Catalyst for heavy oil catalytic cracking and preparation method thereof

A cracking catalyst, catalyst technology, applied in catalytic cracking, cracking, petroleum industry and other directions, can solve problems such as small unit cell constant

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

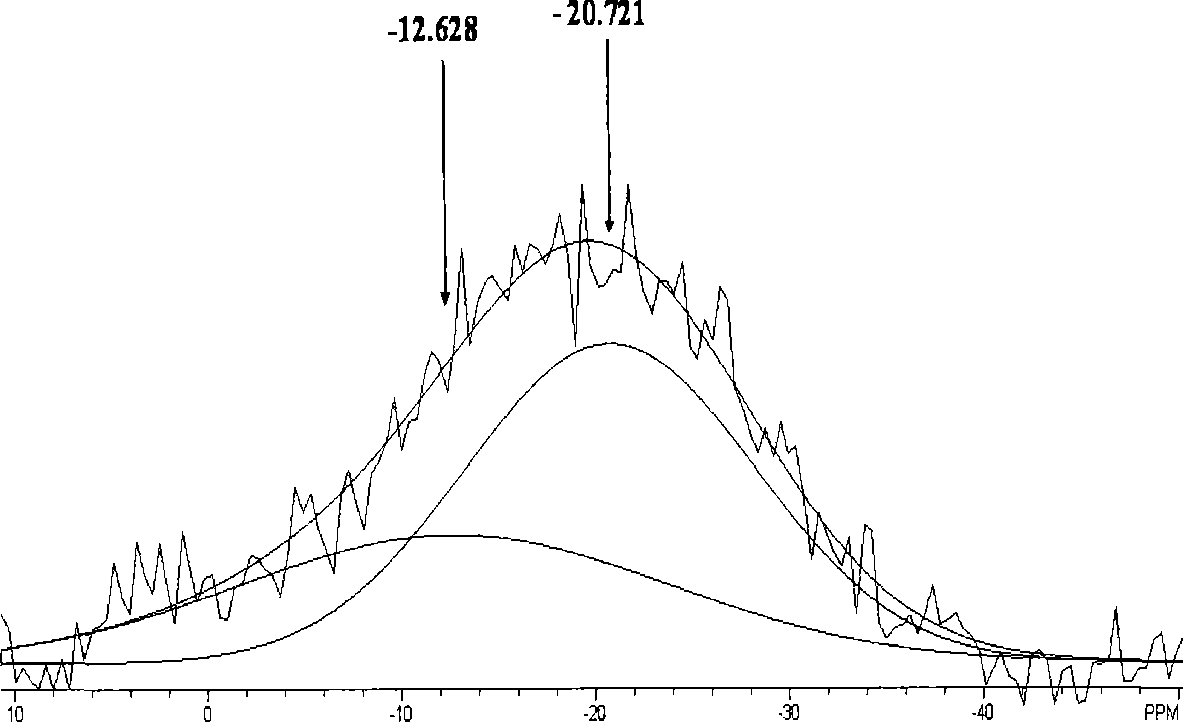

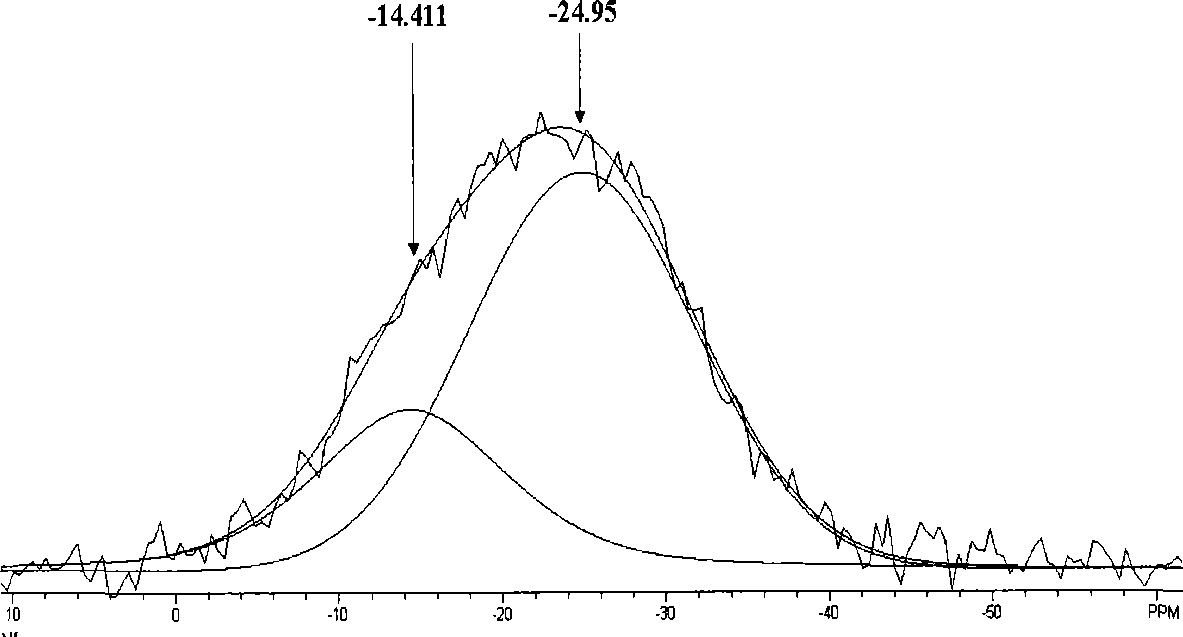

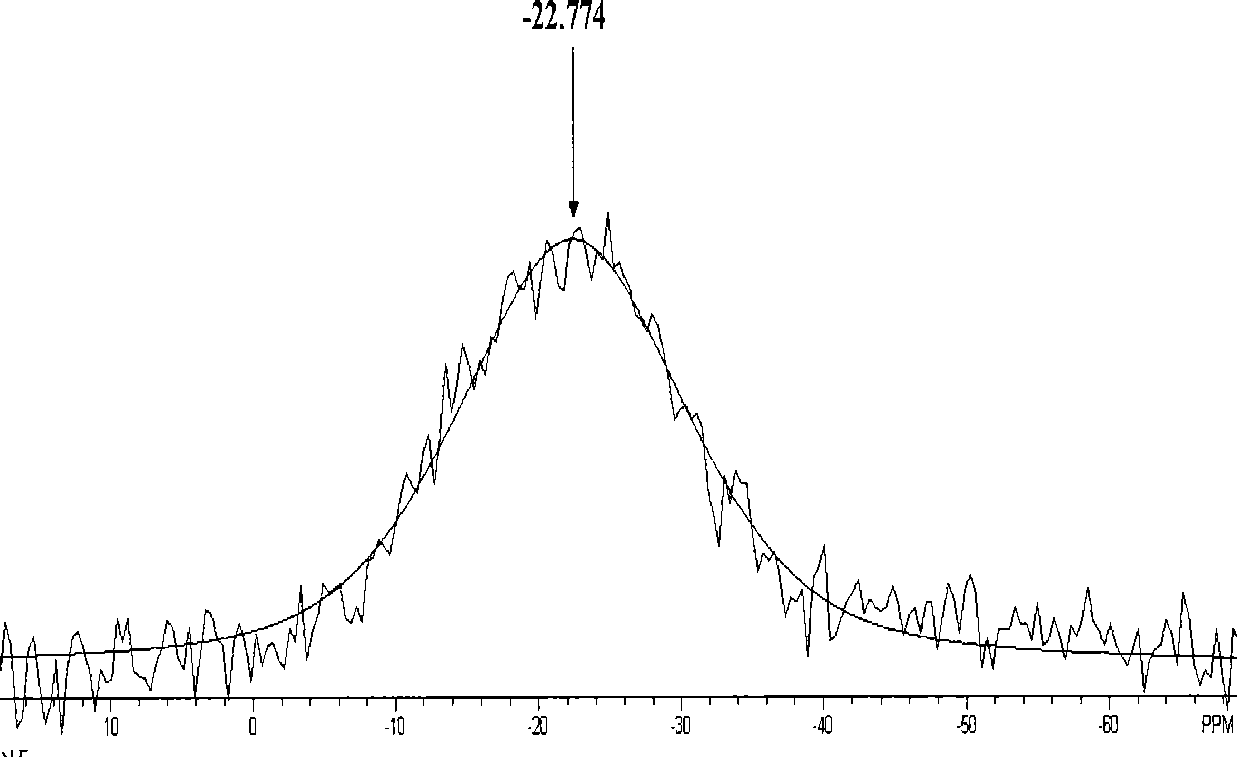

Image

Examples

preparation example Construction

[0040] According to catalyst preparation method of the present invention, specifically the preparation method of the Y-type molecular sieve containing phosphorus and rare earth comprises the following steps:

[0041] (1) NaY molecular sieve with a silicon-aluminum ratio≥4.5 is contacted with an aqueous solution containing rare earth ions and an aqueous solution of a phosphorus-aluminum modifier, wherein, in terms of rare earth oxides, the ratio of rare earth ions to molecular sieve solid weight is 0.12-0.30, with The ratio of phosphorus pentoxide meter, phosphorus aluminum modifier and molecular sieve solid weight is 0.01-0.1, the liquid-solid ratio is 4-20, the reaction temperature is 60-95°C, the reaction time is 10-120min, after filtering and rinsing Afterwards, a filter cake product is obtained; the phosphorus-aluminum modifier is to combine the aluminum-containing ion solution or colloid and the phosphorus-containing compound aqueous solution at a phosphorus-aluminum molar...

Embodiment 1

[0060] At room temperature, the (NH 4 ) 3 PO 4 (chemically pure, produced by Beijing Hongxing Chemical Factory, the same below) 82 grams are added to 1200 grams of water for dissolving, slowly added to 360 grams of aluminum sol (Al 2 o 3 Accounting for 22%, produced by Qilu Catalyst Factory, the same below), stirring was continued for 2 hours to obtain phosphorus-aluminum modifier 1 with a phosphorus-aluminum molar ratio of 0.36.

[0061] Get 1500 grams of NaY molecular sieves (dry basis weight, produced by Qilu Catalyst Factory, the same below), after beating with 12 liters of deionized water, add RECl with a concentration of 231g / l 3 Solution (Qilu Catalyst Factory provides, wherein La 2 o 3 52.5% by weight, CeO 2 Accounting for 46.5% by weight, Pr 2 o 5 0.6% by weight, Nd 2 o 3 Accounting for 0.4% by weight, the same below) 864 milliliters, exchanged at 85°C for 0.5 hours, then added the above-mentioned phosphorus-aluminum modifier 1, stirred at a constant tempera...

Embodiment 2

[0064] The preparation method of molecular sieve is the same as embodiment 1, just replace the molecular sieve in embodiment 1 with A-1 molecular sieve 1100 grams (dry basis), DASY0.0 molecular sieve 200 grams (dry basis) in the catalyst preparation process, the catalyst obtained, Recorded as C-2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com