Method for preparing aluminum nanostructure array, three-dimensional solar cell and photovoltaic cell

A technology of solar cells and nanostructures, applied in electroforming nanostructures, photovoltaic power generation, circuits, etc., can solve the problems of high cost, controllability, poor scale, and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

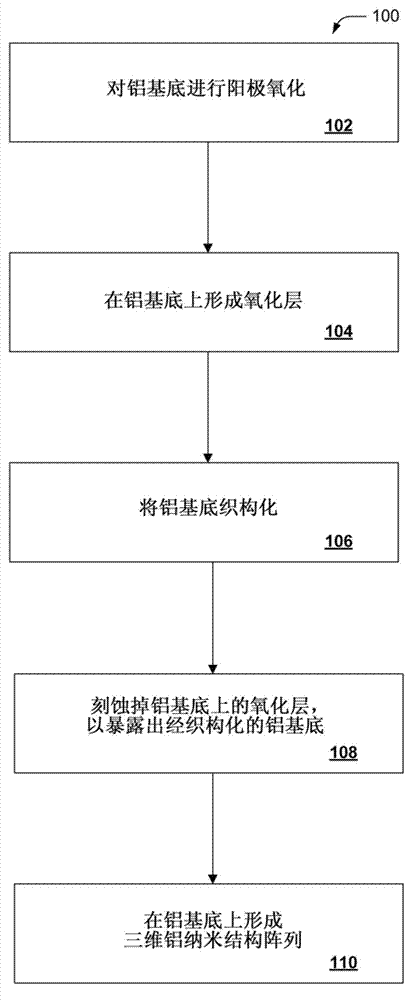

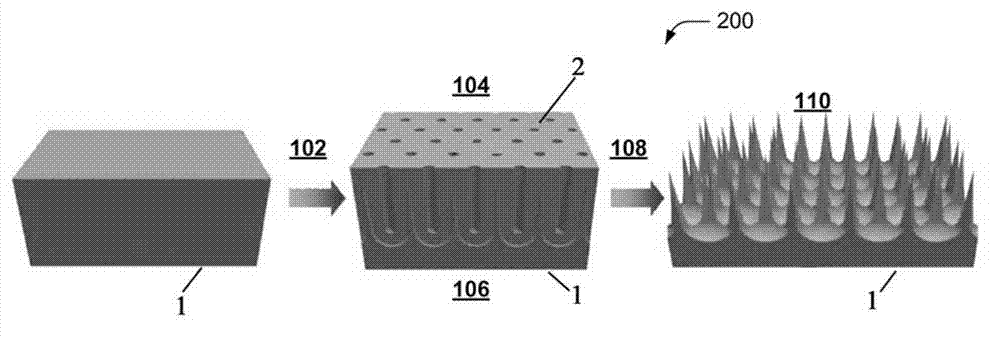

[0044] Various aspects or features in the patent are described according to the drawings, and the same reference numerals in the specification are used to refer to the same elements. In this manual, in order to help better understand the manual, a large number of special details will be explained clearly. However, it should be understood that some aspects of the specification will not mention these details, or will be replaced by other methods, components, molecules, etc. In addition, in various embodiments, well-known structures and devices will be represented by block diagrams to help description and explanation.

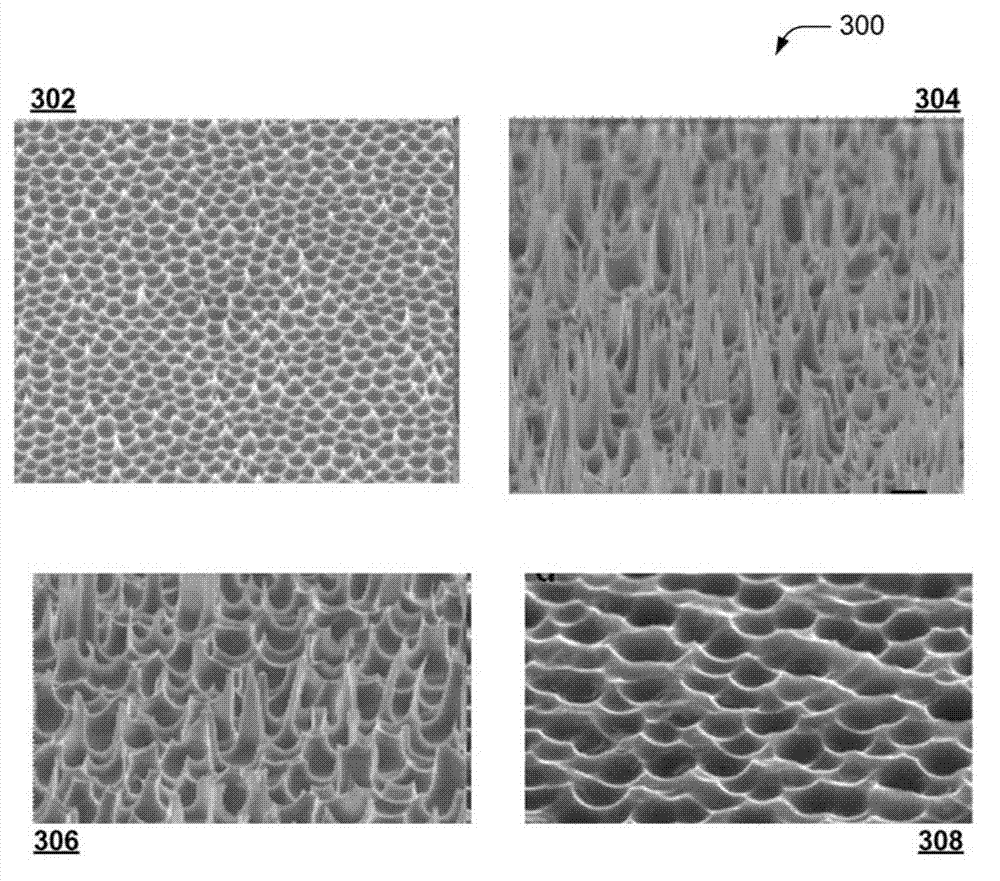

[0045] According to one or more embodiments described in this specification, a three-dimensional nanostructure array self-assembled and grown on an aluminum surface according to a low-cost and large-scale method is described here. After being coated with a light-absorbing film material, the three-dimensional nanostructure array exhibits a more effective light-absorb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com