Microstructured material and process for its manufacture

A technology of microstructuring and products, applied in chemical instruments and methods, liquid crystal materials, shielding materials, etc., can solve problems such as high cost, geometric structure control and precision or material property limitations, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

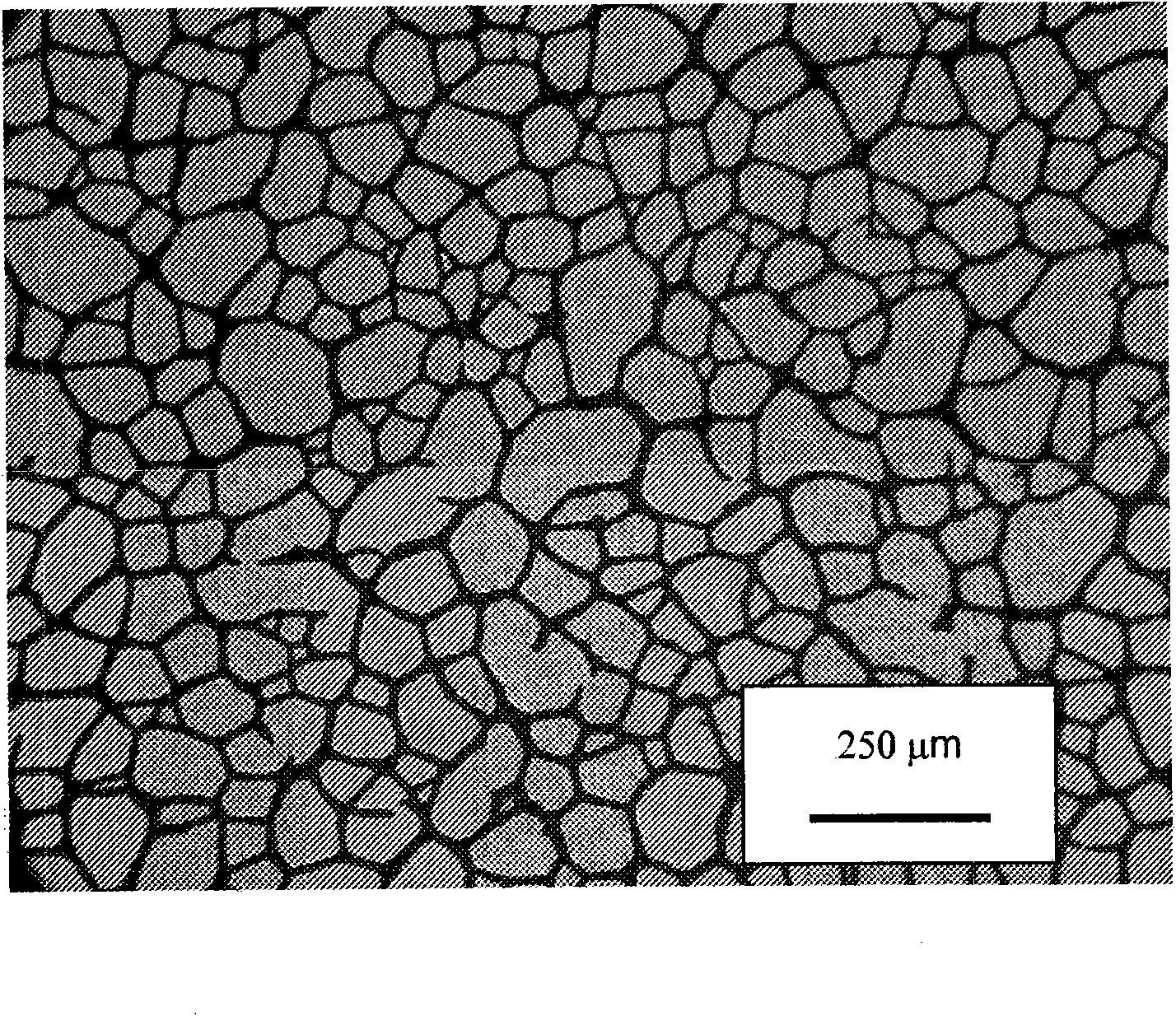

[0072] A 4 mil thick polyethylene terephthalate substrate (Toray Lumirror U46) was used.

[0073] Deposit a layer of primer on the substrate. The primer is composed of 0.28% by weight of [dimethylsiloxane--[3-(2-(2-hydroxyethoxy)ethoxy)propyl]methylsiloxane] copolymer (Aldrich code 480320) and 0.60% by weight of Synperonic NP30 (Fluka No. 86209) in acetone. The materials were mixed by shaking by hand. Approximately 3 milliliters of material was deposited along one side of an 8.5" x 11" sample of the substrate and was knife coated over the entire film using a wire wound rod to form a nominally 12 micron thick (wet) coating. The samples were allowed to dry for approximately 1 minute at room temperature and room humidity.

[0074] The emulsion is prepared by thoroughly mixing the following materials in an ultrasonic dispersion system.

[0075] components

%

Byk 410

0.290%

Span 60

0.165%

5.212%

0...

Embodiment 2

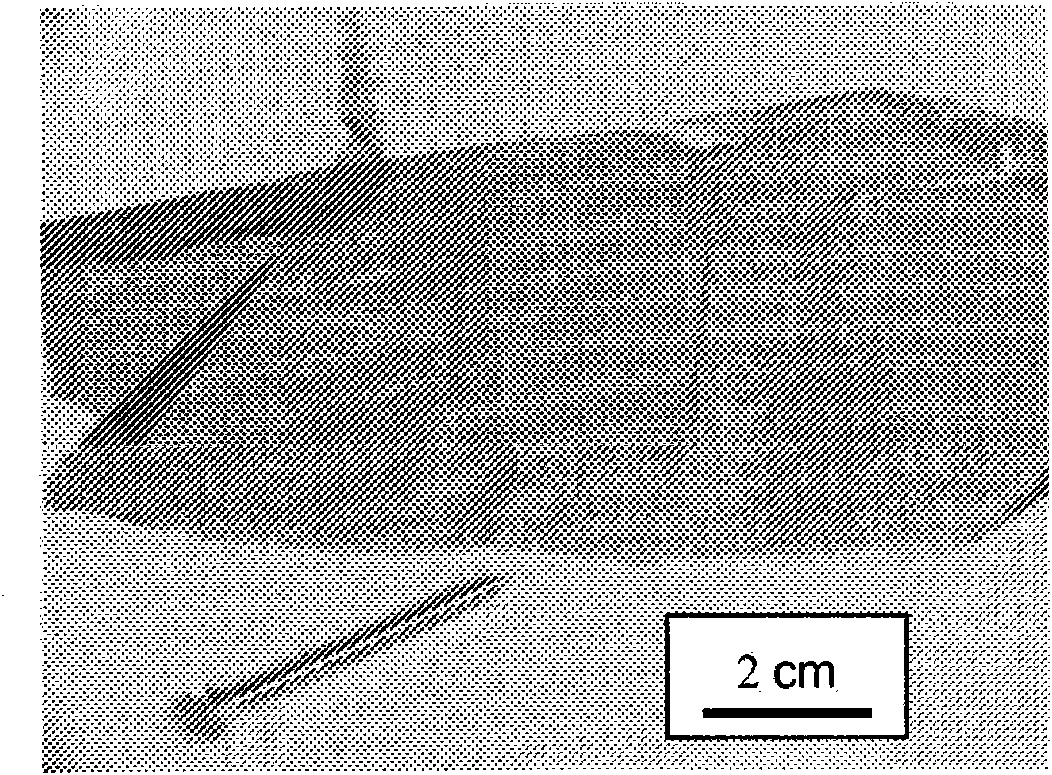

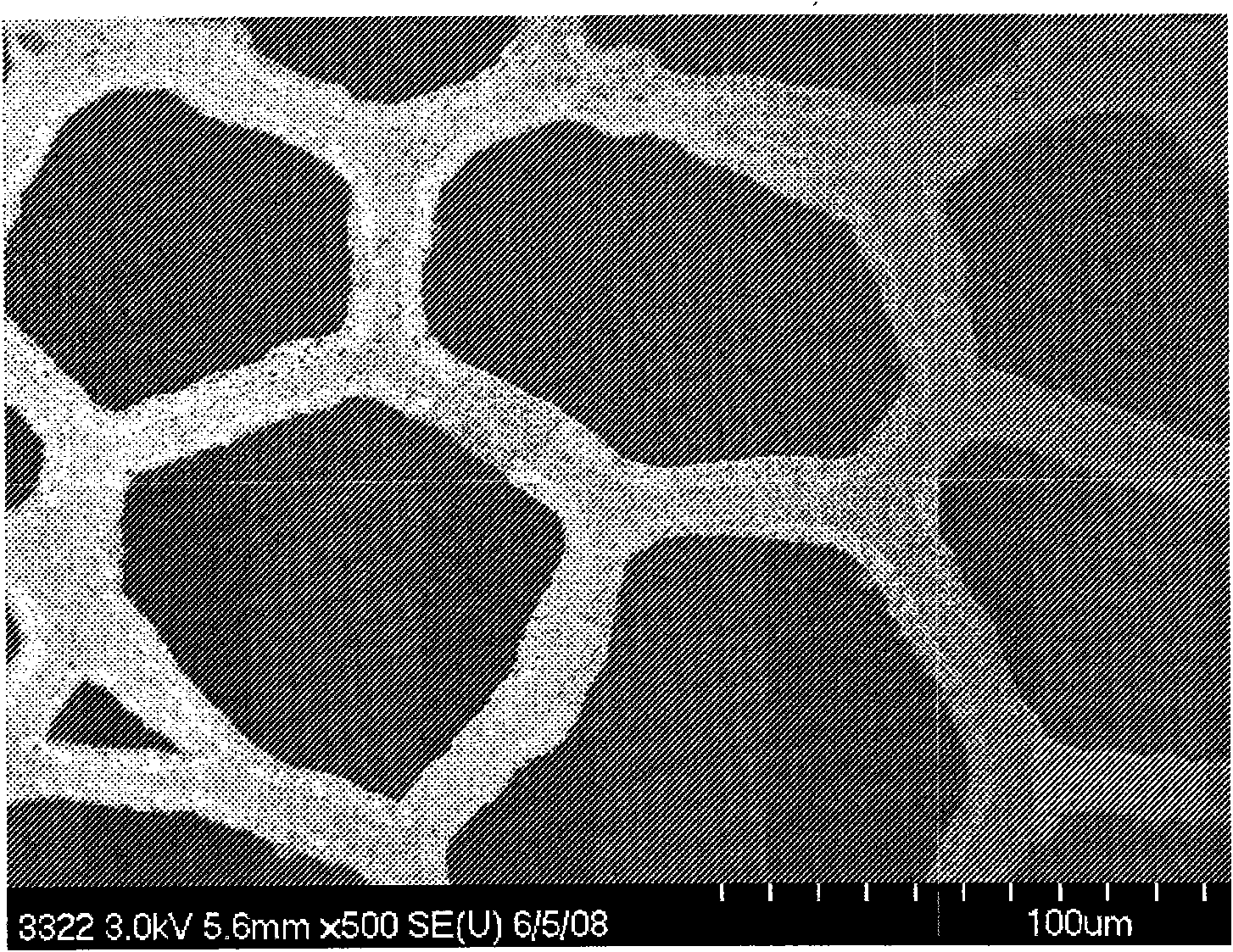

[0094] A web is formed on a glass substrate. The mesh and substrate were immersed in a bath of 5% aqueous hydrofluoric acid for 1 minute at room temperature, removed from the bath, and rinsed with tap water for less than 1 minute. Peel the metal mesh from the substrate by hand.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com