Surface chemical metal plating carbon nanotube field-emission cathode preparation method

A technology of carbon nanotubes and field emission, which is applied in the manufacture of cold cathodes, discharge tubes/lamps, and electrode systems, etc. Poor adhesion between cathode, carbon nanotube film and substrate electrode, etc., to achieve good electron conduction and emission capabilities, increased probability, and high uniformity of luminescence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0039] (3) Preparation of modified carbon nanotube electrophoretic fluid:

[0040] First prepare viscous organic slurry F1, then add the carbon nanotube powder with electroless metal plating on the surface obtained in step (2) to the organic slurry F1 to disperse into carbon nanotube slurry F2, and finally take the carbon nanotube Slurry F2 is added to the electrophoretic solvent, and metal ions are added to assist the ultrasonic dispersion of salts to make carbon nanotube electrophoretic fluid F3:

[0041] The concrete process of preparing the organic slurry F1 with viscousness among the present invention is to get ethyl cellulose ([C 6 h 7 o 2 (OC 2 h 5 ) 3 ] n ) 10-20g, terpineol (C 10 h 18 O) 300-500mL, 0-3g of polyvinylpyrrolidone, mixed together, the temperature is 60-120 ℃, through one or two or more combinations of magnetic stirring, heating stirring, ultrasonic dispersion or ultrasonic cell crushing After 2-24 hours, various materials are uniformly mixed, and...

Embodiment 1

[0053] The invention provides a method for preparing a field emission cathode with chemically plated metal silver carbon nanotubes on the surface. The process steps of the present invention will be described below in conjunction with the accompanying drawings.

[0054] 1. Activation treatment of carbon nanotubes:

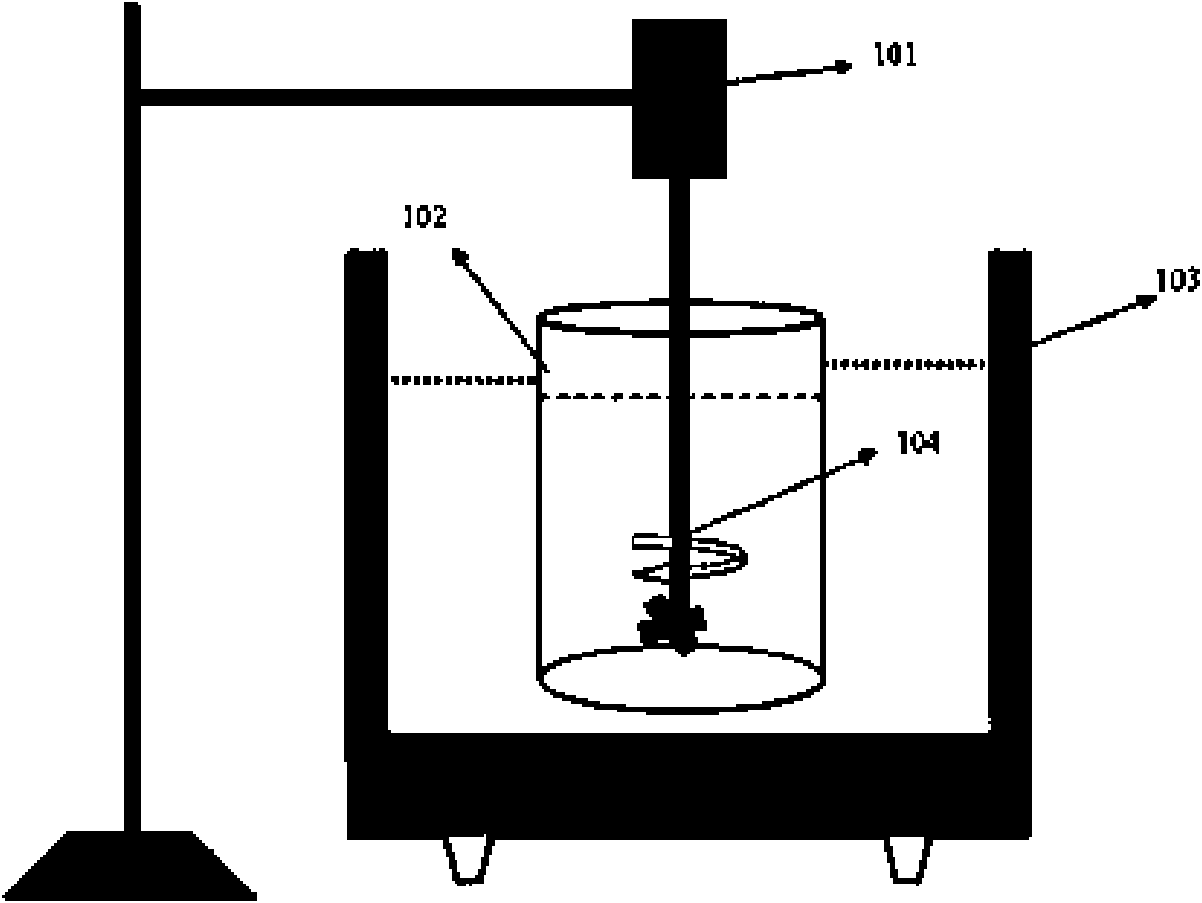

[0055] (1) The principle diagram of carbon nanotube purification and cutting process is as follows figure 1 Shown: in beaker 102, add the original powder of carbon nanotube of 4g, the 98.3wt% concentrated sulfuric acid (H of 500mL 2 SO 4 ) and 65wt% concentrated nitric acid (HNO 3 ) with a volume ratio of 1:1 mixed solution, and it was placed in a water bath heating tank 103 at 100°C, and under the stirring of the glass stirring rod 104 of the stirrer 101, it was treated for 3h, centrifuged and vacuum filtered carbon nanometer The tubes were washed repeatedly with deionized water until the pH value was neutral, and finally the purified and chopped carbon nanotub...

Embodiment 2

[0075] The invention discloses a method for preparing a field emission cathode with electroless metal-plated nickel carbon nanotubes on the surface. The process steps of the present invention will be described below in conjunction with the accompanying drawings.

[0076] 1. Activation treatment of carbon nanotubes:

[0077] (1) The principle diagram of carbon nanotube purification and cutting process is as follows figure 1 Shown: in beaker 102, add the original powder of carbon nanotube of 4g, the 98.3wt% concentrated sulfuric acid (H of 500mL 2 SO 4 ) and 65wt% concentrated nitric acid (HNO 3) with a volume ratio of 1:3 mixed solution, and placed it in a water bath heating tank 103 at 100° C., while being stirred by the glass stirring rod 104 of the stirrer 101, treated for 3 h, centrifuged and vacuum filtered the carbon nano The tubes were washed repeatedly with deionized water until the pH value was neutral, and finally the purified and chopped carbon nanotubes were dri...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com