Fixing device of printed circuit board and frame

A technology for printed circuit boards and fixed equipment, applied in the direction of electrical components, electrical components, etc., can solve the problems of low production efficiency, easy damage of push clamps, and many labors, so as to achieve high yield and efficiency, increase diversity, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

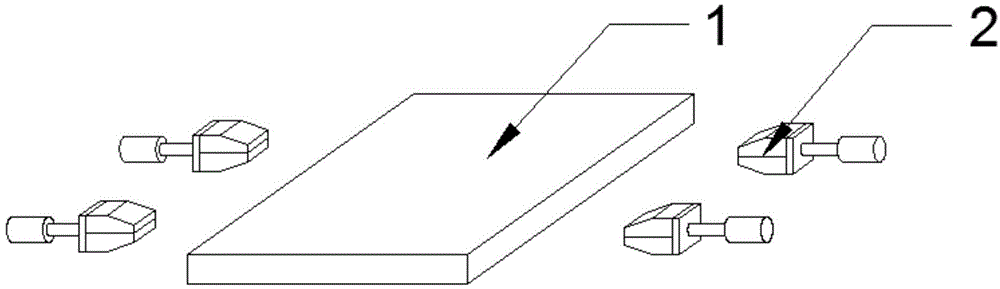

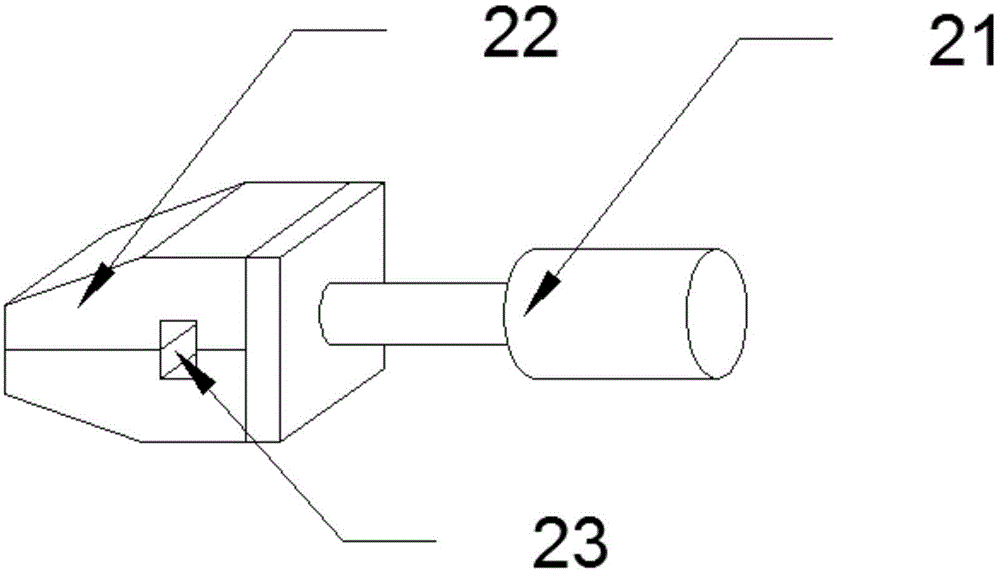

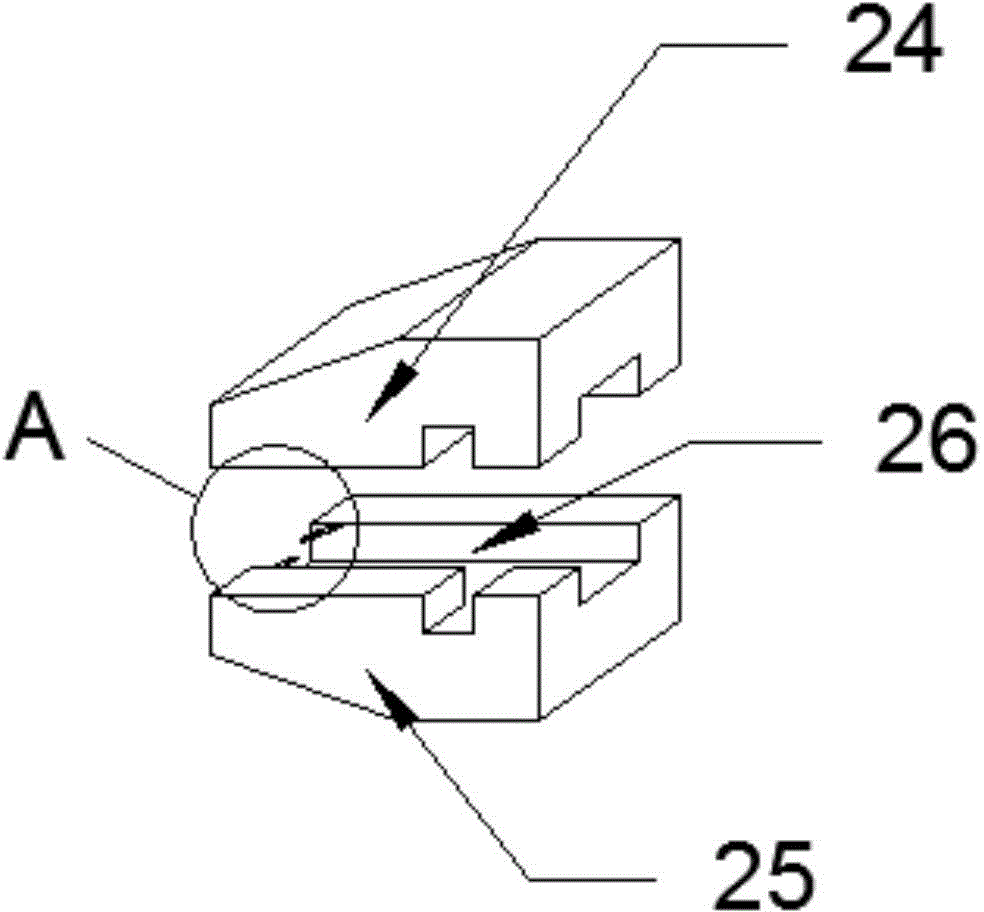

[0044] see figure 1 , the present invention relates to a fixing device for a printed circuit board and a frame, comprising a frame (not shown in the figure), a platform 1 arranged horizontally is installed on the frame, and the left and right sides of the platform are also provided with At least one telescopic clamping mechanism 2.

[0045] The details are as follows:

[0046] Regarding the platform, the platform is a rectangular flat plate on which a printed circuit board (such as an FPC board) is placed.

[0047] It should be noted that usually the shape of the printed circuit board is also rectangular, and the width of the printed circuit board is greater than the width of the platform, and the length of the printed circuit board is smaller than the length of the platform, so that after the printed circuit board is placed on the platform, The left and right (width direction) sides of the printed circuit board are exposed on the outside of the platform, which is convenient...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com