Molecular sieve composition and particle containing molecular sieve active component and preparation methods thereof and catalytic cracking catalyst

An active component and catalytic cracking technology, which is applied in molecular sieve catalysts, physical/chemical process catalysts, catalytic cracking, etc., can solve the problems of increasing catalyst usage, increasing catalyst consumption, low catalyst activity, etc., and achieve good heavy oil conversion capacity, low coke yield, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0032] According to a specific embodiment of the present invention, the preparation method of the molecular sieve composition and particles containing molecular sieve active components includes the following specific steps:

[0033] (1) Mix the zeolite with the MFI structure and the organic amine solution (0.05-15% by weight) and stir for 30-60 minutes;

[0034] (2) zeolite beta is divided into multiple batches and mixed with the mixture that step (1) obtains, and the addition of every batch of zeolite beta is at most 80% by weight of the total amount of zeolite beta, preferably 30-70% by weight, and the time interval is 5- 120 minutes, and stirred for 60-120 minutes; obtain the molecular sieve composition;

[0035] (3) filtering and drying the molecular sieve composition obtained in step (2) to obtain a solid;

[0036] (4) prepare the silica sol whose pH value is 1-3, the preparation method of described silica sol can be prepared according to conventional methods, for exampl...

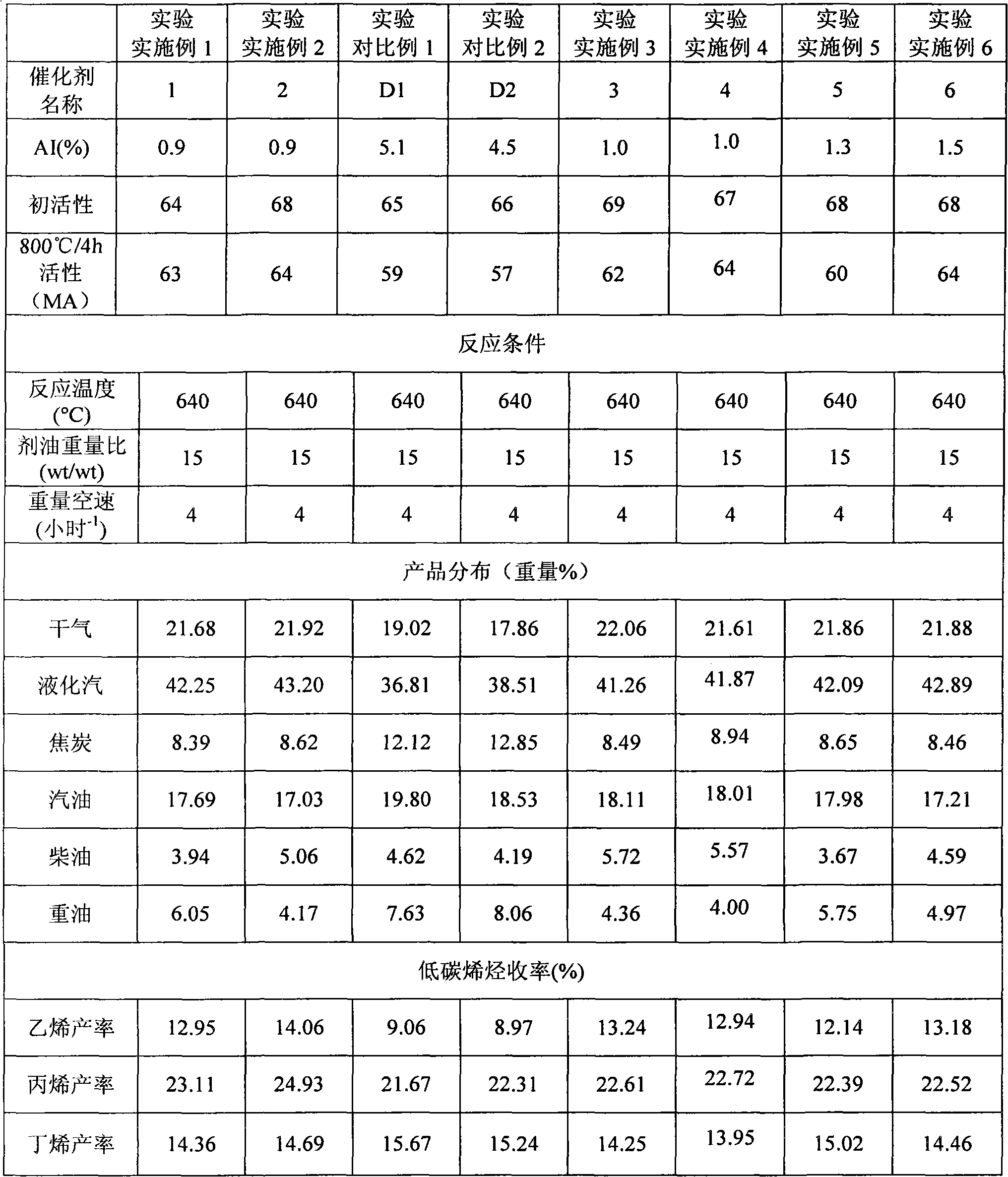

Embodiment 1

[0053] This example is used to illustrate the preparation of catalytic cracking catalyst.

[0054] A: Preparation of Molecular Sieve Composition and Particles a

[0055] (1) At 30°C, 14kg ZSP-3 molecular sieve (product of Sinopec Catalyst Qilu Branch Company, ZSP-3 silicon-aluminum molar ratio=40), and 100kg polyvinylamine aqueous solution (the number-average molecular weight of polyvinylamine is 1800( Purchased from Westernization Instrument (Beijing) Technology Co., Ltd.), the mass percent concentration of polyvinylamine aqueous solution is 3%), mixed and stirred for 40 minutes to obtain 114 kg of slurry;

[0056] (2) At 40° C., 4 kg of β molecular sieve (product of Sinopec Catalyst Qilu Branch Company, with a silicon-aluminum molar ratio of 20) was mixed with the slurry obtained in step (1), and stirred for 40 minutes to obtain 118 kg of slurry;

[0057] (3) At 40°C, 4 kg of β molecular sieve (product of Sinopec Catalyst Qilu Branch Company, with a silicon-aluminum molar r...

Embodiment 2

[0068] This example is used to illustrate the preparation of catalytic cracking catalyst.

[0069] Prepare the catalyst according to the method of Example 1, the difference is that in the step of preparing particle a: change the 100kg polyvinylamine solution into 280kg polyethyleneimine aqueous solution (the number average molecular weight of polyethyleneimine is 3000 (purchased from Beijing Kesijia company), the mass percentage concentration of polyethyleneimine solution is 5%), the ZSP-3 molecular sieve of 14kg is replaced by 20kg ZRP (Sinopec Catalyst Qilu Branch Company product, silicon-aluminum molar ratio is 60), β zeolite (silicon The amount of aluminum molar ratio=40) is 3kg (1kg and 2kg are added in steps (2) and (3) respectively), while particle a and particle b are mixed in a weight ratio of 5:1 to obtain catalyst 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com