High Cu-RE interalloy refining agent for refining scrap copper and preparation and application thereof

A technology with high rare earth content and master alloy, applied in the field of new materials, can solve the problems of rare earth burning, difficulty in mastering the method and amount of addition, increasing the complexity of the process and production cost, and achieving easy batching and not easy secondary pollution. , The effect of reducing the burning rate of rare earth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Preparation of Refining Agent for Cu-RE Master Alloy

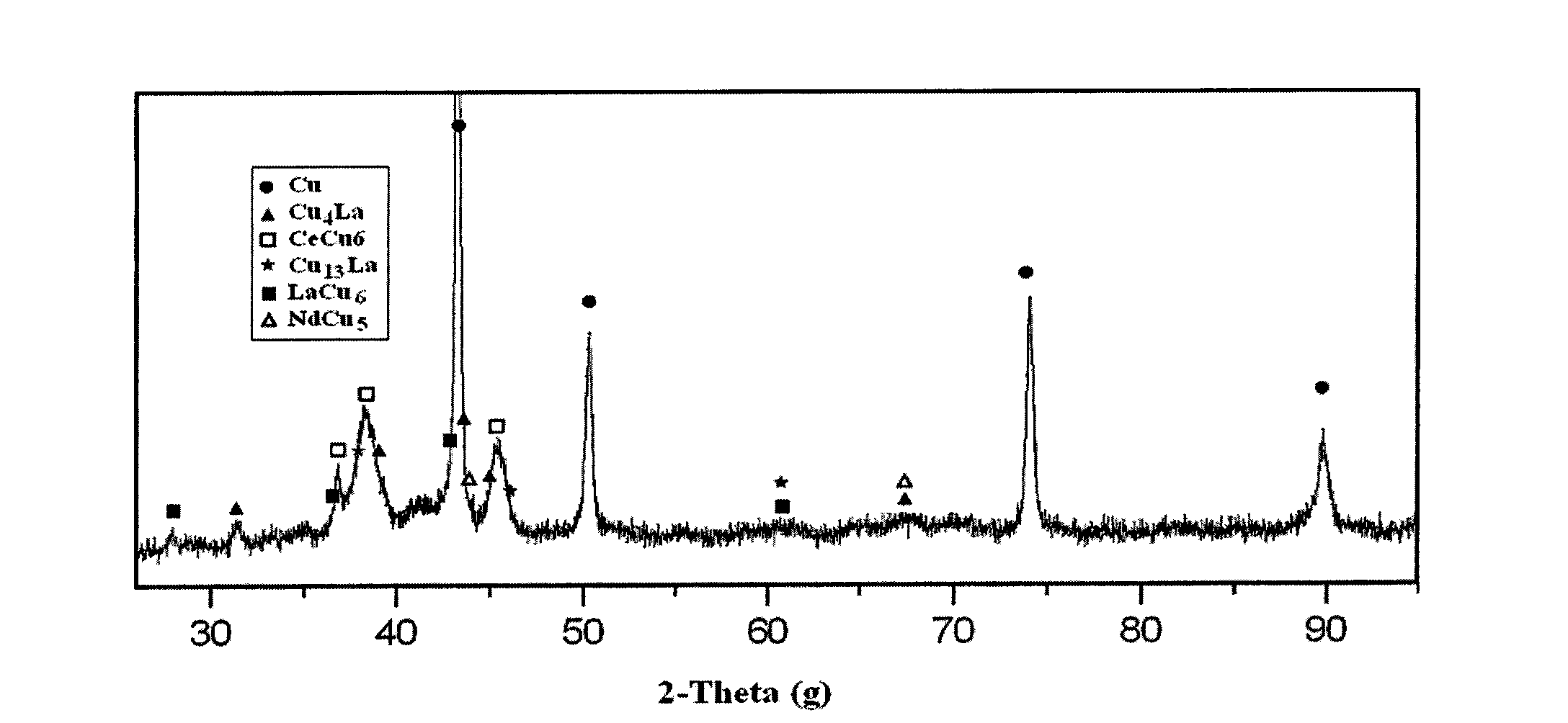

[0043] Prepare raw materials according to the batching scheme in Table 1, and prepare Cu-RE master alloy by vacuum melting technology, and the melting temperature is 1150-1250 °C; during smelting, electrolytic copper is first added, and after melting, rare earth is added to the copper melt by encapsulation with pure copper tubes; After standing still and removing slag, pour it into a block sample in an iron mold. Such as figure 1 Shown, through X-ray diffraction analysis, the rare earth element La and Ce in the Cu-RE master alloy refining agent of the present invention are mainly in the form of compound LaCu 6 、CeCu 6 、LaCu 4 、LaCu 13 A series of intermediate compounds exist in the form.

Embodiment 2

[0045] Application of Cu-RE Master Alloy Refining Agent in Scrap Copper

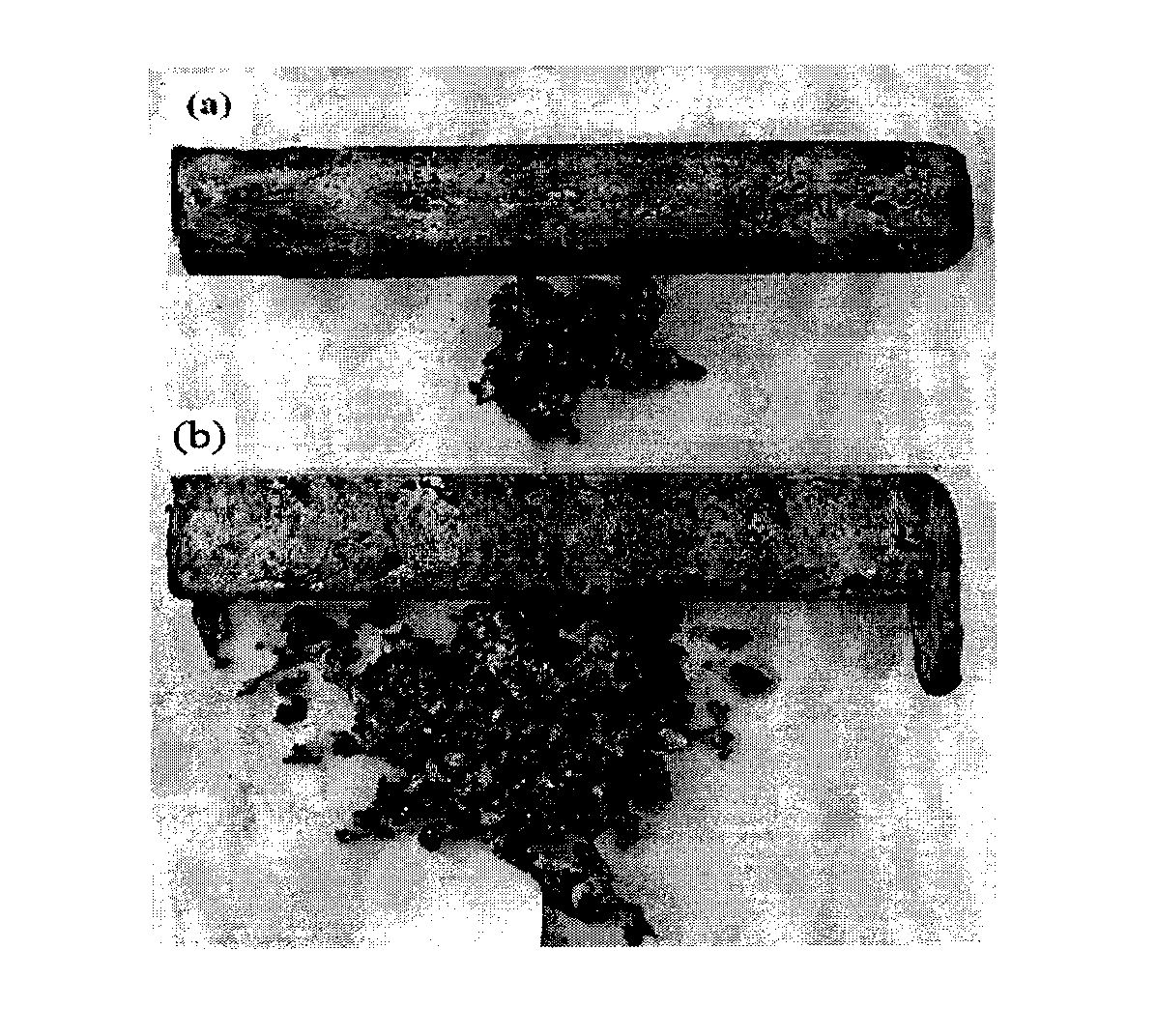

[0046] The high rare earth content Cu-RE master alloy refining agent of the present invention is applied to the remelting and refining of red miscellaneous copper such as waste wires and waste air-conditioning pipes. The addition amount is only 2-6g / kg melt, and good refining and metamorphic effects are obtained. Realized the direct recycling of red copper. Such as figure 2 Shown is the slagging situation during the remelting refining experiment.

[0047] Depend on figure 2 It can be seen that the red copper without this refining agent produces very little slag during the smelting process, so the remelting is not sufficient for the slag removal of the melt; while the red copper added with the rare earth refining agent of the intermediate alloy produces little slag. A large amount of slag greatly reduces the content of impurity elements in the copper melt, showing an obvious refining effect.

[0048...

Embodiment 3

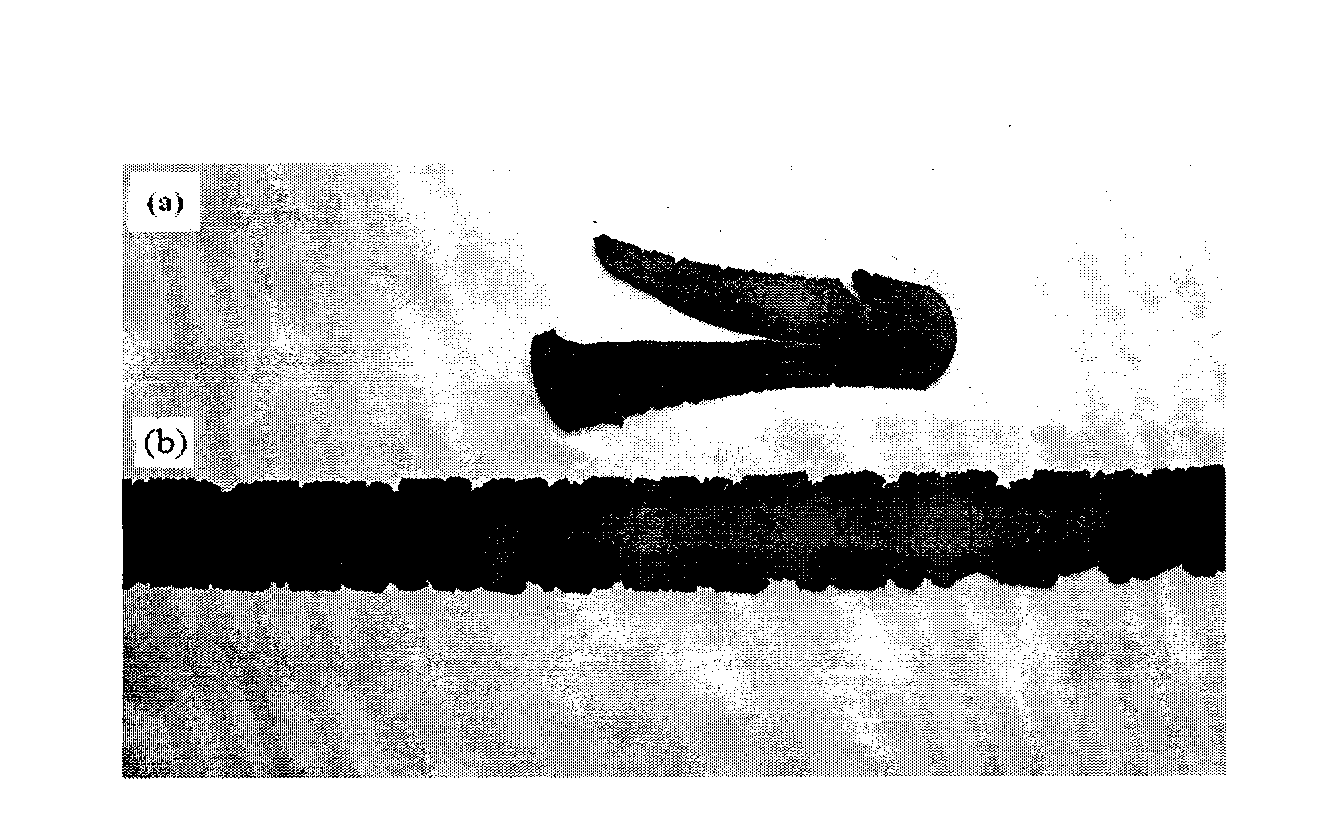

[0053] Cu-RE Master Alloy Refining Agent Applied to Industrial Production of White Copper Tubes

[0054] The Cu-RE master alloy refining agent of the present invention is applied to the industrial production of white copper tubes of a certain domestic enterprise. Add 50-70% of Cu-Ni-Fe (white copper) process waste during smelting, and add a proper amount of rare earth to the refining and modification of the white copper melt to reduce harmful impurities in the white copper, purify the grain boundaries, refine the grains, and improve Thermoplasticity of cupronickel alloy; combined with micro-alloying of rare earth in copper alloy to improve its corrosion resistance. After semi-continuous casting, peeling extrusion with large extrusion ratio on a large-tonnage extruder, and then cold-rolled with a large deformation rate, on-line bright annealing, and high-speed inverted disc stretching, the cupronickel condensing coil was successfully produced. Similarly, through rare earth ref...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com