Dual-rotor combined sand making machine

A double-rotor, sand making machine technology is applied to sand making machines. It can solve the problems of reduced efficiency, energy loss, and large consumption of wearing parts, so as to achieve the effects of reducing wear, improving efficiency, and reducing energy consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

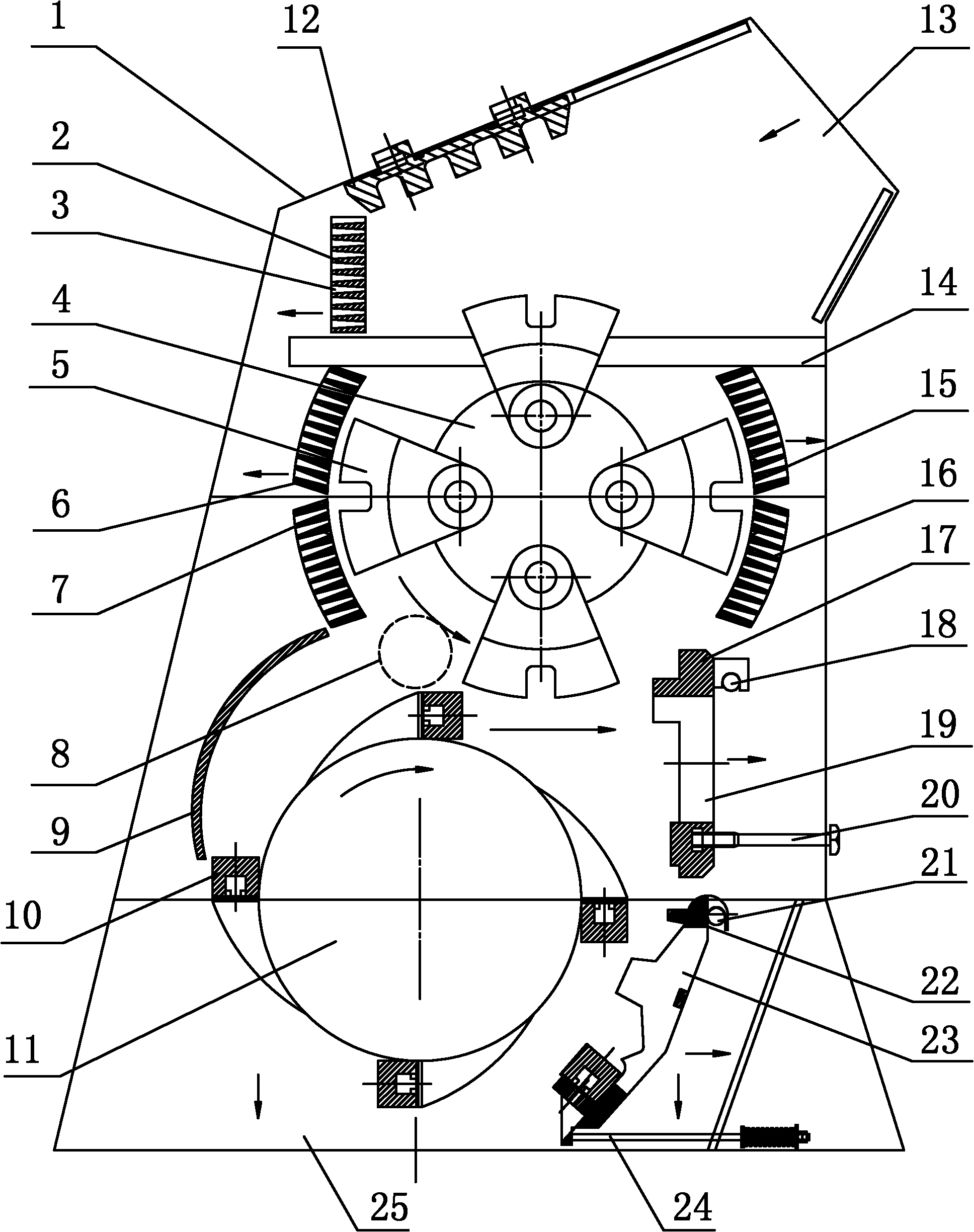

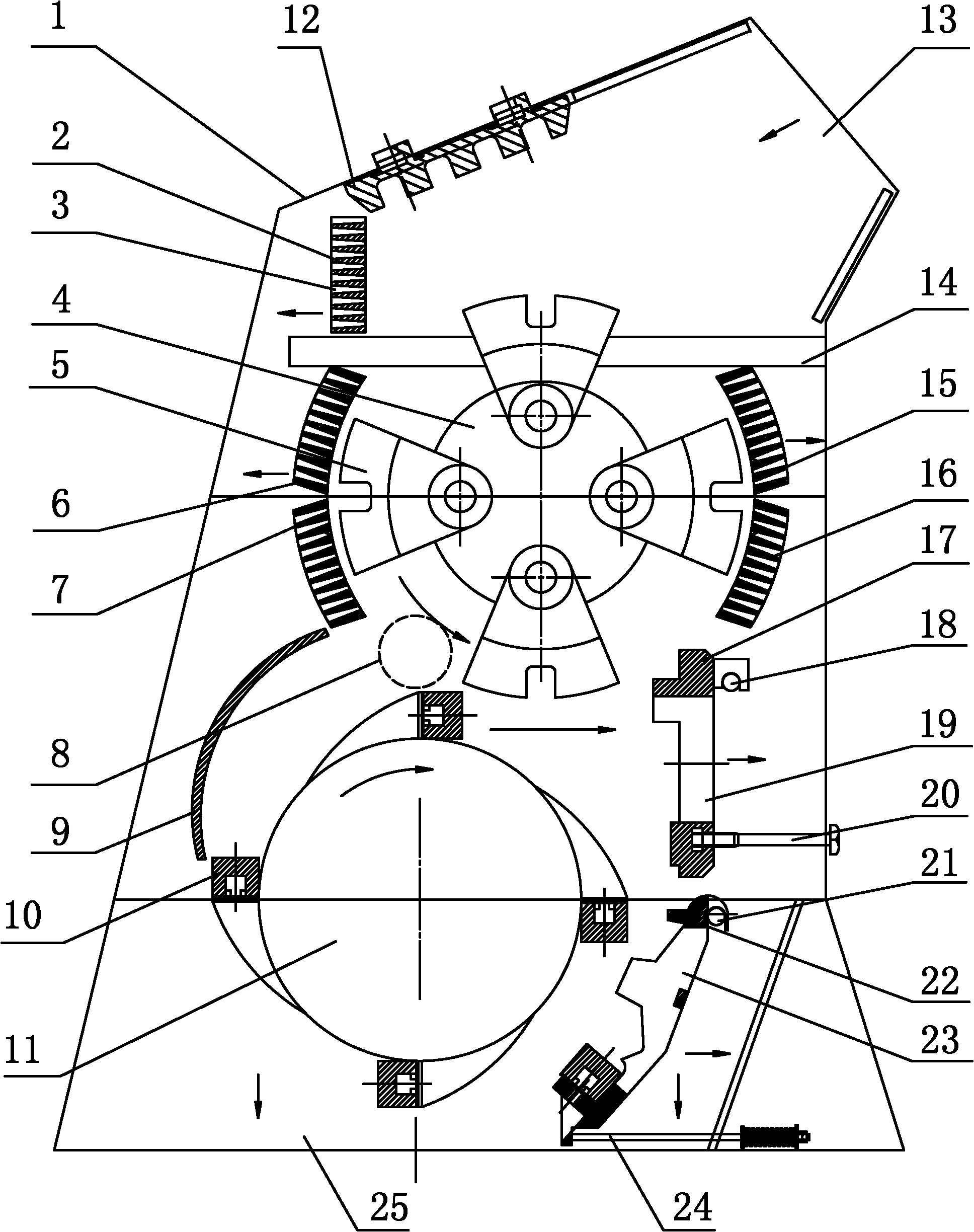

[0017] Such as figure 1 As shown, the double-rotor composite sand making machine includes a body 1, a first crushing plate 2, an upper rotor 4, a pendulum 5, a second crushing plate 6, a third crushing plate 7, a partition 9, a plate hammer 10, and a lower The rotor 11, the fourth crushing plate 12, the fifth crushing plate 15, the sixth crushing plate 16, the rotary drive device, the first screen plate, the second screen plate, the body 1 is a cavity, and the upper end of the body 1 is provided with a feed Port 13, the lower end of the body 1 is provided with a discharge port 25; the upper rotor (disc) 4 is located in the upper part of the cavity of the body 1, the upper rotor 4 is fixed on the upper rotating shaft, and the two ends of the upper rotating shaft are respectively The bearing is connected to the body 1 (that is, the upper rotating shaft can rotate). One end of the upper rotating shaft is located outside the body 1 and connected to the rotating drive device (the ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com