R(Fe,M)12 type rare earth permanent magnet material and preparation method thereof

A technology of rare earth permanent magnets and rare earth elements, which is applied in the fields of magnetic materials, inductance/transformer/magnet manufacturing, magnetic objects, etc., can solve the problems of lack of grain boundary phase structure in magnetic alloys, difficulty in preparing high-performance bulk magnetic materials, etc., and achieve The effect of small rare earth ratio, cost reduction, and rare earth resources saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] a R(Fe,M) 12 The preparation method of the rare earth permanent magnet material of type, concrete steps are as follows:

[0029] (1) According to the stoichiometric atomic percentage R(Fe,M) 12 Ingredients, where R is a rare earth element and M is a transition element. Rare earth elements R are in excess of 5-20% during batching, and the purity of rare earth raw materials is greater than 99.5%. Mixed rare earths with a certain ratio can also be used to reduce costs.

[0030] (2) The prepared R(Fe,M) 12 Alloy raw materials are put into the smelting furnace, and the vacuum degree reaches 10 -2 Start heating when the Pa is above, and wait until the vacuum degree reaches 10 again. -2When the pressure in the furnace reaches -0.05MPa, adjust the power of the smelting furnace to the smelting power for smelting. After the alloy raw materials are completely melted, stir for 5-10 minutes. After refining, the alloy The liquid is poured on a water-cooled copper roll to obtain ...

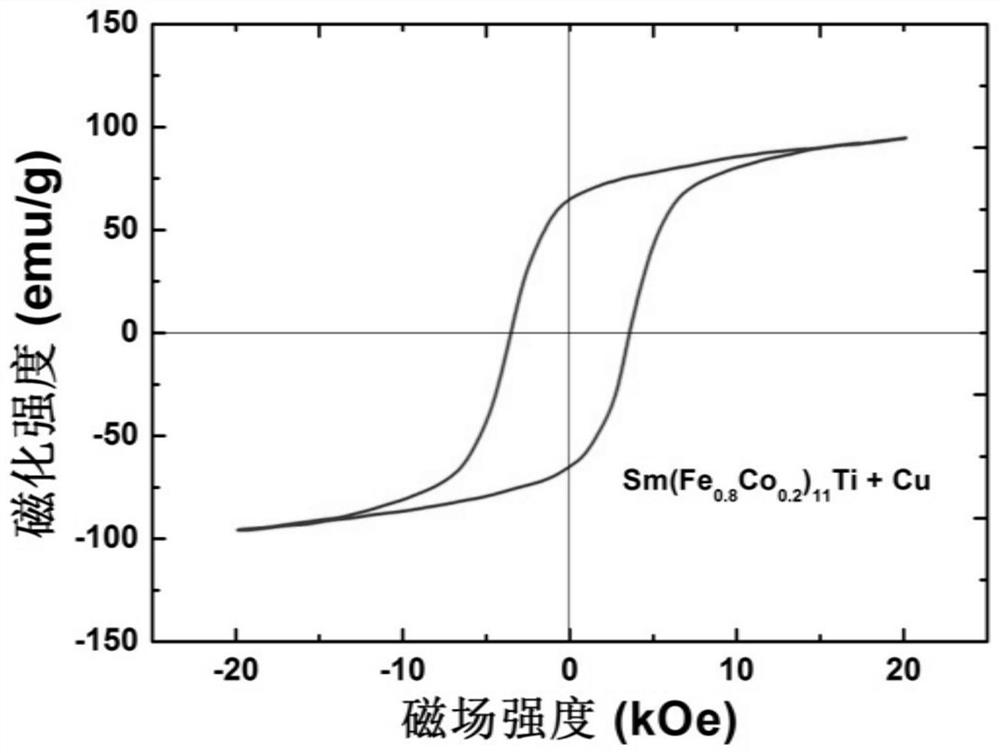

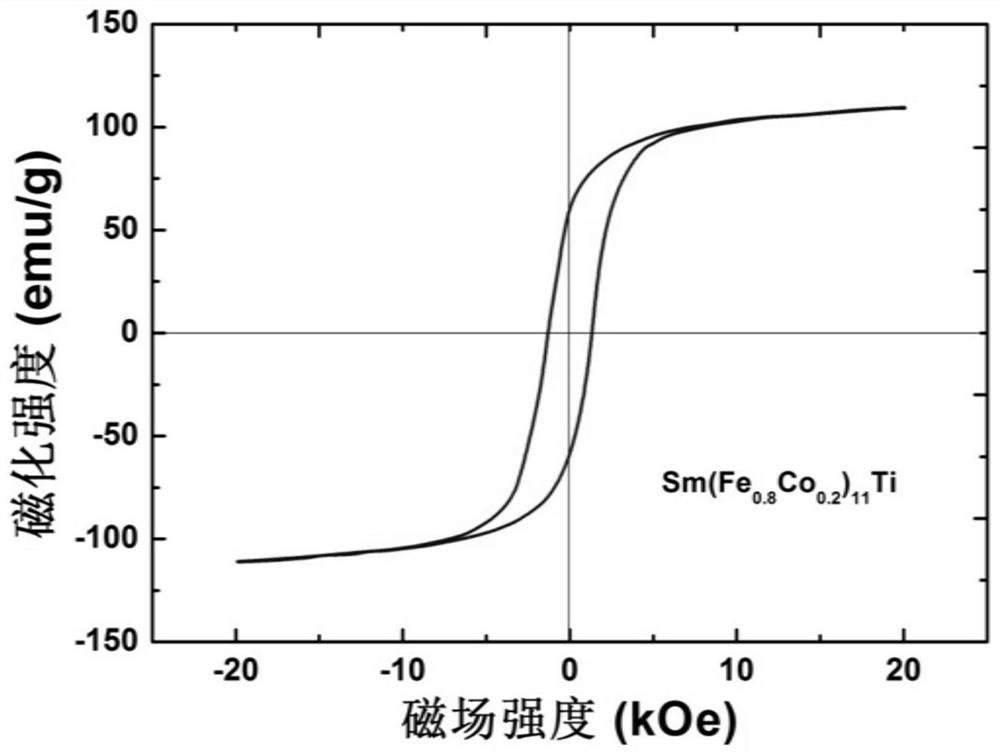

Embodiment 1

[0035] (1) According to the chemical formula Sm(Fe 0.8 co 0.2 ) 11 Ti batching, the raw materials used are rare earth Sm with a purity greater than 99.5%, pure Fe, Co, Ti with a purity greater than 99.9%, and Sm in excess of 10%.

[0036] (2) The prepared Sm(Fe 0.8 co 0.2 ) 11 Put the Ti alloy raw material into the melting quick-setting crucible in the medium-frequency induction furnace, and when the vacuum degree reaches 10 -2 When Pa is above, power on and preheat until the vacuum degree reaches 10 again. -2 Stop vacuuming after Pa is above and fill with high-purity Ar gas. When the Ar pressure in the furnace reaches -0.05MPa, adjust the power of the melting furnace to the melting power for smelting. After all the raw materials are melted, stir and refine for 3 minutes. After refining, pour the alloy liquid onto a water-cooled copper roll to obtain Sm(Fe 0.8 co 0.2 ) 11 Ti alloy flakes.

[0037] (3) Sm(Fe 0.8 co 0.2 ) 11 After the Ti quick-quenching alloy is coa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle size | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com