Production device for super-huge type new energy battery box body

A production device and new energy technology, which is applied in the direction of liquid injection device, injection device, battery pack parts, etc., can solve the problems of troublesome clamping and low processing efficiency, so as to improve efficiency, improve processing efficiency, and clamp operation quick and easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

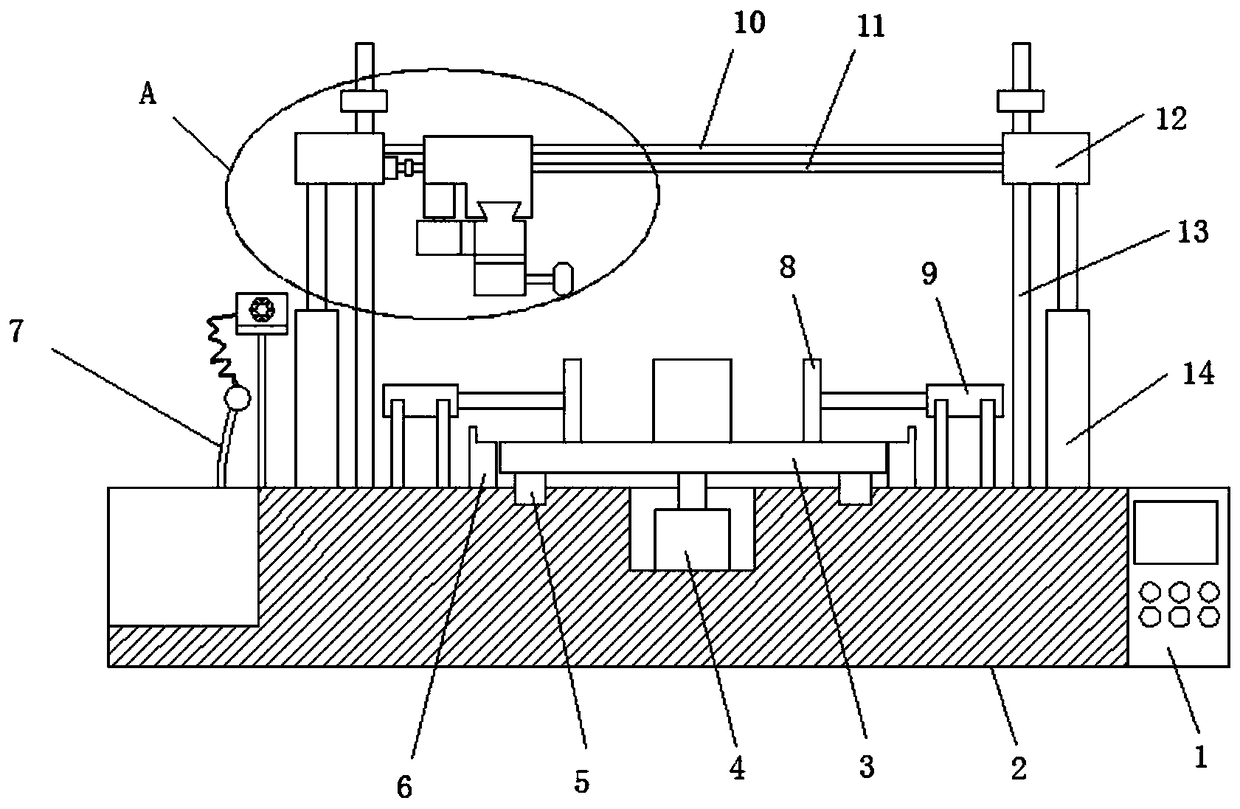

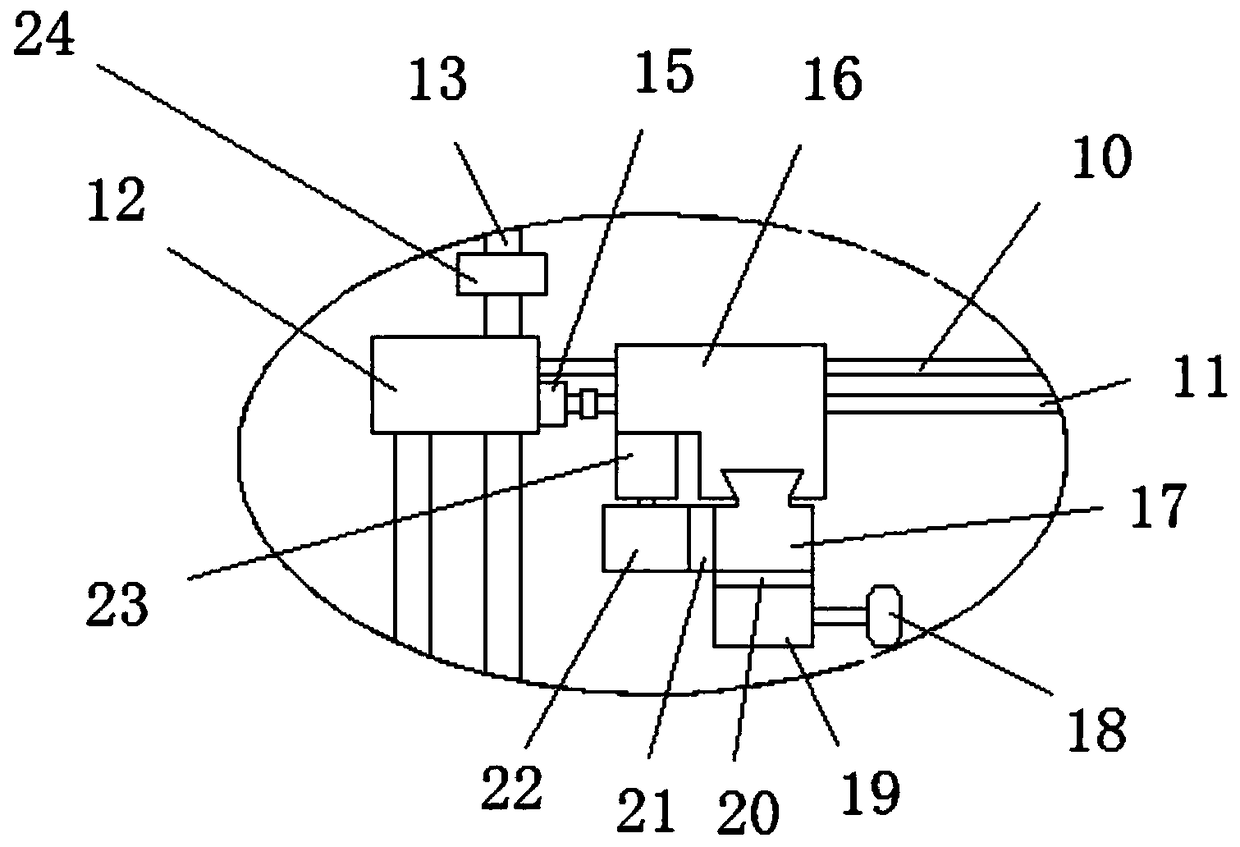

[0030] refer to figure 1 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , a production device for an extra-large new energy battery box, including a base 2, the top of the base 2 is provided with an installation groove and a first chute, the first chute is a ring structure, and the first chute is located outside the installation groove, A first motor 4 is installed inside the installation groove, and a turntable 3 is installed on the output shaft of the first motor 4. The bottom of the turntable 3 is fixed with an annular first slider 5, and the first slider 5 is slidably installed on the top of the base 2. Inside the first chute;

[0031] The top of base 2 is equipped with support base 6, the first cylinder 9, the second cylinder 14, the second slide bar 13 and painting device 7, support base 6 is provided with four groups, and the top of support base 6 offers notch, the first Cylinder 9 is provided with four groups, and the end of the piston rod of first cyl...

Embodiment 2

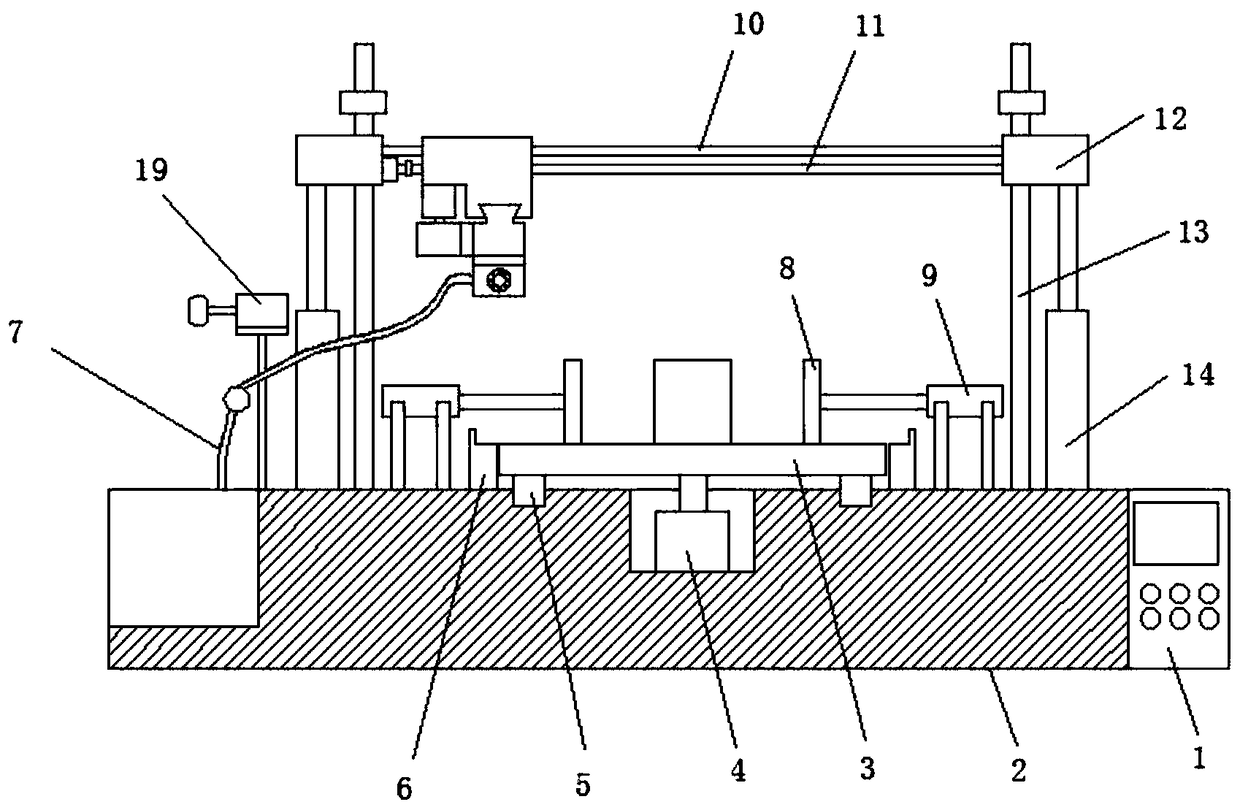

[0035] refer to figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7, a production device for an extra-large new energy battery box, including a base 2, the top of the base 2 is provided with an installation groove and a first chute, the first chute is a ring structure, and the first chute is located outside the installation groove, A first motor 4 is installed inside the installation groove, and a turntable 3 is installed on the output shaft of the first motor 4. The bottom of the turntable 3 is fixed with an annular first slider 5, and the first slider 5 is slidably installed on the top of the base 2. Inside the first chute;

[0036] The top of base 2 is equipped with support base 6, the first cylinder 9, the second cylinder 14, the second slide bar 13 and painting device 7, support base 6 is provided with four groups, and the top of support base 6 offers notch, the first Cylinder 9 is provided with four groups, and the end of the piston rod of first cyl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com