel

The invention discloses a spiral reciprocating based eel slicing device for processing canned eel, relating to the technical field of eel processing. The spiral reciprocating based eel slicing devicefor processing canned eel comprises a cutting board, a connecting mechanism is fixedly connected to each of the left and right sides of the upper surface of the cutting board, a chute is formed in theupper surface of the cutting board and between the left and right connecting mechanisms, a sliding block is connected to the inner wall of the chute in a sliding manner, and a clamping mechanism is fixedly connected to the upper surface of the sliding block. According to the spiral reciprocating based eel slicing device for processing canned eel, the cutting mechanism reciprocates left and right,and the eel skin is cut by a cutter to facilitate cutting of the eel, thereby effectively solving the problems that most of the eel slicing devices in the conventional market slice the eel by directextrusion of cutters, but the eel skin is relatively tough, the direct extrusion does not facilitate cutting of the skin, and over large extrusion force easily separates the skin from the meat.

Owner:邵改臣

Clip and illuminant device

InactiveUS8021015B2Easy to clipSnap fastenersPoint-like light sourceEngineeringMechanical engineering

Owner:SHARP KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com